Page iii

Table of Contents

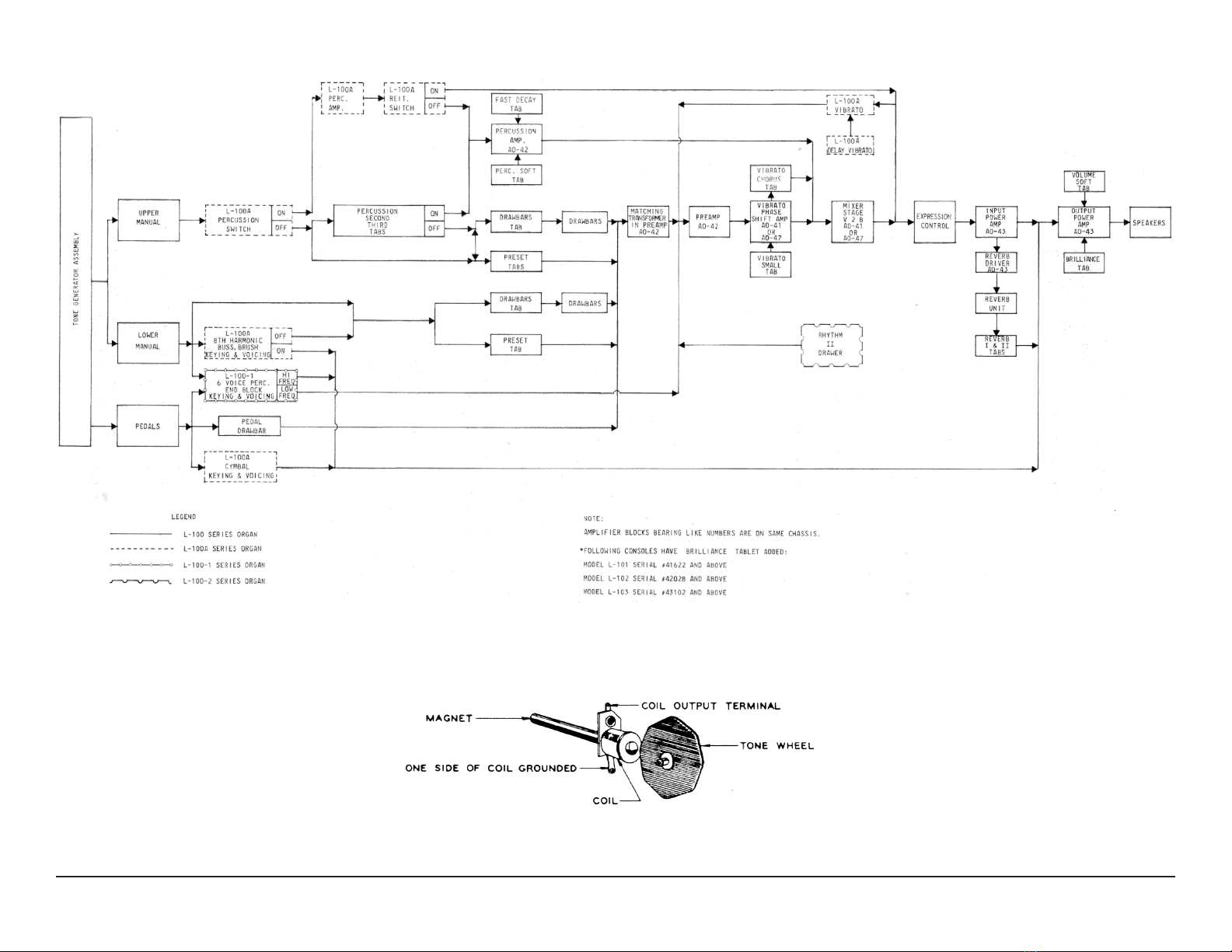

1. How the Organ Operates ...........................7

1-1. General....................................7

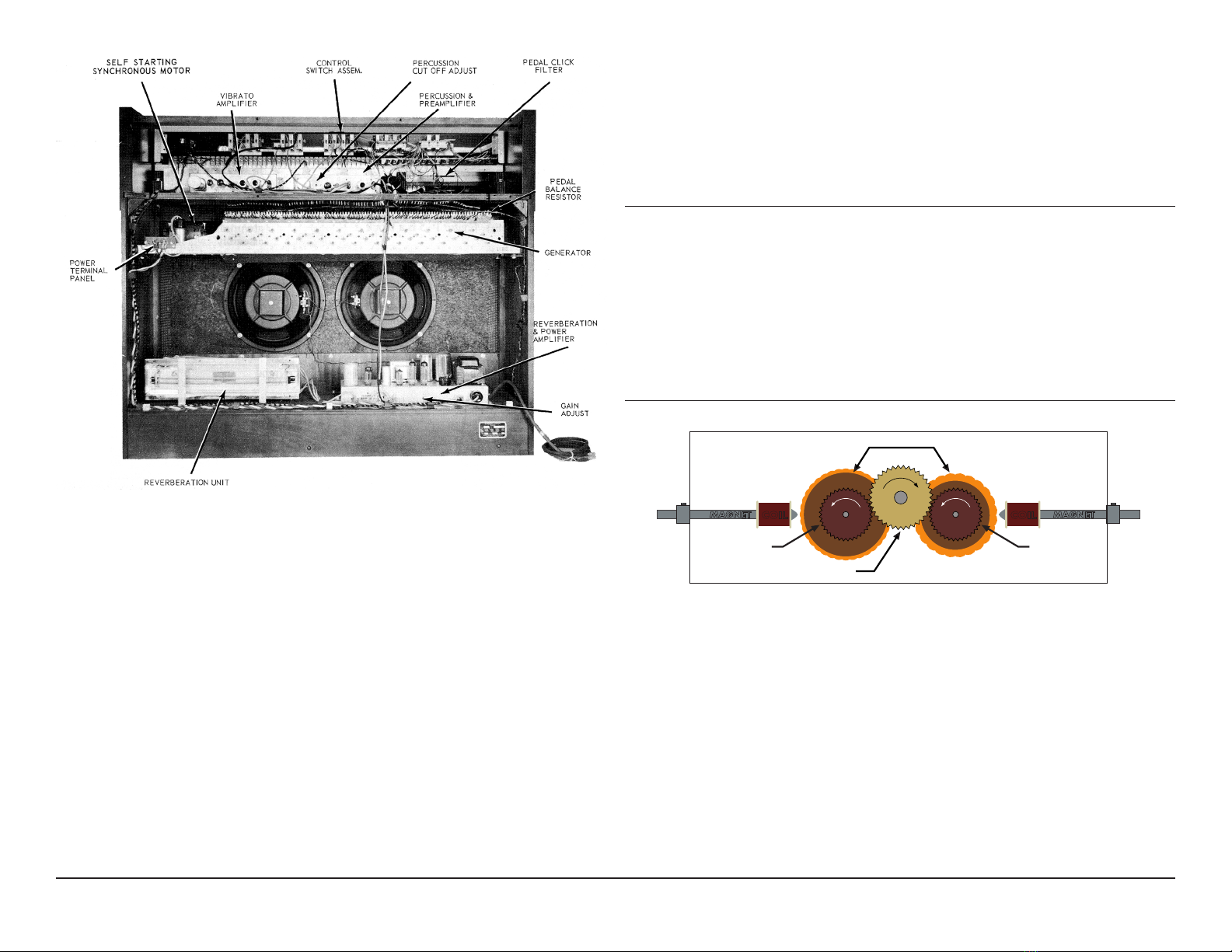

1-2. Tone Source ................................7

1-3. Motor and Power Switch ......................8

1-4. Tone Generator..............................8

1-5. Manuals ..................................11

1-6. Harmonic Drawbars .........................13

1-7. Pedal Drawbar .............................13

1-8. Pedal Keyboard ............................13

1-9. Expression Pedal ...........................14

1-10. Control Tabs ...............................14

1-11. Preset Tabs ...............................14

1-12. Vibrato Tabs ...............................14

1-13. Reverberation And Volume Soft Tabs ...........14

1-14. Percussion Control Tabs .....................14

1-15. L–100A Preset Percussion Unit ................14

1-16. L–100–1 Six-Voice Percussion Feature...........15

1-17. External Equipment .........................16

1-18. Extension Speakers .........................16

1-19. External Sound Source ......................16

1-20. Earphones ................................16

2. Theory of Operation ..............................17

2-1. General...................................17

2-2. Pre-Ampliers..............................17

2-3. Vibrato Phase Shift Amplier ..................17

2-4. Percussion Amplier. . . . . . . . . . . . . . . . . . . . . . . . . 18

2-5. Reverberation and Power Amplier .............19

2-6. Power Supply ..............................19

2-7. L–100A Percussion Voicing Circuitry ............19

2-8. L–100–1 Six-Voice Percussion Circuitry ..........21

3. Disassembly ....................................24

3-1. General...................................24

3-2. Access ...................................24

3-3. Upper Manual Key ..........................24

3-4. Lower Manual Key ..........................24

3-5. Drawbar Contact Spring. . . . . . . . . . . . . . . . . . . . . . 24

3-6. Drawbar, Drawbar Knobs or Drawbar Assembly ...25

3 -7. Upper Manual..............................25

3-8. Lower Manual..............................26

3-9. Generator .................................26

3-10. Motor ....................................26

3-11. Pedal Keyboard ............................26

3-12. Swell Assembly ............................27

3-13. To Replace a Broken Tab .....................27

3-14. Pilot Light or Power Switch ...................27

3-15. Percussion Circuitry, L–100A ..................28

3-16. Six-Voice Percussion Circuitry, L–100–1..........28

4. Practical Service Suggestions......................29

4-1. General...................................29

4-2. Organ Performance Check ...................29

4-3. Equipment Required.........................29

4-4. Procedure ................................29

4-5. Vibrato ...................................30

4-6. L–100A Percussion Performance Check .........32

4 -7. L–100–1 Six-Voice Percussion Performance Check

And Troubleshooting ..............................34

5. Diagrams ......................................37

5-1. General...................................37

5-2. Interactive Schematic Instructions ..............37

6. L-Series Parts List ...............................55

6-1. Overview .................................55

6-2. Changes from Source Document...............55

6-3. Assembly List ..............................56

6-4. Parts List .................................58

7. Modifications ...................................81

7-1. Overview .................................81

7-2. Connecting a Leslie or Other External Speaker ....81