HANG 102-00 User manual

Operating Instruction Eyeleter

Model 102 - 00

Part no. 701 - 0060

Eyelet 24 / 25

For future use, take note

and keep on hand with

the Eyeleter.

Maschinen - Produktion GmbH

Jahnstraße 82

D - 73037 Göppingen

Telefon +49 (0) 7161 / 6005-0

Telefax +49 (0) 7161 / 6005-78

https://www.hang.de

https://www.hang-shop.de

Operating manual Eyeleter 102-00

Contents

1Introduction.............................................................................................................................. 1

2Before you use the device....................................................................................................... 1

3Notes and explanation of terms............................................................................................... 1

4Intended use............................................................................................................................ 1

5Warranty .................................................................................................................................. 1

6Scope of delivery..................................................................................................................... 1

7Commissioning........................................................................................................................ 2

8How to operate ........................................................................................................................ 2

9Setting the side stop................................................................................................................ 3

10Setting the rear stop ................................................................................................................ 3

11Refilling with eyelets................................................................................................................ 3

12Pressure setting (eyelet pressure) .......................................................................................... 4

13Replacing the lower stamp...................................................................................................... 4

14Replacing the upper stamp...................................................................................................... 5

15Malfunctions in the eyelet feed................................................................................................ 5

16Replacing the bristle disk......................................................................................................... 6

17Maintenance and servicing...................................................................................................... 7

18Cleaning................................................................................................................................... 7

19Lubrication............................................................................................................................... 8

20Recommended lubricants........................................................................................................ 8

21Servicing.................................................................................................................................. 8

© 2018 Constantin Hang, Maschinen - Produktion GmbH

Jahnstraße 82, D-73037 Göppingen

All rights reserved

Reproduction, in whole or in part, is permissible only with the prior consent of the

manufacturer.

Operating manual Eyeleter 102-00

BA_09/2018en 1

1 Introduction

By purchasing this Eyeleter, you have chosen a robust, reliable, proven model from Hang.

We constantly strive to improve Hang products. This also includes the operating manual.

Please notify us of any deficiencies, errors or ambiguities you notice in our products.

Send us your comments, criticisms and opinions by mail or fax. You will find a form in the

appendix.

2 Before you use the device

Read this operating manual carefully and follow the instructions.

The Eyeleter will thank you by providing a long, trouble-free service life.

3 Notes and explanation of terms:

Indicates a potentially hazardous situation that may lead to minor physical injuries.

This signal word may also be used for warnings related to property damage.

Indicates a potentially damaging situation in which the product or an object near it

may be damaged.

Indicates usage notes and other useful information.

4 Intended use

The Eyeleter is for inserting eyelets.

Any other application is considered unintended use.

The manufacturer assumes no liability for unintended use that causes property

damage or injury. In such cases the user bears the risk.

5 Warranty

12 months from the date of delivery.

The General Business Conditions of

Constantin Hang Maschinen-Produktion GmbH as published at

www.hang.de apply, and are accepted upon conclusion of the contract.

6 Scope of delivery

1 Eyeleter 2 Tool

Operating manual Eyeleter 102-00

BA_09/2018en 2

7 Commissioning

The Eyeleter is delivered in stable packing.

Keep the packing for possible return dispatch for reconditioning purposes.

Put the Eyeleter in a stationary position on a stable

surface according to the purpose of use. Work surface,

desk, etc.

8 How to operate

Do not operate the hand lever without first inserting a stack of paper. The stamp

can be damaged by multiple eyelets!

Figure A

Insert the material to be eyeleted against the end stops [1]

through the lower stamp. Figure A.

Pull the hand lever [2] quickly forward.

The eyelets are inserted.

Let go of the hand lever [2].

Spring force will pull it back to its original position.

The eyeletting process is complete.

Depending on the eyelet size, use more or less force.

The favourable gear ratio allows even heavy eyelets to be

inserted easily.

Operating manual Eyeleter 102-00

BA_09/2018en 3

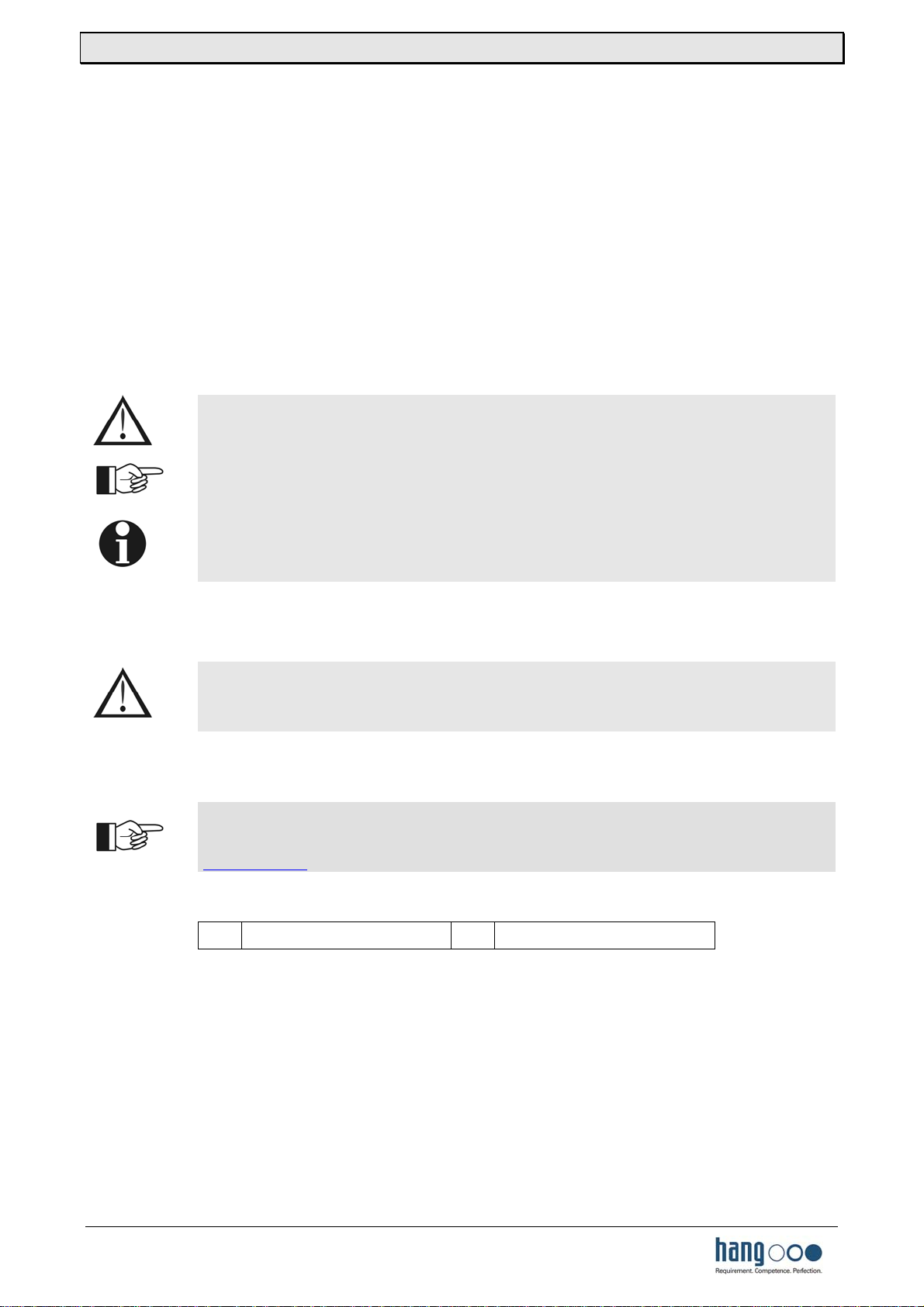

9 Setting the side stop

Figure B

Loosen the knurled screw [4] and set the distance by

sliding the side stop [5].

Then tighten the knurled screw [4].

Figure B.

10 Setting the rear stop

Figure C

Loosen the screw [6] and set the distance by sliding the

rear stop [7].

Then tighten the screw [6].

Figure C.

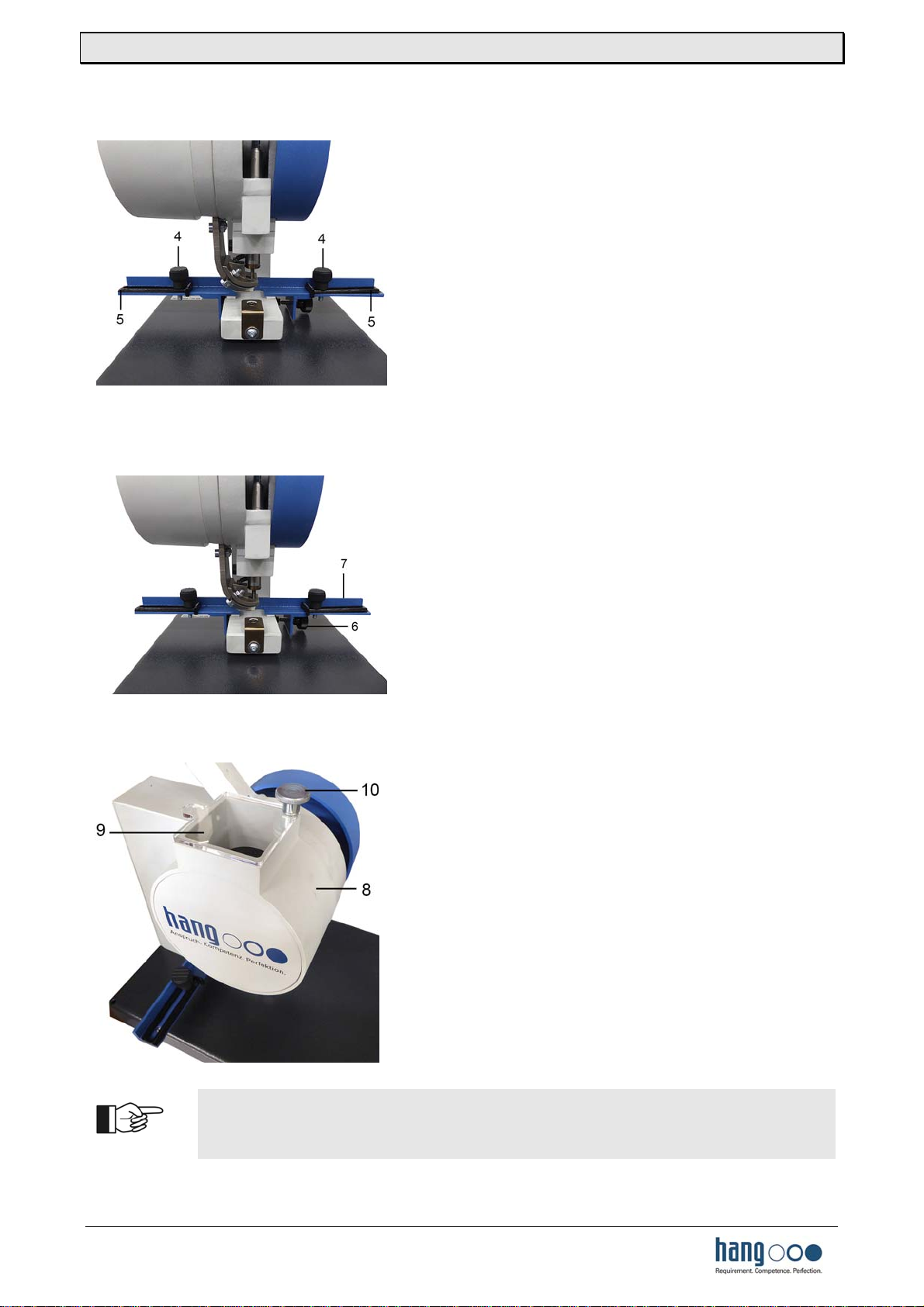

11 Refilling with eyelets

Figure D

Fill the eyelet holder [8] about 2/3 with eyelets by

loosening the knurled screw [10] and turning the

cover [9] to the side.

Figure D.

The Eyeleter is set up for a single eyelet size.

Always refill it only with the prescribed eyelets.

The wrong eyelets can cause malfunction or damage the device.

Operating manual Eyeleter 102-00

BA_09/2018en 4

12 Pressure setting (eyelet pressure)

Figure E

If you wish the eyelets to be pressed harder or if the

eyelets are being pressed too hard, you must regulate

the pressure by moving the lower stamp [11].

Figure E.

Release the threaded pin [12].

Use the threaded pin [13] to move the lower stamp

[11].

Use the threaded pin [12] to clamp the lower stamp

[11] tight again.

To increase the pressure:Turn the threaded pin clockwise.

To decrease the pressure: Turn the threaded pin anticlockwise.

13 Replacing the lower stamp

Press the eyelet channel to the side to allow easier handling.

Figure F

Loosen the clamping screw [15] on the stripping spring [14]

and swivel it aside. Figure F.

Release the clamping screw [17] on the lower stamp [16].

Pull out the lower stamp [16] upwards.

Install the new lower stamp in the opposite sequence.

Operating manual Eyeleter 102-00

BA_09/2018en 5

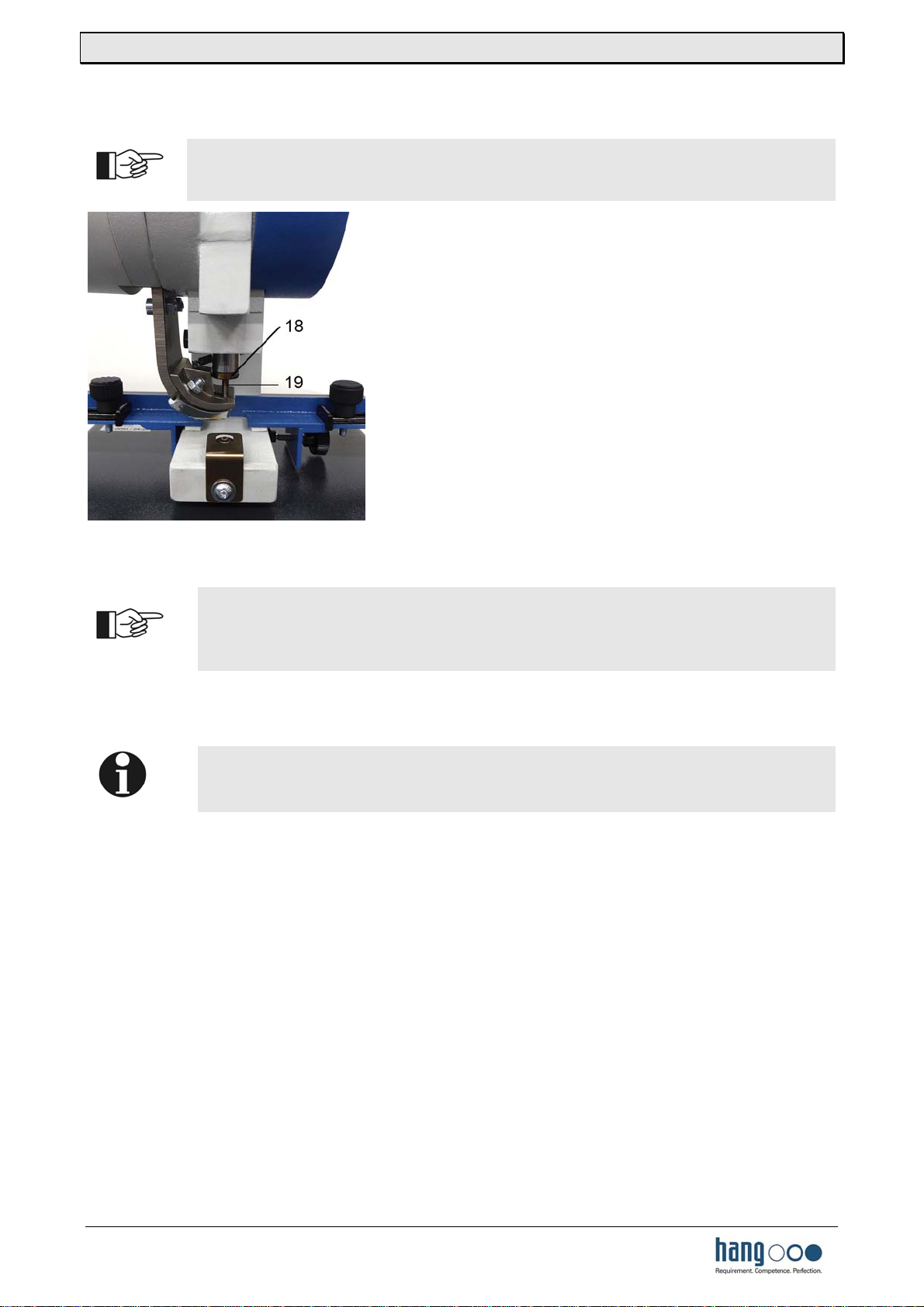

14 Replacing the upper stamp

Press the eyelet channel to the side to allow easier handling.

Figure G

Screw out the upper stamp [18] using the (size 12)

open-ended spanner provided.

If the catch pin [19] also has to be replaced, user

pliers to pull it down and out. Figure G.

Insert the new catch pin through the new upper

stamp and turn both of them together into the tappet.

Do an eyeleting test and, if necessary, readjust the

pressure. (See “Adjusting the pressure”).

15 Malfunctions in the eyelet feed

The eyelet feed is set up for a single eyelet size. If eyelets of a different size,

defective eyelets, dirt or other foreign objects get into the eyelet container or the

feed, malfunctions will occur.

Remove the tension spring that holds the eyelet channel to the body.

Remove the eyelet container (see “Replacing the bristle disk”). (Figures H–K)

First empty the eyelet container, or the eyelets will scatter everywhere.

Repair the cause of the malfunction.

Reinstall the eyelet container.

Operating manual Eyeleter 102-00

BA_09/2018en 6

16 Replacing the bristle disk

Caution: The worm spring is pre-tensioned!

Figure H

There will also be malfunctions if the bristles on the

bristle disk are worn.

Loosen and remove the screw [20].

Remove the cover [21].

Figure H.

Figure I

Loosen and remove the screws [22].

Figures I and J.

Figure J

Operating manual Eyeleter 102-00

BA_09/2018en 7

Figure K

Remove the eyelet container [23] by pulling it off

to the left.

Figure K.

Figure L

Loosen the screw [24].

Pull off the bristle disk [25].

Figure L.

Install in the opposite sequence.

17 Maintenance and servicing

Cleaning and lubrication are the only maintenance the eyeleting machine requires.

18 Cleaning

Clean the Eyelter at regular intervals. Make sure that no dirt deposits in the slide grooves of

the eyelet feed.

Operating manual Eyeleter 102-00

BA_09/2018en 8

19 Lubrication

If the Eyeleter machine is used daily, oil it once a week.

Carefully use an oil can to put one drop of oil at each location [26].

Figure M.

Wipe up excess oil with a rag.

Figure M

20 Recommended lubricants:

ARAL BP ESSO SHELL MOBIL DEA

Machine oil Dural MR 68 Energol EM 68 Coray 68 Carnea 68 Heavy Medium Viscoma,68

21 Servicing

Check the condition of the stamp and bristle disk at regular intervals (every three

months).

If parts are worn, order new ones from the replacement part list.

Form for Operating Personnel

The knowledge of the operating personnel has been checked by a competent person (e.g. supervisor,

safety representative) prior to the start of work.

It is recommended that the test be repeated every six months.

I herewith confirm that I have read and understood Chapters ....... and Chapter 1 „Safety

Precautions“ completely.

Date Chapter Last Name, First Name Signature

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

................... .................................... ......................................... .................................

Table of contents

Other HANG Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Nexen

Nexen AIR CHAMP 625 user manual

SAMCHULLY

SAMCHULLY SD-E instruction manual

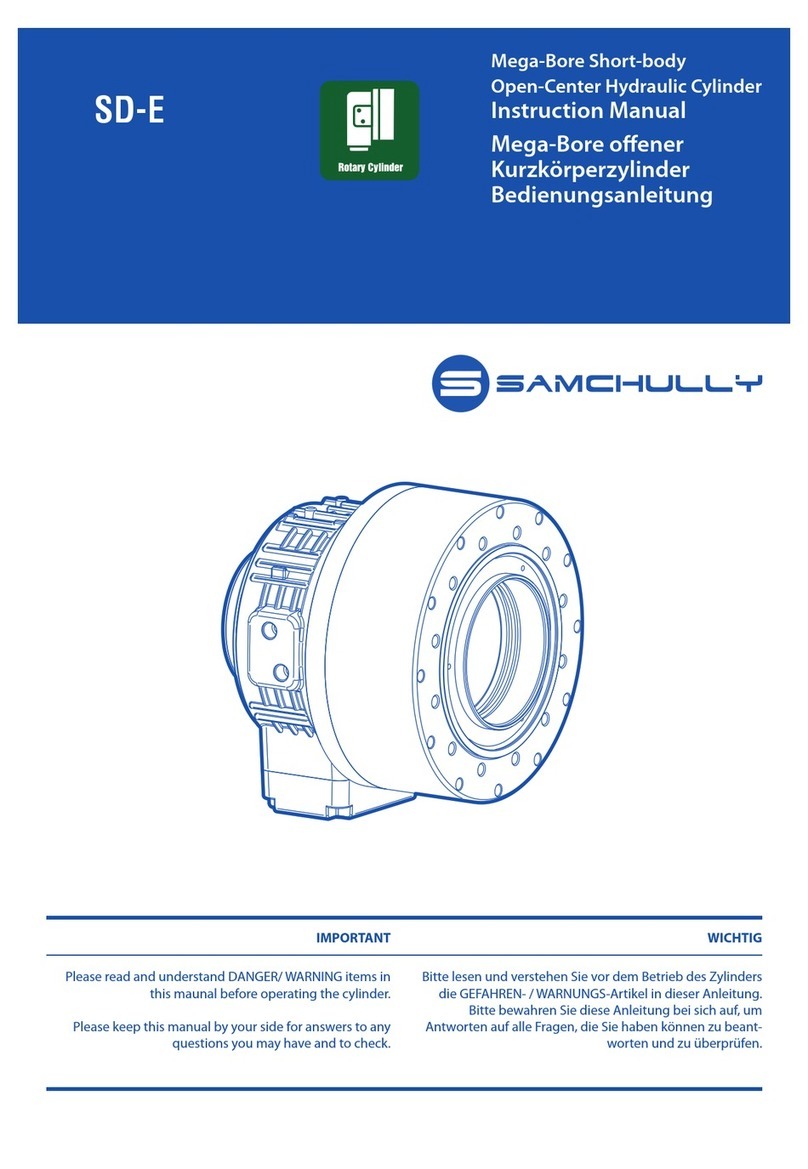

Anest Iwata

Anest Iwata PR-B5B instruction manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS LowViscosity Unit CoalescerDiesel LVU-CD-40 Installation and maintenance instructions

Conquip

Conquip Manhole Box user guide

VIBCO

VIBCO BBS-100 manual