Haier RF-8888-46 User manual

Other Haier Refrigerator manuals

Haier

Haier HRF08WNDWW User manual

Haier

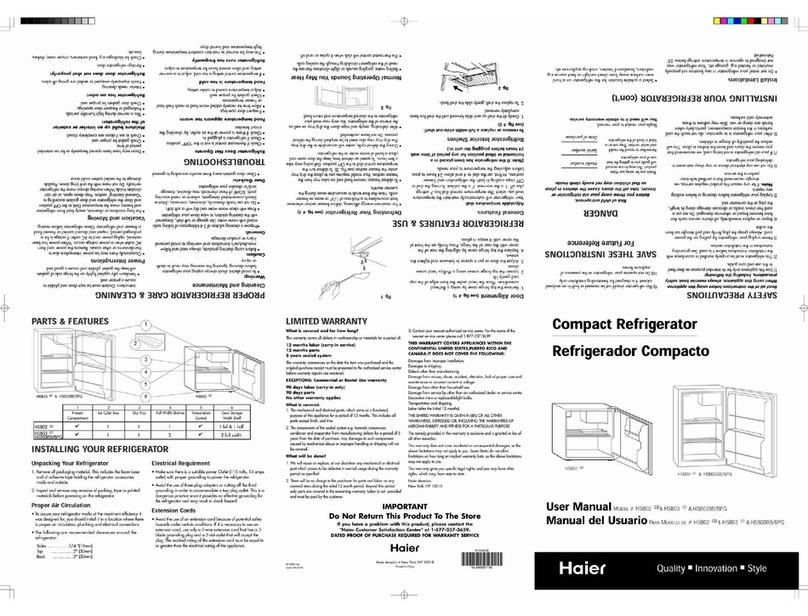

Haier HSB03 User manual

Haier

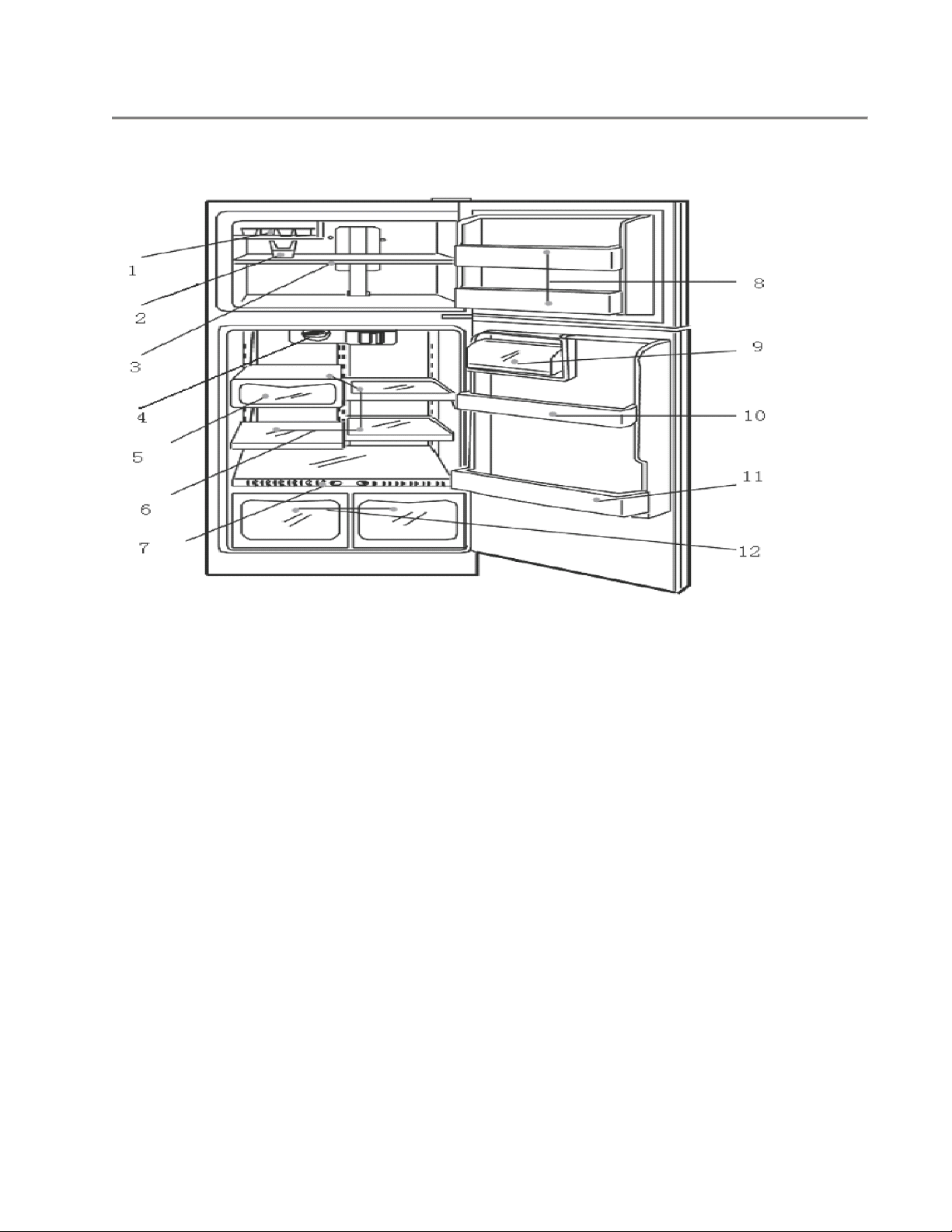

Haier HRT18RCP User manual

Haier

Haier HB16WMAA User manual

Haier

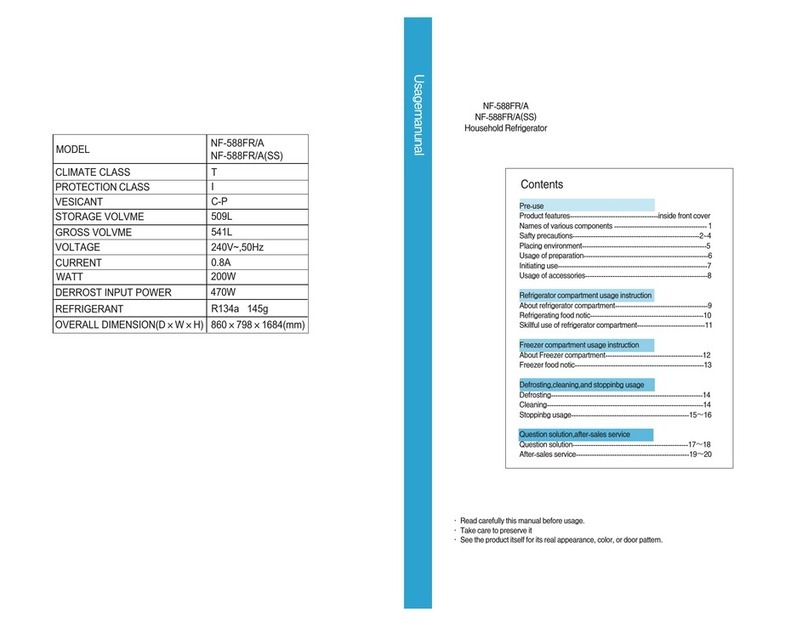

Haier NF-588FR/A Parts list manual

Haier

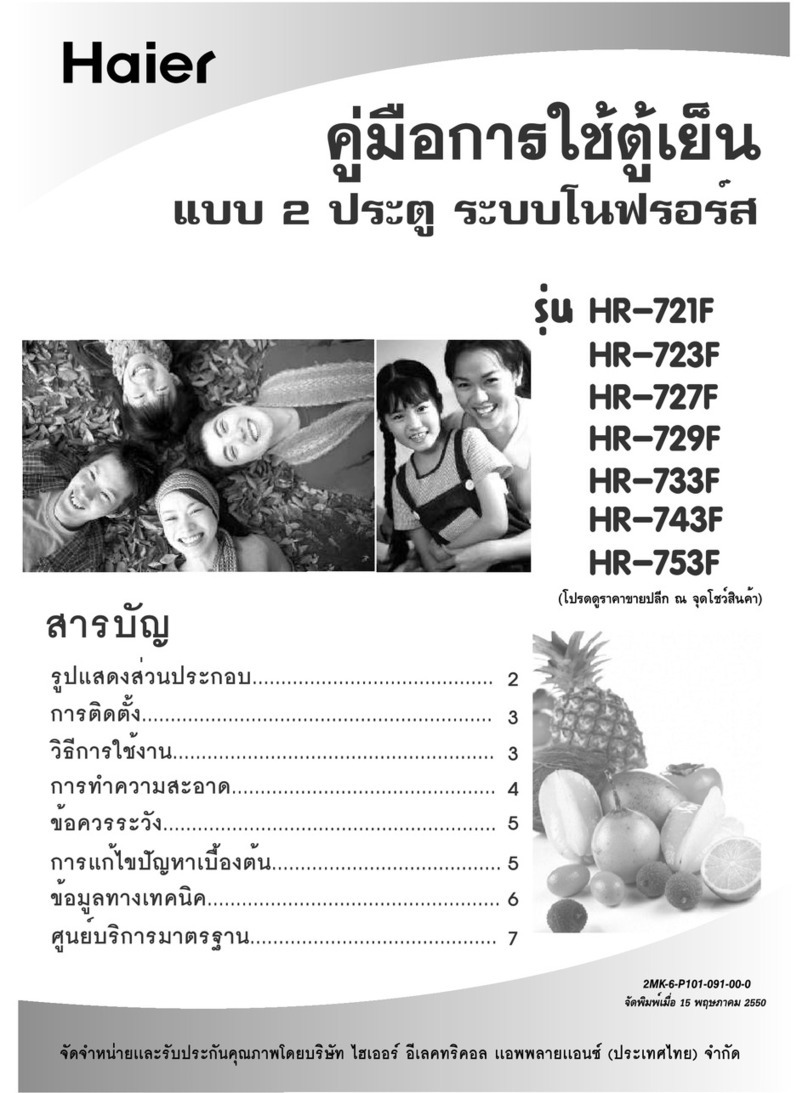

Haier HR-727F User manual

Haier

Haier HRF-663ISB2U User manual

Haier

Haier A2FE735CXJ User manual

Haier

Haier HTW5618 Series User manual

Haier

Haier HRF-656FF/A User manual

Haier

Haier PRTS Series User manual

Haier

Haier HTF-540DGG7 User manual

Haier

Haier C121 User manual

Haier

Haier HYC-68 User manual

Haier

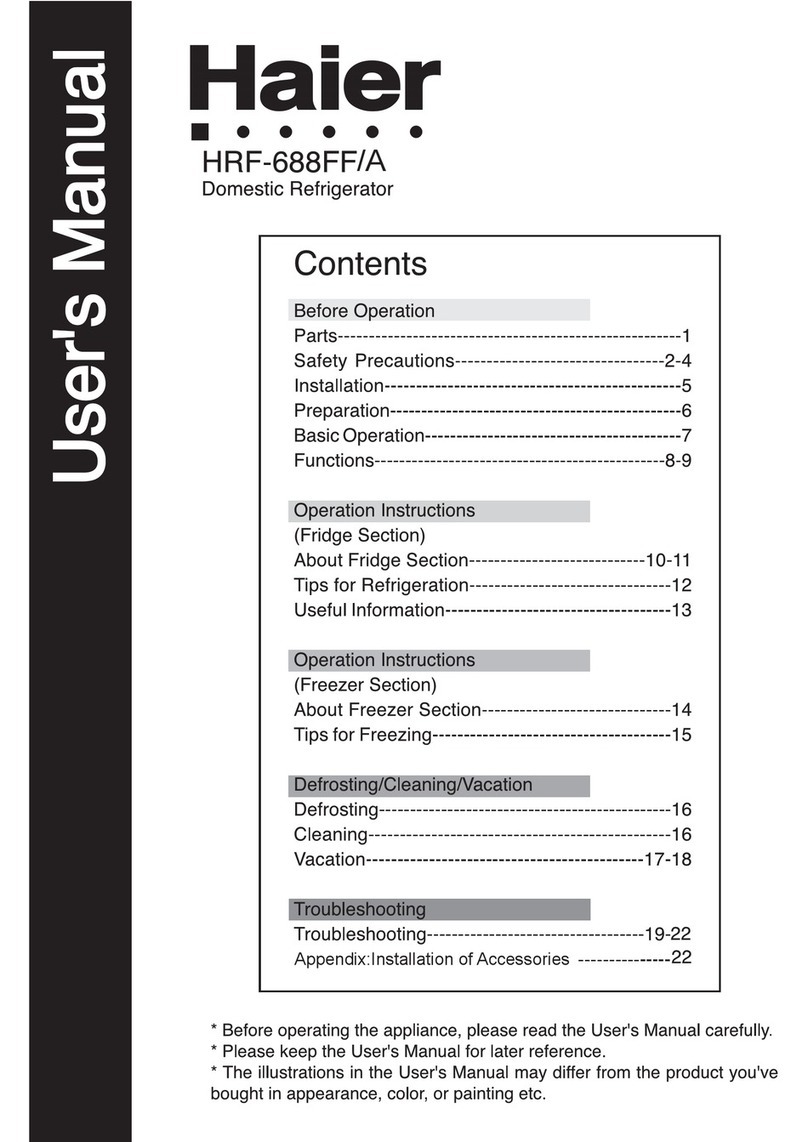

Haier HRF-688FF User manual

Haier

Haier HB21FSSAA User manual

Haier

Haier HBW5518E User manual

Haier

Haier DW-86L288 User manual

Haier

Haier HYC-68 User manual

Haier

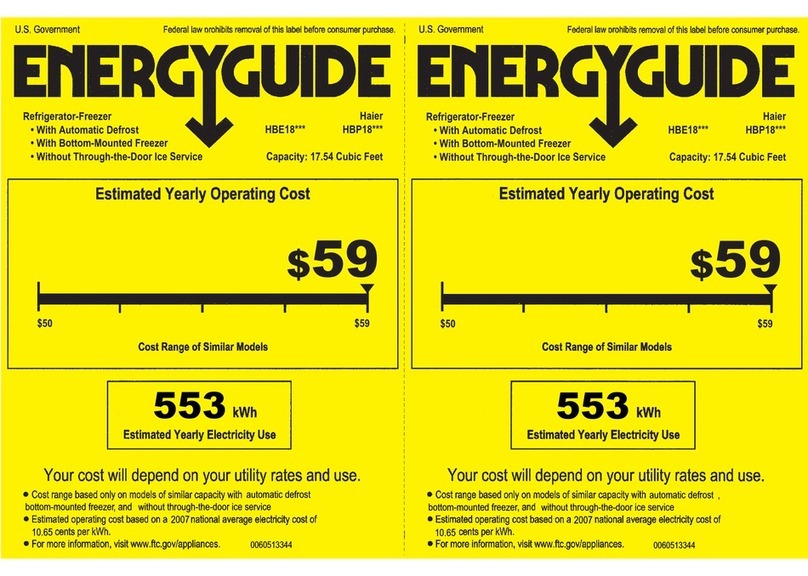

Haier HBE18WADW Assembly instructions