H&H US-501 User manual

www.hh.com.hk

t = 852.24813068

f = 852.24813727

Room 1117, 11/F, Asia Trade Centre, 79 Lei Muk Road, Kwai Chung, N.T., Hong Kong

US-501 Sewfree Ultrasonic Multi-Purpose Welder

Operation Manual

is powered by

H&H Asia Group Limited

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 1 of 31

Table of Contents

Precautions Regarding to Safety

Name Plate

Introduction

Specifications

Features

Identification of Components

Front View

Rear View

Power ON/OFF Switch

Welding Head Assembly

Principle of Ultrasonic Welding

Preparation for Installation

Control Method

Touch Screen Control Panel

Foot Switch

Knee Switch

Control Menu Navigation

Start Up And Shut Down Procedures

Start Up Procedures

Shut Down Procedures

Basic Operation

Control Panel Main page

Pattern Cutting

Cutter Pressure Adjustment

Signal Feedback Monitoring

Alarm Page

Program Version

Procedures of Basic Cutting

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 2 of 31

Table of Contents (cont.)

Maintenance

Preventative

Procedures for Replacing Parts

Cutter Self Calibration

Power Meter

Trouble Shooting

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 3 of 31

> Precautions Regarding to Safety

Please observe these safety tips for a safe, efficient, and injury free operation of your equipment.

By strictly following all instructions contained in this manual you will certainly obtain an excellent

performance from the use of this equipment for many years.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 4 of 31

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 5 of 31

> Precautions Regarding to Safety (cont.)

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 6 of 31

> Name Plate

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 7 of 31

> Introduction

Thank you for choosing US-501 sewfree ultrasonic machine by H&H.

The US-501 Sewfree Ultrasonic Multi-purpose Welder was specially designed for cutting and welding

different type of fabric. Various operations such as ‘line bonding’, anti-fray cutting, button hole

opening can be carried out using US-501.

In order to fully understand how to use this machine properly, and avoid damage to both the machine

and operating personnel, please read this manual carefully and keep it safe for future reference.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 8 of 31

> Specifications

Model : US-501

Voltage : AC 220 V, single phase

Frequency : 50/60 Hz

Power Consumption : 700 W

Cutting Frequency : 1-25 stroke/sec

Sonic Frequency : 40 kHz

Horn Width : 3 mm

Overall Dimensions : 1.1 m (L) x 0.5 m (W) x 1.2 m (H)

Overall Weight : 120 kg

Note : due to continuous improvement, specifications are subjected to change without prior notification

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 9 of 31

> Features

Quiet Ultrasonic System

Microprocessor control with large panel touch screen operator interface

Unique welding technique ensuring consistent welding energy control.

Precise timing control resulted in no marking, over welding and skip welding during start and

stop operation.

Excellent control in constructing curved seams due to variable speed welding.

3D seam construction.

Variable speed welding on the same seam without affecting welding quality

Easy to adopt sewing machine platform

Memory functions to store and recall operating parameters.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 10 of 31

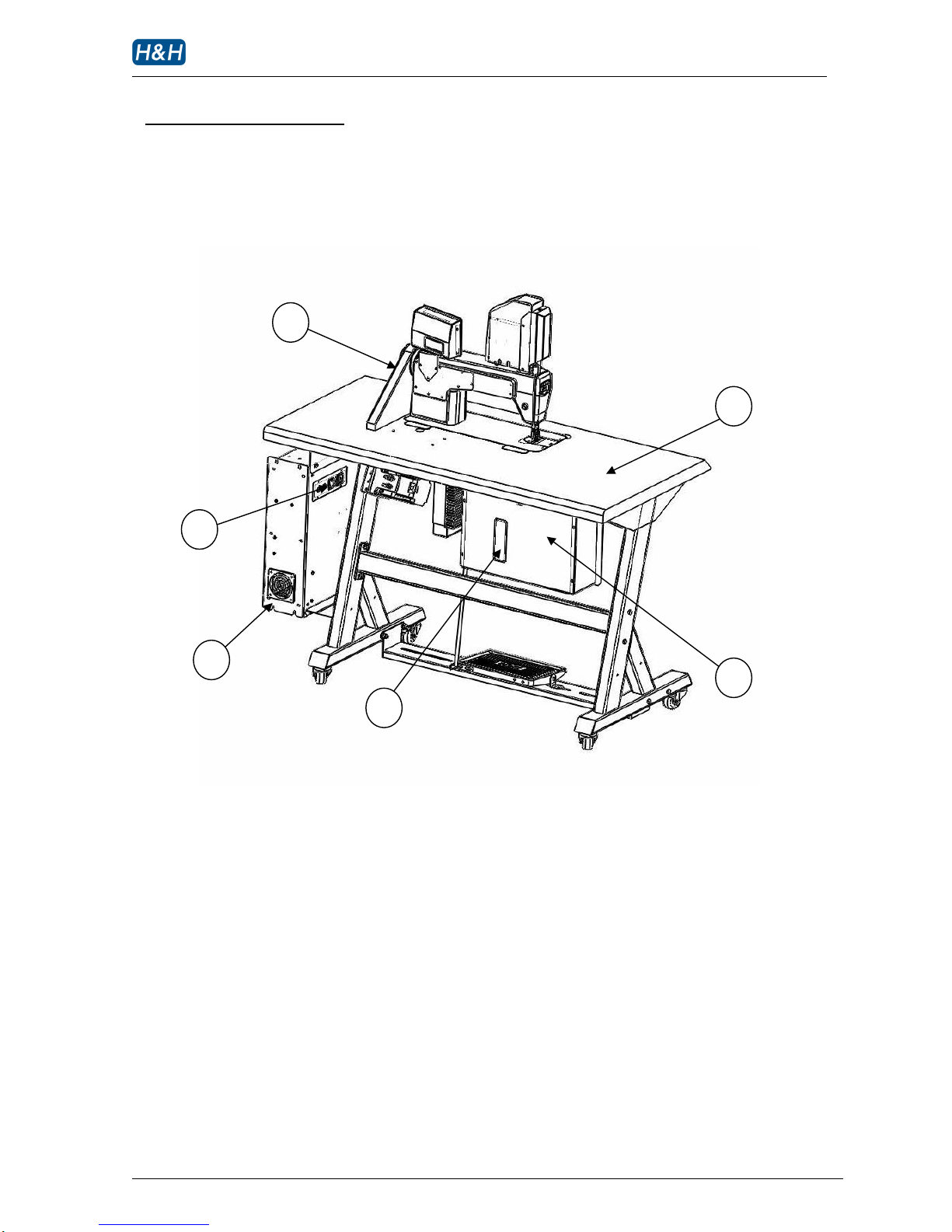

> Identification of Components

>> Front View

1. touch screen panel

2. welding head assembly

3. ultrasonic stack cover

4. foot pedal

5. knee switch

6. transporting castor

7. ultrasonic power supply

8. electronic actuator

9. sewing machine feed pitch adjusting knob

4

6

1

7

3

5

8

2

9

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 11 of 31

> Identification of Components (cont.)

>> Rear View

1. belt shroud

2. ultrasonic power supply access panel

3. cooling fan inlet

4. circuit breaker reset access hole

5. main electrical box

6. table top

1

3

2

4

5

6

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 12 of 31

> Identification of Components (cont.)

>> Power ON/OFF switch

1. power ON button

2. power OFF button

>> Welding Head Assembly

1. press foot

2. feed dog

3. bottom utility plate

4. ultrasonic horn

5. cutter bit

6. cutter mount

1

2

1

2

3

4

5

6

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 13 of 31

> Principle of Ultrasonic Welding

Ultrasonic energy is a form of physical vibration. The commonly used vibration frequencies are 20

kHz, 30 kHz, 35 kHz and 40 kHz. Different materials exhibit different behaviors under ultrasonic

vibration. Synthetic material generates internal heat under ultrasonic vibration. The US-501

machine generates vibration on the surface of the horn. Fabric with at least 50% synthetic material

is placed on the surface of the horn. A special tool called cutter bit is press against the horn so that

fabric between the horn and the cutter bit is exposed to vibration. The heat generated in the fabric

portion under pressure is heated up instantly and the temperature is high enough to melt the fabric,

hence resulting in an ultrasonic cut.

US-501 is engineered to careful manage this vibrating energy in order to slice fabric consistently in

single layer or multi-layer application.

During single layer operation, fabric is melted and separated resulting in a fray free edge. While

during multi-layer operation, layers of fabrics are cut but at the same time the edges of the fabric

are melted and fused together resulting in a ‘weld’. This process is sometimes referred as a ‘cut and

seal’or ‘line bonding’operation.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 14 of 31

> Preparation for Installation

Installation must be carried out by authorized personnel. Follow the steps below:

1. Position the machine on a flat surface and allow at least 50cm clearance on both sides as well as

the back side, this is essential to allow enough room for carrying out necessary service and

maintenance

2. Cut loose all packing cable ties and materials in order to free up all machine movements.

3. Connect the power plug to a suitable outlet with at least 15A capacity.

4. Make sure there is enough lubricate oil in the sewing machine. Oil may be drained at the time of

shipping.

5. Prepare some fabric for testing

6. The machine is now ready for operation.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 15 of 31

> Control Method

>> Touch Screen Control Panel

Almost all setting and timing control of the machines can be input from the touch screen control

panel. Use you fingertip to touch the parameter to be modified. Switch to different pages to

modify other parameters (refer to section on control menu navigation). The screen has a

protective cover to prevent the surface from damage and scratch, however, avoid using

excessive force when touching the panel. You can also change the contrast of the display so as to

obtain the best picture when viewing at a different angle.

>> Foot Switch

The foot pedal is to control the speed of the sewing machine head. Use it as the same way as an

ordinary sewing machine.

To start cutter - press forward.

To change the speed of cutting –ease back slightly from the forward position. The speed of

cutting is proportional to the pedal position in the forward

direction.

>> Knee Switch

The knee switch is to lift the press foot and stamp. When press foot is needed to be raised, apply

pressure to the knee switch. The pressure foot is lifted mechanically while the stamp is lifted up

electronically. Release the knee switch to lower the press foot and the stamp.

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 16 of 31

> Control Method (cont.)

>> Control Menu Navigation

The US-501 has a number of parameters that can be adjusted according to the operational

situations. These parameters are arranged in different menu pages on the touch screen control

panel according to their functionality. The structure of the menu page arrangement is

represented in the following diagram.

US-501 Menu Structure

H&H

main

cutter calibration

monitor

alarm

program version

pattern

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 17 of 31

> Start Up and Shut Down Procedures

Please take steps to follow the procedures described below:

Location of power ON/OFF switch

1power ON button

2power OFF button

>> Start up Procedures

Turn on the machine by pressing the green power ON button

The 1st page is welcome note will show once the machine is powered on.

2

1

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 18 of 31

> Start Up and Shut Down Procedures (cont.)

>> Start up Procedures (cont.)

The 2nd page is program loading page, it will process for several seconds and carry to the main

page.

Briefly after the power is turned on, the electronic positioning system will direct the stamp to

predefined position called home position. The stamp will use this position as a reference for all

future movement. At the home position, the positioning system has a coordinate equal to ‘0’.

During the homing process, do not interfere with the motion of the stamp as the machine may

pick up incorrect data resulting in incorrect position in the subsequence operation.

>> Shut down Procedures

WARNING !

Please follow the shut down procedures strictly to avoid damage to the ultrasonic

system.

1Always allow at least 5 seconds idle before turning off the power.

2Always allow at least 5 seconds after the shut down before turning on the machine again.

3Turn off the machine by pressing the red power OFF button

US-501 operation manual

US-501 R02 13.07.09 Display version 4, PLC version 4 P. 19 of 31

> Basic Operation

>> Control Panel Main page

Going into the operation main page. Basic parameters are needed to be set before operating the

machine. Refer to the corresponding sections for detail explanation.

1cutter assembly

2cutter pressure regulator (the number is the real time pressure, selecting range is -10 to +5)

3sonic on/off switch, ready is sonic power on while off is sonic power off

4cloth thickness selector (the number is the real time relevant speed, selecting range is 0 to 4) R1

5sonic on/off switch, ready is sonic power on while off is sonic power off

6sonic frequency

7sonic power regulator (the number is the real time power, selecting range is 1 to 10)

8sonic cooling fan speed

9cutter operation mode indicator (continuous working mode or pattern on processing mode)

10 to next page

11 sonic power consumption indicator

R1: Thicker cloth will be more difficult to cut, a slower speed will be more appropriate; conversely,

thinner cloth will be easier to cut, can apply with a faster speed

1

8

7

2

9

2

4

2

5

2

2

2

6

2

3

2

1

1

0

2

1

0

Table of contents

Other H&H Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric IDEALARC CV-305 Operator's manual

HTP

HTP Invertig 301 manual

Car-O-Liner

Car-O-Liner CM Series instruction manual

Taurus

Taurus MIG 280 PLUS Operation manual

Lincoln Electric

Lincoln Electric PRO-MIG 175 IM810 Operator's manual

Weldcote

Weldcote TIG STRIKER 200 AC Quick guide manual