UWW-301 TP

Page 2 of 38 Revision: 1.0/June-/2020

TABLE OF CONTENTS

1 INTRODUCTION ..................................................................................................................................................................................... 3

2 INSTALLATION ...................................................................................................................................................................................... 3

2.1 CONNECTIONS TO THE MAINS POWER SUPPLY .............................................................................................................................. 3

2.2 FRONT PANEL........................................................................................................................................................................................ 4

2.3 REAR PANEL .......................................................................................................................................................................................... 4

2.4 PREPARING FOR MMA WELDING ........................................................................................................................................................ 4

2.5 PREPARING FOR TIG WELDING .......................................................................................................................................................... 6

2.6 PREPARING FOR MIG/MAG WELDING ................................................................................................................................................ 7

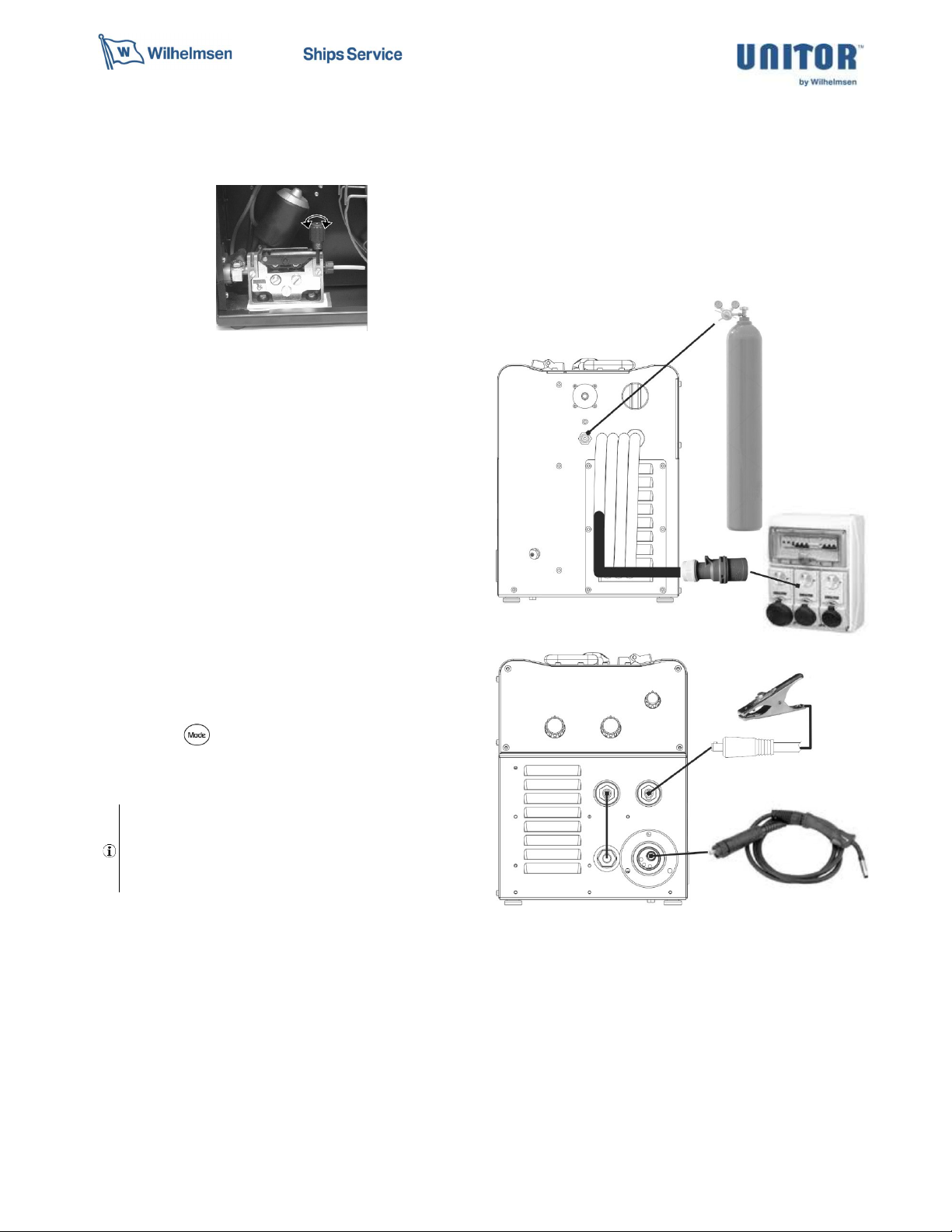

2.6.1 WIRE SPOOL POSITIONING.......................................................................................................................................................................................... 7

2.6.2 POSITIONING THE WIRE IN THE WIRE FEEDER ........................................................................................................................................................ 7

2.6.3 CONNECTIONS TO SOCKETS ...................................................................................................................................................................................... 8

3 COMMISSIONING ................................................................................................................................................................................... 9

3.1 USER INTERFACE ................................................................................................................................................................................. 9

3.2 UNIT POWER-UP.................................................................................................................................................................................. 11

3.3 RESET (LOAD FACTORY SETTINGS) ................................................................................................................................................ 11

3.4 GAS FLOW ADJUSTMENT IN MIG/MAG MODE ................................................................................................................................. 11

3.5 ALARM MANAGEMENT........................................................................................................................................................................ 12

4 WELDING SETTINGS ........................................................................................................................................................................... 13

4.1 TORCH TRIGGER MODES .................................................................................................................................................................. 13

4.2 SELECTION OF THE WELDING MODE AND TORCH TRIGGER PROCEDURE ............................................................................... 14

4.3 PARAMETERS ACTIVATION ............................................................................................................................................................... 14

4.4 WELDING PARAMETERS .................................................................................................................................................................... 15

4.5 ELECTRODE WELDING (MMA) ........................................................................................................................................................... 16

4.5.1 PARAMETERS SETTING: WELDING CURRENT ........................................................................................................................................................ 16

4.5.2 PARAMETERS SETTING: HOT-START ....................................................................................................................................................................... 16

4.5.3 PARAMETERS SETTING: ARC-FORCE ...................................................................................................................................................................... 16

4.6 DC TIG WELDING ................................................................................................................................................................................. 16

4.6.1 PARAMETERS SETTING: WELDING CURRENT ........................................................................................................................................................ 16

4.7 MIG/MAG WELDING ............................................................................................................................................................................. 17

4.7.1 PARAMETERS SETTING: MIG/MAG WELDING VOLTAGE ....................................................................................................................................... 17

4.7.2 PARAMETERS SETTING: WIRE FEED RATE ............................................................................................................................................................. 17

4.7.3 PARAMETERS SETTING: INDUCTANCE SETTING ................................................................................................................................................... 17

4.7.4 PARAMETERS SETTING: POST GAS TIME ............................................................................................................................................................... 17

4.7.5 PARAMETERS SETTING: SPEED LIMIT ..................................................................................................................................................................... 17

5 TECHNICAL DATA ............................................................................................................................................................................... 18

6 SPARE PARTS ..................................................................................................................................................................................... 20

6.1 WIRE FEED MOTOR ............................................................................................................................................................................ 22

6.2 WIRE FEEDER ROLLS ......................................................................................................................................................................... 23

7 ROUTINE MAINTENANCE ................................................................................................................................................................... 25

8 ORDERING INFORMATION BASIC ACCESSORIES .......................................................................................................................... 27

9 TIG AND WIRE TORCHES WITH SPARES ......................................................................................................................................... 28

10 ELECTRICAL DIAGRAM ...................................................................................................................................................................... 31

10.1 UWW 301 TP ......................................................................................................................................................................................... 31

11 SAFETY INSTRUCTIONS..................................................................................................................................................................... 33