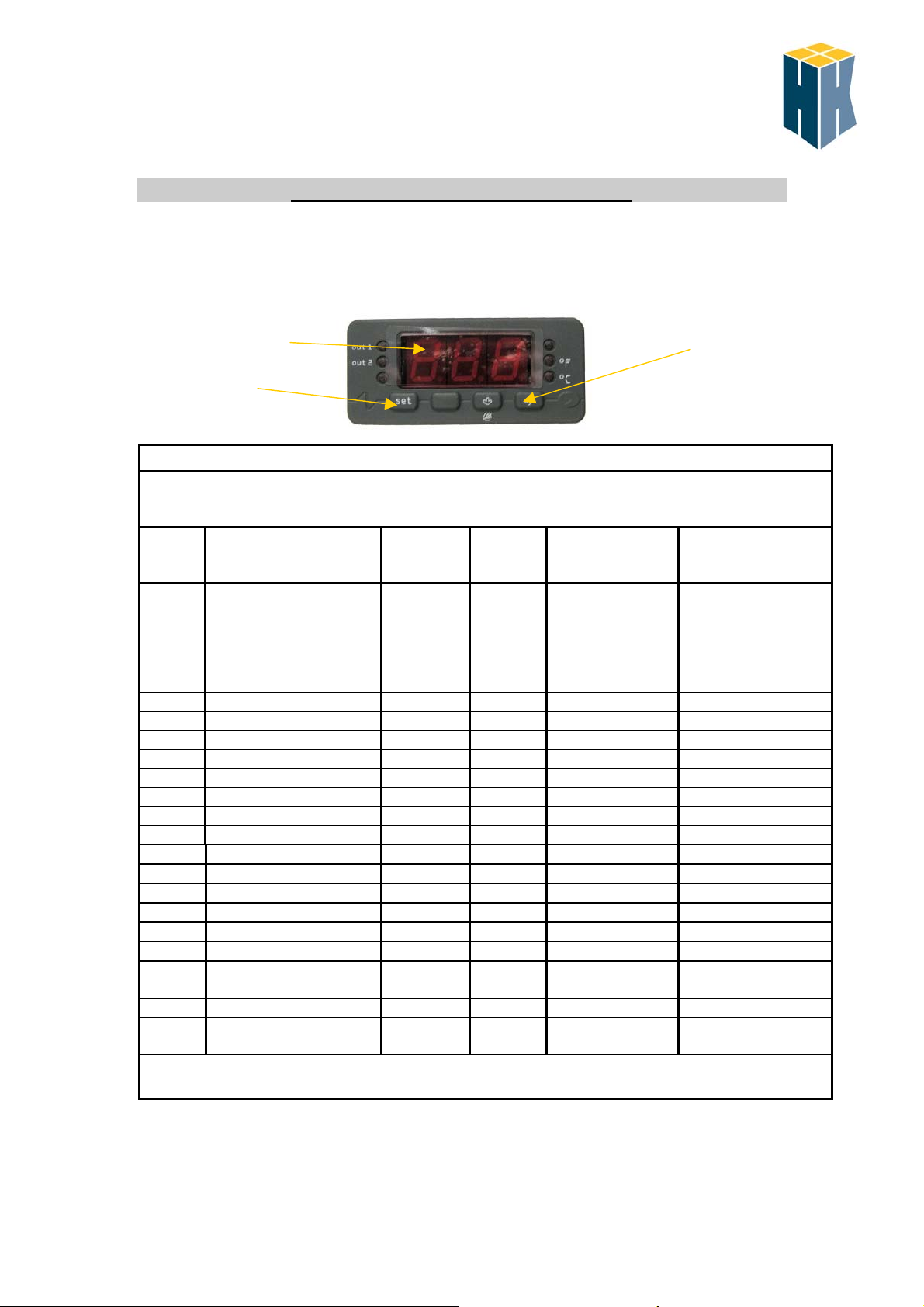

FK 401A Controller configuration

Read following instructions fully before commencing any alterations

This controller has been factory pre-set and should only be changed under instruction from H&K

Set key

Display Adjustment keys

Programming the controller to the cabinet

Commence with the unit switched on

If before all of the proceeding steps are completed no key action is detected for 60 seconds the

controller will revert back to its running mode.

Step Press Display

reads

Press Display reads Adjust display

(¿and Àkeys)

to read

1 ¿and À

simultaneously and

hold for approx. 4sec.

PA

Set

0

-19

2 ¿and À

simultaneously

hold

- / 0

Set

previous setting

2

3 ¿key / 0 Set previous setting 11

4 ¿key / 1 Set previous setting 2

5 ¿key / 2 Set previous setting 3

4 ¿key / 5 Set previous setting 1

5 ¿key / 6 Set previous setting -20

6 ¿key / 7 Set previous setting 80

7 ¿key / 8 Set previous setting 1

8 ¿key rA0 Set previous setting -2

9 ¿key rA1 Set previous setting 93

10 ¿key rA2 Set previous setting 93

11 ¿key rA3 Set previous setting 1

12 ¿key rA4 Set previous setting 0

13 ¿key rA5 Set previous setting 0

14 ¿key rb0 Set previous setting -2

15 ¿key rb1 Set previous setting 86

16 ¿key rb2 Set previous setting 86

17 ¿key rb3 Set previous setting 1

18 ¿key rb4 Set previous setting 0

19 ¿key rb5 Set previous setting 0

On completion of the proceeding steps press ¿and Àkeys simultaneously. The controller will adopt the new settings.

Issue 1:2 06.05.03 9