Hankscraft Runxin HS Series User manual

Innovative Solutions for Your Water

HS / HL Valves & Systems

Service Manual

Hankscraft Runxin, LLC

300 Wengel Drive

Reedsburg, WI 53959

608.524.9465

hrh2o.co

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

2

Table of Contents

1. Introduction .................................................................................................................................................... 3

2. System Specifications Form for Record Keeping .............................................................................................. 4

3. Pre-Installation Checklist ............................................................................................................................. 5-6

4. System Installation .................................................................................................................................... 7-16

a. Product Di ensions, Rough-Ins, Unit Location, Plu bing & Mechanical Setup .................................. 7-8

b. Control Valve Installation, Syste Sizing Chart, Bypass Installation ................................................... 9-10

c. Plu bing Connections, Drain Line Installation ...................................................................................... 11

d. Brine Line Installation, Brine Tank Installation .................................................................................. 12-15

e. Syste Installation Chart ....................................................................................................................... 16

5. Valve Start-up Procedure ......................................................................................................................... 17-24

a. HS-STC / HL-STC Ti er Valve Start-Up Procedure ............................................................................ 17-18

b. HS-FTC / HL-FTC Filter Ti er Valve Start-Up Procedure ................................................................... 19-20

c. HS-SMM / HL-SMM Meter Valve Start-Up Procedure ...................................................................... 21-24

6. Sanitizing Procedure ..................................................................................................................................... 25

7. Water Flow iagrams............................................................................................................................... 26-28

8. Assembly rawing and Parts List ............................................................................................................. 29-44

a. HS-STC, HS-FTC, HS- SMM / HL-STC, HL-FTC, HL-SMM Valve Asse bly and Parts List ..................... 29-40

b. HS / HL Valve Body Asse bly and Parts List ..................................................................................... 41-42

c. HS-SMM / HL-SMM Meter Asse bly and Parts List .............................................................................. 43

d. Stainless Steel Bypass ............................................................................................................................. 44

9. Service Instructions .................................................................................................................................. 45-53

a. Replacing Brine Valve, Injectors, and Screen .................................................................................... 45-46

b. Replacing Ti er ................................................................................................................................. 46-47

c. Replacing Piston Asse bly ................................................................................................................ 48-49

d. Replacing Seals and Spacers .............................................................................................................. 49-50

e. Replacing Meter ................................................................................................................................ 51-52

f. Replacing Meter Cover and I peller ................................................................................................ 52-53

10. Troubleshooting ....................................................................................................................................... 54-55

a. Softener Syste s .................................................................................................................................... 54

b. Filter Syste s ......................................................................................................................................... 55

11. Hankscraft Runxin Warranty Statement .................................................................................................. 56-57

12. Contact Information...................................................................................................................................... 58

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

3

1. Introduction

Thank you for choosing a Hankscraft Runxin HS / HL Mechanical Valve. HS and HL control valves take

the ti eless design of industry standard piston valves and updates the to exceed odern

perfor ance de ands. Their durable, high-perfor ance construction has down-flow regeneration,

industry co patible pistons, injectors and seal/spacers, and an L bracket design for hassle-free

operation and aintenance.

These valves utilize high efficiency that lowers annual power use and can be configured with optional

24V otors and extended eters. HS and HL valves also feature a quick-connect drain with optional

offset, increasing flexibility for installs.

Hankscraft Runxin’s echanical control valves are anufactured using i proved aterials and process

and are put through a rigid, 100% quality inspection before they leave the factory. Our products will

give you peace of ind that will result in fewer warranty callbacks, provide a better product to your

custo ers, and put ore oney in your pocket.

HS / HL Valves Feature:

• I proved anufacturing and durability, lower power usage

• 24V otor and extended eter options

• Quick-connect drain with optional offset

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

4

2. System Specifications Form for Record Keeping

Installer

Na e: _______________________________________________________________________________

Address: ___________________________________________________ City/State: _________________

Phone: ____________________________________________________ Install Date: ________________

Softener System Configuration

Tank Size: Dia. _______in. Height _______in. Resin Volu e: ________cu/ft.

Brine Tank Capacity: 85L 100L 130L

Media: ______________________________________________________________________________

Control Valve Serial Nu ber (label located on valve body front): ________________________________

Valve Style:

HS-FTC HS-STC HS-SMM HL-STC HL-SMM HL-SMM-24 HL-SMM-24-EXT

Day/Ti e of Regeneration: ______________________________________________________________

Drain Line Flow Control (DLFC): __________ gp Brine Line Flow Control (BLFC): __________ gp

Injector Size: ____________________________________ Salt Setting: __________________________

Meter Gallon Setting: _____________________________ gallons

Water Conditions and Quality

Total Hardness: _______ grains Iron (Fe): _______ pp Acid (pH): _______ TDS: _______ pp

Pressure of Inlet Water: _________ psi Other: ____________________________________________

Water Source: Well Water City Water Other: ________________________

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

5

3. Pre-Installation Checklist

IMPORTANT NOTICE

Read through the instructions thoroughly and obtain all aterials and tools before proceeding with the

installation. Be sure to follow all applicable national, state, county, and local plu bing codes and

regulations.

All plu bing and electrical work should be perfor ed by an accredited professional to ensure all local,

state, and unicipal guidelines are et.

During cold weather it is reco ended that the installer war the valve to roo te perature before

operating.

Required Operating Conditions

Working Conditions

Working Pressure 25psi

~

120psi

Water Te perature 40 °F

~

100 °F

Working Environment

Environ ent Te perature 40 °F

~

100 °F

Relative Hu idity ≤95%

Power Source AC100

~

240V / 50

~

60Hz

CAUTION

Do not exceed 120 psi water pressure.

Do not exceed 40° C / 100° F water te perature.

Do not subject unit to freezing conditions.

Failure to use this product within the described conditions ay void the warranty.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

6

•All plu bing and electrical work should be perfor ed by an accredited professional to ensure all

local, state, and unicipal guidelines are et.

•An uninterrupted alternating current (A/C) supply is required. Please ake sure voltage supply is

co patible with unit before installation.

•Conditions of existing plu bing should not be clogged with li e or iron build-up. Replace piping

that has heavy li e and/or iron build-up. If there is an iron concern, install an iron filter unit

ahead of the water softener. Plu bing that has heavy li e and iron buildup inhibits the

operation of softening syste .

•When there is oderate to high turbidity, a filter should be installed on the inlet before the

water softening syste .

•If the water pressure exceeds 120psi, a pressure reducing valve ust be installed before the

water inlet. If the water pressure exceeds 80 psi, installing a pressure reducing valve before the

water inlet is highly reco ended. If the water pressure is under 25psi, a booster pu p ust

be installed before the water inlet.

•Ensure there is salt in the brine tank at all ti es when this valve is used for softening. The brine

tank should contain clean water and softening salt only, at least 99.5% pure. Do not use s all

grain salt.

•Always install a bypass valve.

•Replace ent parts for the valve should only be purchased through Hankscraft Runxin resellers.

•Regular interval onitoring of the water quality and work environ ent is reco ended to

insure proper operation of the valve and syste .

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

7

4. System Installation

Product imensions – HS / HL Control Valves

Length (max.) Width (max.) Height (max.) Regeneration Mode

7.5" 4" 7.5" Down-flow

Inlet Port Outlet Port rain Port Brine Port Base Riser Pipe

3/4" 3/4" 1/2" NPTF 3/8" 2.5"NPSM 1.05"

The

se

valve dimensions are for reference only.

Plumbing Rough-Ins – HS / HL Control Valves

Bypass

Tank

Center to

End of

Bypass

Inlet/

Outlet

Center

Inlet/

Outlet

Height

9x48 Tank

Inlet/

Outlet

Height

10x44 Tank

Inlet/

Outlet

Height

10x54 Tank

Inlet/

Outlet

Height

12x52 Tank

Inlet/

Outlet

Height

13x54 Tank

1" Metal Bypass 5-3/8" 2" 50" 46-5/8" 56-3/4" 54-7/8" 56-7/8"

3/4" Metal Bypass 5-1/4" 2" 50" 46-5/8" 56-3/4" 54-7/8" 56-7/8"

The

se

valve

dimensions are for reference only.

Unit Location

•Locate the filter or softener close to a clean working floor drain away fro direct sunlight and any

heat sources. This will ini ize consu er i pact in the event of alfunction.

•Ensure the unit is installed with enough space for operation and aintenance.

•The installation surface should be clean, level and stable for both the pressure tank and brine tank.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

8

Plumbing and Mechanical Setup

•Co plete all plu bing according to local, state, and federal plu bing codes.

oA 1/2" (13 ) ini u drain pipe should be used. However, if the backwash flow rates

exceed 7gp or the length exceeds 20 feet (6 ) then a 3/4" (19 ) drain pipe should

be used.

oThere ust be an air gap between the drain line and the drain to prevent siphoning of

conta inated water back into the resin tank.

•Use only Teflon tape on the drain fitting.

•Solder joints should be co pleted prior to connecting piping to the valve. Solder joints near the

drain ust be done before connecting the Drain Line Flow Control fitting (DLFC). Leave at least 6"

(152 ) between the DLFC and solder joints when soldering pipes that are connected on the

DLFC. Failure to do this could cause interior da age to valve. The valve anufacturer is not

responsible for da age incurred during installation.

•When turning threaded pipe fittings onto plastic fitting, take precaution not to cross thread or over

tighten.

•Ensure the unit is installed with enough space for operation and aintenance.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

9

Control Valve Installation

1. Cut the 1" (25 ) distributor tube (1.05" O.D.) flush with the top of the tank. Take care to keep

foreign aterial out of ineral tank. If purchased as a co plete syste , the tube has already been

cut and installed.

2. Insert distributor tube with lower basket into the center of the

pressure tank.

3. Plug the riser pipe and fill the pressure tank with resin. If purchased as a

co plete syste fro Hankscraft Runxin the edia has been installed.

Media quantity is relative to desired capacity and tank size.

4. Lubricate the valve center hub O-ring with silicone lubricant only.

5. Install the upper basket with a twist and lock action to center hub of

the valve.

6. Lubricate, with silicone lubricant, and install the valve base O-ring around

the neck of the valve.

7. Place valve on tank with the distributor tube inserted down the iddle of

the upper basket. Twist the valve on to the tank to secure valve to the tank.

System Sizing Chart

Tank Size Injector Slow Rinse

@ 40 psi

Brine raw

@ 40 psi

¹

BLFC

²

LFC

9" #1 White .45 gp .28 gp .25 gp 2.0 gp

10" #1 White .45 gp .38 gp .5 gp 2.4 gp

12" #2 Blue .84 gp .56 gp 1.0 gp 3.5 gp

13" #2 Blue .84 gp .56 gp 1.0 gp 4.0 gp

14" #4 Green 1.0 gp .63 gp 1.0 gp 5.0 gp

16" #4 Green 1.0 gp .63 gp 1.0 gp 7.0 gp

Due to varying water conditions, tank sizes, and water pressures, use the above as guidelines only.

¹BLF (Brine Line Flow ontrol), refill rate for filling brine tank.

²DLF (Drain Line Flow ontrol), backwash and rapid rinse flow rates.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

10

Bypass Installation

Stainless Steel Bypass – 1606K/1606KB

1. Grease bypass O-rings and press onto valve.

2. Secure with clips.

Before running the valve for the first ti e,

flush out the water line and bypass:

3. Be sure the bypass is closed.

4. Turn the water source on at the inlet to the house.

5. Disconnect the bypass fro the valve.

6. Put a container under the bypass. Open the bypass to re ove any foreign aterial out of the

water lines.

7. Close the bypass.

8. Re-connect the bypass to the valve.

9. Open the bypass slowly, to avoid water ha ering.

10. Let water flow into the pressure tank. When water flow stops, slowly open a cold water tap

nearby and let water run until it runs clear and air is purged fro the unit. Then close tap.

11. Check for and repair any leaks.

12. Start-up procedures are shown on the following pages for each different valve type. Locate your

valve type and follow the start-up procedures listed.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

11

Plumbing Connections Installation

1. Connect inlet pipe with inlet connector of bypass.

2. Connect outlet pipe with outlet connector of bypass.

3. See Fig. 1

rain Line Installation

1. Install drain line with an air gap to the floor drain.

(Valve drain hose not supplied)

2. See Fig. 2

Fig. 1

Fig. 2

CAUTION

An air gap is required between the drain line

and the drain (sewer). This avoids a syphon

effect and reverse conta ination.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

12

Brine Line Installation

1. Slide brine nut and Ferrule (with the tapered end

facing the inside of the brine nut) onto the 3/8"

brine tubing.

2. Install the filter screen into the tube insert and press

both into the end of brine tube.

3. Insert tube into brine connector and secure brine

nut to the brine connector.

4. See Fig. 3

Brine Tank Installation

1. Unpack brine tank co ponents

•Brine tank standoff with nut and washer

•Overflow elbow with nut and washer

•Optional quick connect clips

2. Open brine well and re ove float. Ensure the

inside of the tank and brine well are free of debris.

Fig. 3

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

13

3. Asse ble salt grid (4 feet, 1 base). Feet clip into the botto of the base.

4. Insert asse bled salt grid into brine tank by lining up the cut out hole with the

drilled holes on the brine tank.

5. Hold float and connected ABS tubing (at the botto ; securing the ABS

tubing), turn the black nut counterclockwise while the tubing is secured

in place. Set to desired salt setting and retighten float nut.

Tank Size

Letter

Salt Level (See Fig. 4) Salt Setting

9x48

To white tape or above 9 lbs.

10x44

Halfway between white/blue tape or above ~ 10.5 lbs.

10x54

To blue tape or above 12 lbs.

12x52

To green tape or above 15 lbs.

13x54

To green tape or above > 15 lbs.

A

B

A

B

C

E

E

C

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

14

6. Insert the brine well, aking sure the botto brine well cap is attached. Insert

the float asse bly by lining up the top cut out holes.

Through testing there have been so e instances where the botto float

asse bly cap can co e off of the tube when force is applied. Therefore we

strongly suggest using Gorilla Glue or any equivalent glue to glue the botto

(only) float asse bly cap to the tube to prevent this cap fro co ing off the

tube.

7. Install brine tank standoff over the float asse bly and insert into top cut

out hole. Attach washer on outside of tank and secure unit.

8. Insert brine line into the top cut out hole, through the standoff, and

into the quick connect elbow (optional: attach blue clips). Press fir ly

to ake sure brine line is fully inserted into the quick connect.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

15

9. Install overflow elbow fitting with washer on the outside of tank. Fasten

nut on the inside of the tank.

10. Replace brine well lid.

11. Replace brine tank lid.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

16

System Installation Chart

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

17

5. Valve Start-Up Procedures

HS-STC / HL-STC Timer Control Valve Start-Up Procedure

1. Make sure the bypass valve is in the service position. Manually index the valve to the Service

position and allow water to flow into the resin tank (pressure tank). When the water flow stops,

open a softened water tap until all air is released fro the lines. Close tap.

Regeneration cycles ay be dialed anually by turning the knob clockwise until the desired

cycle appears.

2. Manually index the valve to Backwash position; allow water to flow out the drain for 3 to 4

inutes for color throw.

3. Re ove back cover plate. Make sure the salt wheel is set to desired dosage.

4. Manually index the control to the Brine Refill position and allow the brine tank to fill to the top of

the air check.

5. Manually index the valve to the Brine Draw position, allow the valve to draw water fro the

brine tank until it stops.

6. Plug the valve into an approved power source. Preferably a GFI grounded outlet. Look in the sight

hole in the back of the otor to see that it is running.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

18

7. Set the days that regeneration is to occur by sliding tabs on Skipper Wheel outward. Each tab is

one day. Move clockwise fro indicator to obtain the desired regeneration schedule. The tab at

the red indicator is tonight.

8. Manually advance the valve to the beginning of the Brine Refill position and allow the valve to

return to the In Service position auto atically. This will fill the brine tank with the correct

a ount of water.

9. Now add salt to the brine tank. (40 lbs. ini u , 120 lbs. axi u )

We reco end using pellet salt, NOT solar or rock salt. Install brine tank cover.

10. Replace back cover plate on the valve. Be sure cable is not pinched between cover and housing.

11. Turn a faucet on, away fro the installation location, until the water fro the plu bing lines has

been purged.

12. Softening syste is now fully operational.

13. Take a water sa ple to verify and test for hardness reduction.

Hardness

PPM

(GPG)

17-85

(1-5)

86-170

(6-10)

171-

256

(11-15)

257-

342

(16-20)

343-

427

(21-25)

428-513

(26-30)

514-

598

(31-35)

599-684

(36-40)

685-769

(41-45)

770-855

(46-50)

856-940

(51-55)

941-

1026

(56-60)

1027-

1111

(61-65)

1112-

1197

(66-70)

1198-

1282

(71-75)

1283-

1368

(76-80)

No. Of

People Softeners - Calendar Clock Regeneration Frequency – Number Of Tab Pulls

2 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3

3 1 1 2 2 3 3 3 3 3 3 4 4 4 4 4 4

4 1 2 2 2 3 3 3 4 4 4 6 6 6 6 6 6

5 2 2 3 3 4 4 4 4 6 6 6 6 12 12 12 12

6 2 2 3 3 4 4 4 6 6 12 12 12 12 12 12 12

7 2 3 3 4 4 6 6 6 12 12 12 12 12 12 12 12

8 2 3 3 4 6 6 6 6 12 12 12 12 12 12 12 12

9 3 3 4 4 6 6 12 12 12 12 12 12 12 12 12 12

10 3 4 4 6 6 12 12 12 12 12 12 12 12 12 12 12

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

19

HS-FTC / HL-FTC Timer Control Valve Start-Up Procedure

1. Manually index the valve to the Service position and allow water to flow into the resin tank

(pressure tank). When the water flow stops, open a water tap until all air is released fro the

lines. Close tap.

Regeneration cycles ay be dialed anually by turning the knob clockwise until the desired

cycle appears.

2. Manually index the valve to Backwash position; allow water to flow out the drain for 3 to 4

inutes for color throw.

3. Plug the valve into an approved power source. Preferably a GFI grounded outlet. Look in the sight

hole in the back of the otor to see that it is running.

4. Set the days that regeneration is to occur by sliding tabs on the Skipper Wheel outward. Each tab

equals one day. Move clockwise fro indicator to obtain the desired regeneration schedule. The

tab at the red indicator is tonight.

5. Turn a faucet on, away fro the installation location, until the water fro the plu bing lines has

been purged.

6. Filtering syste is now fully operational.

HS / HL Valves & Systems Service Manual

Hankscraft Runxin, LLC 300 Wengel rive 608.524.9465 hrh2o.com sales@hrh2o.com

20

Sand

Filter Sediment Turbidity Mild Average Extreme

Carbon

Filters Taste and Odor Mild Average Extreme

Iron

Filters

PPM Ironx1

PPM Manganesex1

PPM Sulfurx1

.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8

No. Of People Softeners - Calendar Clock Regeneration Frequency – Number Of Tab Pulls

2 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 3

3 1 1 2 2 3 3 3 3 3 3 4 4 4 4 4 4

4 1 2 2 2 3 3 3 4 4 4 6 6 6 6 6 6

5 2 2 3 3 4 4 4 4 6 6 6 6 12 12 12 12

6 2 2 3 3 4 4 4 6 6 12 12 12 12 12 12 12

7 2 3 3 4 4 6 6 6 12 12 12 12 12 12 12 12

8 2 3 3 4 6 6 6 6 12 12 12 12 12 12 12 12

9 3 3 4 4 6 6 12 12 12 12 12 12 12 12 12 12

10 3 4 4 6 6 12 12 12 12 12 12 12 12 12 12 12

This manual suits for next models

8

Table of contents

Other Hankscraft Runxin Control Unit manuals

Popular Control Unit manuals by other brands

elsner elektronik

elsner elektronik KNX A3-B2 Installation and adjustment

Pentair

Pentair F251 Installation & maintenance instructions

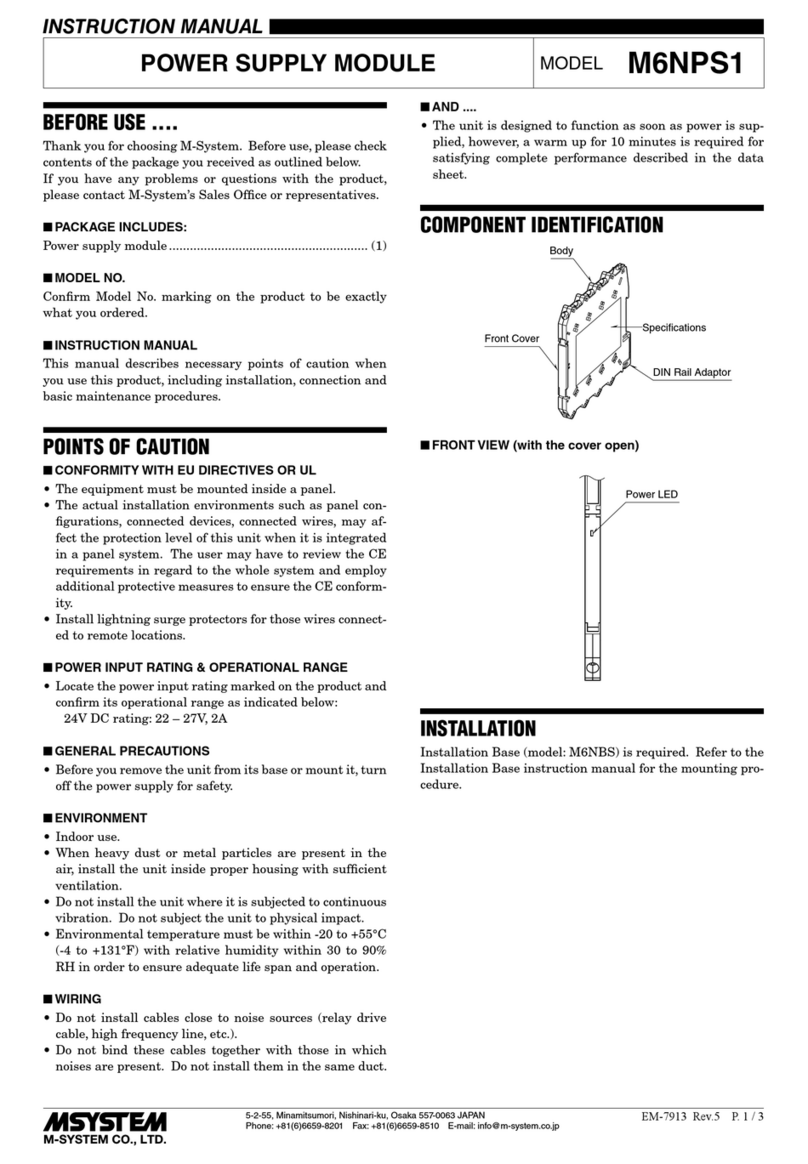

M-system

M-system M6NPS1 instruction manual

Siemens

Siemens SINAMICS RAILCTRL Function manual

Dixon

Dixon 3030SQ Installation & operating instructions

Aulisa

Aulisa Guardian Angel Rx Instructions for use