HANMEY AM60 User manual

1

Operate & Parts Manual

Hedge cutter AM60/AM80/AM100

2

LIST OF CONTENTS

SAFETY PRECAUTIONS Page 5

FITTING Page 9

INITIAL ATTACHMENT TO TRACTOR Page 12

FLAILHEAD ATTACHMENT Page 24

REMOVAL FROM TRACTOR Page 25

STORAGE Page 26

OPERATION Page 27

OPERATION GUARD Page 28

MACHINE CONTROLS Page 28

BREAKAWAY Page 29

MOVING INTO THE TRANSPORT POSITION Page 31

MOVING FROM TRANSPORT TO WORK Page 32

ROTOR OPERATING SPEED Page 33

HIGH VOLTAGE CABLES Page 34

OVERHEAD OBSTRUCTIONS Page 34

WORKING ON ADVERSE SLOPES Page 36

MAINTENANCE Page 36

LUBRICATION

General Page 36

P.T.O. shaft Page 37

HYDRAULIC SYSTEM Page 38

HYDRAULIC HOSES Page 39

PARTS LIST Page 40

3

READ THE BOOK FIRST

It might save hours and pounds later !

When ordering spare parts always quote

The Machine Type

The Machine Serial Number

The Part Number

Factory re-built service exchange units of the major

hydraulic components are available from your Dealer

4

NOISE

The equivalent daily personal noise exposure from this machine, measured at the

operators’ ear, is within the range 78 – 85 DB. These figures apply to a normal distribution

of use where the noise fluctuates between zero and maximum. The figures assume that

the machine is fitted to a tractor with a quiet cab with the windows closed in a generally

open environment. We recommend that the windows are kept closed. With the cab rear

window open the equivalent daily personal noise exposure will increase to a figure within

the range 82 –88 DB. At equivalent daily noise exposure levels of between 85 and 90 DB,

ear protection is recommended, it should be used if any window is left open.

5

GENERAL INFORMATION

Read this manual before fitting or operating the machine. Whenever any doubt exists contact

your dealer or the McConnel Service Department for assistance.

Use only McConnel Genuine spare parts on McConnel equipment and machines.

DEFINITIONS The following definitions apply throughout this manual:

WARNING

An operating procedure, technique etc., which can result in personal injury or loss of life if not

observed carefully.

CAUTION

An operating procedure, technique etc., which can result in the damage of either machine or

equipment if not observed carefully.

NOTE

An operating procedure, technique etc., which is considered essential to emphasise.

LEFT AND RIGHT HAND

This term is applicable to the machine when fitted to the tractor and viewed from the rear.

This also applies to tractor references.

Record the serial number of your machine on this page and always quote this

number when ordering spares. Whenever information concerning the machine

Is requested remember to also state the type of tractor to which it is fitted.

MACHINE

INSTALLATION

SERIAL

DATE

NUMBER

MODEL

DETAILS

DEALERS

NAME

DEALERS

TELEPHONE

NUMBER

6

SAFETY

INFORMATION

4

7

SAFETY INFORMATION

This machine has the potential to be extremely dangerous, in the wrong hands it can kill or

maim. It is therefore imperative that the owner, and the operator of this machine, read the

following section to ensure that they are both fully aware of the dangers that do, or may

exist, and their responsibilities surrounding its use.

The operator of this machine is responsible not only for their own safety but equally for the

safety of others who may come into the close proximity of the machine, as the owner you

are responsible for both.

POTENTIAL SIGNIFICANT DANGERS ASSOCIATED WITH THE USE OF THIS

MACHINE:

●Being hit by debris thrown by rotating components.

●Being hit by machine parts ejected through damage during use.

●Being caught on a rotating power take-off (PTO) shaft.

●Being caught in other moving parts i.e.: belts, pulleys and cutting heads.

●Electrocution from Overhead Power Lines (by contact with or ‘flashover’ from).

●Being hit by cutting heads or machine arms as they move.

●Becoming trapped between tractor and machine when hitching or unhitching.

●Tractor overbalancing when machine arm is extended.

●Injection of high pressure oil from hydraulic hoses or couplings.

●Machine overbalancing when freestanding (out of use).

●Road traffic accidents due to collision or debris on the road.

BEFORE USING THIS MACHINE YOU MUST:

●Ensure you read all sections of the operator handbook.

●Ensure the operator is, or has been, properly trained to use the machine.

●Ensure the operator has been issued with and reads the operator handbook.

●Ensure the operator understands and follows the instructions in operator handbook.

●Ensure the tractor front, rear and side(s) are fitted with metal mesh or

polycarbonate guards of suitable size and strength to protect the operator against

thrown debris or parts.

●Ensure tractor guards are fitted correctly, are undamaged and kept properly

maintained.

●Ensure that all machine guards are in position, are undamaged, and are

kept maintained in accordance with the manufacturer’s recommendations.

8

●Ensure flails and their fixings are of a type recommended by the manufacturer, are

securely attached and that none are missing or damaged.

●Ensure hydraulic pipes are carefully and correctly routed to avoid damage by chaffing,

stretching or pinching and that they are held in place with the correct fittings.

●Always follow the manufacturer’s instructions for attachment and removal of the

machine from the tractor.

●Check that the machine fittings and couplings are in good condition.

●Ensure the tractor meets the minimum weight recommendations of the machine

manufacturer and that ballast is used as necessary.

●Always inspect the work area thoroughly before starting to note obstacles and remove

wire, bottles, cans and other debris.

●Use clear suitably sized warning signs to alert others to the nature of the machine

working within that area. Signs should be placed at both ends of the work site. (It is

recommended that signs used are of a size and type specified by the Department of

Transport and positioned in accordance with their and the Local Highways Authority

guidelines).

●Ensure the operator is protected from noise. Ear defenders should be worn and tractor

cab doors and windows must be kept closed. Machine controls should be routed

through proprietary openings in the cab to enable all windows to be shut fully.

●Always work at a safe speed taking account of the conditions i.e.: terrain, highway

proximity and obstacles around and above the machine.

●Extra special attention should be applied to Overhead Power Lines. Some of our

machines are capable of reach in excess of 8 metres (26 feet) this means they have

the potential to well exceed, by possibly 3 metres (9’ 9”), the lowest legal minimum

height of 5.2 metres from the ground for 11,000 and 33,000 volt power lines. It cannot

be stressed enough the dangers that surround this capability, it is therefore vital that

the operator is fully aware of the maximum height and reach of the machine, and that

they are fully conversant with all aspects regarding the safe minimum distances that

apply when working with machines in close proximity to Power Lines. (Further

information on this subject can be obtained from the Health & Safety Executive or your

Local Power Company).

●Always disengage the machine, kill the tractor engine, remove and pocket the

key before dismounting for any reason.

●Always clear up all debris left at the work area, it may cause hazard to others.

●Always ensure when you remove your machine from the tractor that it is left in a safe

and stable position using the stands and props provided and secured if necessary.

WHEN NOT TO USE THIS MACHINE:

●Never attempt to use this machine if you have not been trained to do so.

●Never uses a machine until you have read and understood the operator handbook, are

familiar with, and practiced the controls.

●Never use a machine that is poorly maintained.

9

●Never use a machine if guards are missing or damaged.

●Never use a machine on which the hydraulic system shows signs of wear or damage.

●Never fit, or use, a machine on a tractor that does not meet the manufacturer’s

minimum specification level.

●Never use a machine fitted to a tractor that does not have suitable front, rear and

side(s) cab guarding made of metal mesh or polycarbonate.

●Never use the machine if the tractor cab guarding is damaged, deteriorating or badly

fitted.

●Never turn a machine cutting head to an angle that causes debris to be ejected

towards the cab.

●Never start or continue to work a machine if people are nearby or approaching - Stop

and wait until they are at a safe distance before continuing. WARNING: Some Cutting

Heads may continue to ‘freewheel’ for up to 40 seconds after being stopped.

●Never attempt to use a machine on materials in excess of its capability.

●Never use a machine to perform a task it has not been designed to do.

●Never operate the tractor or machine controls from any position other than from the

driving seat, especially whilst hitching or unhitching the machine.

●Never carry out maintenance of a machine or a tractor whilst the engine is running –

the engine should be switched off, the key removed and pocketed.

●Never leave a machine unattended in a raised position –it should be lowered to the

ground in a safe position on a level firm site.

●Never leave a tractor with the key in or the engine running.

●Never carry out maintenance on any part or component of a machine that is raised

unless that part or component has been properly substantially braced or supported.

●Never attempt to detect a hydraulic leak with your hand –use a piece of cardboard.

●Never allow children near to, or play on, a tractor or machine under any circumstances.

10

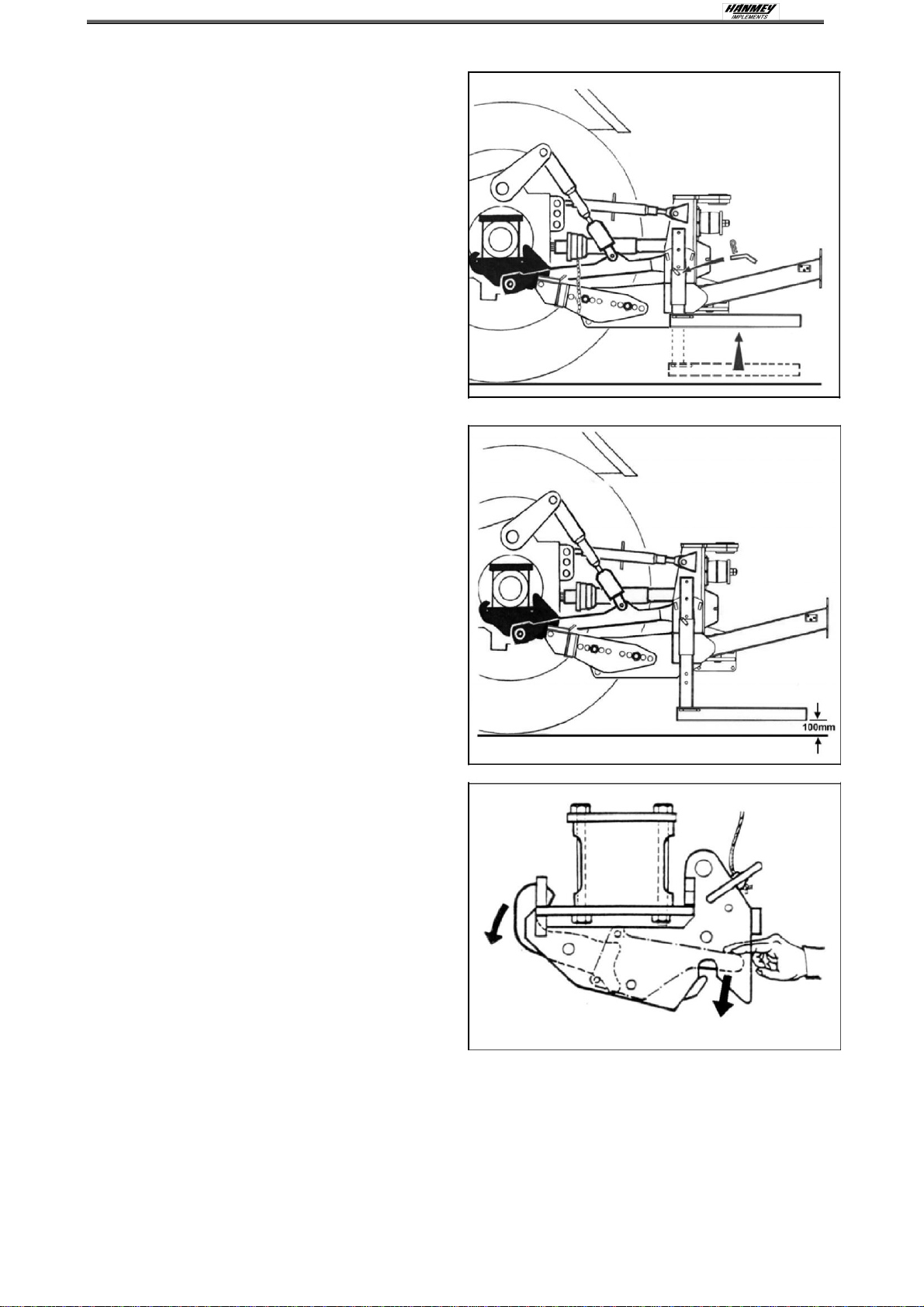

INITIAL ATTACHMENT TO TRACTOR

The machine will be delivered in a partially dismantled condition, secured with transport

strap and banding.

Choose a firm level site.

Remove the transport strap, banding

straps and loose items.

Raise the machine using overhead

lifting equipment with a minimum

capacity of 1500kg SWL.

LEAVE IN POSITION AT THIS STAGE.

Lower the legs and pin in position

selecting the holes that position the

machines gearbox stub shaft approx.

75 mm below the tractors P.T.O. shaft.

Note: Leg pin position used.

Unbolt stabiliser from machine and

remove the stabiliser nose quadrant pin.

Locate axle-mounting arms onto the mainframe and secure in position using the correct

nuts and bolts supplied, tighten nuts when correct hole location has been selected - see

following page for details on mounting hole selection.

11

AXLE BRACKET/CATCH ASSEMBLY - FITTING BY DEALER

Bolt axle plates to the tractor axle at either 1.0 M or 1.1 M apart - this may necessitate the

to removal of the tractor's check chains and/or assister ram brackets, if this is the case, the

axle plate will include replacement brackets for these functions.

The axle brackets supplied will be accompanied by a fitting sheet with instruction for their

attachment to your tractor, follow the instructions exactly as they are specific to your

particular make and model of tractor. Replace assister ram(s) if fitted.

Hook the catch assemblies onto the rear

of the axle plates, push firmly against

the plate and vigorously pivot the catch

in a forward and up direction until the

spring loaded hook 'snaps' into position.

Pass the release cords up into the cab.

NOTE:

On some tractors fitted with auxiliary fuel tanks,

there is insufficient space for the spring

catches to be fitted, in these instances special

axle brackets and catches with a

'pin on' facility are available on request. Ensure catch-locking pin 'A' is removed.

12

STANDARD TYPE BRACKETS

With the frame in the vertical position, measure dimensions 'A' and 'B', subtract 'B' from 'A'

to obtain measurement 'X'. Measure dimension 'C'.

Select mounting holes which position the mounting bars in the end of the latch arms so

that dimension 'D' equals dimension 'C' minus measurement 'X' and also when the draft

link is horizontal and the rocking draft pin is in the upright position dimensions 'E' and 'F'

are equal.

13

ALTERNATIVE TYPE BRACKETS

With the frame in the vertical position, measure dimensions 'A' and 'B', subtract 'B' from 'A'

to obtain measurement 'X'. Measure dimension 'C'.

Select mounting holes which position the mounting bars in the end of the latch arms so

that dimension 'D' equals dimension 'C' minus measurement 'X' and also when the draft

link is horizontal and the rocking draft pin is in the upright position dimensions 'E' and 'F'

are equal.

14

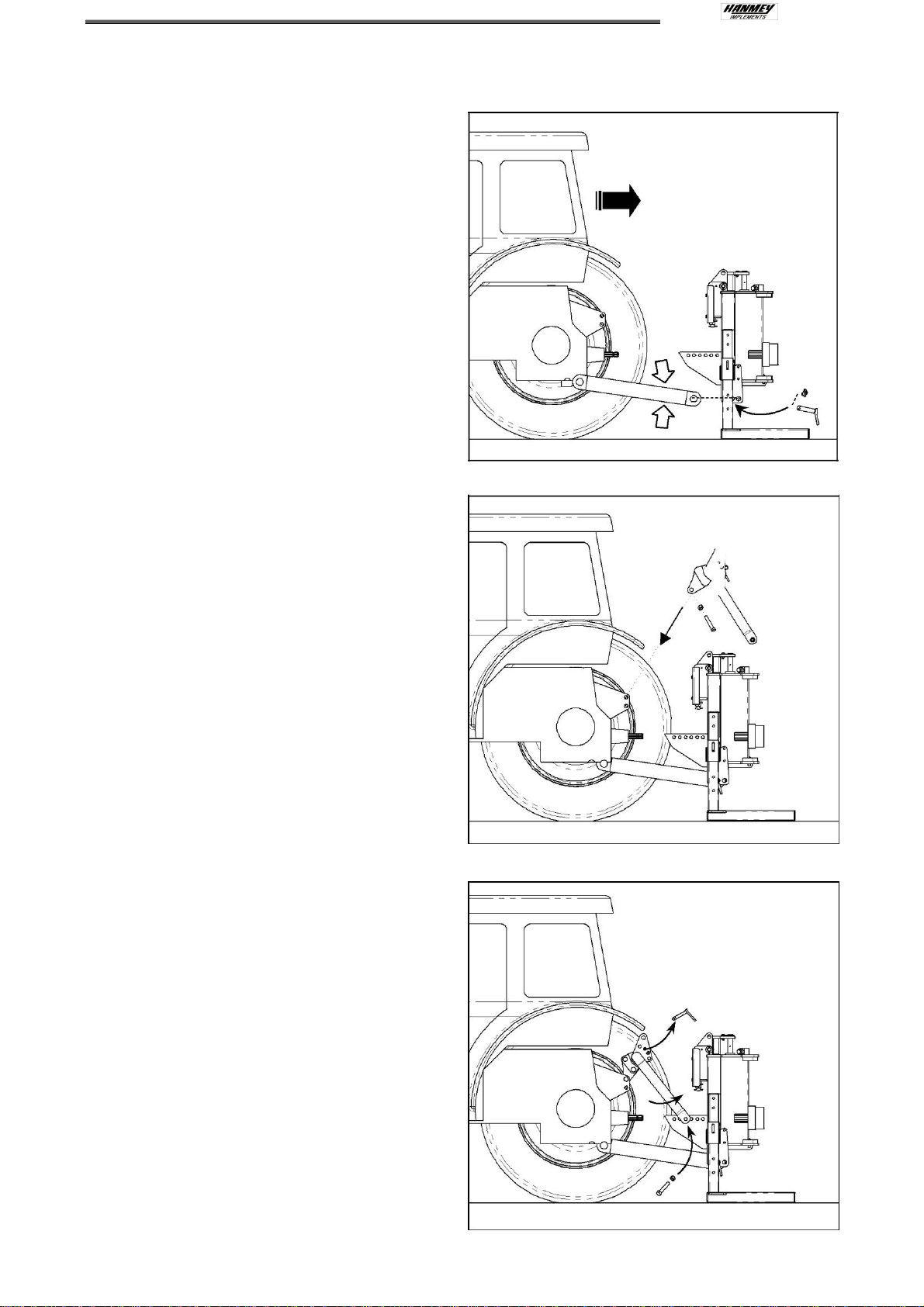

TRACTOR ATTACHMENT - BY CUSTOMER OR DEALER

Reverse tractor squarely into position

adjacent to the machine and connect the

draft links to the machine - maneuver tractor

until both draft pin rockers are vertical.

Raise the machine on the tractors

linkage sufficient only for the latch bar to

fully engage in the axle catch.

WARNING!

The quadrant lever or machine controls

must only be operated from the tractor

seat. Ensure no one is standing close

to or within the linkage arms or bars.

NOTE:

Be aware -as lift occurs the machinery

may tilt slightly.

Insert catch lock pins –refer to

diagrams below for specific type

Locking Pins on this type of bracket

pass through the arms above the

latches and are secured with linch pins.

Standard Type Bracket

Alternative Type Bracket

15

Raise the machine on the tractors

linkage until the frame is vertical.

Fit top link.

Measure PTO shaft and cut to dimension

shown (distance ‘A’ minus 75mm) - see

diagram opposite and refer to maintenance

section for further details.

NOTE:

For subsequent use on a different tractor

measure again - there must be a minimum

of 6" (150mm) of shaft overlap.

16

Fit PTO shaft into position.

Attach the torque chains to a convenient

location to prevent rotation of the shaft

guards.

Fit machine controls into the cab - refer to

the specific page on this subject for further

details.

FIRST FITTING ONLY - for Dealer reference

Request assistance. Operate 'Lift up' on machine controls sufficient only for the dipper

arm to clear the ground. Pivot out the dipper until the tension link can be reconnected.

17

Raise the stand legs into the work position

and secure with their pins - see diagram

opposite.

Tighten check chains and/or stabiliser bars.

The machine should now be carefully

operated throughout its full range of

movements to check hoses are not being

strained, pinched, chafed or kinked, and

that all movements are functioning correctly.

The machine can now be folded into the

transport position ready to proceed to the

work site - Refer to the section on Transport

Position for details on this subject.

REMOVAL FROM TRACTOR

Select a firm safe site to remove

the machine

Locate parking legs into their housings.

NOTE: The correct, and most stable,

position for removing the machine from the

tractor is with the arm positioned to the rear

of the machine.

Position the flail head on the ground

directly to the rear of the machine at

approximately half reach.

Disengage PTO.

Remove latch security pins.

Take machine weight on draft links

sufficient only to allow the top link to

be disconnected.

Open axle catches using the release

cord and lower the machine.

Disconnect draft links and remove the

PTO shaft.

Remove control units from the tractor cab

and stow clear of the ground in a location

where they are protected from the

weather or risk of accidental damage.

Drive tractor away from machine.

Locate parking legs into their housings.

Remove the axle catches from the tractor.

Replace check chains / stabiliser bars

–The axle plates can remain permanently in position.

STORAGE

If the machine is to be left standing for extended periods of time, lightly coat the exposed

portions of the ram rods with grease. Subsequently this grease should be wiped off before

the rams are next moved. If the machine is to be stored outside tie a piece of tarpaulin or

canvas over the control assembly - do not use a plastic bag as this can lead to corrosion

in the unit.

18

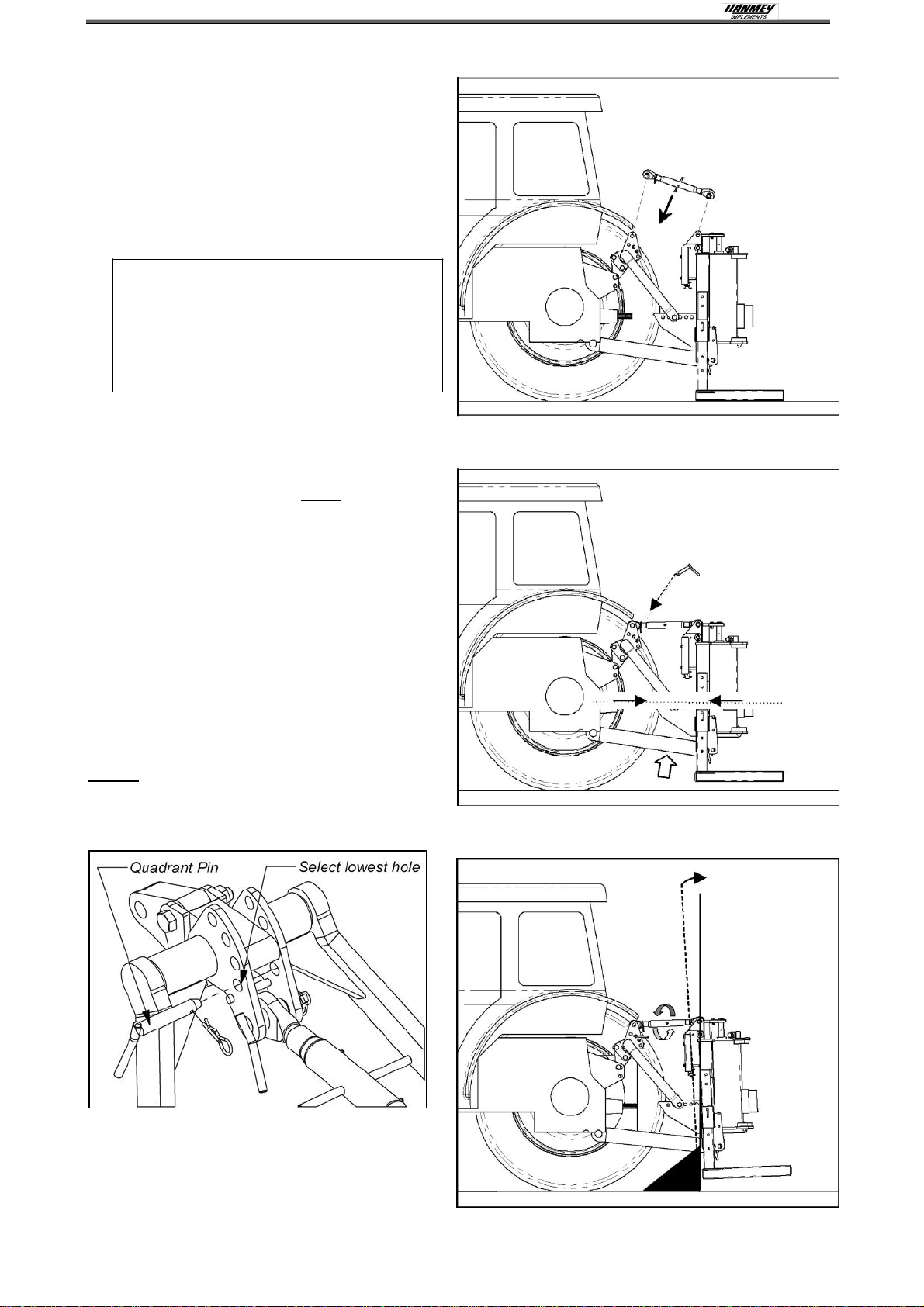

TRACTOR ATTACHMENT –Linkage Mounted Machines

With the machine positioned on a firm

level site and securely supported,

maneuver the tractor squarely up to

the machine with the tractor’s draft

links set to a height level with the

machines lower link brackets.

Fig.1

Connect the tractor’s draft links to the

machine’s lower link brackets, retain

in position with the linkage and lynch

pins supplied. Ensure that the same

‘hole position’ is selected on each side

of the machine.

NOTE: The hole selected on the lower

link bracket should be the rear most

that permits the machine to be

mounted without fouling the tractor.

LIFTING EQUIPMENT MAY NOW BE

REMOVED.

Fit and secure stabiliser nose into the

tractors top link selecting the highest

position available avoiding any load

sensing properties. Fig.2

NOTE: The bolt on nose of the

stabiliser is reversible in order to

accommodate variations of tractor

linkage designs.

Figure 1

Figure 2

1

2

Remove the ‘R’ clip and quadrant pin

from stabiliser and swing it rearwards

to locate with one of the holes on the

mainframe -select the hole that is

furthest away from the tractor and

secure loosely with the bolt provided.

DO NOT TIGHTEN AT THIS STAGE

and DO NOT REPLACE QUADRANT

PIN AT THIS STAGE.

Fig.3

Figure 3

1

2

3

19

Fit the machines top link.

Fig.4

Raise the machine on the tractors

linkage to a position where the tractor

PTO and the machines gearbox stub

shaft are approximately in line with

each other. Note: As lift occurs be

aware the machine may tilt slightly.

WARNING

The quadrant lever or machine

controls must be operated from

the tractor seat. Ensure no one is

standing on or between the

linkage arms or bars.

Replace the stabiliser quadrant pin

and secure with the ‘R’ clip.

Fig.5

NOTE: The quadrant pin must be fitted in

the lowest hole on the stabiliser in order

that it acts as a ‘bottom stop’ - this will

prevent the machine from dropping when

stopped and permit the tractor’s inbuilt

transport protection system to function

correctly during operation and

transportation.

Ensure the tractor’s linkage is in ‘position

control’ and the linkage raised sufficiently

to hold the hedgecutter at the correct

height and remove the load from the

quadrant pin.

Never fit the quadrant pin in a location

hole that locks the stabiliser as this can

cause damage to the machine and/or

tractor.

Adjust the top link to bring the

machine frame into the vertical

position.

Fig.6

Figure 4

Figure 5

2

1

Figure 6

90º

20

Fully tighten the stabiliser lower bolts

Fig.7

Figure 7

Measure the PTO shaft and cut to the

dimension shown –the finished length

of the PTO shaft should be 75mm (3”)

less than the measured distance ‘A’ -

between tractor shaft and gearbox

stub shaft - to enable fitting.

Fig.8

NOTE:

For subsequent use with different

tractors measure again, there must be

a minimum shaft overlap of 150mm

(6”).

Fit PTO in position and attach the

torque chains to a convenient location

to prevent the shaft guards from

rotating.

Fig.9

Figure 8

Figure 9

This manual suits for next models

2

Table of contents

Popular Trimmer manuals by other brands

ATIKA

ATIKA HS 680-61 - operating manual

Black & Decker

Black & Decker LHT341 instruction manual

Qualcast

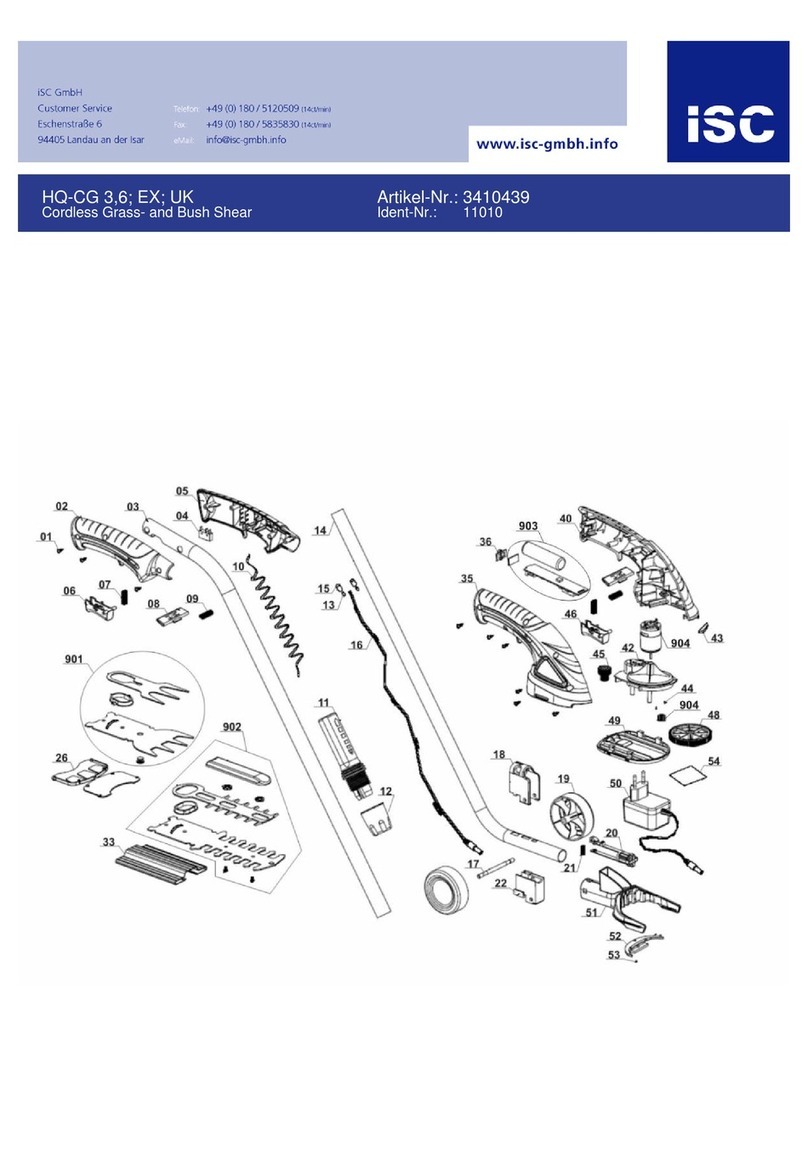

Qualcast HQ-CG 3.6 Original operating instructions

Shindaiwa

Shindaiwa T242X Owner's/operator's manual

Echo

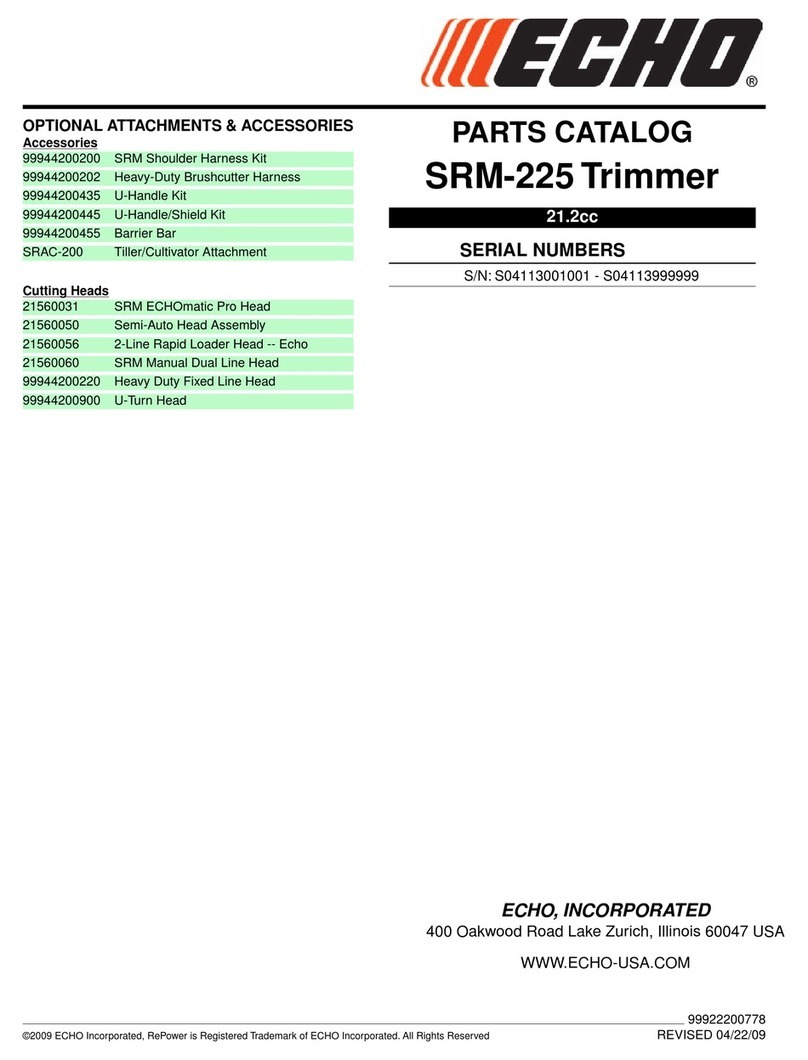

Echo SRM-225 - PARTS CATALOG SERIAL NUMBER... parts catalog

Makita

Makita UR013G instruction manual