32

PRELIMINARY EXAMINATION

Remove the instrument from the packing ma-

terial and examine it carefully to make sure

that no damage has occurred during ship-

ping. If there is any noticeable damage, notify

your Dealer.

Note: Save all packing material until you are

sure that the instrument functions cor-

rectly. All defective items must be re-

turned in the original packing material

together with the supplied accessories.

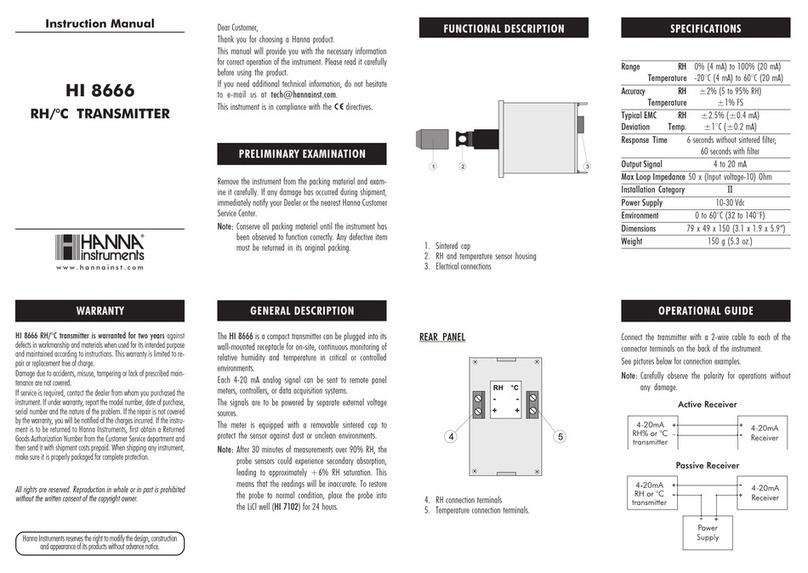

GENERAL DESCRIPTION

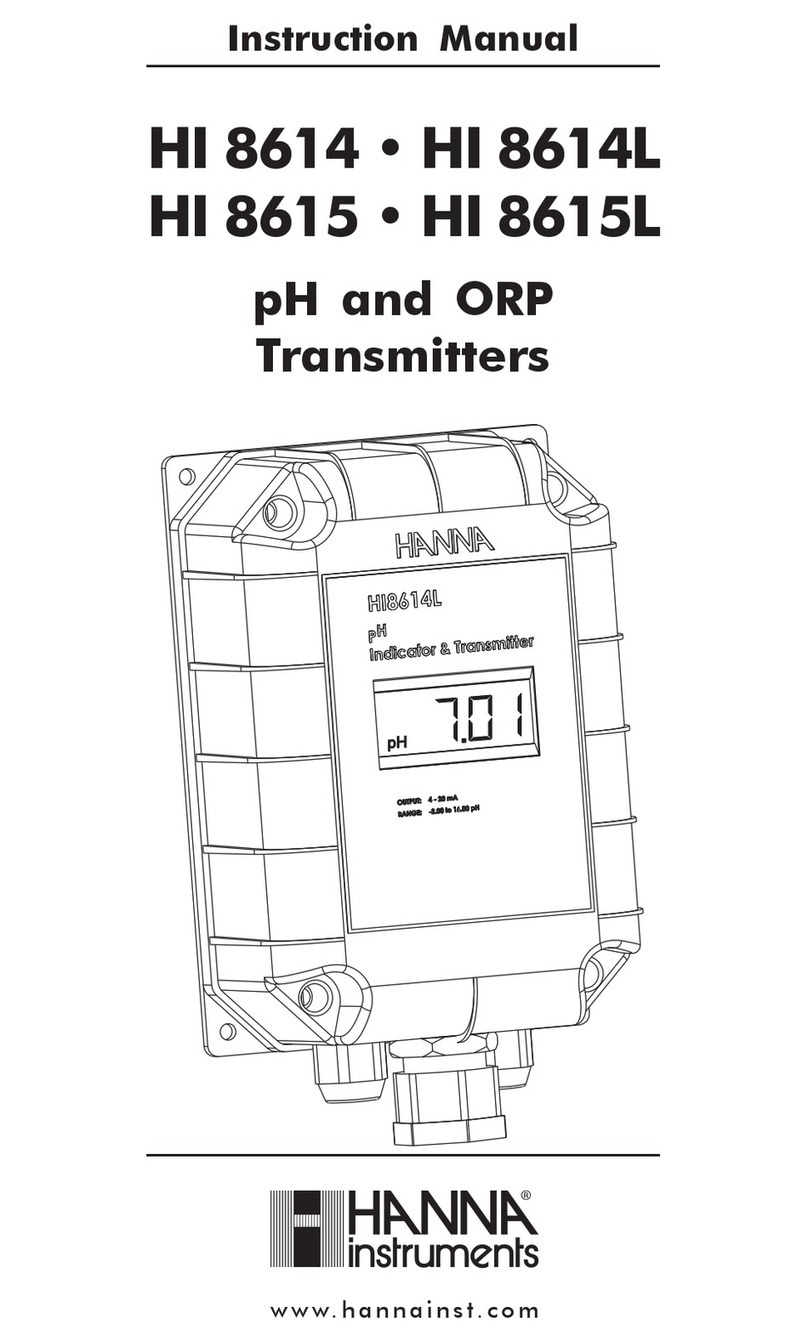

HI 8614/HI 8614L (pH) and HI 8615/HI 8615L

(ORP) are 2-wire water-resistant transmitters

specially designed for long distance mea-

surement of pH or ORP in industrial applica-

tions.

Two versions are available: the standard

HI8614 and HI8615, and the HI8614L and

HI8615L models with LCD.

The LCD allows easy verification and moni-

toring of measured values, and provides easier

calibration and maintainance.

The pH or ORP signal is transmitted in a 2-

wire current loop in the range of 4 to 20 mA.

HI8614 and HI8614L can be connected to

the Hanna process instruments HI8510T,

HI8710T or HI8711T, or to any recorder,

computer or data monitoring device that ac-

cepts 4 to 20 mA input.

HI8615 and HI8615L can be connected to

the Hanna meters HI8512T, HI8720T or to

any recorder, computer or data monitor that

accepts 4 to 20 mA input.

DearCustomer,

Thank you for choosing a Hanna Instruments

Product.

Please read this instruction manual carefully

before using the instrument.

Thismanualwillprovideyouwithalltheneces-

sary information for the correct use of the

instrument.

If you need additional technical information,

do not hesitate to e-mail us at

These instruments are in compliance with the

directives.

TABLEOFCONTENTS

Preliminary Examination............................. 3

General Description .................................... 3

Specifications of HI8614 & HI8614L .......... 5

Specifications of HI8615 & HI8615L........... 6

Terminal Board Connections ....................... 7

pH Calibration withAutomatic Temperature

Compensation (HI8614 & HI8614L) .......... 9

pH Calibration with Manual Temperature

Compensation (HI8614 & HI 8614L) ....... 13

ORP Calibration (HI8615 & HI 8615L).... 14

Electrode Conditioning and Maintenance.. 19

Temperature-Resistance Correlation for

HANNA pH Sensitive Glass .................... 23

Installation Procedure and Examples...... 25

Accessories .............................................. 28

Warranty .................................................. 34

CE Declaration of Conformity ................. 35