HANG 102-50 User manual

Translation of the Original Operating Instruction

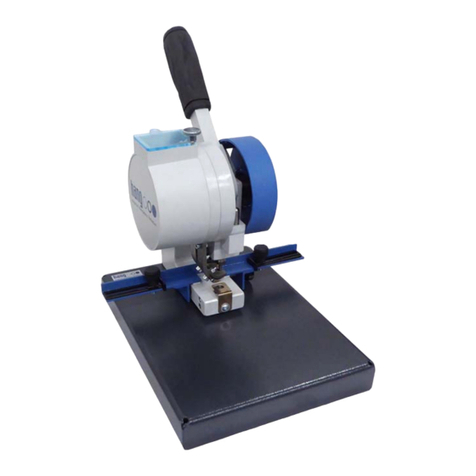

Eyeletting Machine

Model 102 - 50

Part no. 706 - 0043

Eyelet 24 / 25

For future use, take note

and keep on hand with

the Eyeleter.

Maschinen - Produktion GmbH

Jahnstraße 82

D - 73037 Göppingen

Telefon +49 (0) 7161 / 6005-0

Telefax +49 (0) 7161 / 6005-78

http://www.hang.de

https://www.oesen-hang.de

Constantin Hang Maschinen-Produktion GmbH

Hang OM Automatic eyeletting machine 102-50 1

Your help is important to us:

We endeavour to continuously improve our products and their design safety. This also includes the

operating manual.

Please inform us about any deficiencies or errors that you may notice in relation to our products.

English edition, as of February 2021

Constantin Hang, Maschinen-Produktion GmbH, Jahnstraße. 82, D-73037 Göppingen

This manual has been printed on reduced-chlorine bleached, wood-free paper.

Table of contents

2 Automatic eyeletting machine 102-50 Hang OM

1 Table of contents

1 Table of contents ......................................................................................................... 2

2 Introduction .................................................................................................................. 4

2.1 Eyeletting machine equipment .............................................................................................. 4

2.2 Explanation of symbols ......................................................................................................... 4

3 Safety regulations ........................................................................................................ 5

3.1 Basic safety regulations ........................................................................................................ 5

3.2 Intended use ......................................................................................................................... 6

3.3 Safety information ................................................................................................................. 7

3.4 Workstation ........................................................................................................................... 7

3.5 Authorised operators............................................................................................................. 7

3.6 Emergency procedures ......................................................................................................... 7

3.7 Residual risks ....................................................................................................................... 8

3.8 Protective equipment ............................................................................................................ 9

4 Transport and installation ......................................................................................... 10

4.1 Safety regulations ............................................................................................................... 10

4.2 Damage during transport .................................................................................................... 10

4.3 Interim storage .................................................................................................................... 10

4.4 Installation ........................................................................................................................... 10

5 Design and function .................................................................................................. 11

5.1 Technical data .................................................................................................................... 11

5.2 Structural design ................................................................................................................. 12

5.3 Function .............................................................................................................................. 13

5.3.1 Work procedure ............................................................................................................. 13

6 Operation .................................................................................................................... 14

6.1 Safety regulations ............................................................................................................... 14

6.2 Controls............................................................................................................................... 14

6.3 Preparation for operation .................................................................................................... 15

6.3.1 Footswitch / manual operation ...................................................................................... 15

6.3.2 Refilling with eyelets ...................................................................................................... 16

Table of contents

Hang OM Automatic eyeletting machine 102-50 3

6.4 Use during operation........................................................................................................... 16

6.4.1 Switching on .................................................................................................................. 16

6.4.2 Inserting eyelets ............................................................................................................ 16

6.4.3 Switching off .................................................................................................................. 17

6.4.4 In case of emergency .................................................................................................... 17

6.5 Changing the riveting pressure ........................................................................................... 17

6.5.1 Setup ............................................................................................................................. 18

6.6 Adjusting the stops ............................................................................................................. 21

6.6.1 Adjusting the rear stop .................................................................................................. 21

6.6.2 Adjusting the lateral stop ............................................................................................... 21

7 Maintenance ............................................................................................................... 23

7.1 Safety regulations ............................................................................................................... 23

7.2 Maintenance and inspection list .......................................................................................... 23

7.2.1 Lubrication ..................................................................................................................... 24

7.3 Cleaning the feed channel .................................................................................................. 25

8 Faults .......................................................................................................................... 26

9 Repairs ........................................................................................................................ 27

9.1 Safety regulations ............................................................................................................... 27

9.2 Tool change ........................................................................................................................ 28

9.3 Emptying storage containers .............................................................................................. 32

9.4 Changing the bristle disk .................................................................................................... 33

10 Decommissioning - packaging ................................................................................. 35

10.1 Safety regulations ............................................................................................................... 35

10.2 Preparation for storage ....................................................................................................... 35

11 Disposal ...................................................................................................................... 36

11.1 Safety regulations ............................................................................................................... 36

11.2 Procedure ........................................................................................................................... 36

12 List of images ............................................................................................................. 38

13 List of abbreviations .................................................................................................. 39

14 Glossary ..................................................................................................................... 40

15 Appendix .................................................................................................................... 41

Introduction

4 Automatic eyeletting machine 102-50 Hang OM

2 Introduction

2.1 Eyeletting machine equipment

Operating manual

Tool

Foot switch (optional)

The tool bag is included in the cardboard box which the eyeletting machine is

delivered in.

2.2 Explanation of symbols

[1] Parts numbers detailed in the images are shown in squared parenthesis. The

images can be found in the corresponding chapters. Subsequently detailed

parts which are no longer listed will be taken as read.

[7/6.3.1] In this example, component [7] is referred to in image (6.3.1).

/ – Lists are marked by means of dots or indent markings for a paragraph.

/ These symbols are used to describe actions.

This symbol is used to identify actions that are described in a different

section of the operating manual.

Arrows are used to identify automatic processes or situations that should

adjust automatically.

Safety regulations

Hang OM Automatic eyeletting machine 102-50 5

3 Safety regulations

3.1 Basic safety regulations

The eyeletting machine corresponds to the applicable safety regulations and

standards. These are listed in the Declaration of Conformity in accordance

with EC Machinery Directive 2006/42 EC.

Please also observe the national guidelines and laws as well as the accident

prevention regulations, in particular:

Electrical plants and equipment (VBG 4 in Germany)

Power tools (VBG 5 in Germany)

Riveting machines (VBG 13 in Germany)

Instruction

Individuals who are involved in the transport, installation, operation,

maintenance, repair and disposal of the eyeletting machine must be instructed

on how to perform these activities or have been trained specifically for these

activities and know the potential hazards.

We recommend that you have participation in instruction sessions confirmed

in writing by the personnel concerned. You can make use of the form in the

appendix.

Operating manual

The operating manual

is a component of the machine.

must be provided when the machine is sold or hired out.

must be stored near the machine in a location that is close to hand so it can

be used regularly until the machine is disposed of.

Faults

Never use the eyeletting machine if it is in a defective condition.

Report faults or other damage to the individual in charge immediately.

Safeguard the eyeletting machine against misuse or accidental use.

Only qualified specialists are permitted to carry out repairs.

Never bridge or bypass protective and safety equipment.

Dismantled safety equipment must

be replaced before recommissioning and

checked to ensure that it is functioning correctly.

Safety regulations

6 Automatic eyeletting machine 102-50 Hang OM

3.2 Intended use

The eyeletting machine has been designed exclusively for inserting eyelets

into unpunched paper stacks (documents / certificates).

The eyeletting machine has been designed for the domestic and

commercial sectors in accordance with EMC law.

The level of immunity to interference is too low for the industrial sector – the

machine could be destroyed.

Materials Eyelet Internal diameter of 3 mm to 6 mm

Paper

stack

Certificates ; documents ; the height of the paper stack to be

processed is based on the length of the eyelet

Any use that deviates from the conditions specified above will be considered

an improper use.

If the machine

is used incorrectly,

is incorrectly maintained or

is incorrectly operated,

the manufacturer will accept no responsibility for any resulting damage. In

this case, the user alone shall bear the risk.

Only the eyelet type for which the machine was built can be processed.

The eyelet feed with container, as well as possibly also cylinder and

punch, must be adjusted so that other eyelets can be processed.

Contact Customer Service at Hang for this purpose.

Examples of

improper use

Riveting of:

plastics,

unpunched, metallic materials and

textiles.

Safety regulations

Hang OM Automatic eyeletting machine 102-50 7

3.3 Safety information

Warning of impending danger which could lead to serious injury or death.

Caution due to an impending risk which could lead to minor injuries. This

signal word may also be used for warnings related to property damage.

For a possible situation which could lead to damage to the product or

property in its vicinity.

Indicates usage notes and other useful information.

3.4 Workstation

The worktop and chair must meet ergonomic requirements.

Subject to the scope of the work, the operator sits or stands freely in front of

the eyeletting machine when loading the paper stack.

3.5 Authorised operators

Operation:

Maintenance:

Repair:

Mechanical system

Electrical system

Disposal:

all individuals over the age of 16

Skilled workers (e.g. industrial mechanics)

Skilled workers (e.g. industrial mechanics)

Electrical specialists (e.g. industrial electricians)

Skilled workers

3.6 Emergency procedures

Press the toggle switch [7/6.2.1] and remove the mains plug.

Only ABC extinguishers may be used to extinguish fires involving the

eyeletting machine.

Safety regulations

8 Automatic eyeletting machine 102-50 Hang OM

3.7 Residual risks

The eyeletting machine is equipped with protective equipment.

However, the following residual risks are inevitable:

Image 3.7.1 Residual risks

Risk of crushing fingers with the tool.

Only ever operate the eyeletting machine when the protective hood is

completely closed [2].

Never manipulate the safety limit switch [1].

Risk of crushing fingers beneath the falling protective hood.

Close the protective hood [2] in such a way that your fingers cannot

become trapped in the housing.

Risk to life due to electric shock when carrying out repairs on switches,

cables or when the protective hood is open [3].

Prior to performing repair work, set the toggle switch to "OFF" and remove

the mains plug.

These activities may be performed by a skilled electrician only.

Safety regulations

Hang OM Automatic eyeletting machine 102-50 9

3.8 Protective equipment

Image 3.8.1 Protective equipment

Pos. Protective

equipment

Function Inspection

1 Safety limit

switch

Prevents the gear motor from

starting up when the

protective hood is open.

If the protective hood is

opened, this causes the

eyeletting machine to stop

immediately.

Weekly functional inspection

- Must be screwed down

tightly at all times

2 Protective hood Prevents access to the

danger zone

Visual inspection

- Must be closed at all

times

3 Proximity

switch

Switches the gear motor off

after each work cycle.

Self-checking

- Does not stop in the

event of a defect

- Overruns the stopping

point (continuous

operation)

4 Warning sign “Danger of death from high

voltage!”

Visual inspection

- Must be present

5 Cover plate Prevents life-threatening

contact between live parts.

Visual inspection

- Must be screwed down

tightly

Transport and installation

10 Automatic eyeletting machine 102-50 Hang OM

4 Transport and installation

4.1 Safety regulations

Risk of falling

This can result in serious injuries.

Please note the warnings on the overpack

Carry out all the tasks taking into account the "Safety regulations"

chapter.

Always use suitable transport equipment.

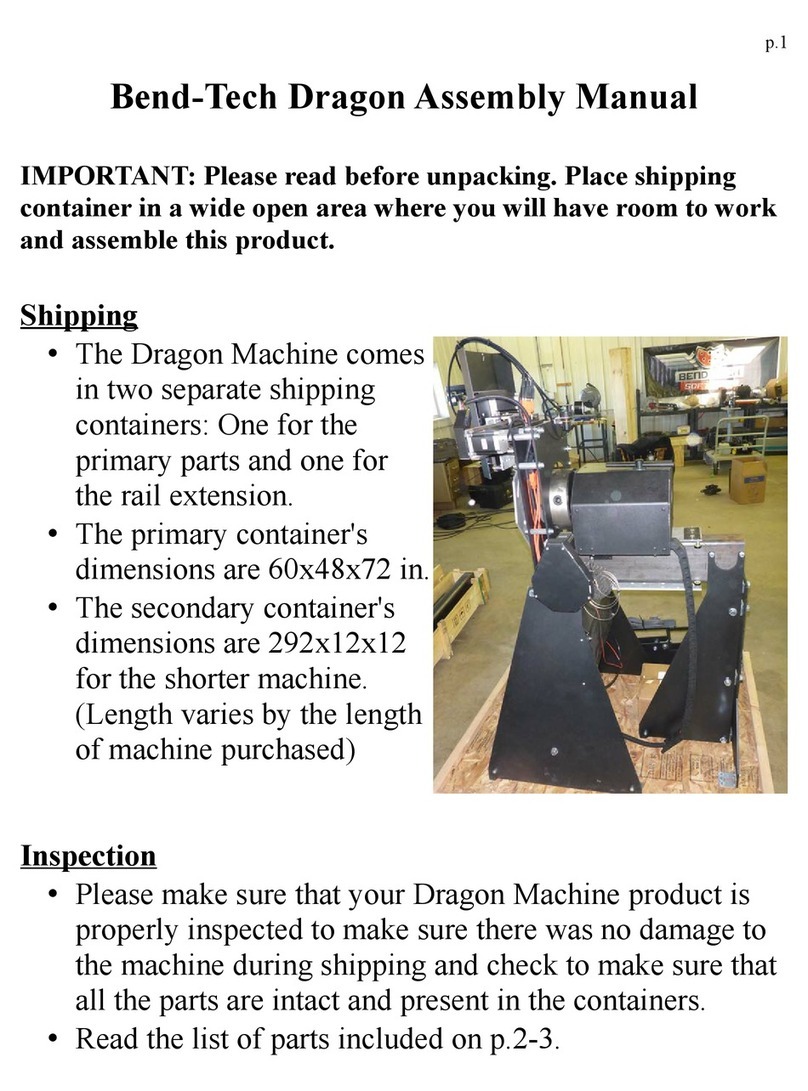

4.2 Damage during transport

Check the cardboard box for external damage.

Open the cardboard box.

Check that the delivery is complete and undamaged, see the section

“Equipment” in the “Introduction” chapter regarding this.

If it is apparent that there is damage due to transport or the delivery is

incomplete, report this to the forwarder or Hang immediately.

4.3 Interim storage

If the eyeletting machine has to be stored for an intermediate period, this

should preferably be done in the original packaging. The following points apply

to the storage space:

Store only in dry, indoor rooms.

Observe the chapter “Design and function - technical data”.

4.4 Installation

First of all, carefully read the chapter “Safety information” and “Operation”

of the operating manual.

Place the eyeletting machine on a table or worktop.

The distance between the eyeletting machine and the mains socket

must not exceed 2 m.

There must be enough space at the side to store the documents.

Design and function

Hang OM Automatic eyeletting machine 102-50 11

5 Design and function

5.1 Technical data

General data

Space requirement L x W x H 500 mm x 540 mm x 355 mm

Working height Dependent on the table height

Weight 36 kg

Cycle time 0.5 s

Riveting pressure max. 0.2 t

Work area

Internal diameter of eyelet 3 mm to 6 mm

Paper stack thickness Depends on length of eyelet, however, max.

35 sheets (80 g/m²)

Radius max. 60 mm

Power supply

Mains voltage 230 V

Frequency 50 Hz

Power consumption 200 W

Ambient conditions

Storage temperature -5 C° to +55 C°

Operating temperature +5 C° to +40 C°

Installation site Office premises protected against dew point,

free of dust, horizontal and even

Working height Min. 750 mm

Environmental impact

Sound pressure level 71 dB(A) peak value as defined in EN CEN TC

198 WG 3 N 14 DEF - J.11.6 - KL 3

Design and function

12 Automatic eyeletting machine 102-50 Hang OM

5.2 Structural design

Image 5.2.1 Structural design of the eyeletting machine

Pos. Structural component Function

1 Table surface Placement area for the paper stack to be punched

2 Handles Attachment points for transportation without packing

3 Feeding device Automatic feeding of eyelets

4 Protective hood Guard

5 Gear motor (hidden) Drives the eyeletting machine

6 Electrical system (switch box) Controls the sequence of operations

7 Eyeletting tool Takes up the eyelet and rivets the paper stack

8 Rear stop Holds the paper stack in place

9 Lateral stop Holds the paper stack in place

Design and function

Hang OM Automatic eyeletting machine 102-50 13

5.3 Function

The eyelets are held in the storage container of the feeding device [3/5.2.1].

This moves the eyelets out of the storage container in the correct position

and into the feed channel. The eyelets are buffered in the feed channel and

then fed to the eyeletting tool.

The gear motor drives the crank handle which, together with the rod, moves

the lever arm up and down.

The lever arm is equipped with a strap and a gear segment.

The strap transfers the force to the cylinder. At the other end of the cylinder

is the upper punch with catch pin which presses in and rivets the eyelet.

5.3.1 Work procedure

The riveting process creates a non-detachable, frictional, load-bearing

connection between the parts being joined (e.g. paper stack) by

reshaping the eyelet.

Reshaping is carried out by pressing the tool onto the eyelet.

The upper punch introduces the eyelet and cuts through the paper stack.

The lower punch reshapes the lower end of the eyelet (see image

below). The upper punch moves back and releases the eyelet

connection.

Image 5.3.1 Eyelet connection

1 Upper punch 4 Eyelet

2 Lower punch 5 Paper stack

3 Catch pin

Operation

14 Automatic eyeletting machine 102-50 Hang OM

6 Operation

6.1 Safety regulations

Check all of the safety equipment prior to initial commissioning.

The eyeletting machine may only be operated by trained, instructed

persons over the age of 16.

Carry out a test run after each change to the settings.

Carry out all the tasks taking into account the "Safety regulations"

described in chapter 2.

6.2 Controls

Image 6.2.1 Controls

Pos. Control Function

1 Lateral stop Positions the paper stack for eye punching

2 Rear stop Positions the paper stack for eye punching

3 Protective hood

(pivoting)

Safeguards the hazard zone

4 Cover

5 Palm button (fuse) Protects the motor against an overload

6 Pushbutton Triggers a work cycle

7 Toggle switch "ON" and "OFF" switch

Operation

Hang OM Automatic eyeletting machine 102-50 15

6.3 Preparation for operation

Plug the eyeletting machine's mains plug into the socket.

Fold the protective hood [3/6.2.1] up.

Adjust the rear and lateral stop [1./6.2.1] [2/6.2.1] in such a way that the

document is punched at the correct position.

6.3.1 Foot switch / manual operation

If you are operating the eyeletting machine without a foot switch, you must

connect the jumper [1] to the plug coupling [2] of the foot switch.

Image 6.3.1 Jumper for manual mode

Operation

16 Automatic eyeletting machine 102-50 Hang OM

6.3.2 Refilling with eyelets

Ensure that there are eyelets available in the storage container at all times.

Only fill up with eyelets up to the bottom edge of the container axis.

Fold the protective hood [3/6.2.1] up.

Remove the knurled screw [2] and slide the cover plate [1] to the side.

Fill the storage containers [3] no further than the container axis. Always

use the specified eyelets.

Close the filling port using the cover plate [1] and lock the cover plate with

the knurled screw [2].

Fold the protective hood [3/6.2.1] down.

Image 6.3.2 Filling port for eyelet

6.4 Use during operation

6.4.1 Switching on

Set the toggle switch [7/6.2.1] to "ON".

The control lamp in the toggle switch lights up.

6.4.2 Inserting eyelets

Push the documents to be eyeletted against the stops [1/6.2.1] [2/6.2.1].

Initiate the eyeletting process by pressing the pushbutton or the foot switch

(optional).

A work cycle takes place automatically.

Operation

Hang OM Automatic eyeletting machine 102-50 17

6.4.3 Switching off

Wait until the eyeletting machine has completed the operating cycle.

Set the toggle switch [7/6.2.1] to "OFF".

“Switching off" as described above is sufficient for breaks, the end of the

working day, weekends, and interruptions of work lasting up to a week.

Pull the mains plug out of the mains outlet in the event of longer work

interruptions.

6.4.4 In case of emergency

Press the toggle switch [7/6.2.1] (e.g. in an "emergency stop situation" or

during set-up).

The motor remains in an indefinite position.

Press the pushbutton before starting work after set-up or fault removal.

The eyeletting machine moves to its home position.

6.5 Changing the riveting pressure

Test the eye punch (as you would when “Introducing eyelets”).

If the pressure exerted by the punch is too high or too low, it will need to be

recalibrated.

Danger from operational eyeletting machine.

Risk of hand injuries.

Set the toggle switch to "OFF” before commencing work.

Secure the eyeletting machine against restarting

(e.g. remove the mains plug).

Operation

18 Automatic eyeletting machine 102-50 Hang OM

6.5.1 Setup

* Setup

“Switch off the eyeletting machine”

Secure the eyeletting machine to prevent it from restarting (remove the mains

plug).

Pull the eyeletting machine forwards so it sits approximately 130mm

beyond the edge of your work table.

Fold the protective hood [3 / 6.2.1] up.

Operation

Hang OM Automatic eyeletting machine 102-50 19

Image 6.5.1 Pressure setting

Remove the four screws [1/6.5.1] using a hexagon key.

Image 6.5.2 Pressure setting

Carefully pull the worktop [1/6.5.2] forwards, remove it and set it to one

side.

This manual suits for next models

1

Table of contents

Other HANG Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Parker

Parker 2003-IP-00 Technical manual

Parker

Parker Aries AR-01xR Quick reference guide

Wilo

Wilo Comfort-Vario COR-1***-/VR Series Installation and operating instructions

Siemens

Siemens GAMMA instabus 5WG1 204-2AB11 Product and Application Description

L3Harris

L3Harris NARDA AMS-8061 user manual

Baileigh Industrial

Baileigh Industrial B8105 Operator's manual