6

4.HOWTOOPERATE

5.MALFUNCTIONSANDSOLUTIONS

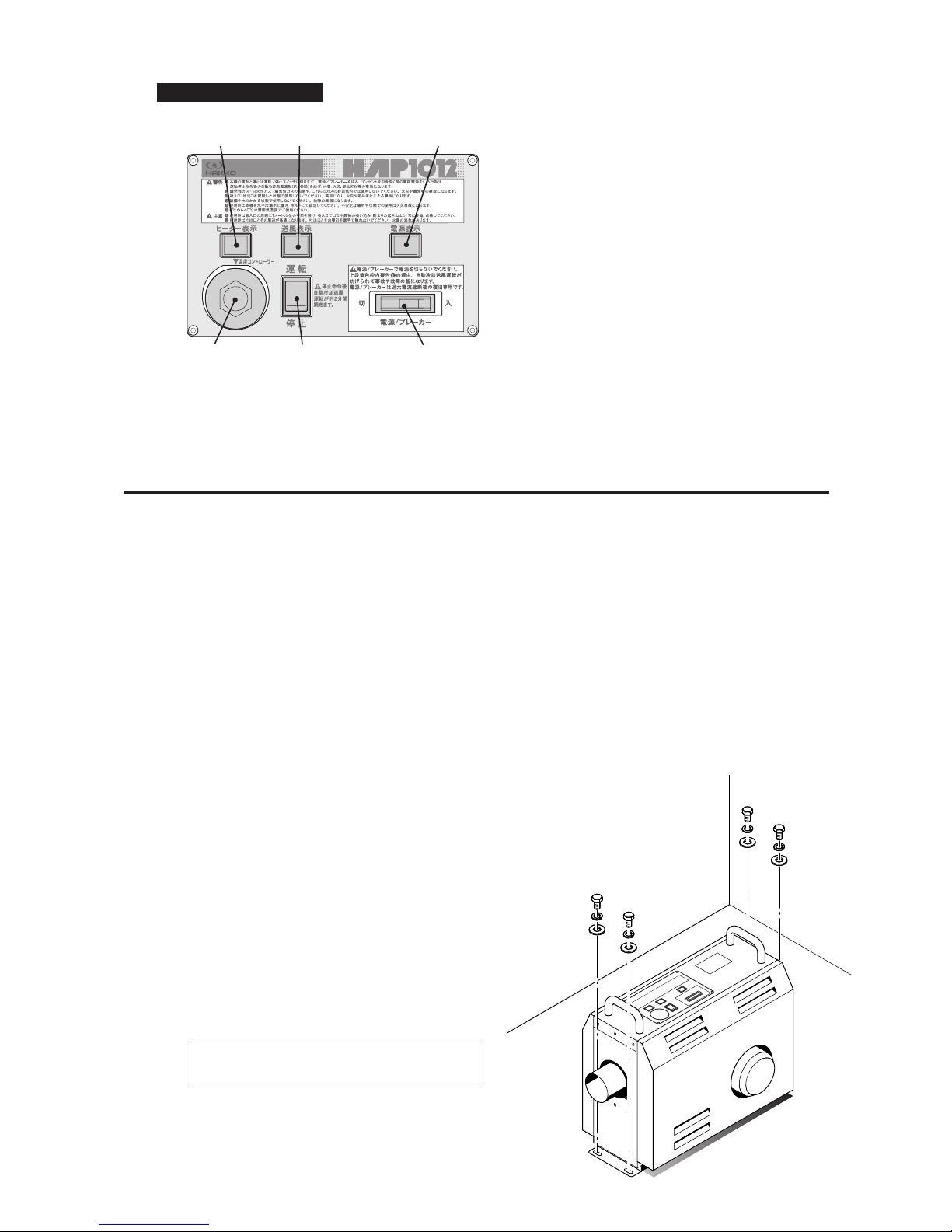

(1)Turnonthepowerbreakeronthecontrolpanel.Thepowerlamp(orange)lightsup.

(2)Turnonthe operationswitch.

(3)Rotatethetemperaturecontroldialinaclockwisedirection.Hotaircomesoutfromtheoutlet

andtheblowerlamp(green)lightsup.Theheaterlamp(red)lightsupaslongasthepreset

temperatureishigherthanthatofair.

(4)Adjustthetemperaturecontroldialontemperatureinuse.

(5)Adjusttheairvolumeandtemperaturebycontrollingthemovableplatedamperoftheinlet.

Temperaturewillincreaseasthedampercloses.

(6)Afterreachingthepresettemperature,theheaterlampisalternatelyturnedonandoffby

temperaturecontrol.

(7)Whenyoustopthedevice,turnofftheoperationswitchfirst.Theheateristurnedoffandthe

blowerisgoingonfortwomoreminutes.Aftertheblowerstops,turnoffthepowerbreaker.

MALFUNCTION POSSIBLECAUSE SOLUTION

Thedevicedoesn't

workthoughthe

operationswitchis

on.

Nopowersupply.

Checkiftheplugisconnectedintothesocket

andthepowerbreakeristurnedon.

Checkiffeedingvoltageisasmuchas100V.

Noaircomesout.

Presettemperatureofthecontrolleristoolow. Increasethepresettemperature.

Failuresinthethermostatorthefan. Repairorreplacethethermostatorthefan.

Thetemperatureof

airdoesn'tincrease.

Presettemperatureofthecontrolleristoolow. Increasethepresettemperature.

*1:AskyourdistributorsortheSalesHeadOfficeofHAKKOCO.,LTD.

Stopoperationandpoweroffimmediatelyaftermalfunctionarises.

Cooldownandsolvetheproblembeforeyoure-start.AskyourdistributorortheSalesHead

OfficeofHAKKOCO.,LTD.ifthedevicewouldnotrecover.

Thetemperatureof

airistoohigh.

Thedamperisfullyclosed. Openthedamper.

Failuresinthethermostatorthefan.

Repairorreplacetheheaterorthethermostat.

*1

Failureinthethermostat. Repairorreplacethethermostat.

Duetomalfunctionoftheblower,athermostat

works.

Checkiftheinletandthefanoftheblower.

Blowoutofthethermalfuse. Replacethethermalfuse.*1

Blowoutofthethermalfuse. Replacethethermalfuse.*1

Donotturnoffthepowerbreakerwithoutcoolingfortwo

minutes.Otherwiseitmaycausefailures.