8

components are usuallycalled ElectrostaticallySensitive(ES) Devices. ExamplesoftypicalES

devices are integratedcircuitsandsome fieldeffect transistors and semiconductor “chip”

components. Thefollowing techniquesshouldbeused to help reducethe incidenceofcomponent

damage caused bystaticelectricity.

1) Immediatelybefore handlinganysemiconductorcomponent orsemiconductor- equipped

assembly,drainoffanyelectrostatic chargeonyour bodyby touching aknownearthground.

Alternatively,obtain and wear acommerciallyavailabledischargingwrist strap device,which should

be removed to preventpotentialshock prior to applyingpowerto the unitunder test.

2) After removing an electricalassemblyequipped with ES devices, placethe assemblyona

conductivesurface suchasaluminumfoil, to prevent electrostaticcharge buildup or exposure ofthe

assembly.

3) Use onlyagrounded-tipsolderingiron to solderorunsolder ES devices.

4) Useonly ananti-statictype folderremovaldevice. Somesolder removaldevices not classified as

“anti-static”can generateelectricalchargessufficient todamageES devices.

5) Donotusefreon-propelledchemicals.Thesecan generateelectrical charges sufficient to

damage ES devices.

6) Donot removeareplacement ES device from itsprotectivepackage untilimmediatelybefore you

are readytoinstallit.(Most replacementES devicesare packaged withleads electricallyshorted

togetherby conductivefoam,aluminum foil or comparable conductive material).

7) Immediatelybeforeremoving the protectivematerial fromtheleads ofareplacementES device,

touch the protectivematerialto the chassis or circuit assemblyinto which the device will be installed.

CAUTION: Be sure no power is applied to thechassis or circuit, andobserve allother safety

precautions.

8) Minimize bodilymotionswhenhandlingunpackaged replacementES devices.(Otherwiseeven

some normallyharmless motions suchas mutualbrushingofyour clothes fabricor liftingofyour

foot from a carpeted floor might generate static electricitysufficientto damage an ES device.)

General Soldering Guidelines

1) Use agrounded-tip, low-wattage solderingironandappropriatetipsize and shapethat will

maintain tip temperature within the rangeof500oF to600oF.

2) Use anappropriate gauge ofRMAresin-core solder composed of 60 parts tin/40 parts lead.

3) Keepthesoldering iron tip cleanand well tinned.

4) Thoroughlyclean thesurfaces to besoldered. Use amallwirebristle (0.5inch,or 1.25cm) brush

with a metalhandle. Do not use freon-propelled spay-oncleaners.

5) Use the following unsoldering technique

a. Allowthe soldering irontipto reachnormaltemperature.(500o F to 600o F)

b. Heatingthecomponent leaduntil the solder melts.

c.Quicklydrawthe meltedsolderwithan anti-static,suction-type solder removal device with

solder braid.

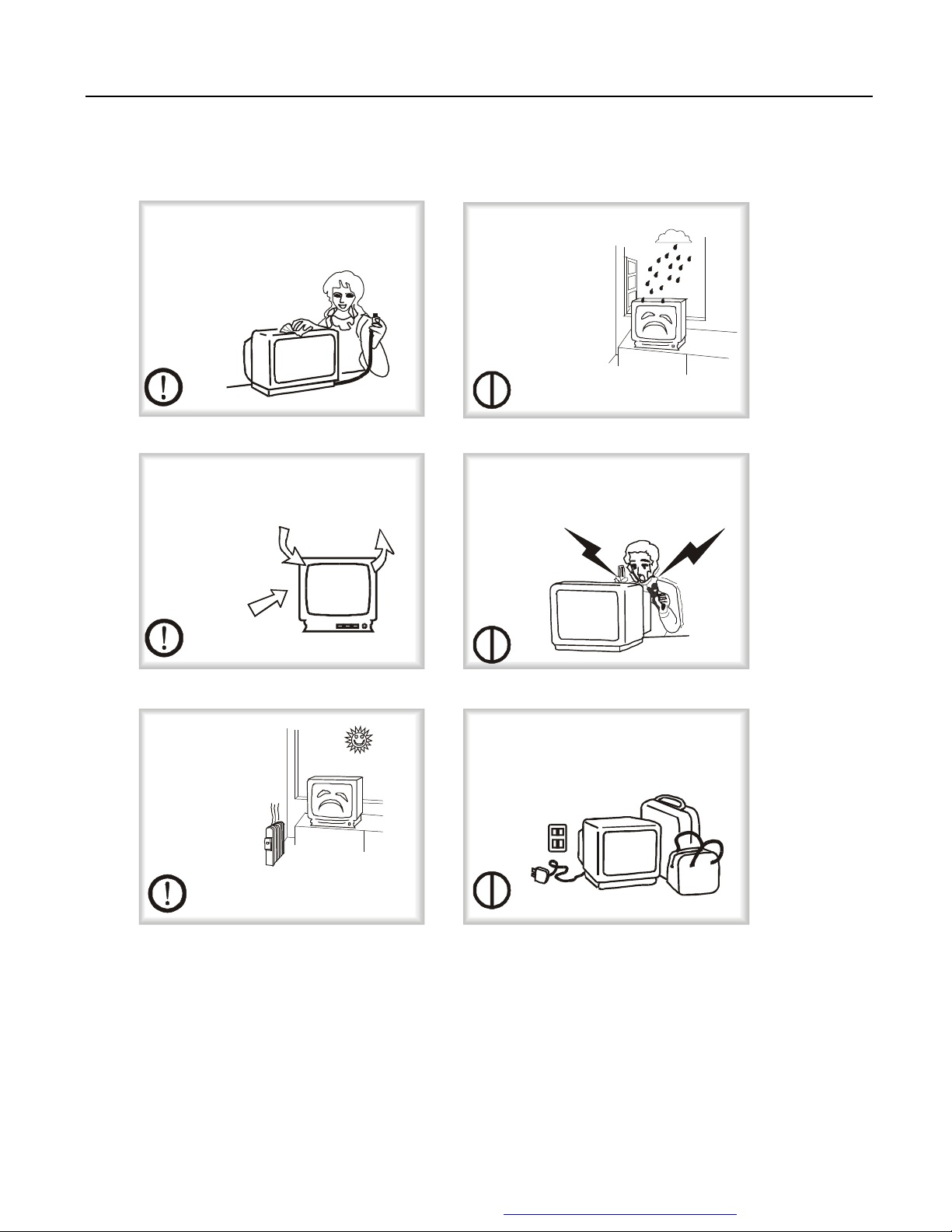

Warningand Cautions

PDF 件以 "FinePrint pdfFactory Pro" 试用版创建 http://www.pdffactory.com