-2

D) Do no block the air being discharged. Pump must have sufficient room to allow for heat

dissipation.

Under the extreme operating temperature conditions which may be caused by failure to

Observe cautions C) or D), pump will automatically switch off until cool. DO NOT REMOVE

PUMP CASING UNTIL UNIT IS DISCONNECT FROM MAIN SUPPLY.

E) Always unplug pump prior to servicing. Grasp plug to remove cord form outlet. Do not

remove by pulling on power cord.

F) Do not use the air pump for any other purpose which different from its original use. Use of

unauthorized replacement parts may jeopardize safety.

G) Do not store pump under freezing condition.

H) Ensure pump is securely mounted prior to operation.

I) Read and observe all important markings on pump.

J) Ensure that extension cords (if require) have the correct or higher rating (amperes or watts).

Ensure cord is properly positioned to avoid tripping.

INSTRUCTIONS NOTES

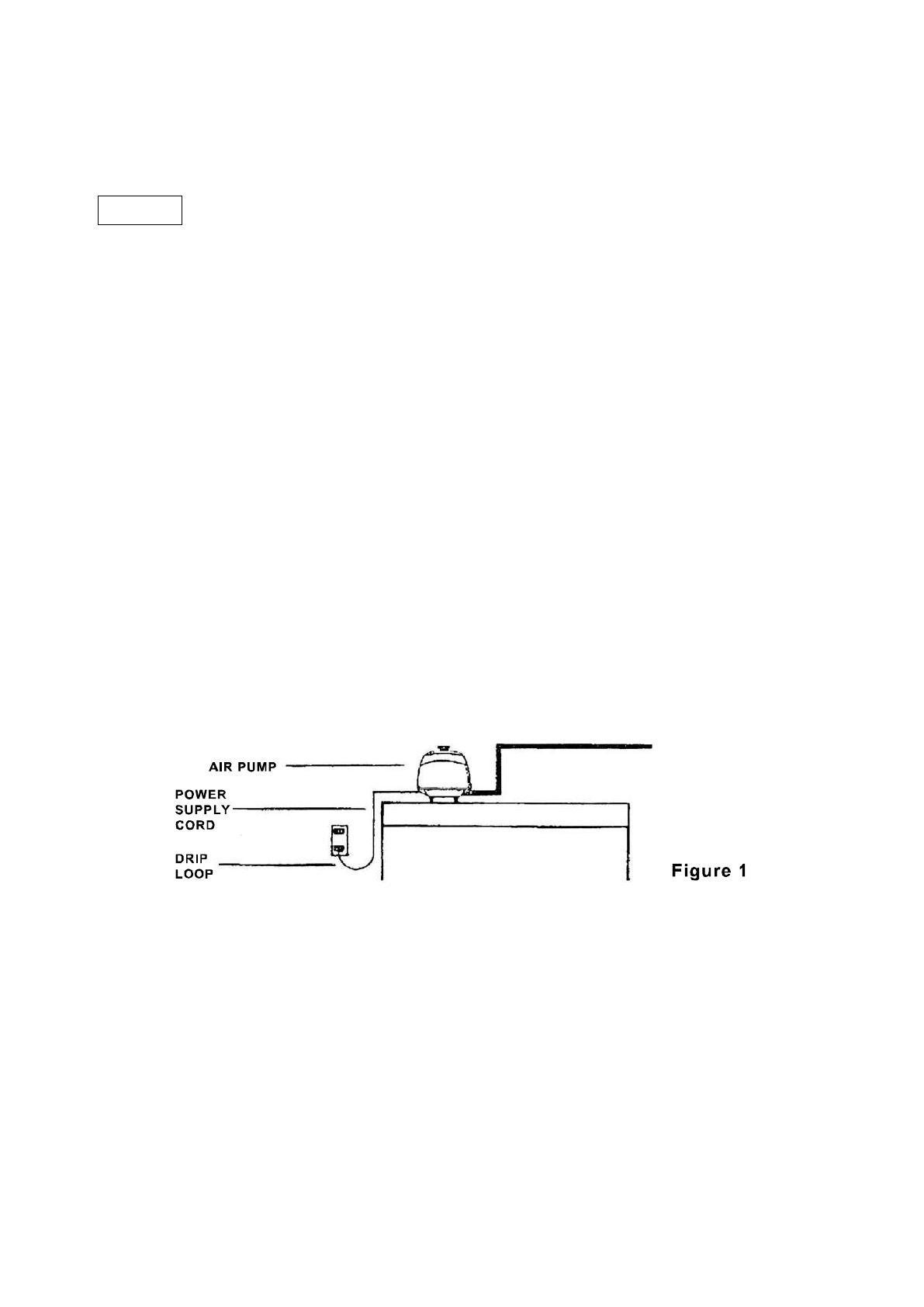

1. INSTALLATION

A) When using the pump to inject air into a liquid, ensure the pump is placed higher than the

surface level of the liquid, otherwise the liquid may run back into the pump when the power is

turned off.

B) Do not keep the air pump in a damp and stuffy place.

C) Please ensure the air pump is placed on a strongly built place horizontally.

2. GROUNDING

This air pump must be grounded to minimize the possibility of electric shock.

This air pump is equipped with an electric cord having an equipment grounding conductor and a

grounding type plug. The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all appropriate codes and ordinances.

DANGER –Improper Installation of the grounding plug can result in a risk of electric shock. If

repair or replacement of the cord or plug is necessary, do not connect the grounding wire to

either flat blade terminal. The wire with insulation having other surface that is green with or

without yellow stripes is the grounding wire.

Check with a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded. Do not modify the plug

provided; if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

This air pump is for use on a nominal 110-120 volt circuit as indicated on the sticker, and has a

grounded plug which is illustrated in (Figure 2). Carefully read the specification on the nominal