Torin BigRed T83502A User manual

Other Torin Jack manuals

Torin

Torin T43004 User manual

Torin

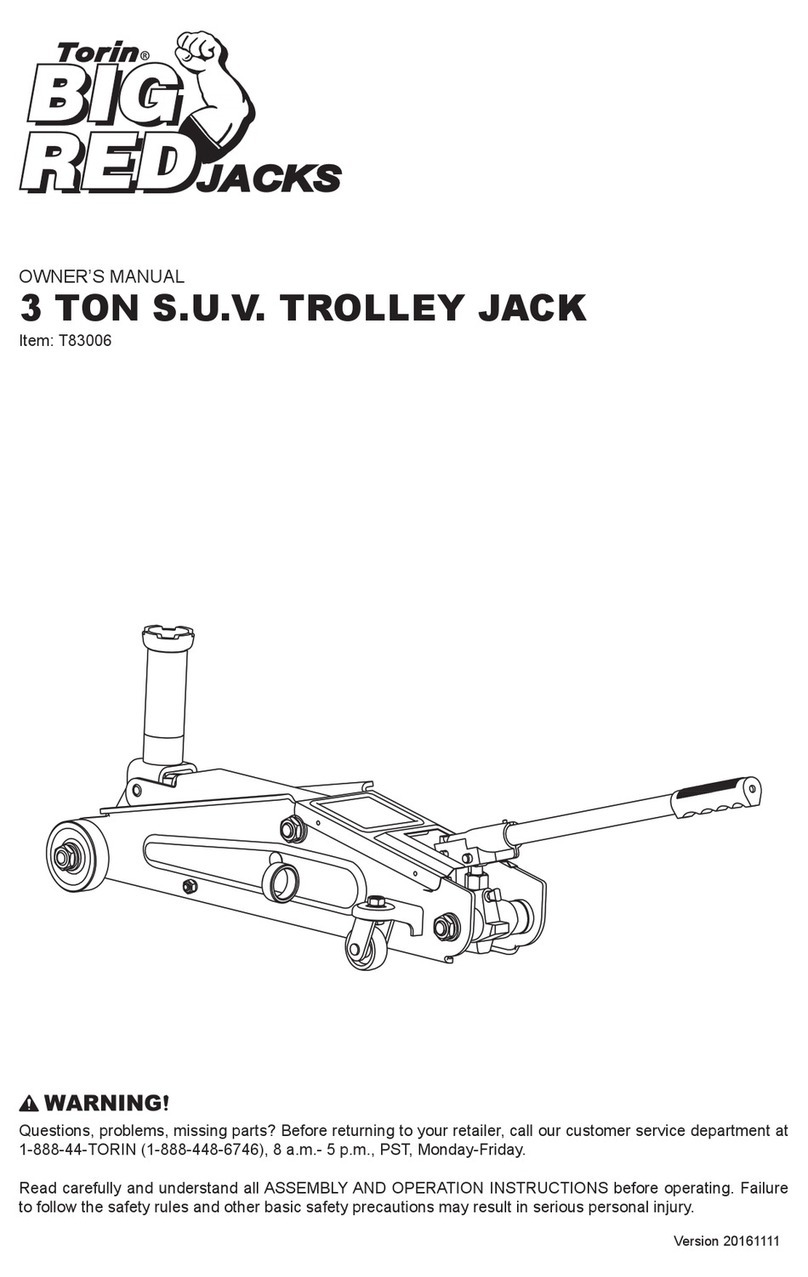

Torin BIG RED T83006 User manual

Torin

Torin BIG RED T83508 User manual

Torin

Torin BIG RED T825013S User manual

Torin

Torin TA91206 User manual

Torin

Torin T815016LT Assembly instructions

Torin

Torin T91207A User manual

Torin

Torin T92007AT Assembly instructions

Torin

Torin BIG RED T82253 User manual

Torin

Torin Big Red SJ05 User manual

Torin

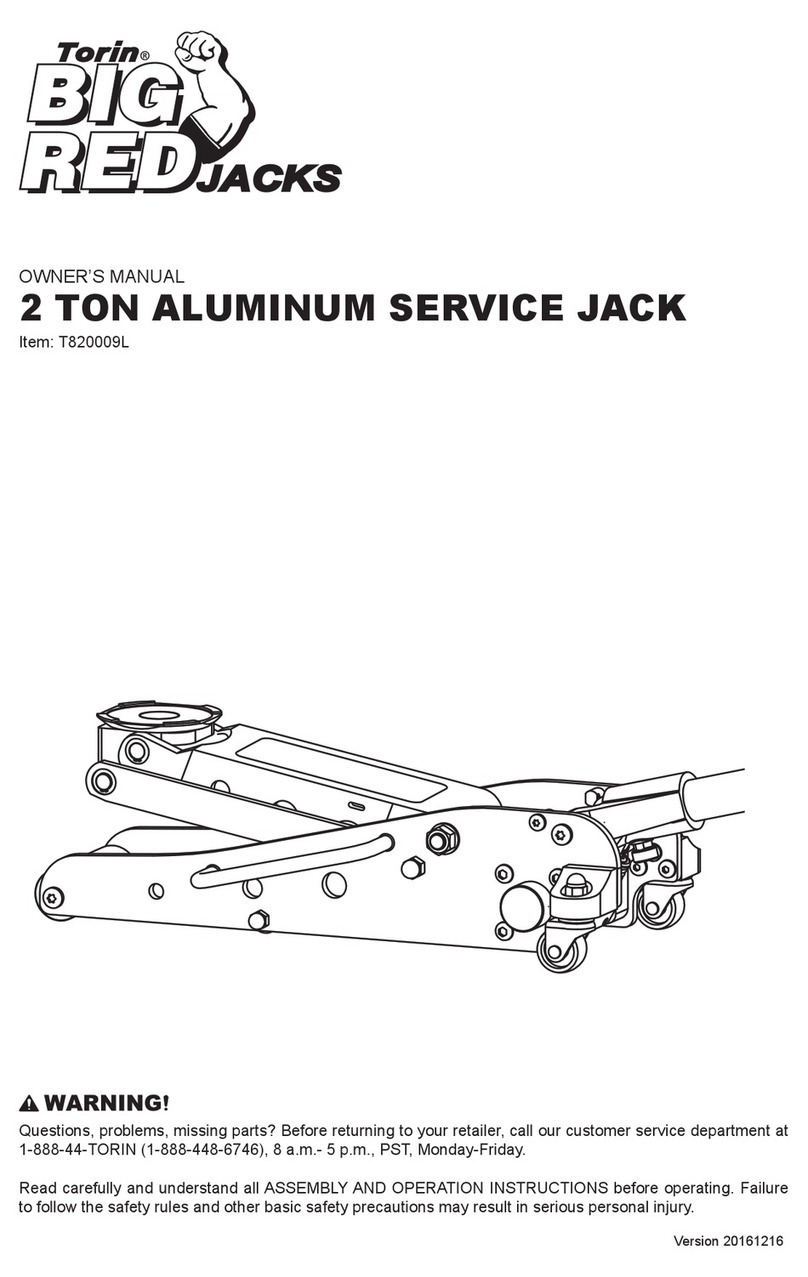

Torin BIG RED T820009L User manual

Torin

Torin BIG RED T90203 User manual

Torin

Torin BIG RED T83014 User manual

Torin

Torin BIG RED JACKS TR80303 User manual

Torin

Torin BIG RED T82002 User manual

Torin

Torin BIG RED T64017 User manual

Torin

Torin TQ22001 User manual

Torin

Torin BIG RED T815016L User manual

Torin

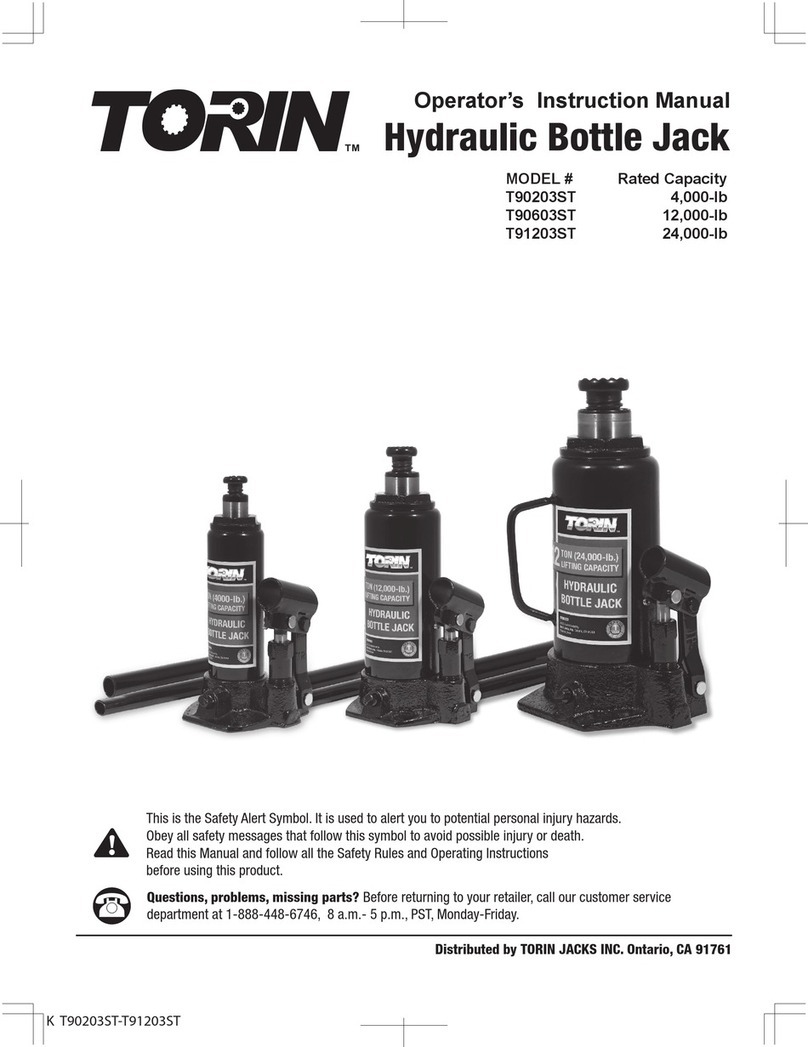

Torin T90203ST Assembly instructions

Torin

Torin BIG RED T82751 User manual

Popular Jack manuals by other brands

K Tool International

K Tool International KTI-63505A owner's manual

K Tool International

K Tool International KTI-63500A owner's manual

RHINOMOTIVE

RHINOMOTIVE HYDRAULIC CROCODILE R3101 user manual

Omega

Omega 32035 Operating instructions & parts manual

Grob

Grob HMC Basic operating instructions

CLAS

CLAS OH 5304 manual