2

PRELIMINARY EXAMINATION ....................................................................... 3

GENERAL DESCRIPTION ............................................................................. 3

SPECIFICATIONS OF HI 8614 & HI 8614L .................................................. 5

SPECIFICATIONS OF HI 8615 & HI 8615L .................................................. 6

TERMINAL BOARD CONNECTIONS ................................................................ 7

pH CALIBRATION WITH AUTOMATIC TEMPERATURE COMPENSATION

(HI 8614 FAMILY) ................................................................................... 9

pH CALIBRATION WITH FIXED TEMPERATURE COMPENSATION

(HI 8614 FAMILY) ................................................................................. 12

ORP CALIBRATION (HI8615 FAMILY) ........................................................ 13

ELECTRODE CONDITIONING & MAINTENANCE ............................................... 17

TEMPERATURE CORRELATION FOR pH SENSITIVE GLASS ............................... 20

INSTALLATION PROCEDURE AND EXAMPLES ................................................. 22

ACCESSORIES ........................................................................................ 25

TABLE OF CONTENTS

HI 8614, HI 8614L, HI 8615 and HI 8615L are guaranteed for two

years against defects in workmanship and materials when used for

their intended purpose and maintained according to instructions.

Electrodes and probes are guaranteed for six months. This warranty is

limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed

maintenance is not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the problem. If the repair

is not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments,

first obtain a Returned Goods Authorization number from the Technical

Service department and then send it with shipping costs prepaid.

When shipping any instrument, make sure it is properly packed for

complete protection.

WARRANTY

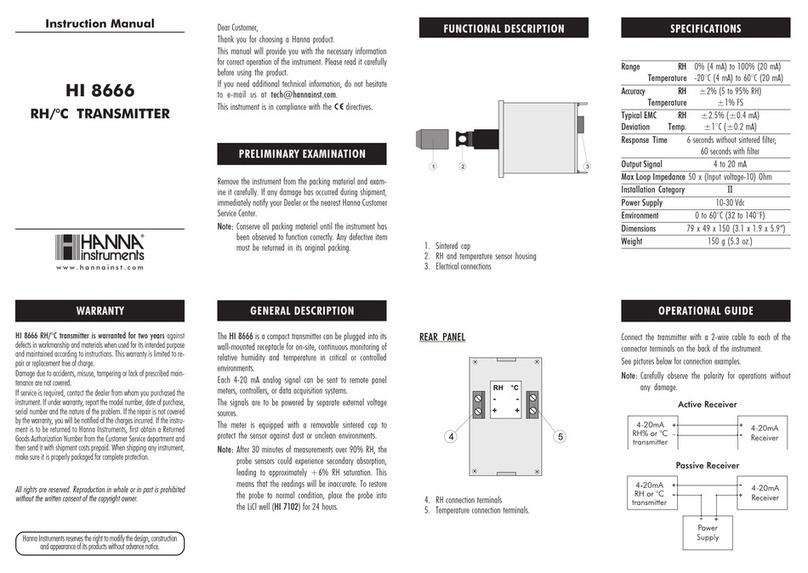

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using these

instruments.

This manual will provide you with the necessary information for correct

use of these instruments, as well as a precise idea of their versatility.

If you need additional technical information, do not hesitate to e-mail

www.hannainst.com.