H&H US-511 User manual

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 1 of 22

Content

> Precautions with Regard to Safety.......................................................................................2

> Name Plate ..................................................................................................................................3

> Introduction ................................................................................................................................4

> Specifications.............................................................................................................................5

> Features .......................................................................................................................................6

> Component Names ................................................................................................................... 7

> Principle of Seam Sealing....................................................................................................... 8

> Preparation for Installation..................................................................................................... 9

> Selection and Replacement of Cutter Wheel ...................................................................10

>> Selection of the cutter wheel ....................................................................................10

>> Replacement of the Cutter Wheel............................................................................10

>Operation and Controls ......................................................................................................... 11

>> Touch Screen Control................................................................................................. 11

>> Main Page ...................................................................................................................... 12

>> Parameter.......................................................................................................................13

>> Fixed Length Mode...................................................................................................... 15

>> Monitor............................................................................................................................16

>> Maintenance ..................................................................................................................17

>> Program Version .......................................................................................................... 18

>> Language .......................................................................................................................19

> Maintain...................................................................................................................................... 20

> Appendix A . Pneumatic Scheme........................................................................................21

> Appendix B . Wiring Scheme ...............................................................................................22

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 2 of 22

> Precautions with Regard to Safety

Please observe these safety tips for safe, efficient, and injury-free operation of your equipment. By

strictly following all instruction contained in this manual you will certainly obtain an excellent

performance from the use of this equipment for many years.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 3 of 22

> Name Plate

Figure 1 Name Plate

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 4 of 22

> Introduction

Thank you for your choosing of US-511 which is manufactured by H&H.

The US-511 ultrasonic rotary welding machine was specially designed for cutting and welding

different type of fabric. Various operations such as “line bonding”, anti-fray cutting, button hole

opening can be carried out using US-511.

In order to fully understand how to use this machine properly, and avoid damage to both the machine

and operating personnel, please read this manual carefully and keep it safe for future reference.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 5 of 22

> Specifications

Model : US-511

Voltage : 220 V, Single Phase

Frequency : 50/60 Hz

Power Consumption : 700 W

Compressed Air : 0.4~0.6 Mpa

Sonic Frequency : 28kHz

Overall Dimensions : 1200mm x 650mm x 1230mm (length x width x height)

Net Weight : 108 kg

Note : due to continuous improvement, specifications are subjected to change without prior

notification

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 6 of 22

> Features

Quiet ultrasonic system.

Microprocessor control with large panel touch screen operator interface.

Unique welding technique ensuring consistent welding energy control.

Precise timing control resulted in no marking, over welding and skip welding during start and stop

operation.

Excellent control in constructing curved seams.

3D seam construction.

Easy to adopt sewing machine platform.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 7 of 22

> Component Names

13

3

4

1

5 6

12

11

10

9

7

8

15 14

16

2

Figure 2 Machine parts names

1. pressure adjusting knob 9. power switch

2. cylinder 10. pre-pressure (working pressure) gauge

3. cutter wheel 11. pre-pressure (working pressure) adjustment

knob

4. lower wheel 12. pressurized pressure gauge

5. pressure pedal 13. pressurized pressure adjustment knob

6. working pedal 14. supervisor control key

7. side pedal, control cutter wheel up and down 15. USB socket

8. electric box 16. touch screen

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 8 of 22

> Principle of Seam Sealing

Ultrasonic energy is a form of physical vibration. The commonly used vibration frequencies are 20kHz,

30kHz, 35kHz and 40kHz. Different materials exhibit different behaviors under ultrasonic vibration. Synthetic

material generates internal heat under ultrasonic vibration. The US-511 machine generates vibration on the

surface of the horn. Fabric with at least 50% synthetic material is placed on the surface of the horn. A special

tool called cutter bit is pressed against the horn so that fabric between the horn and the cutter bit is exposed

to vibration. The heat generated in the fabric portion under pressure is heated up instantly and the

temperature is high enough to melt the fabric, hence resulting in an ultrasonic cut.

US-511 is engineered to careful manage this vibrating energy in order to slice fabric consistently in single

layer or multi-layer application.

During single layer operation, fabric is melted and separated resulting in a fray free edge. While during

multi-layer operation, layers of fabrics are cut but at the same time the edges of the fabrics are melted and

fused together resulting in a “weld”. This process is sometimes referred as a “cut and seal” or “line bonding”

operation.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 9 of 22

> Preparation for Installation

Installation must be carried out by authorized personnel. Follow the steps below:

1. Position the machine on a flat surface and allow at least 50cm clearance on both sides as well as

the back side, this is essential for the hot air ventilation and also to allow enough room for

maintenance personnel to carry out necessary service and maintenance.

2. Adjust the foot stand so that the machine is level and stable.

3. Loosen all packing cable ties and materials in order to free up all machine movements.

4. Connect the power plug to a suitable outlet with at least 10A capacity. Make sure grounded and

reliable.

5. Locate the air hose supplied with the machine. Connect one end to the inlet of the compressed air

water filter at the back side of the machine; connect the other end to a compressed air supply such

as air compressor or central air supply. Make sure the compressed air supply has at least 0.4Mpa (4

bar) of pressure.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 10 of 22

> Selection and Replacement of Cutter Wheel

>> Selection of the cutter wheel

According to different fabrics and process, you can choose to buy a cutter wheel with different

angle. Straight knife is 0 degree angle knife. Normally, the straight knife is easy to cut the fabric, and the

cutting surface is smooth, but have small incision fusion point. The greater opposite blade angle, the

better incision adhesion will achieve. (as shown in Figure 3).

Figure 3

>> Replacement of the Cutter Wheel

Cutter wheel is a vulnerable product. When it is difficult to cut even the pressure is increased, or fusion

point becomes very large, you should replace the cutter wheel, otherwise, high work pressure will speed up

the mold wear.

Remove the three screws which fix the wheel, then you can change the cutter wheel (shown as figure

4).

Change the position of the gasket next to the cutter wheel can move the position of the cutter wheel.

The lower wheel must be adjusted at the same time once the position of the upper cutter wheel is changed.

Otherwise it will lead to different speed in upper and lower wheel which affecting the cutting effect.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 11 of 22

fix screws

Figure 4

>Operation and Controls

>> Touch Screen Control

The 1st & 2nd pages are welcome note & program loading pages. It will show up once the

machine is powered on.

Figure 5 Greeting Figure 6 Loading

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 12 of 22

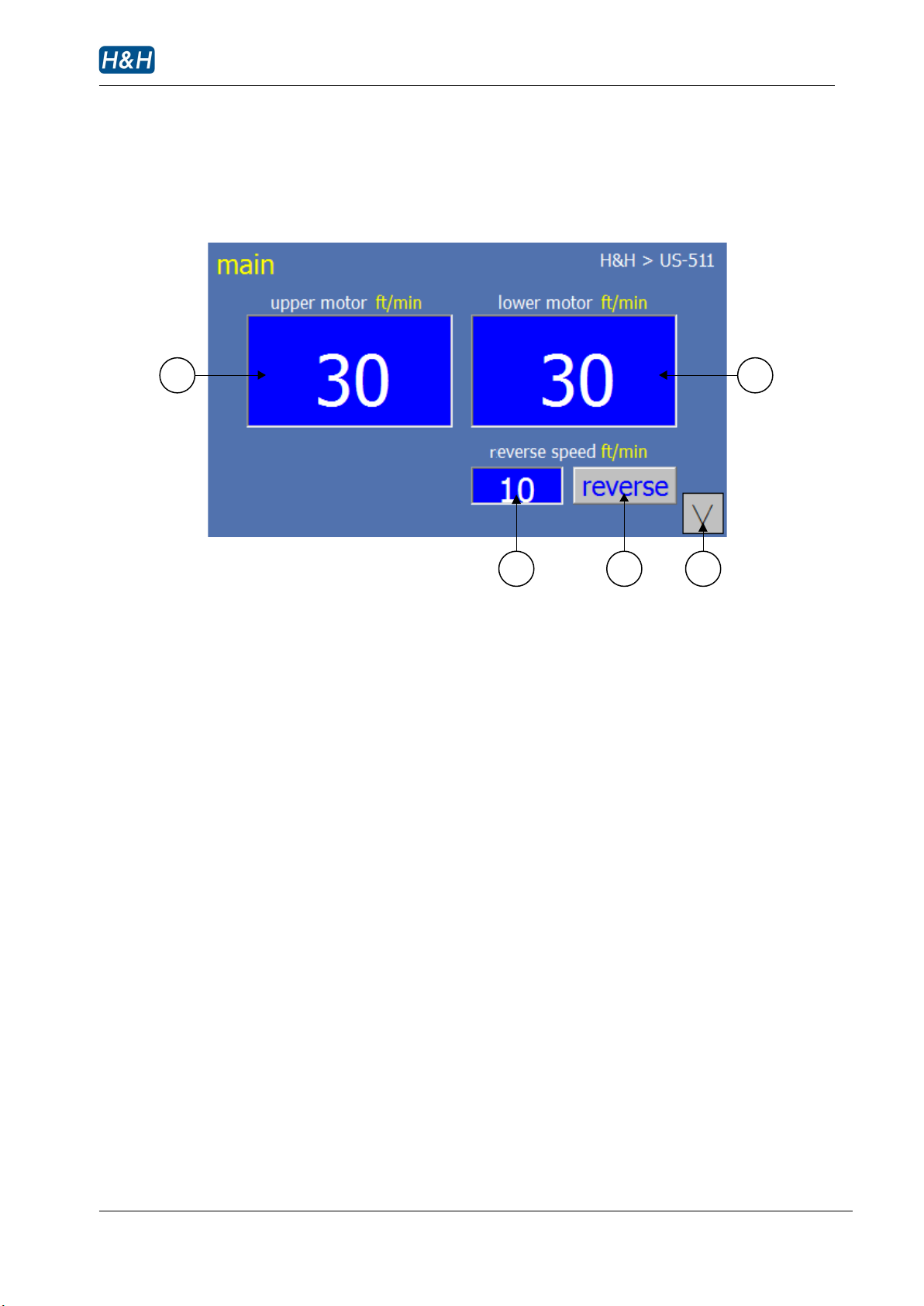

>> Main Page

The 3rd page of the panel is named “main” means it is the main control of the machine.

1

345

2

Figure 7 Main Page

1. Upper motor (cutter wheel) speed setting button & display.

2. Lower motor (lower wheel) speed setting button & display.

3. Reverse speed setting button & display.

4. Click to make the machine to reverse.

5. Turn to next page.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 13 of 22

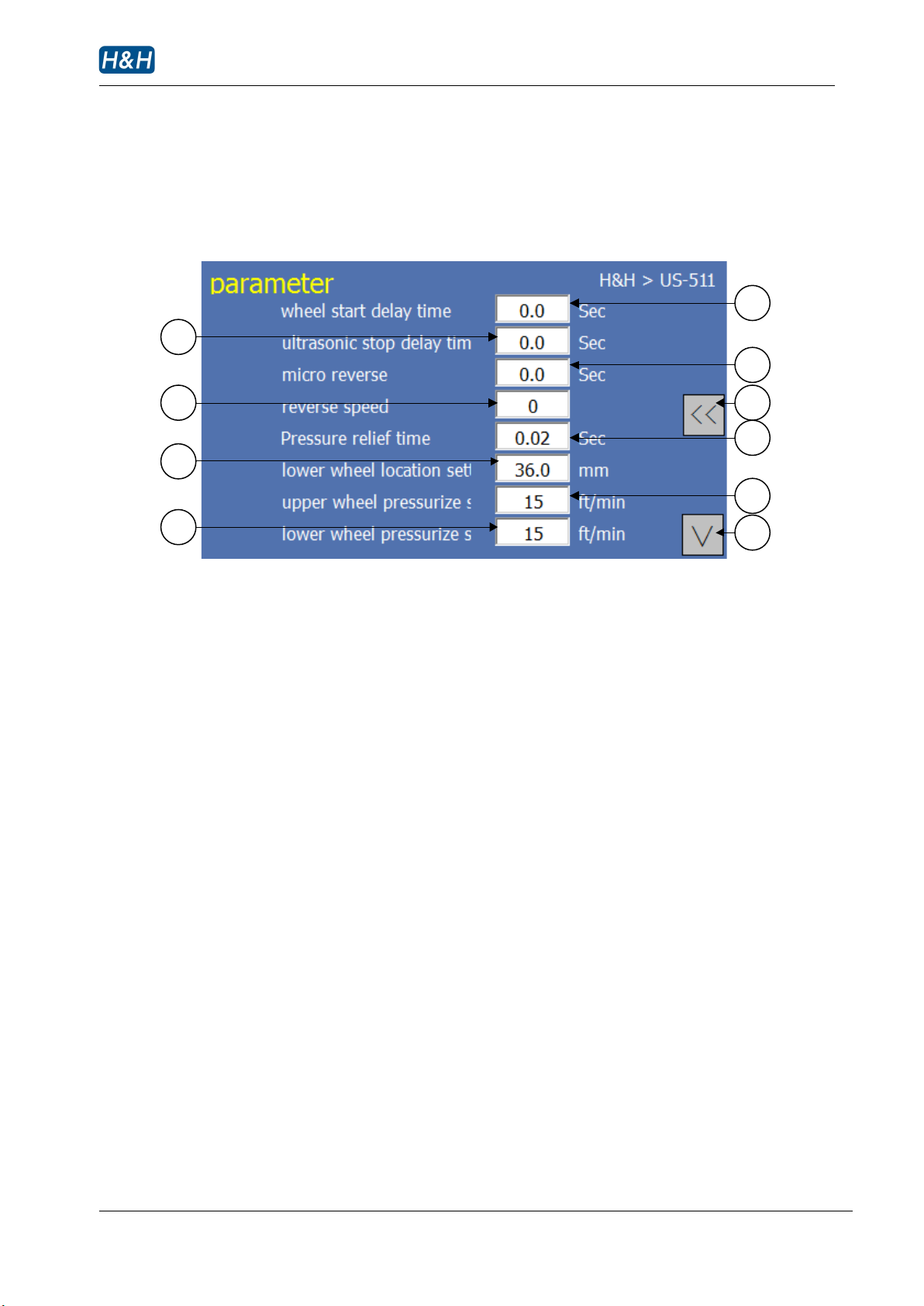

>> Parameter

The page after main page is “parameter” page, shown as figure 8.

1

2

3

5

6

8

10

4

7

9

Figure 8 Parameter Page

1. Wheel start delay time setting. The time from when the right pedal is depressed to when the

upper and lower wheels start to rotate. This setting aims to prevent poor cutting result

because the ultrasonic may not function immediately at the beginning.

2. Ultrasonic stop delay time setting. Time from when the right foot pedal is released to when

the ultrasound stops. This setting aims to prevent poor cutting result because the ultrasonic

may stop earlier than the upper and lower wheels at the end.

3. Micro reverse time setting.

4. Reverse speed setting.

5. Back to main page.

6. Pressure relief time setting. When pressing the left pedal to pressurize, the air pressure

needs to be converted from working pressure to pressurized pressure, pressure relief time

refers to the time from when the left pedal is depressed to when the working pressure relief

to zero.

7. Lower wheel location setting. The location of cutter wheel may need to be changed, the

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 14 of 22

lower wheel position must be changed at the same time. Otherwise it will lead to different

speed in cutter wheel and lower wheel which may affect the cutting effect.

8. Upper wheel pressurize speed setting. When processing fabric position such as bone

position, pressurize is needed. Then the cutter wheel working speed will change to this

speed instead of the speed set in main page during pressurizing.

9. Lower wheel pressurize speed setting. When processing fabric position such as bone

position, pressurize is needed. Then the lower wheel working speed will change to this

speed instead of the speed set in main page during pressurizing.

10. Turn to next page.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 15 of 22

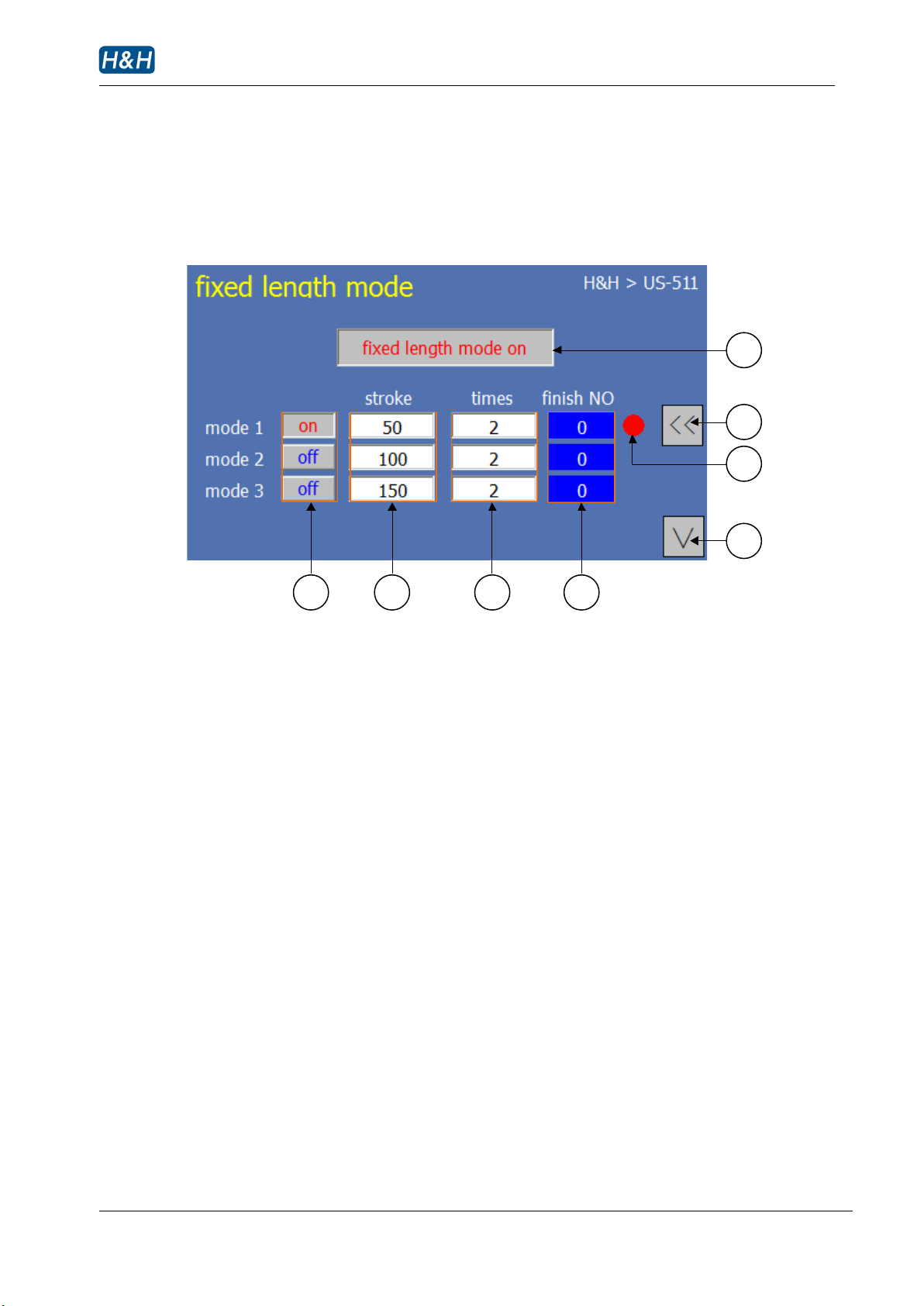

>> Fixed Length Mode

The page after parameter page is “fixed length mode” page, shown as figure 9.

1

2

4

5678

3

Figure 9 Fixed Length Page

1. Fixed length mode on/off button. When the fixed length mode is on, the mode with the status

“on” will be completed in order; when the fixed length mode is closed, the setting of fixed

length mode will not work.

2. Back to main page.

3. Ared dot indicates that the machine is performing a fixed length operation of mode 1,

and which mode the red dot follows indicates which mode is in progress.

4. Turn to next page.

5. Press to turn on/off the corresponding fixed length mode.

6. Press to preset the additional strokes of corresponding fixed length mode.

7. Press to preset the times of corresponding fixed length mode.

8. Display the number of completions of corresponding fixed length mode. When the

number is equal to the number of setting times, it will turn to zero.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 16 of 22

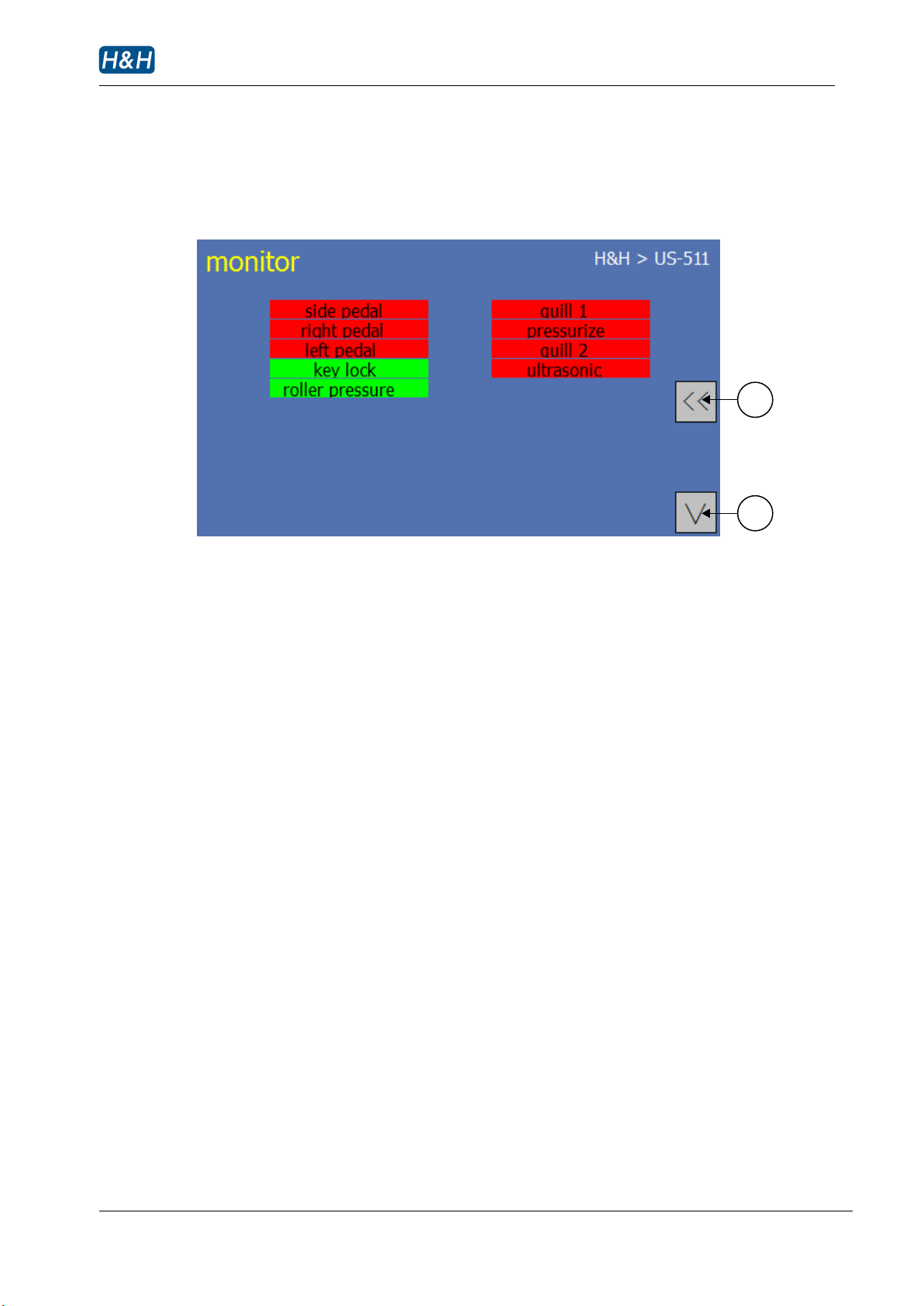

>> Monitor

The page after fixed length mode page is “monitor” page, shown as figure 10.

1

2

Figure 10 Monitor Page

1. Back to main page.

2. Turn to next page.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 17 of 22

>> Maintenance

When the supervisor control key is turned right, the page after monitor page is “maintenance” page,

shown as figure 11. When the supervisor control key is turned left, the maintenance page is hidden.

1

2

3

Figure 11 Maintenance Page-1

Figure 12 Maintenance Page-2

1. Parameter lock, different numbers represent different meanings. For details, press “?” to

view the corresponding numbers’ meanings, as shown in figure 12 “Maintenance Page-2”.

2. Back to main page.

3. Turn to next page.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 18 of 22

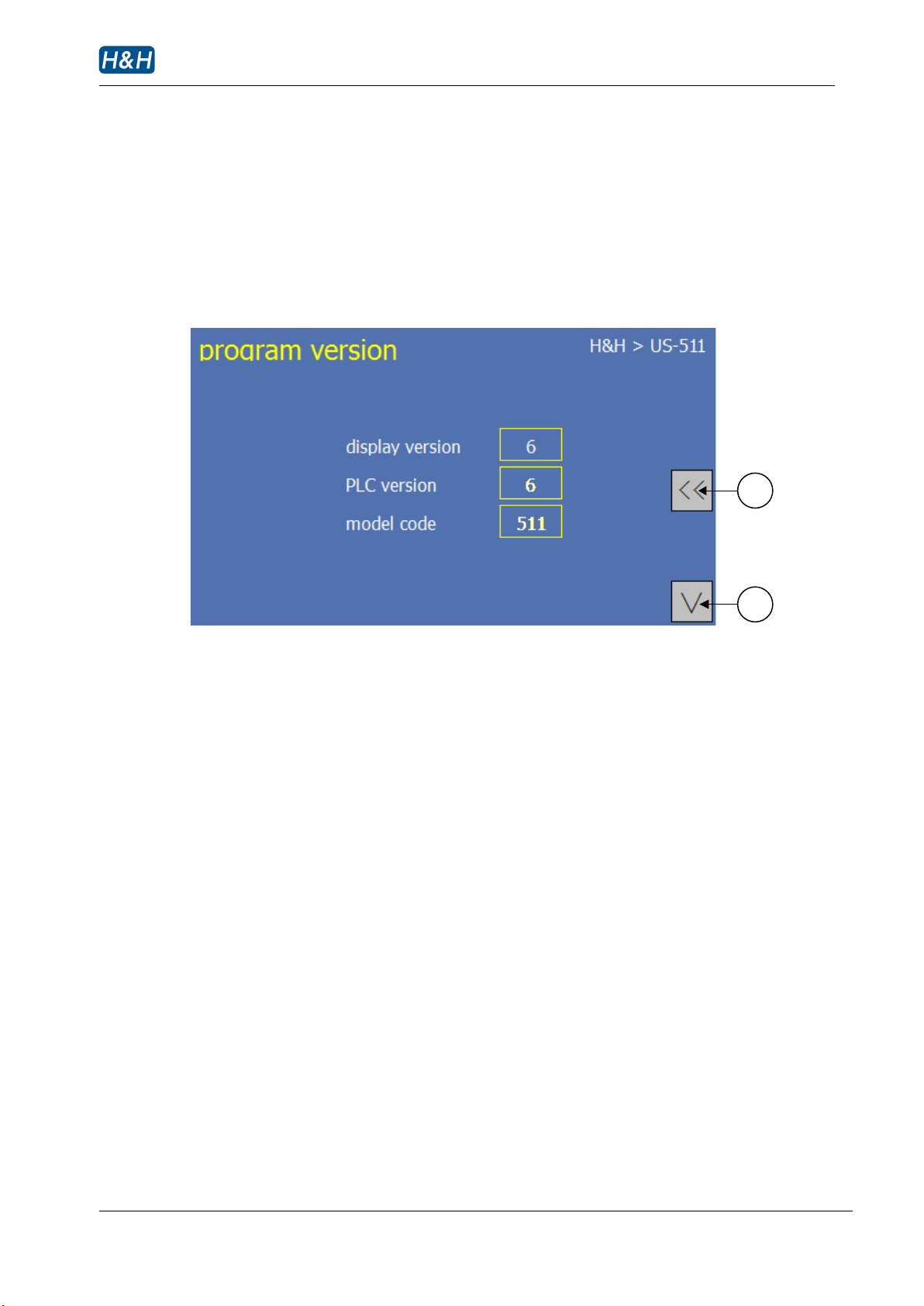

>> Program Version

When the supervisor control key is turned right, the page after maintenance page is “program version”

page, shown as figure 13. When the supervisor control key is turned left, the page after monitor page is

program version page.

1

2

Figure 13 Program Version Page

It is an information page for your reference and we can use these data for future maintenance

usage.

1. Back to main page.

2. Turn to next page.

US-511 operation manual

issue 1 20.07.27 display version 6 . plc controller version 6P. 19 of 22

>> Language

The page after program version page is “language” page, shown as figure 14.

12

Figure 14 Program Version Page

1. You can change the language between English, Chinese and Vietnamese by pressing the

button #1.

2. Turn to next page (main page).

Table of contents

Other H&H Welding System manuals

Popular Welding System manuals by other brands

GYS

GYS TRIMIG 385-4S manual

Miller Electric

Miller Electric MT-24-12-1 owner's manual

Thermal Dynamics

Thermal Dynamics MERLIN 6000 Service manual

Thermal Dynamics

Thermal Dynamics CUTMASTER 60i operating manual

Parweld

Parweld XTT-200 DC P Operator's manual

Migatronic

Migatronic PILOT 2000 instruction manual