H&H VIP 3000 User manual

(+)

30

AMP

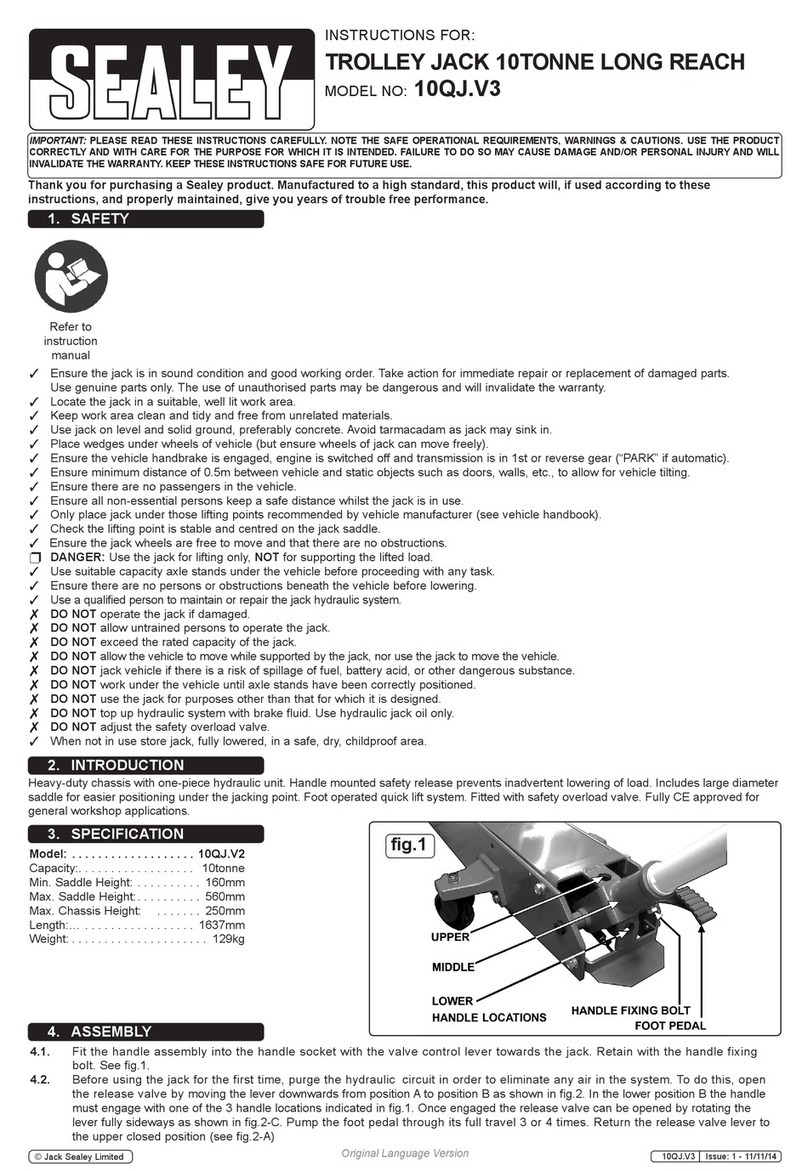

VIP 3000 POWER JACK OWNER'S INSTRUCTIONS

P/N 30826(WHITE) OR P/N 31696, 31837 (BLACK )

GENERAL SAFETY:

Read and understand the Jack installation instructions. Always block trailer wheel when using

the jack. Remove jewelry (watches, rings, etc.)

30 amp slow blow fuse

VIP Jack travel trailer

battery

Connect the lead-wire directly to the positive (+) lead

of the travel trailer's battery using a twelve (12) gage wire.

Be sure the connection is a good one.

THE 30 AMP SLO-BLO FUSE MUST BE INSTALLED

AS SHOWN.

INSTALLATION:

IMPORTANT NOTICE:

If it is necessary to change the position of the powerhead relative to the post and flange (in order to

provide clearance between powerhead and LP gas bottle or LP gas cover, or more clearance between

the lift gate and the powerhead) loosen set screws and rotate head without lifting off coupling. Retighten

set screws when head is in desired position.

H&H ENGINEERING

DIVISION OF BARKER MFG. CO.

730 E. MICHIGAN AVE. / P.O. BOX 460

BATTLE CREEK MI 49016 / (269) 965-2371

PAGE: DATE: FORM #:

REV. LETTER: ECN#: APPROVED:

1 OF 4 21 APR 08 30842

E13855

BEFORE INSTALLATION:

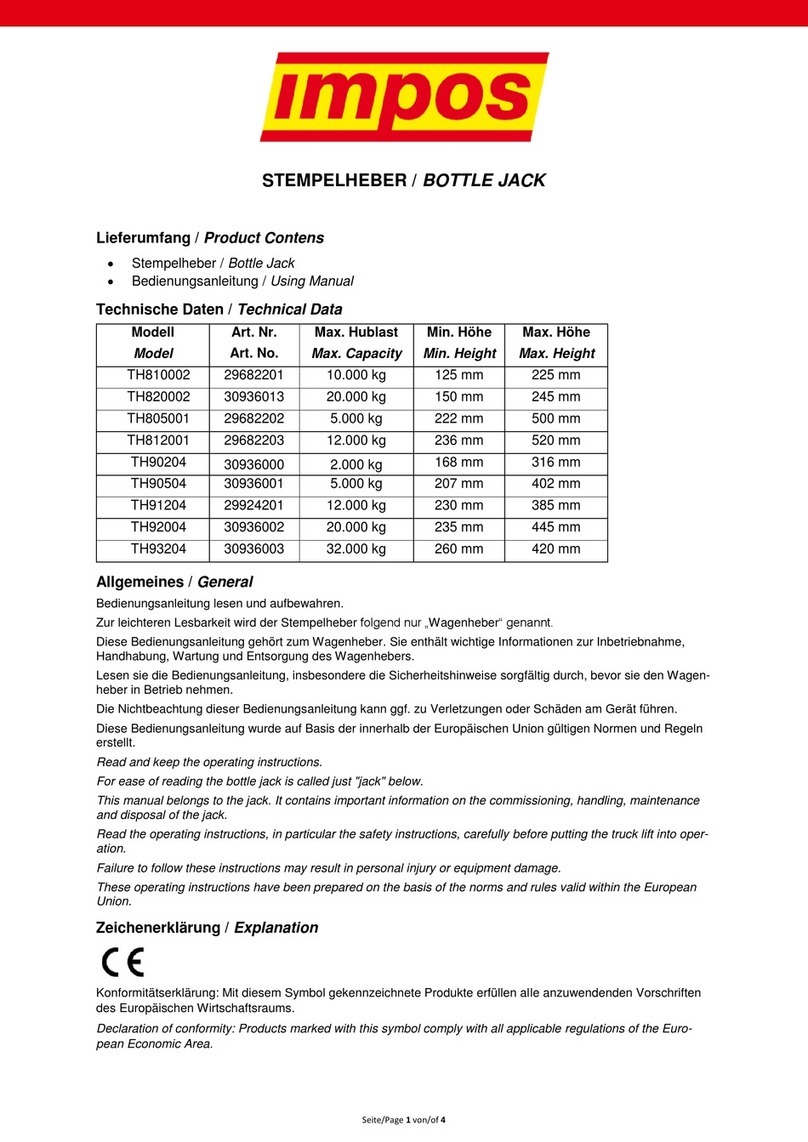

Raise your travel trailer's front end and place blocks or stabalizing jacks under the front "A" frame.

Lower the trailer until it rests securely on stabilizing jacks or blocks. Retract present jack and remove.

H&H Engineering VIP 3,000 Power Jack is designed to lift up to 3,000 pounds a full 18". It's design

also includes a night light, a build in leveling device, attached foot plate, and an emergency crank handle.

An important part of owning and using VIP Jack is being sure it is properly installed and serviced.

Remove present

jack

"A" frame coupler

IMPORTANT

To insure a good

electrical ground an

internal tooth lock-

washer must be in

place for this bolt.

Make sure powdercoat

or paint is removed from

"A" frame coupler under

washer and that tagged

hole is used.

Supplied by customer

© Copyright H&H Engineering 1989

Install Jack in hole and secure with 3 bolts & 3 internal tooth lockwashers

(bolt holes are threaded)

Attach the foot plate to VIP Jack with .50-20 bolt and .50" lockwasher

HIGH POWER

SERIES

3000

OPERATION (ELECTRIC)

REMEMBER TO KEEP HANDS AND FEET FROM

UNDER THE FOOT PLATE WHEN USING POWER JACK.

When VIP JACK reaches the end of it's travel

(either raising or lowering) the internal clutch activates

Dolly wheels are not recommended.

Warning

AVOID THE RISK OF INJURY OR DEATH TO YOURSELF AND OTHERS:

USE THE JACK FOR LIFTING THE TRAVEL TRAILER ONLY.

.NEVER GET BENEATH THE TRAILER WHEN IT IS SUPPORTED BY THE JACK.

.SUPPORT THE VEHICLE WITH THE APPROPRIATE MEANS.

.

OPERATION (MANUALLY):

H&H ENGINEERING

DIVISION OF BARKER MFG. CO.

730 E. MICHIGAN AVE. / P.O. BOX 460

BATTLE CREEK MI 49016 / (269) 965-2371 © Copyright H&H Engineering 1989

WARNING!!!

Do not use toggle switch with

crank handle in place.

Breaking this rule will cause

serious injury or death.

REMEMBER TO KEEP HANDS AND FEET OUT FROM UNDER THE FOOT PLATE WHEN

USING THE POWER JACK!!

DOLLY WHEELS ARE NOT RECOMMENDED.

BREAKING THESE RULES WILL CAUSE SERIOUS INJURY OR DEATH.

WARNING

19989

Don't risk serious injury or

death in a shearing or

squeezing accident. Keep

body, hands, and feet away.

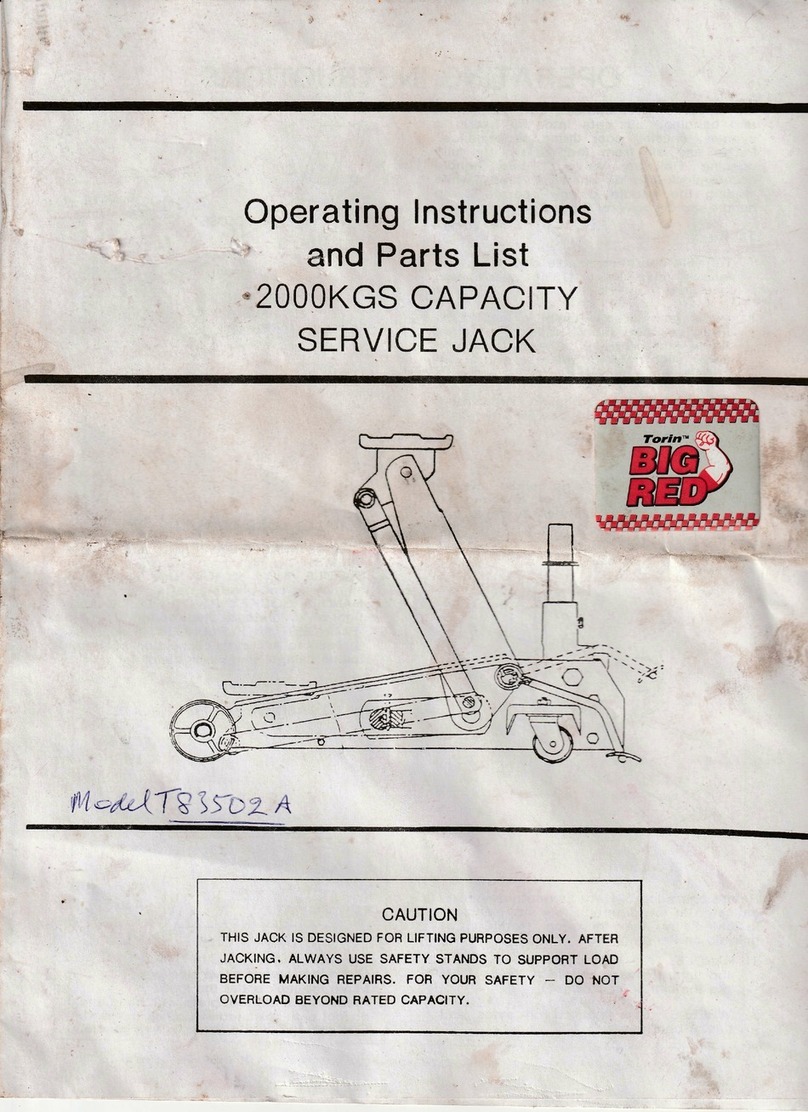

VIP 3000 POWER JACK OWNER'S INSTRUCTIONS

P/N 30826(WHITE) OR P/N 31696, 31837 (BLACK )

If an electrical failure should occur the emergency handle

may be inserted into the jack post and the jack can be

raised or lowered.

(Access can be obtained by twisting cap off.)

If the powerhead is removed crank can still be used to

raise and lower jack.

.

.

Jack will raise and

lower by this

toggle switch

The "night-light" is

controlled by this

toggle switch

UP

DOWN

PAGE: DATE: FORM #:

REVISION LETTER: ECN#: APPROVED:

2 OF 4 21 APR 08 30842

E13855

Performance

SERIES

3000

High

HIGH POWER

SERIES

3000

MAINTENANCE:

Once a year, the powerhead should be removed and a

liberal amount of grease (preferably a grease with high

melting point) applied directly to the coupling on which

the drive pin rests.

DO NOT POUR OIL into top of the jack post.

Once a year, the housing cover should be removed and

the gears inspected for proper lubrication.

Remove 4 screws and tap around edge of housing to

free cover.

DO NOT insert screw driver blade! (This may damage

mating surfaces.)

Before replacing cover, clean mating surfaces.

If lubrication is needed, use Mobilith 460 grease or

equivalent.

PAGE: DATE: FORM #:

REVISION LETTER: ECN#: APPROVED:

3 OF 4 21 APR 08 30842

E13855

H&H ENGINEERING

DIVISION OF BARKER MFG. CO.

730 E. MICHIGAN AVE. / P.O. BOX 460

BATTLE CREEK MI 49016 / (269) 965-2371

© Copyright H&H Engineering 1989

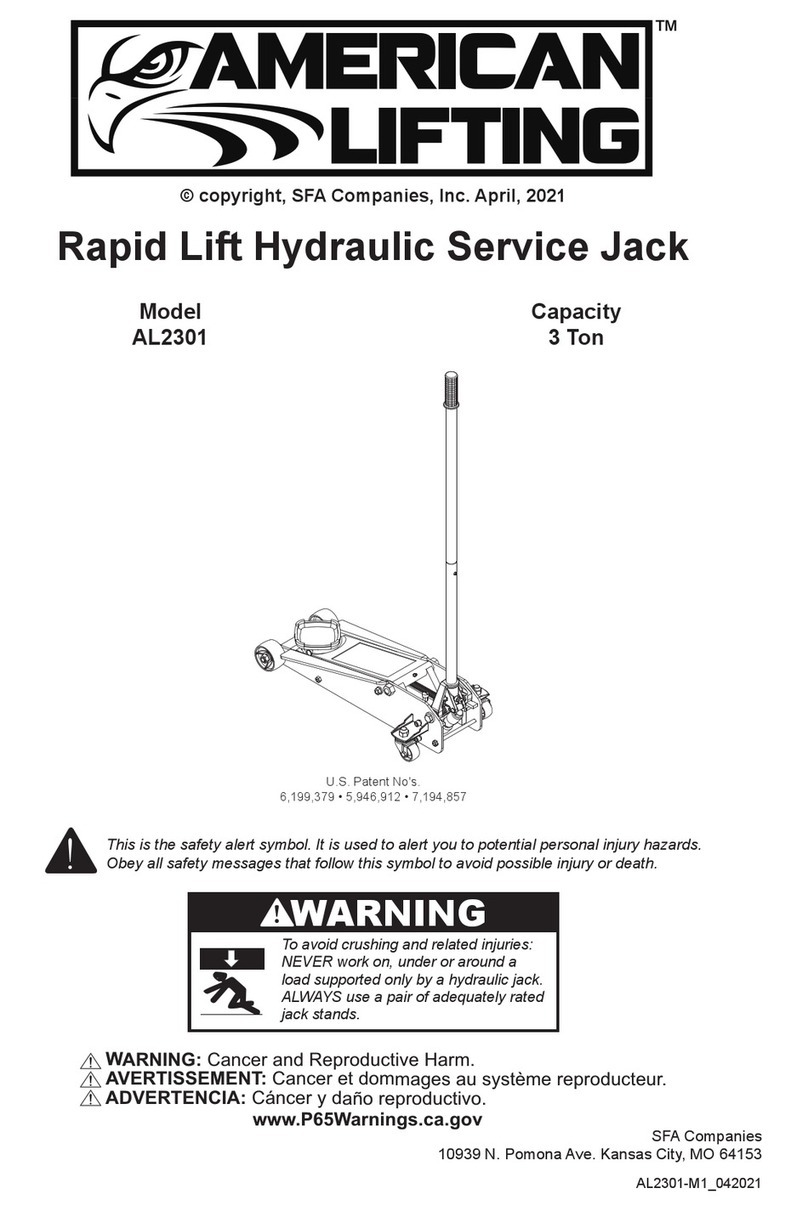

SCHEMATIC WIRING DIAGRAM

STRAP ATTACHMENT:

1. Press strap (1) onto the stud (2) at

the bottom of the cap.

2. Press the retaining ring (3) on stud

(2) snug it down against the strap (1).

3. Repeat this process (4) on the stud

found on the inside of the cover.

THIS WILL SECURE YOUR CAP.

2

31

4

COVER,

INSIDE

BOTTOM OF CAP

VIP 3000 POWER JACK OWNER'S INSTRUCTIONS

P/N 30826(WHITE) OR P/N 31696, 31837 (BLACK )

P/N 16263

MOTOR

H&H ENGINEERING

DIVISION OF BARKER MFG. CO.

730 E. MICHIGAN AVE. / P.O. BOX 460

BATTLE CREEK MI 49016 / (269) 965-2371

© Copyright H&H Engineering 1989

VIP 3000 POWER JACK OWNER'S INSTRUCTIONS

P/N 30826(WHITE) OR P/N 31696, 31837 (BLACK )

PAGE: DATE: FORM #:

REV. LETTER: ECN#: APPROVED:

4 OF 4 21 APR 08 30842

E13855

24

16

37

23

PARTS:

12

25

6

4

20

35

32

33

28

27

30

18

29

8

34

22

3

18

17

15

1

2

7

10

21

19

14

13

ITEM PART# REQ'D DESCRIPTION

1 613-0000 2 #10-32 ACORN NUT

2 27344 1 MOTOR SLEEVE (WHITE)

2 27276 1 MOTOR SLEEVE (BLACK)

3 30847 1 BASE FINISHED(WHITE)

3 30717 1 BASE FINISHED (BLACK)

4 606-0010 2 #10-16 X .75TEK SCREW (ZINC PLATED)

4 606-0008 2 #10-16 X .75TEK SCREW (BLACK HEAD)

5 16392 2 CABLE TIE

6 27338 1 COVER WHITE MACHINED

6 27259 1 COVER BLACK MACHINED

7 29541 1 MOTOR SEAL

8 611-2100 2 HEX LOCKNUT

9 736-0010 1 TOGGLE SWITCH

10 16263 1 MOTOR

11 30331 1 CAP ASSEMBLY- WHITE

11 30330 1 CAP ASSEMBLY- BLACK

12 30835 1 COVER LABEL

13 30683 1 LOCK INDICATOR LABEL

14 16434 2 HOLE PLUG

15 623-1216 1 GROOVE PIN

16 619-0003 3 LOCKWASHER INTERNAL TOOTH

17 608-0006 3 SET SCREW .313-18 X .50"

18 621-0004 2 DOWEL Ø.13" X .75

19 17808 1 WIRE CLAMP

20 736-0008 1 TOGGLE SWITCH

21 29880 1 CONNECTOR/FUSE HOLDER ASSEMBLY

22 645-0024 1 BUSHING

23 618-1002 1 LOCKWASHER .50

24 600-0011 1 HEX BOLT .50-20 X .75

25 634-0028 2 RETAINING RING

26 30839 1 TORQUE LIMITER ASSEMBLY

27 10055 1 BUSHING

28 29306 1 GASKET

29 80501 2 BUSHING

30 80208 1 WASHER, SPACER

31 28207 1 GEAR DRIVE ASSEMBLY

32 17419 1 COVER MACHINED

32 30774 1 COVER FINISHED (BLACK)

33 27257 1 BLACK WIRE ASSEMBLY

34 605-0012 4 SCREW

35 26236 1 RUBBER GROMMENT

36 27335 1 POST ASSEMBLY BLACK

36 31840 1 POST ASS'Y-ALTERED FLANGE-BLACK

37 21349 1 BASE H.T.

38 618-1009 2 #10 SPLIT LOCKWASHER

39 617-0071 2 M5 WASHER

40 30850 2 STUD #10-32

41 30313 1 LENS GASKET

42 27262 1 LENS

43 606-5001 2 SCREW #10 X .50 PHILLIPS

44 27253 1 LAMP WIRE ASS'Y

45 10017 1 POST ADAPTER

46 28259 1 CRANK HANDLE

9

Hi-Torque

Jack

HEAVY DUTY

1

38

39

38

39

5

44

45

46

43

42 41

26

36

40

40

11

31

This manual suits for next models

3

Popular Jack manuals by other brands

Norco

Norco 72450A Setup, operating, maintenance instructions

Strongway

Strongway 113239 owner's manual

Eagle Pro

Eagle Pro TL-1525P Operator's manual

Esco

Esco CYCLONE X Series operating instructions

Napa

Napa 791-6402 A Operating manual & parts list

Westward

Westward 3ZC66 Operating instructions & parts manual