Function Blocks PSx-3__-PN

10

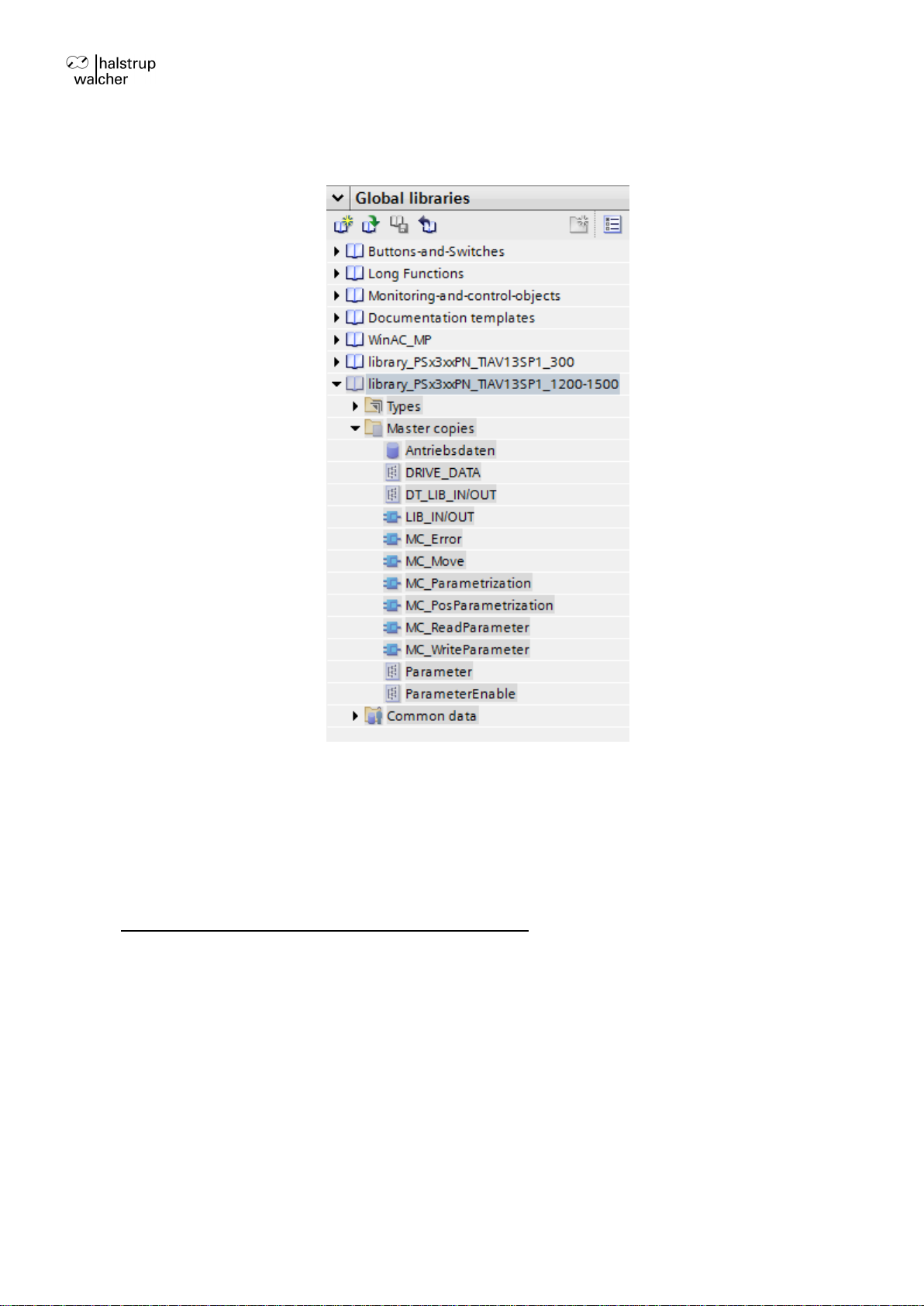

When using one of the library versions for Step 7 TIA V13 + V14:

Copy into “Program blocks”of the desired CPU:

Data type DRIVE_DATA

Data type DT_LIB_IN/OUT

Function block LIB_IN/OUT

These elements serve for the communication to the drive. The functions and function blocks of

this group must NOT be called in the program.

Besides the desired function blocks “MC_...” have to be copied into the user project, e.g. all or

a choice of the following blocks:

MC_Move

MC_Error

MC_ReadParameter

MC_WriteParameter

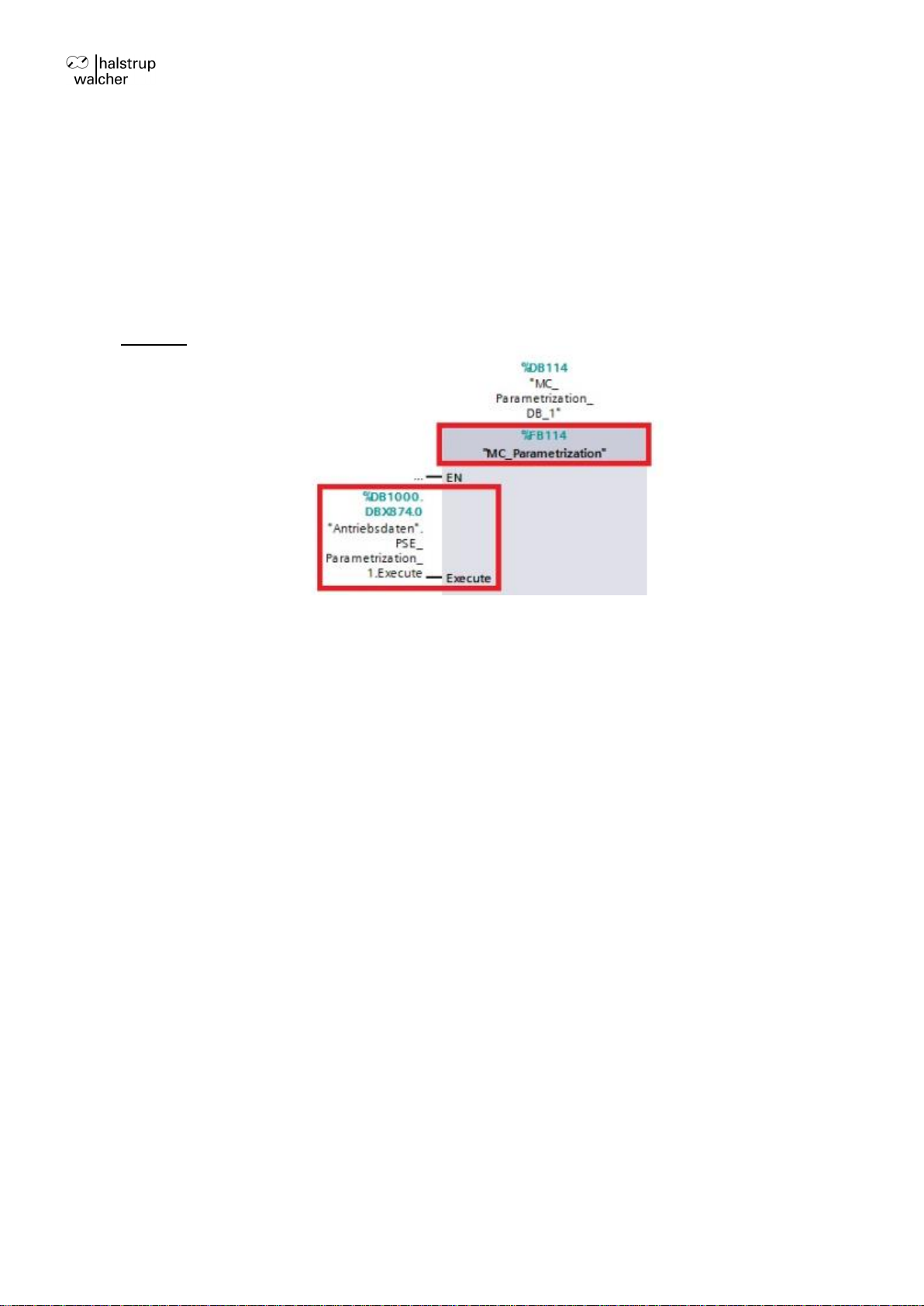

MC_Parametrization

MC_ PosParametrization

In the versions for the TIA Portal additionally the data component “Antriebsdaten”may be

taken over as a template for connecting the inputs and outputs of the function blocks. In ist

standard implementation, the data types “Parameter”and “ParameterEnable”also have to be

taken over (see chapter 3).

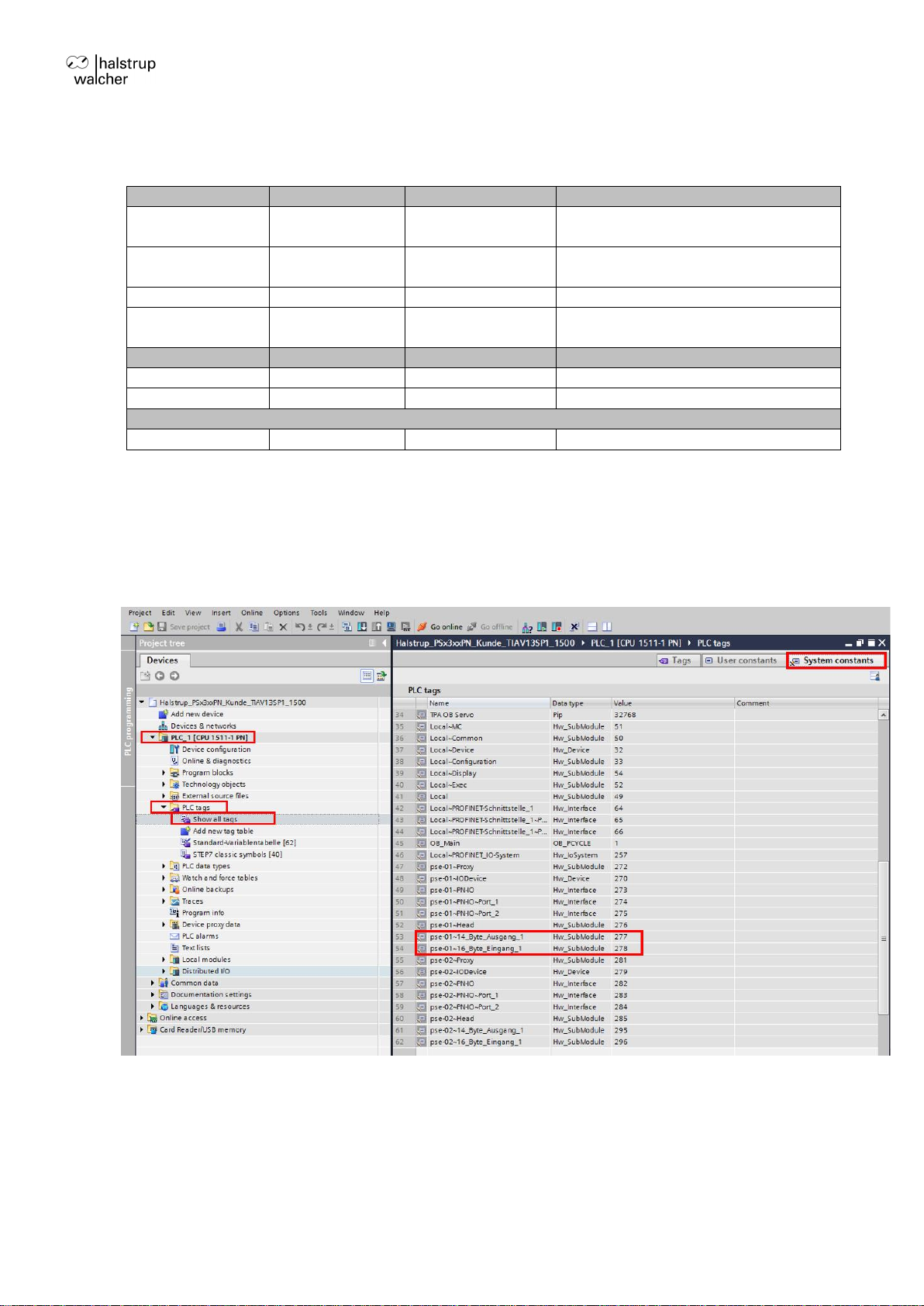

5.3 Generating instance data blocks

Per axis and per desired function block an instance data block has be generated.

5.4 Generating global data

Per axis one global variable of the type DRIVE_DATA has to be generated (size: 94 byte in

Classic Step 7, 144 byte in TIA Portal). Additionally those variables have to be generated

which are connected to the inputs and outputs of the particular blocks.

If applicable, it’s reasonable to generate an additional data block of the type “global” for this

data (e.g. DB1000), in case of the TIA Portal also the template “Antriebsdaten” may be used

(see chapter 3).

It’s not necessary to connect all inputs and outputs. If parts of a block are not used, the

associated inputs may stay unconnected, then the respective initial value for this input is valid.

Outputs not used also may stay open.

5.5 Commonalities of all function blocks

The function blocks are inserted in a part of the program that is called cyclically (e.g. in the

OB1) and immediately be linked with their respective instance data blocks.