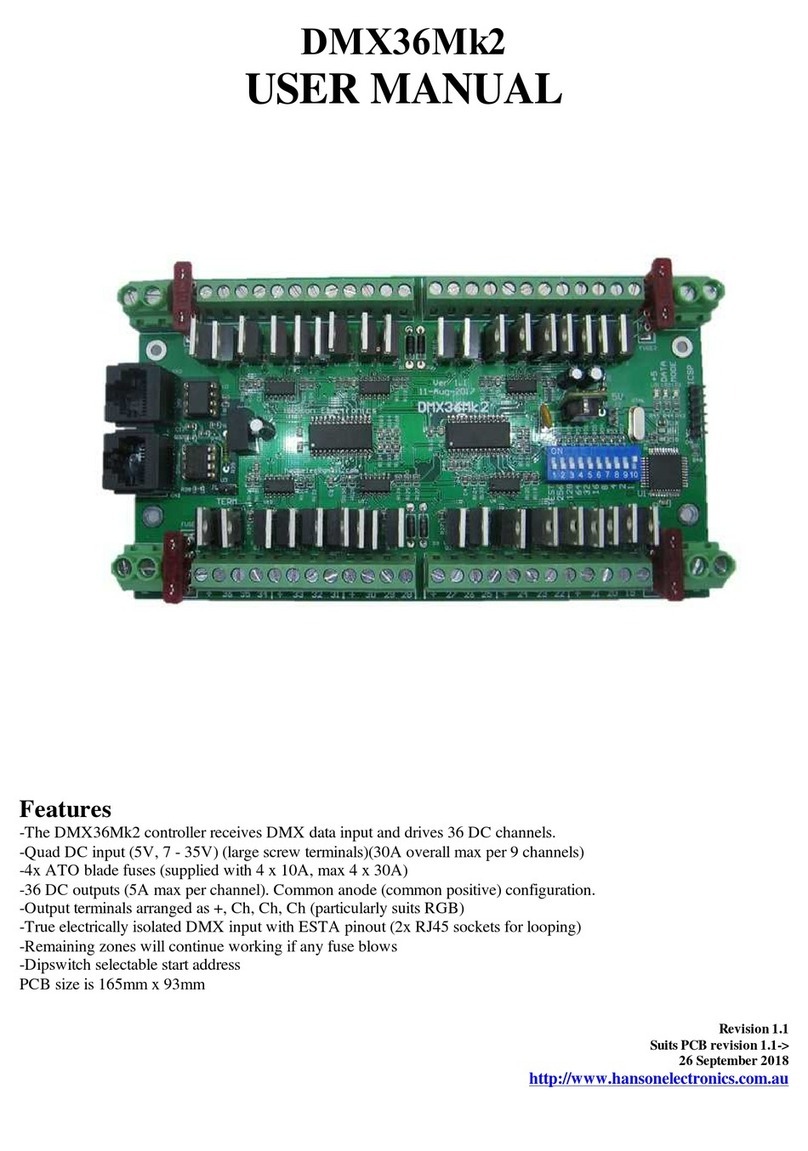

Firmware Updates

Firmware update can be loaded through the ICSP header with a Pickit3 (or PicKit2) pic programmer.

Pin 1 of the ICSP header is marked on the pcb and is shown to the left. Ensure the pin 1 (the arrow) of

the header is aligned with pin 1 of the programmer.

Via MPLAB

MPLAB must be installed. It is available from microchip.com

Plug your PicKit 3 into a spare USB port, then start MPLAB X IDE (or version 8.84 or whatever). Once

it has loaded, click Configure > Select Device to bring up the device selection window. From the device

drop-down list, select PIC16F1823 and click OK.

A dialog saying "New firmware must be downloaded for PicKit 3 to work with the part selected." may pop up at this stage. If

it does, click OK and wait for MPLAB to download the programming firmware to the Pickit 3. You will see some activity in the

PicKit 3 tab of the output window for up to a minute or so. When MPLAB is ready you will see "PicKit 3 Connected" and possibly

an error stating "PK3Err0045: You must connect to a target device to use Pickit 3". This is not a problem and just a warning that

the PicKit 3 cannot "see" the chip yet.

Then, click File > Import and browse to the DMX18 1.0 HEXFILE.hex file (latest version at time of writing) and click Open. The

last line of the build tab of the output window should read "Loaded C:\...DMX18****.HEX."

Now, connect the PicKit 3 the 6 pin ICSP header next to the micro. Make sure the arrows on the Pickit 3 and the 6 pin header

are aligned. Then power up the DMX18. The PicKit 3 tab of the output window should now read "Target Detected”.

Click Programmer > Program to initiate the ICSP operation. The PicKit 3 tab of the output window will show "Programming...",

then "Programming/Verify complete" once it is done. Disconnect the PicKit 3. The PicKit 3 tab of the output window will show

"Target Removed".

Via “Programmer To Go” feature of PicKit3

If a PicKit 3 has been preprogrammed with firmware then all is required is that the DMX18 board is powered up. Plug the PicKit3

onto the header as shown above. Power the PicKit3 by plugging it into any usb socket. The power led on PicKit will light, the status

led will be green and the blue active led will be flashing. Press the pushbutton. The status led will turn red, the active led will turn

solid red. When then Status led turns green again and the blue Active led starts flashing the firmware has been updated.

Via “PicKit 3Programmer” software

T h e P i c k i t 3 p r o g r a m m e r s o f t w a r e c a n b e d o w n l o a d e d a t

http://ww1.microchip.com/downloads/en/DeviceDoc/PICkit%203%200.3.3.0%20Setup%20A.zip .

Extract and run in. Select PIC16F1823 as the Device. Select File>Import Hex> and browse to the DMX18 1.2 HEXFILE.hex

file (latest version at time of writing) . Plug in the PicKit 3. If the DMX18 is powered then click on write and it will update the

firmware. If the board isn’t powered then click on the “On” button in the “Target Power” section. The power and mode light

on DMX18 should then power up. Click on “Write”.

Faultfinding

Fault Solution/solutions

Power Led (red led) not lit -Fuse/s blown (note the control only needs power to 1 zone for power led to be on and for that zone to

work). Check fuses

-Power supply faulty or not turned on.

-Power supply section of pcb damaged. No user repairable parts. Return for repair

-Power jumper set for too high a voltage for what is powering the pcb

1 or more Zones not working -Fuse for that zone is blown, power supply powering that Zone is faulty or there is a wiring fault

Channel failing to turn on -Mosfet transistor has been damaged. Can be replaced but warranty may be voided. The mosfet must be

replaced with the exact same type to ensure correct operation

-PCB track has been burnt out. Should be evident if bottom of pcb is inspected

Channel turned on all the time -Mosfet transistor has been damaged. Can be replaced but warranty may be voided. The mosfet must be

replaced with the exact same type to get correct operation

No DMX signal -Termination jumper is installed when both DMX sockets are in use

-No data is being sent. Check software, dongle, cable etc

-DMX (RS485) receive IC is damaged. IC is socketed for easy replacement. It is U3 (a MAX1483 or

compatible). Ensure the polarity is correct. A notch or dot on the IC must match the notch in the IC socket

-Optoisolation IC is damaged. This would usually only be caused by applying excessive voltage to the

DMX data line. The IC is socketed for easy replacement. It is U2 (a 6N137).Ensure the polarity is correct. A notch or dot on the IC must match

the notch in the IC socket

-Insufficient channels being sent by sequencing/test software

Fuse blowing -Fuse selection too low for lights that are connected

-1 or more lights connected have short circuited wires

5

-5-