Flintec EM100-C User manual

EM100-C User Manual

0084292

Page 1of 81

User Manual

EM100-C

v1.5 February 2020

EM100-C User Manual

0084292

Page 2of 81

Table of Contents

1. EM100 Module..........................................................................................................................7

1.1. Introduction.......................................................................................................................7

1.2. Disclaimer .........................................................................................................................8

1.3. Safety Instructions ...........................................................................................................9

2. Specification ..........................................................................................................................10

3. Getting Started.......................................................................................................................11

3.1. Labelling..........................................................................................................................11

3.2. Dimensions.....................................................................................................................12

3.3. Connections....................................................................................................................13

3.3.1. Load-Cell Connections ..............................................................................................14

3.3.2. Power Connection.....................................................................................................15

3.3.3. RS-232 Connection ...................................................................................................16

3.3.4. RS-485 Connection ...................................................................................................17

3.3.5. CANopen Connection................................................................................................18

3.3.6. USB Connection........................................................................................................18

3.3.7. EM100 with Adaptor Board........................................................................................19

3.4. Driver Check ...................................................................................................................20

3.5. Calibration.......................................................................................................................21

3.5.1. Calibration Commands..............................................................................................21

3.5.2. Preparing for Calibration............................................................................................21

3.5.3. Calibration Sequence ................................................................................................22

4. Commands Overview ............................................................................................................23

5. Command Descriptions.........................................................................................................26

5.1. System Diagnostic Commands –FPN, FFV, IS, SR, RS................................................26

5.1.1. FPN Get Device Identity............................................................................................26

5.1.2. FFV Get Firmware Version........................................................................................26

5.1.3. IS Get Device Status .................................................................................................26

5.1.4. SR Software Reset....................................................................................................27

5.1.5. RS Read Serial Number ............................................................................................27

5.2. Calibration Commands – CE, CM’n’, CI, MR, DS, DP, CZ, CG, ZT, FD, IZ, ZR, ZI, TM,

TN, ZN, AZ, AG, WT...................................................................................................................28

5.2.1. CE Read TAC Counter/Open Calibration Sequence..................................................28

5.2.2. CM ‘n’ Set Maximum Output Value...........................................................................28

5.2.3. CI Set Minimum Output Value ...................................................................................29

5.2.4. MR Set Multi-Range/Multi-interval .............................................................................29

EM100-C User Manual

0084292

Page 3of 81

5.2.5. DS Set Display Step Size ..........................................................................................29

5.2.6. DP Set Decimal Point Position...................................................................................30

5.2.7. CZ Set Calibration Zero Point....................................................................................30

5.2.8. CG Set Calibration Gain (Span).................................................................................30

5.2.9. ZT Enable/Disable Zero-Tracking..............................................................................31

5.2.10. FD Reset to Factory Default Settings.....................................................................31

5.2.11. IZ Correction of System Zero.................................................................................31

5.2.12. ZR Zero Range......................................................................................................32

5.2.13. ZI Initial Zero Range...............................................................................................32

5.2.14. TM Tare Mode .......................................................................................................32

5.2.15. TN Set/Clear Non-Volatile Tare..............................................................................33

5.2.16. ZN Set/Clear Non-Volatile Zero..............................................................................33

5.2.17. AZ Absolute Zero Point Calibration (eCal)..............................................................33

5.2.18. AG Absolute Gain Calibration (eCal)......................................................................34

5.2.19. WT Warm-Up Time................................................................................................34

5.3. Motion Detection Commands – NR, NT.........................................................................35

5.3.1. NR Set No-Motion Range..........................................................................................35

5.3.2. NT Set No-Motion Time.............................................................................................35

5.4. Filter Setting Commands – FM, FL, UR.........................................................................36

5.4.1. FM Filter Mode ..........................................................................................................36

5.4.2. FL Filter setting..........................................................................................................36

5.4.3. UR Update Rate & Averaging....................................................................................38

5.5. Taring & Zeroing Commands – SZ, RZ, ST, RT, SP, TMV, RMV...................................39

5.5.1. SZ Set System Zero ..................................................................................................39

5.5.2. RZ Reset Zero...........................................................................................................39

5.5.3. ST Set Tare...............................................................................................................40

5.5.4. RT Reset Tare...........................................................................................................40

5.5.5. SP Set Preset Tare....................................................................................................40

5.5.6. TMV Set Tare (mV/V)................................................................................................40

5.5.7. RMV Reset Tare (mV/V)............................................................................................41

5.6. Output Commands – GG, GN, GT, GS, GMV, GW, GA, GL, OF, GH, TH, GM, RM, GO,

GV, HW.......................................................................................................................................42

5.6.1. GG Get Gross Value..................................................................................................42

5.6.2. GN Get Net Value......................................................................................................42

5.6.3. GT Get Tare Value ....................................................................................................42

5.6.4. GS Get ADC Sample Value.......................................................................................42

5.6.5. GMV Get mV/V Value................................................................................................42

EM100-C User Manual

0084292

Page 4of 81

5.6.6. GW Get Data String (Net, Gross & Status)................................................................43

5.6.7. GA Get Triggered Average Value..............................................................................44

5.6.8. GL Get Data String (Average, Gross & Status)..........................................................44

5.6.9. OF Output Format of Data String...............................................................................44

5.6.10. GH Get Hold Value ................................................................................................45

5.6.11. TH Trigger Hold Value ...........................................................................................45

5.6.12. GM Get Peak Value...............................................................................................45

5.6.13. RM Reset Peak Value............................................................................................45

5.6.14. GO Get Peak-to-Peak Value..................................................................................45

5.6.15. GV Get Valley Value..............................................................................................46

5.6.16.HW Hold Weight ....................................................................................................46

5.7. Auto–Transmit Commands – SG, SN, SX, SMV, SA, SL, SW.......................................47

5.7.1. SG Send Gross Value Continuously..........................................................................47

5.7.2. SN Send Net Value Continuously..............................................................................47

5.7.3. SX Send ADC Sample Value Continuously ...............................................................47

5.7.4. SMV Send mV/V Sample Value Continuously ...........................................................47

5.7.5. SA Send Triggered Average Value Continuously.......................................................47

5.7.6. SL Send Data String Continuously (Average, Gross & Status) ..................................48

5.7.7. SW Send Data String Continuously (Net, Gross & Status).........................................48

5.8. Commands for External I/O Control – IN, OM, IO .........................................................49

5.8.1. IN Read Status of Logic Inputs ..................................................................................49

5.8.2. OM Control of Logic Outputs by Host Application......................................................49

5.8.3. IO Read/Modify Status of Logic Outputs....................................................................49

5.9. Set-Point Output Commands – S’n’, H’n’, A’n’ .............................................................51

5.9.1. S‘n’ Set-Point Value...................................................................................................51

5.9.2. H’n’ Hysteresis & Switching Action for Set-Point........................................................51

5.9.3. A’n’ Source Allocation for Set-Point...........................................................................52

5.10. Communication Setup Commands – AD, NA, NS, BR, DX, CL, OP, TD, CTR, STR,

SBR 53

5.10.1. AD Device Address – Serial Channel.....................................................................53

5.10.2. NA Network Address – CANopen...........................................................................53

5.10.3. NS Network Settings – CANopen...........................................................................53

5.10.4. BR Baud-Rate – Serial Channel.............................................................................54

5.10.5. DX Full-Duplex – Serial Channel............................................................................54

5.10.6. CL Close Device Address ‘n’..................................................................................54

5.10.7. OP Open Device....................................................................................................54

5.10.8. TD Transmission Delay..........................................................................................55

EM100-C User Manual

0084292

Page 5of 81

5.10.9. CTR Set CAN Bus Termination Resistance............................................................55

5.10.10. STR Set RS-485 Termination Resistance ..............................................................55

5.10.11. SBR Set RS-485 Biasing Resistance.....................................................................55

5.11. Save Calibration & Setup Data Commands – CS, WP, SS ...........................................56

5.11.1. CS Save Calibration Data ......................................................................................56

5.11.2. WP Save Setup Parameters ..................................................................................56

5.11.3. SS Save Set-Point Parameters..............................................................................56

5.12. Trigger Commands – SD, MT, TE, TR, TL......................................................................57

5.12.1. SD Start Delay Time ..............................................................................................57

5.12.2. MT Measuring Time...............................................................................................57

5.12.3. TE Trigger Edge.....................................................................................................57

5.12.4. TR Software Trigger...............................................................................................58

5.12.5. TL Trigger Level.....................................................................................................58

5.13. Re-Trigger Commands – RW, TT, TS, DT, TW, TI, HT...................................................59

5.13.1. RW Re-Trigger Window .........................................................................................59

5.13.2. TT Average Time for Re-Trigger Function..............................................................59

5.13.3. TS Stop Value for Re-Trigger Function ..................................................................59

5.13.4. DT Short-Time Averaging Period ...........................................................................60

5.13.5. TW Window for Automatic Taring...........................................................................60

5.13.6. TI Average Time for Automatic Taring....................................................................60

5.13.7. HT Hold-Time for All Set-Points .............................................................................60

6. CANopen Interface ................................................................................................................62

6.1. General Interface Specification .....................................................................................62

6.1.1. PDOs.........................................................................................................................63

6.1.2. TPDO Frame (TPDO1, TPDO2 & TPDO3) ................................................................65

6.1.3. TPDO Frame (TPDO4)..............................................................................................65

6.1.4. Receive PDOs (RPDO1 & RPDO2)...........................................................................66

6.1.5. SDOs.........................................................................................................................67

6.2. Communication Profile...................................................................................................68

6.2.1. Object Dictionary .......................................................................................................68

6.3. CANopen Frames............................................................................................................76

6.3.1. SDO CAN Frame.......................................................................................................76

6.4. Overall CAN Frame.........................................................................................................77

6.4.1. SDO Write .................................................................................................................78

6.4.2. NMT Master Message ...............................................................................................79

6.4.3. Heartbeat Message ...................................................................................................79

6.4.4. Emergency Message.................................................................................................79

EM100-C User Manual

0084292

Page 6of 81

6.4.5. SDO Abort Codes......................................................................................................80

7. Approved Applications..........................................................................................................81

7.1. Restrictions in Approved Applications.........................................................................81

7.2. The Traceable Access Code (TAC)................................................................................81

EM100-C User Manual

0084292

Page 7of 81

1. EM100 Module

1.1. Introduction

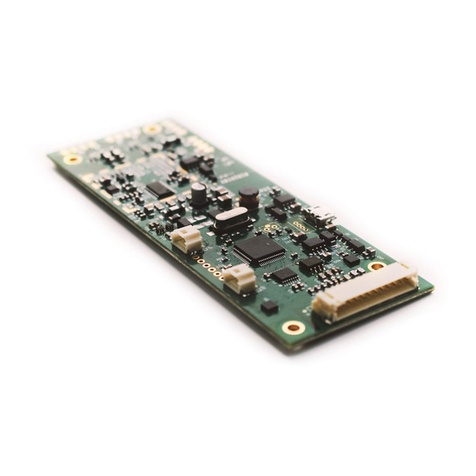

The Electronics Module, EM100-C, is a precise amplifier with integral 24-bit sigma-delta analogue-

to-digital converter for weighing and force measurements with strain gauge sensors. The module

includes an extensive selection of standard weighing and calibration functions for accurate static or

dynamic weighing applications. Its high-speed measuring rate, advanced filters and optimised

software functions are especially useful for check-weighing and other dynamic processes.

The EM100-C model is an approved accuracy class III module examined under OIML R51. The

measurement module forms part of an approved (‘legal-for-trade’) weighing system. The EM100-C

can be used in ‘legal-for-trade’ and industrial applications.

The device features a CAN interface with support for the CANopen protocol as well as full-duplex

RS-232 and RS-485 interfaces. A USB interface has been included for ease of use and is only for

configuration, setup and firmware upgrade.

Communication to the module is based on ASCII characters sent to a variety of serial interfaces

making it easy to connect to a PC, PLC or other devices. Setup of the module is simple using a

terminal emulation program or FDC application software (available from Flintec.com).

EM100-C User Manual

0084292

Page 8of 81

1.2. Disclaimer

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Flintec.

No patent liability is assumed with respect to the use of the information contained herein. While

every precaution has been taken in the preparation of this book, Flintec assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained herein.

The information herein is believed to be both accurate and reliable. Flintec, however, would be

obliged to be informed if any errors occur. Flintec cannot accept any liability for direct or indirect

damages resulting from the use of this manual.

Flintec reserves the right to revise this manual and alter its content without notification at any time.

Neither Flintec nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident,

misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product,

or failure to strictly comply with Flintec operating and maintenance instructions.

Flintec shall not be liable against any damages or problems arising from the use of any options or

any consumable products other than those designated as Original Flintec Products.

NOTICE: The contents of this manual are subject to change without notice.

EM100-C User Manual

0084292

Page 9of 81

1.3. Safety Instructions

CAUTION: READ this manual BEFORE operating or servicing this equipment.

FOLLOW these instructions carefully. SAVE this manual for future reference. DO

NOT allow untrained personnel to operate, clean, inspect, maintain, service, or

tamper with this equipment. ALWAYS DISCONNECT this equipment from the power

source before cleaning or performing maintenance.

CALL Flintec for parts, information, and service.

WARNING: Only permit qualified personnel to service this equipment. Exercise care

when making checks, tests and adjustments that must be made with power on.

Failing to observe these precautions can result in bodily harm.

WARNING:For continued protection against shock hazard connect to properly

grounded outlet only. Do not remove the ground prong.

WARNING: Disconnect all power to this unit before removing the fuse or servicing.

WARNING: Before connecting/disconnecting any internal electronic components or

interconnecting wiring between electronic equipment always remove power and wait

at least thirty (30) seconds before any connections or disconnections are made.

Failure to observe these precautions could result in damage to or destruction of the

equipment or bodily harm.

CAUTION: Observe precautions for handling electrostatic sensitive devices.

EM100-C User Manual

0084292

Page 10 of 81

2. Specification

EM100-C

Application

Check-Weigher

Bridge Excitation

+5VDC

Load-Cell/Sensor

4-Wire or 6-Wire

Accuracy Class

XIII; XIIII; Y(a) or Y(b)

Weighing Range

Single Interval, Multi-Range or Multi-Interval

Verification Scale Interval

10,000

Minimum Input Sensitivity

0.05µV/Count

Certified Accuracy

0.3µV/vsi

Resolution (External)

±350,000 counts

Minimum Load Cell Impedance

58.3Ω (1x350Ω; 4x350Ω; 4x1100Ω; 6x350Ω)

Maximum Load Cell Impedance

1100Ω

Maximum Analogue Input Range

±15mV Bipolar (±3mV/V @ +5V

DC

Excitation)

Conversion Rate

75sps to 1200sps (Dependent on Settings)

Communication Protocols

USB CDC (Config & Setup Only)

RS-232 (N-bits, Parity, Stop bit) 9.6k, 14.4k, 19.2k, 38.4k, 57.6k, 115.2k, 230.4k,

& 460.8kbits/s (8-N-1)

RS-485 (Half & Full-Duplex) 9.6k, 14.4k, 19.2k, 38.4k, 57.6k, 115.2k, 230.4k,

& 460.8kBits/s

CANopen Data Rate 10k, 20k, 50k, 125k, 250k, 500k, 800k, 1MBit/s

Power Supply

+9.6VDC to +32VDC

Digital Input (30V

DC

max, >10kΩ

Input Impedance)

2

Digital Output (Open-Drain

+30VDCmax, 300mWmax) 2

Filter Mode

Selectable FIR/IIR Filters

Calibration

Software Calibration & Setup

Weight/Measurement Functions

Zero; Gross; Tare; Net; Filter etc.

Operating Temperature Range

-15°C to +55°C

Storage Temperature

-30°C to +70°C

Regulations/Standards

OIML R-51-1:2006 & EN 45501:2015

Dimensions (L x W x D in mm)

80 x 40 x 16.6mm

DIN Rail Mounting

Optional Adaptor Board Available

IP Protection Rating

IP20

EM100-C User Manual

0084292

Page 11 of 81

3. Getting Started

You will require:

•PC or PLC with RS-232, RS-485 or CANopen communication ports.

•Load-cell/scale with test weights or a load-cell simulator.

•+12VDC to +24VDC power supply capable of delivering approximately 200mA.

•A suitable ASCII communication software e.g. Hyper-Terminal, Putty, TeraTerm etc. or

Flintec Device Configuration (FDC) application software. Download the latest copy of FDC

from the Flintec website (www.flintec.com).

Note: The Flintec FDC application was developed in-conjunction with the ‘Peak System’ USB

to CAN adaptor. If using the CANopen interface AND the FDC application, only use the ‘Peak

System’ adaptor. See website below for more details. For all other interfaces listed above,

generic adaptors can be used in accordance with the manufacturer’s instructions and drivers.

https://www.peak-system.com/PCAN-USB.199.0.html?&L=1

3.1. Labelling

EM100-C User Manual

0084292

Page 12 of 81

3.2. Dimensions

External Dimensions (Top Side)

External Dimensions (Underside)

EM100-C User Manual

0084292

Page 13 of 81

3.3. Connections

J3 Load Cell

J1 Power & Comms

J3 Load Cell

J1 Power & Comms

EM100-C User Manual

0084292

Page 14 of 81

3.3.1. Load-Cell Connections

Connect the input using the colour coding for Load-cell connections:

EM100 J3 Load-Cell Pin-Out

Function

2

Excitation+

4

Sense+

6

Signal+

8

Signal-

10

Sense-

12

Excitation-

1, 3, 5, 7, 9 & 11

GND

Note: If using 4-wire configuration, tie the Excitation+ (EXC+) to the Sense+ (S+) & Excitation-

(EXC-) to the Sense- (S-) for correct configuration.

4-Wire Connection:

6-Wire Connection:

EM100-C User Manual

0084292

Page 15 of 81

3.3.2. Power Connection

The power supply is designed to accept a +12VDC or +24VDC supply. The power supply ground is

not the same potential as the comms or main chassis ground pins. Only use the appropriate power

and return pins for the supply, all comms and GPIOs pins to be referenced to the associated comms

or main chassis ground.

EM100 J1 Pin Number

Pin Name

Function

1 & 3

Vin

Power Supply Input.

5 & 7

Vin Return

Power Supply Input GND.

17

GND

Main Chassis GND.

6 & 12

GND C

Communications GND.

9

Input 1

GPIO Input.

11

Input 2

GPIO Input.

13

Output 1

GPIO Output (Open-Drain).

15

Output 2

GPIO Output (Open-Drain).

19

Boot

Firmware Upgrade Facility.

2

CAN L

CANopen Differential Pin-.

4

CAN H

CANopen Differential Pin+.

8

RS-232 RX

Serial Port Input.

10

RS-232 TX

Serial Port Output.

14

RS-485 RX+

Differential Rx+ Pin.

16

RS-485 RX-

Differential Rx- Pin.

20

RS-485 TX+

Differential Tx+ Pin.

18

RS-485 TX-

Differential Tx- Pin.

Note: If using the USB port to setup and configure, it should be noted when a power cycle or

software reset (see ‘SR’ command) is applied, the USB cable may require disconnecting, then

reconnecting after powered up.

EM100-C User Manual

0084292

Page 16 of 81

3.3.3. RS-232 Connection

EM100-C User Manual

0084292

Page 17 of 81

3.3.4. RS-485 Connection

The RS-485 network requires a 120Ω termination resistor at both the host end (EM100) and at the

furthest point in the network. The EM100 has a software selectable terminator built-in (see ‘STR’

command).

Note: For half-duplex (RS-485) operation tie RS-485 TX+ with RS-485 RX+ and RS-485 TX- with

RS-485 RX-.

EM100-C User Manual

0084292

Page 18 of 81

3.3.5. CANopen Connection

Note: For the CAN network to operate properly, it is necessary to place a 120Ω termination resistor

at both the host end (EM100) and at the furthest point in the network. The EM100 has a software

selectable terminator built-in (see ‘CTR’ command).

3.3.6. USB Connection

EM100-C User Manual

0084292

Page 19 of 81

3.3.7. EM100 with Adaptor Board

EM100-C User Manual

0084292

Page 20 of 81

3.4. Driver Check

During the first session, it may be necessary for the PC to install appropriate drivers. If using a CAN

adaptor or USB-to-serial converter, consult the manufacturer for instructions and latest drivers.

If using the USB CDC connection, the following driver from STMicroelectronics will need to be

installed. View the ST.com website for the latest revision:

http://www.st.com/en/development-tools/stsw-stm32102.html

An installation manual is available from the Flintec website (www.flintec.com).

This manual suits for next models

1

Table of contents

Other Flintec Control Unit manuals

Popular Control Unit manuals by other brands

King nutronics

King nutronics 3666-12-101 OVERHAUL INSTRUCTIONS

gAvilar

gAvilar gACC-499E/U manual

Automationdirect.com

Automationdirect.com Productivity 2000 P2-08TD1S manual

Cisco

Cisco GS7000 Installation and operation guide

DOLD

DOLD INFOMASTER SMS RP 5812 Monitoring Technique

Acromag

Acromag ACEX4405-LF user manual

Honeywell

Honeywell 4219 Installation and setup guide

DH Instruments

DH Instruments PG7600 installation instructions

Leonard

Leonard TM-186-30015050-PRV INSTALLATION ADJUSTMENT SERVICE

ESD

ESD CAN-CBM-REL4 Hardware manual

TOPSKY

TOPSKY PRIME-1 quick start guide

VAT

VAT 150 Series Installation, operating, & maintenance instructions