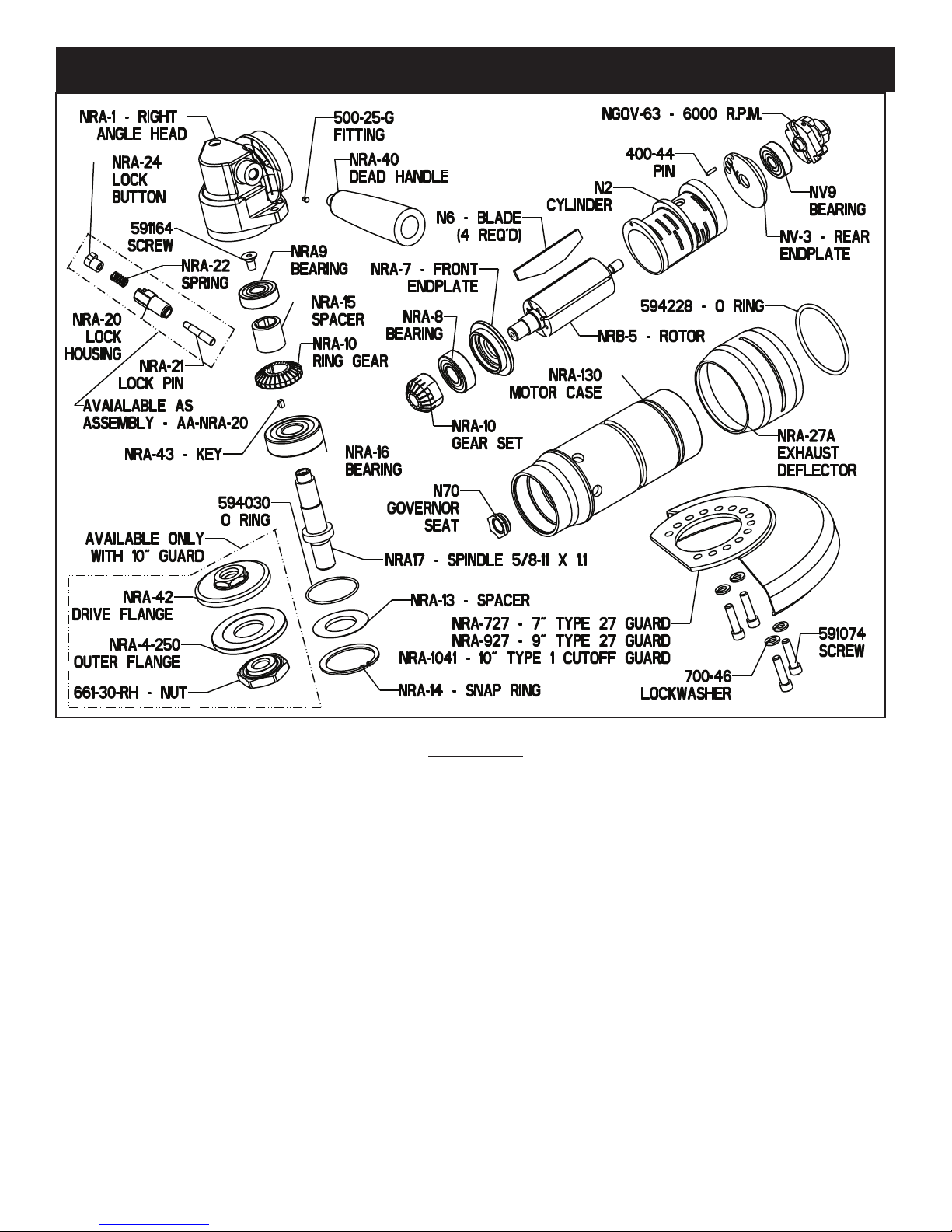

22. Support the spindle assembly vertically on a suitable drill block supporting under the rear bearing (NRA-9).

23. Press spindle out of rear bearing.

25. Slide the gear spacer (NRA-15) off rear of spindle.

26. Support the spindle assembly vertically on a suitable drill block. Press spindle through ring gear (NRA-10). Grasp key

(NRA-43) and remove from key slot.

27. Support the spindle assembly vertically on a suitable drill block. Press spindle through front bearing (NRA-16).

To check throttle valve: Remove live handle from case by removing 4 screws (550-48) and 4 lock washers (550-54).

Clamp handle in vise onto flats on the front square section. Unscrew adapter (652-48), lift out valve spring (652-51) and

plunger (652-47). Inspect o-ring (652-15) for cracks or grooves.

Assembly

1. Be sure all parts are clean and free of any abrasives.

The Motor Assembly

2. Set the front endplate (NRA-7) over the rotor (NRB-5). (The recessed side of the endplate faces the output of the motor

assembly.)

3. Support the assembly with the output end up on a suitable drill block. Press the bearing (NRA-8) onto the shaft and up

to the rotor.

4. Place brass jaws onto vise. Clamp front spindle assembly in vise vertically with output in upward direction. Clamp onto

the large outside diameter of the rotor/spindle. Thread on and tighten the pinion gear (NRA-10) with a wrench. Remove

assembly from vise.

5. With brass jaws still in vise, clamp motor assembly into vise vertically with output down. Clamp onto the sides of the

pinion gear.

6. Place four blades (N6) into blade slots of rotor. Place the cylinder (N2) over the spindle/rotor with the locating pin

pointing away from the pinion gear.

7. Place the rear endplate (NV-3) onto the end of the cylinder. (Align the smaller hole of the endplate over the pin on the

cylinder.)

8. Place the rear bearing (NV-9) over the governor stem of the spindle and drive into place with a bearing driver (1100-

814).

9. Prior to reassemble inspect governor for gouges, nicks or dents. Thread on and tighten the governor with a wrench

(Left hand threads). Remove assembly from vise.

10. Oil governor and inside of motor.

The Angle Head

11. Support the bearing (NRA-16) on a suitable drill block.

12. Press the spindle (NRA17{A}) through bearing until it bottoms on shoulder.

13. Install the key (NRA-43) into the key slot of the spindle.

14. Place the ring gear (NRA-10) over the spindle and key. Align the key with the keyway of ring gear.

15. Support the spindle assembly vertically on a suitable drill block with output toward downward direction.

16. Press the ring gear over the key and up to front bearing. (Take care not to damage the teeth of the gear.)

17. Slide spacer (NRA-15) onto spindle.

18. Support the spindle assembly vertically on a suitable drill block with output toward downward direction.

19. Press the rear bearing (404-3) onto end of spindle.

20. With brass jaws in vise, secure spindle assembly into vise vertically with output toward downward direction. Clamp

onto the threads of the angle spindle.

21. Screw in and tighten screw (591164) into end of spindle. Remove from vise.

22. Grease gear teeth with a lithium soap based, NGLI grade 2 grease.

23. Slide the spindle assembly into right angle head (NRA-1).

24. Install o-ring (594030) and spacer (NRA-13) in front of angle head. Install snap ring (NRA-14) into groove in angle

head housing.

Final Assembly

25. Install o-ring (594228) onto motor housing (NRA-130). Lightly oil o-ring. Install exhaust deflector (NRA-27A) onto

motor housing.

26.Assemble live handle. Bolt live handle onto motor housing with 4 screws (550-48) and lockwashers (550-54).

27. Secure angle head assembly in vise with motor opening toward upward direction. Clamp lightly onto the dead handle

boss.

28. Install motor assembly onto angle head. Jiggle assembly until gears align. Turning the output spindle will aid gear

mesh.

29. Slide motor housing over motor assembly and tighten onto threads of right angle head, using flats at the base of the

live handle.

40. Install spindle lock assembly (AA-NRA-20). Replace guard on tool.

Check RPM with a reliable tachometer. Tool must run at or below speed stamped on tool.