8

B. SAFETY

B.1 General rules

This manual describes the safety regulations to

be followed when using the rake. As most work-

related accidents occur due to non-compliance

with the most basic of safety regulations, it is

mandatory to read this manual before using the

rake and to follow all the instructions.

In its use the equipment must be used by

qualified adult personnel trained. The

Manufacturer cannot be held liable for

accidents due to the operator's negligence

and/or non-compliance with the safety

instructions. In this case the Manufacturer

assumes no responsibility and the warranty

is forfeited.

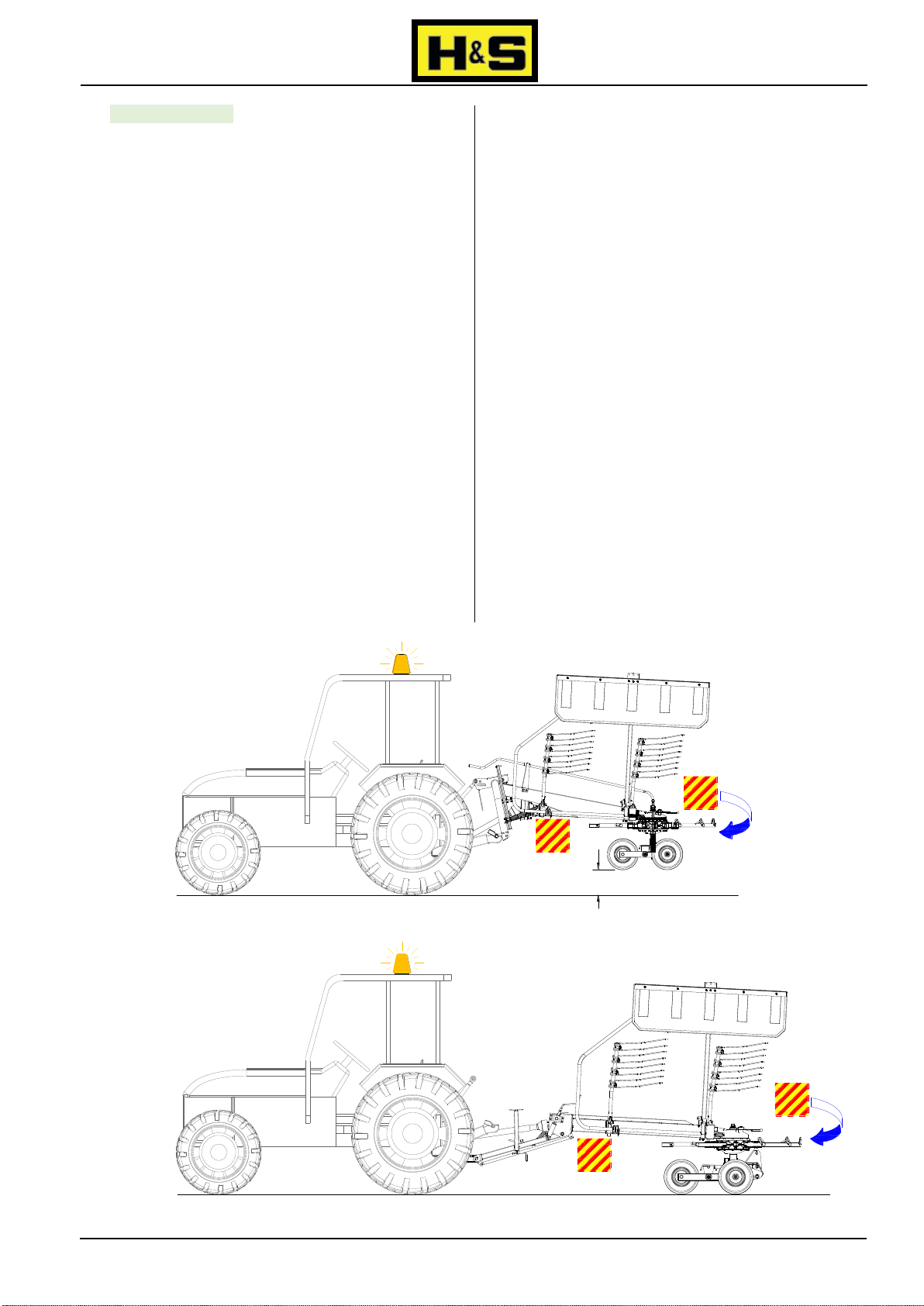

B.2 Transportation, Installation and Movement

Transport (delivery): This operation is carried

out by a vehicle with dimensions and weight

suitable to the equipment. Load and unload

operations from the vehicle can be done either

by using a lifting device or by using appropriate

ramps hooked to the vehicle:

- In the first case, the vehicle must have

suitable features and slings to support the

windrow rotary rake. Trained personnel will

carry out the operation by holding the

equipment in the indicated sections on the

frame, set for this purpose. - Note: to protect

the integrity of the frame, it is recommended

to not handle the windrow rotary rake with

metal chains, but to use approved belts.

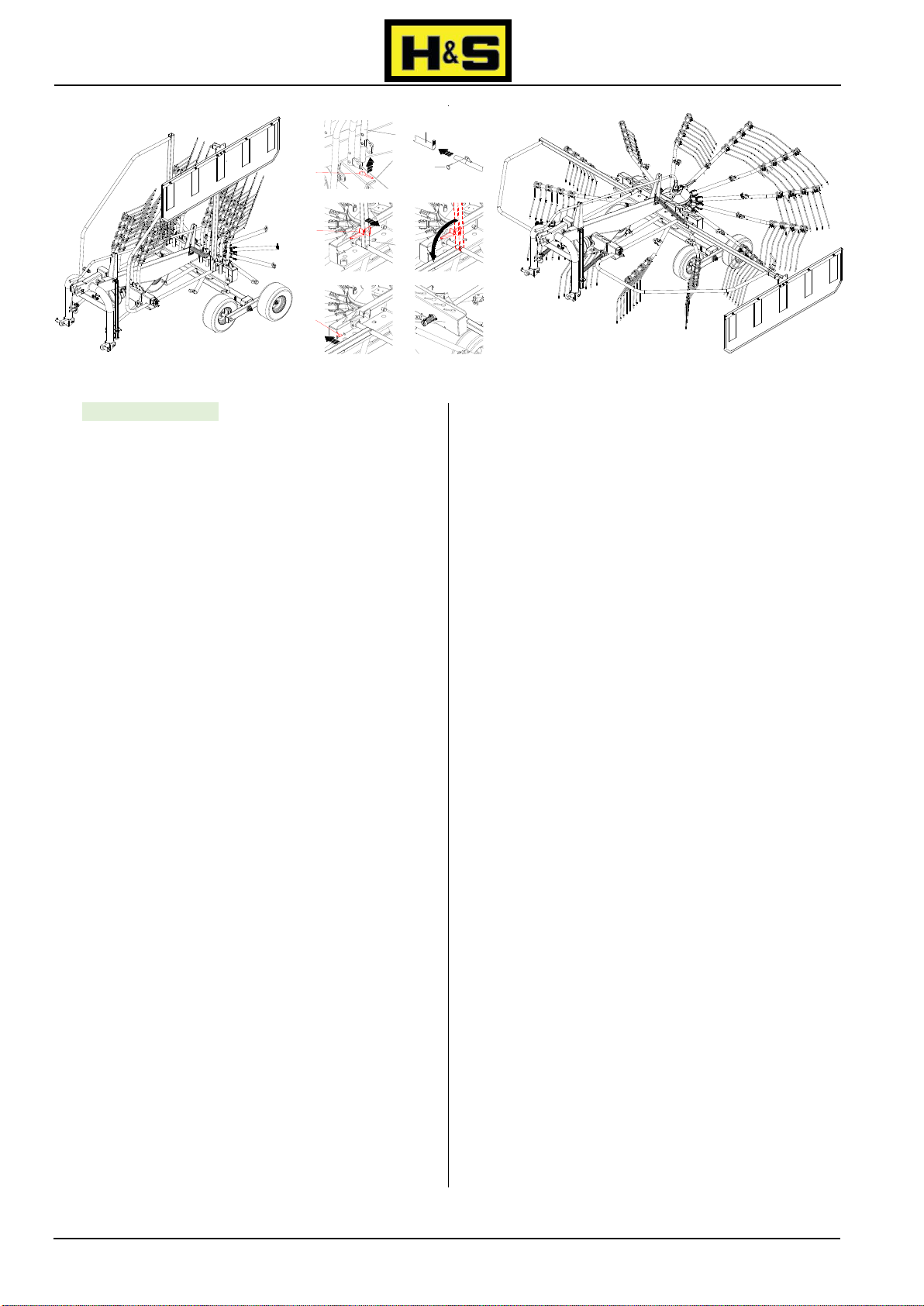

However, an adhesive label

has been applied to the

points where it should be

fixed or sling should pass

through, containing a hook

(as in figure), to highlight its

use.

- In the second case instead, by using a forklift

truck or a tractor, the equipment is pushed in

reverse to the vehicle loading surface.

In both cases, the equipment must be in

compliance with the transport configuration

(forward described) and, once placed on the

vehicle, it must be fastened to its structure and

provided with all the safety devices required for

transportation.

HAZARD

Load and unload operations always entail

dangerous situations, thus requiring the

operators in charge to be very careful.

However, it is recommended to always observe

the following precautions:

-operations must always be carried out on an

even surface and by respecting a safe

distance from escarpment or ditch borders;

-ensure ramps are robust enough to support

the windrow rotary rake, that are firmly

fastened to the vehicle structure, parallel

between them and perpendicular to the

vehicle side;

-ensure ramps are clean, without any trace of

oil, grease or ice;

-do not change direction during

ascent/descent operations of the windrow

rotary rake on ramps. Should the path must

be changed, take back the equipment and

proceed with its correction.

For long distances, the equipment is transported

dismounted inside a wooden box. Once the

components are delivered, detailed instructions

allow the Customer to easily and rapidly

assemble the windrow rotary rake. So in the

event the equipment is sold or transferred to

another user, follow the instructions in the

reverse order to dismount it.

Installation: the pull-type model windrow rotary

rake can be installed on any agricultural tractor,

provided with a tow hitch and rear auxiliary

hydraulic couplings; whereas the mounted one

can be installed on any tractor provided with rear

universal 3-point hitch and of coupling and

hydraulic lift.

IMPORTANT

The tractor must also, by law, be fitted with a

protective Roll-bar or ROPS or FOPS cabin. It is

strictly forbidden to install the equipment on

a tractor without the required protection

equipment.

However, before installing, the Customer must

consult the relative use and maintenance manual

to ensure the tractor has the necessary

requisites for the windrow rotary rake use and

function and/or is equipped with ballasts to

eliminate any unbalances that might cause its

overturn.

For instructions relating to the installation of the

windrow rotary rake and any hydraulic

connections, consult the relative paragraphs. For

information relating to the cardan shaft, follow

those attached to the accessory.