Define Instruments PRO-WEI100 User manual

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

1

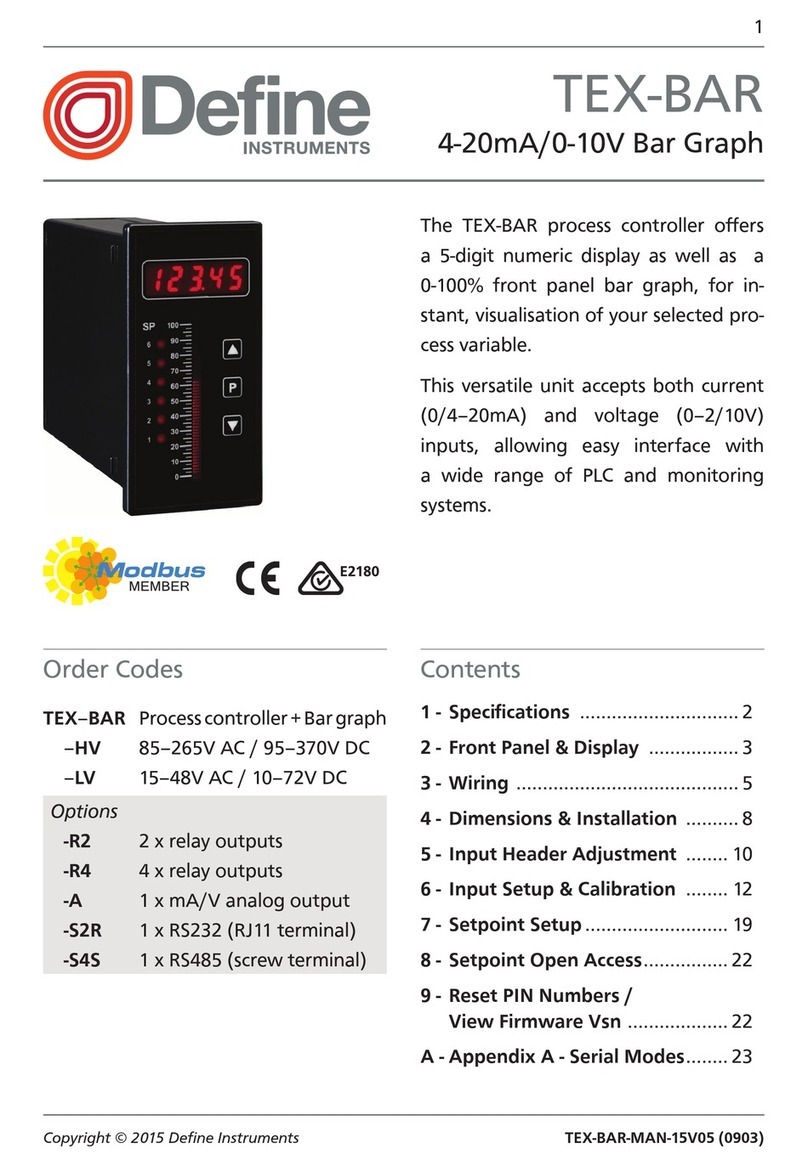

This intelligent weighing controller ac-

cepts input directly from a 4-wire or a

6-wire strain gauge.

The PRO-WEI100 has a number of ad-

vanced functions designed specically

for the weighing industry, and is simple

to set up and operate. It also features

output and input isolation, eliminating

the need for any special consideration

when interfacing to analog/serial in-

puts, or PCs/PLCs/HMIs.

Contents

1 Specications ............................. 2

2 Features ....................................... 3

3 Front Panel & Display................. 6

4 Wiring ........................................ 8

5 Dimensions & Installation ........ 11

6 Input Setup & Calibration ....... 13

7 Setpoint Setup........................... 24

8 Setpoint Direct Access .............. 27

9 Reset PIN Numbers .................. 27

10 Factory Analog Output

Calibration ................................. 28

A Appendix A - Input Functions... 29

B Appendix B - Serial Modes........ 31

PRO-WEI100

Weighing Controller

Order Codes

PRO–WEI100 Strain gauge input

–HV

–LV

85–265V AC / 95–370V DC

15–48V AC / 10–72V DC

Options

-R2

-R4

2 x relay outputs

4 x relay outputs

-A 1 x mA/V analog output

-S2R 1 x RS232 (RJ11 terminal)

-S4S 1 x RS485 (screw terminal)

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

2

1 SPECIFICATIONS

Input

Input 4/6-wire strain gauge, 1–5mV/V

Power HV= 85–265V AC / 95–370V DC,

or LV= 15–48V AC / 10–72V DC

Max power 5W, fully optioned,

8 loadcells

Excitation 5V DC excitation supplied

(powers up to 8 x 350Ω loadcells)

Sampling rate Up to 60Hz

Resolution 18 bit

Accuracy 0.005% of reading

Temperature dri Typically 3ppm/°C

Relay Output

Number of relay outputs None, 2, or 4

Relay output type 5A form A (3A 240V

AC max or 3A 30V DC max)

Analog Output

Number of analog outputs None or 1

Analog output type Isolated 16 bit

4–20mA/0–10V

Comm Port

Number of comm ports None or 1

Comm port options

S2R= Isolated RS232, RJ terminal, or

S4S= Isolated RS485, screw terminal

Serial output Custom ASCII, Modbus

RTU slave, Gedge, Ranger A, or Print

Programming

Front panel buttons Up, Down, Prog,

plus 2 Function Buttons for menu access

Factory calibrated for 0–10,000 counts

(2mV/V sensor gain at full scale). 2 cal

sets for saving/restoring calibrations

Security Input and setpoint setups are

independently PIN protected

Display

Display type LED display, 5 buttons

LED indicators 6 setpoint indicator LED's

Digits 1 row of 6 digits, 13mm (0.5"),

14 segment alphanumeric LED

Construction

IP65 dust/splash proof (face only)

Dimensions (H x W x D)

96 x 48 x 120mm (3.78 x 1.89 x 4.72")

Panel cutout 92 x 45mm (3.62 x 1.77")

OPTIONAL

OPTIONAL

OPTIONAL

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

3

2 FEATURES

2.1 - Batching

To access batching features, the controller's Mode must be set to Batch (see 6.2F).

It is then possible to perform the following functions from the button or rear

input pins:

Batch This function is used to display the live weight of the system but take

regular 'batches' of product without continually changing the setpoint.

When the Batch function is activated the display will tare and SP 1 and

SP 2 will turn on.

Batch Reset Resets the batch value to zero and halts any current batching operations.

Batch Pause Pauses the batching process and holds the current batched weight on

the display.

Batch Resume Resumes the batching process aer it has been paused, or if power was

lost during a previous batch.

See 6.2H–K and Appendix A for instructions on setting up and operating these features.

2.1A - Gain in Weight (GIW) Batching Direction

The Batching Direction parameter is set in 6.2G, and should be set to GIW (Gain

in Weight) for applications where the weight increases as product is added to the

weighing system.

E.g. Setting a setpoint value of 50Kg for SP 1 and 45Kg for SP 2 and enabling GIW batching will al-

low the user to ll a container to 50Kg, with a potential speed change at 45Kg. (See 2.1C for an

alternative method of setting up SP 2.)

The cycle is initiated when the Batch function is triggered. The display will tare, and when 45Kg

net weight is shown, SP 2 will drop out. As product continues to feed, at 50Kg SP 1 will drop

out, halting the ll.

If Flash Gross is enabled (see 6.2L) the gross weight will be displayed (E.g. Now 1050Kg, if the

starting gross weight was 1000Kg). The user can then trigger the Batch function again to call

another 50Kg batch.

2.1B - Loss in Weight (LIW) Batching Direction

The Batching Direction parameter is set in 6.2G, and should be set to LIW (Loss in

Weight) for applications where the weight decreases as product is removed from the

weighing system.

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

4

E.g. Setting a setpoint value of 50Kg for SP 1 and 45Kg for SP 2 and enabling LIW batching will al-

low the user to ll a container to 50Kg, with a potential speed change at 45Kg. (See 2.1C for an

alternative method of setting up SP 2.)

The cycle is initiated when the Batch function is triggered. The display will tare, and when 45Kg

net weight is discharged, SP 2 will drop out. As product continues to be discharged, at 50Kg SP 1

will drop out, halting the product ow.

If Flash Gross is enabled (see 6.2L) the gross weight will be displayed (E.g. Now 950Kg, if the

starting gross weight was 1000Kg). The user can then trigger the Batch function again to call

another 50Kg batch.

In this mode if there is not enough product to drop a batch, then the instrument will advise the

operator by showing the message Low Product. If gross > SP 1, the Batch Value is reset to zero

and the display ashes Batch. SP 1 is turned on (and SP 2 if set up). If gross < SP 1, batching is

not started.

2.1C - Setpoint Tracking

In applications where the batch weight is continuously being changed, it is possible

to congure SP 2 so that it tracks SP 1, and always turns o at a xed amount below

the required batch weight.

E.g. If your initial batch weight was 100Kgs and you wanted SP 2 to turn o 5Kgs before it reached

the batch weight, you would set up the SP 1 value for 100Kgs and the SP 2 value for -5Kgs, and

set the Trail SP 1 option to on (see 6.2D).

This would cause SP 2 to turn o at 95Kgs (i.e. 100Kgs - 5Kgs). Then if you wanted the next

batch weight to be 200Kgs, you only need to change SP 1 to 200Kgs, and without altering

SP 2 it will now turn o at 195Kgs (200Kgs - 5Kgs).

2.2 - Input signal averaging

This controller has input signal averaging (see 6.5), to reduce noise and optimise

stable measurement. If your input signal contains large noise spikes, you can increase

the size of the Averaging Window to ensure that these are still averaged. If the

change in input exceeds the Averaging Window value it will not average, ensuring

fast response when there are large dierences between readings.

Note that increasing the window size too far will reduce the ability of the controller to respond

quickly to real changes in input signal.

2.3 - Tare

To access tare features, the controller's Mode must be set to Normal (see 6.2F). It is

then possible to Tare/Reset Tare from the button or rear input pins:

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

5

Tare This feature 'zeroes' the display, and is usually used to deduct the weight

of the container from the total weight, leaving only the weight of the

product.

Tare Reset This feature clears the current tare value and shows the gross weight on

the display.

See 6.2H–K and Appendix A for instructions on setting up and operating these features.

2.4 - Zero maintenance

The Zero Maintenance feature is used to automatically compensate for slow dri in

loadcell output due to factors such as temperature change, rain and dust accumula-

tion over time.

When Auto Zero is enabled (see 6.4B), the controller display will zero automatically

if changes to the loadcell are within the user specied Capture Band, Motion Band

and Zero Band parameters (see 6.4C–E):

Capture Band (6.4C) This is the maximum number of display counts that the controller

will automatically zero within. The Capture Band is referenced to

the current zero value. If the input value on the load cell is not

within the Capture Band setting then the controller displays the

current loadcell value and does not zero.

Capture Band can be set from 1 to 254 counts, and should always be

set to less than the smallest weight to be measured. Setting the Cap-

ture Band to 0 will turn the auto zero feature o.

Motion Band (6.4D) This provides a rate of change limit setting, to determine the num-

ber of counts/second allowed within the Capture Band. If the

count change is within the Capture Band, but the speed of the

count change is more than the selected Motion Band, then the

controller displays the current loadcell value and does not zero.

The Motion Band can be set from 0 to 255 counts. Typical value is 1

or 2 counts/sec.

Zero Band (6.4E) This provides a limit for the number of counts of zero offset

allowed to accumulate, relative to the calibrated zero setting. If

the accumulated zero offset becomes greater than this window,

then the controller displays the current loadcell value and does

not zero.

The suggested limit for the Zero Band is 2% of the calibrated span. If

the controller fails to zero, check for mechanical or electrical faults.

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

6

3 FRONT PANEL & DISPLAY

3.1 - Front panel

SPX The SP LED's are used to

indicate active setpoints.

NET The net LED indicates

when the net value is being dis-

played, and is also used for the

Flash Gross function (see 6.2L).

96mm (3.78")

48mm

(1.89")

This button is used to access the Input Setup & Calibration menu (Section 6)

and the Factory Analog Output Calibration menu (Section 10).

This button is used to save your settings and advance to the next step in the

setup process. A custom function can also be programmed (see 6.2H).

This button is typically used to scroll through options or increase values in the

setup menu. Pressing this button from the main display will allow you to view/reset

the Peak value, and view the raw input value (see 3.3).

This button is typically used to scroll through options or decrease values in the

setup menu. Pressing this button from the main display will allow you to view/reset

the Valley value (see 3.3).

This button is used to access the Setpoint Setup menu (Section 7) and the Set-

point Direct Access menu (Section 8).

3.2 - Display brightness

To adjust the display brightness, press the and buttons together from the

main display. BRI appears and toggles with the current setting. Use the and

buttons to adjust the LED backlight, and then press to nish.

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

7

3.3 - Up and down button shortcuts

Pressing the and buttons from the main operational display allows instant

access to a number of values held in the controller's memory. These variables will ap-

pear in the order shown in the table below, and will cycle continuously at each press

of the or button. Press at any time to return to normal operating mode.

PEAK and VALLEY may be reset to zero by pressing the and buttons at the

same time while the variable is being displayed.

Up and down button shortcuts

PEAK The maximum measured weight since the instrument was turned on or reset

RAW IP The current raw value of the input signal in mV

VALLEY The minimum measured weight since the instrument was turned on or reset

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

8

4 WIRING

BEFORE YOU BEGIN WIRING, ensure that the unit is switched o and the power

supply is disconnected.

4.1 - Pinouts

B

EF

A C

D

Key

4.1A Relay Output (See 4.3)

4.1B Serial Port (See 4.5)

4.1C Analog Output (See 4.4)

4.1D Analog Input (See 4.2)

4.1E Function Pins (See 4.6)

4.1F Power Supply HV/LV

(See 4.7)

4.2 - Wire the strain gauge input module

Wire your loadcell input module as shown in the dia-

gram. This input module is pre-calibrated for 0–10,000

counts full scale with a 2.000mV/V load cell sensor.

See 4.1D

-

Sense

+ EXC

+ Sense

Input sig. high

Input sig. low

-

EXC

Guard

Not connected

-

Sense

+ EXC

+ Sense

Input sig. high

Input sig. low

-

EXC

Guard

Not connected

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

9

4.3 - Wire the relay outputs (if installed)

If your controller has relay outputs tted, wire them as shown below. Relays can be

programmed to operate within the total span range of the controller.

See 4.1A

SP2 SP1

-R2

SP3SP4 SP1SP2

-R4

4.4 - Wire the analog output (if installed)

If your controller has analog output tted, wire it as shown for either

voltage (0–10V) or current (4–20mA).

See 4.1C

–V

+V

–mA

+mA

-A

4.5 - Wire the serial port (if installed)

If your controller has serial port tted, wire it as

shown in the applicable diagram. (S2R: RS232, RJ11

terminal, S4S: RS485, screw terminal).

See 4.1B

N/C

SGND

+5V DC (option)

RXD

TXD

N/C

-S2R

D

-

D +

SGND

-S4S

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

10

4.6 - Wire the function pins

Connect external switches to enable a function to be

executed when its switch is activated.

Pin functions are user congurable, and can be set up

in 6.2I–K.

See 4.1E and Appendix A

User 1

N/C

User 2

COM

User 3

4.7 - Wire the power supply

DO NOT attempt to wire your controller while the power is on. NEVER connect your

low voltage controller to mains power.

Wire your controller for low or high voltage power supply, as show in the diagrams

below. Check the label on the unit against the colour of the connector:

›Orange =

High voltage (85–265V AC,

95–370V DC)

›Black =

Low voltage (15–48V AC,

10–72V DC)

See 4.1F

High

voltage

(HV)

HV power

supply

−DC

Neutral

AC

+DC

Live

AC

Low

voltage

(LV)

LV power

supply

−DC

Neutral

AC

+DC

Live

AC

Once you have completed the wiring process it is safe to switch on your power

supply. Ensure that your display is functioning before you proceed.

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

11

5 DIMENSIONS & INSTALLATION

5.1 - Case dimensions

Cabling

Allowance

96mm

(3.78")

92mm

(3.62")

120

mm (4.72")

39

mm (1.54")

155mm (6.10") minimum depth required behind panel

4mm (0.16")

Cabling

Allowance

48mm

(1.89")

45mm

(1.77")

120mm (4.72") 39mm (1.54")

155mm (6.10") minimum depth required behind panel

4mm (0.16")

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

12

5.2 - Installation instructions

A Prepare the Panel Cutout to

92 x 45mm ±.5 (3.62 x 1.77" ±.02),

as shown below. Allow at least

155mm (6.10") depth behind the

panel to accommodate the meter

body and protruding cabling.

B Remove the Mounting Clips from

the meter back.

C Slide the Panel Gasket over the

rear of the unit to the back of the

Meter Faceplate.

D From the front of the panel, insert

the meter into the Panel Cutout.

Holding the unit in place, engage

the Mounting Clips so that the tabs

snap into place over the notches on

the case.

E To achieve a proper seal, tighten

the Screws evenly until the unit sits

rmly against the panel. Do not

over-tighten the screws.

Panel Meter Faceplate

Panel

Gasket

Mounting

Clips

Screws 92mm ±.5

(3.62″ ±.02)

45mm ±.5

(1.77″ ±.02)

Panel Cutout

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

13

6 INPUT SETUP & CALIBRATION

6.1 - Enter F1 PIN number

A Enter the calibration mode by pressing the button.

_ _ _ ENTER F1 PIN scrolls across the display and toggles with 0. Use the and

buttons to enter your security code (factory default 1). Then press . If the

correct PIN is entered, setup is started at 6.2.

If an incorrect PIN number is entered, _ _ _ ACCESS DENIED scrolls across the

display and it returns to normal operating mode.

You will have the opportunity to change your PIN number at the end of this section

(6.9). If you have forgotten your PIN number, see Section 9.

6.2 - Input setup

A _ _ _ INPUT SETUP scrolls across the display and toggles with SKIP. Press to

skip to 6.3, or the button and then to ENTER input setup.

B _ _ _ SUPPLY REJECTION FREQUENCY scrolls across the display. Use the

and buttons to select 50HZ or 60HZ, and then press .

C _ _ _ SAMPLING RATE scrolls across the display and toggles with the current

selection. Use the and buttons to select an option from the following list:

1HZ, 2HZ, 5HZ, 10HZ, or 50HZ/60HZ (50 or 60Hz will depend on your selection

in 6.2B above). Then press .

D _ _ _ DECIMAL POINT POSITION scrolls across the display and toggles with the

current selection. Use the and buttons to select NO DP (default), 0.0,

0.00, 0.000 or 0.0000, and then press to accept and continue.

E _ _ _ ROUNDING scrolls across the display and toggles with the current display

rounding. Using the and buttons, select: NONE (default), 2, 5, 10, 20, 50,

100, 200, 500, or 1000. Then press .

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

14

Rounding is quoted in display counts and is not inuenced by decimal point position. For exam-

ple, if your input signal is 5.3, the display will show: 5.3 (for rounding=NONE), 5.4 (for round-

ing=2), 5.5 (for rounding=5), 5.0 (for rounding=10), etc.

F _ _ _ MODE scrolls across the display and toggles with the current weighing

mode. Use the and buttons to select NORMAL (default) or BATCH, and

then press .

¨If you selected NORMAL, skip to 6.2H now.

¨If you selected BATCH, continue to 6.2G now.

In NORMAL (default) mode the controller displays the gross or net weight on the display, and

does not perform any batch calculations. In BATCH mode the controller displays batch or gross

weight, and SP 1 and SP 2 function as dedicated batch control setpoints (see 2.1).

G _ _ _ BATCHING DIRECTION scrolls across the display and toggles with current

selection. Use the and buttons to select either: LIW (loss in weight, for

emptying operations) or GIW (gain in weight, for lling operations). Press .

See Section 2.1 for additional information.

For 6.2H–K, please refer to the list of input functions in Appendix A.

H _ _ _ PROG BUTTON scrolls across the display and toggles with the current

selection. Referring to the table in Appendix A, use the and buttons

to select a function to be performed when the button is pressed: HOLD,

TARE1, BATCH2, ZERO, PEAK, PK RST or PRINT. Then press .

I _ _ _ USER INPUT1 scrolls across the display and toggles with the current selec-

tion. This controls the function that will be performed when the User 1 input pin

at the rear of the meter (see 4.6) is activated. Referring to the table in Appendix

A, use the and buttons to select: LOCK, TARE1, BATCH2, ZERO, PEAK,

PK RST, PRINT, GROSS, START2or STOP2. Then press .

J _ _ _ USER INPUT2 scrolls across the display and toggles with the current selec-

tion. This controls the function that will be performed when the User 2 input pin

at the rear of the meter (see 4.6) is activated. Referring to the table in Appendix

A, use the and buttons to select: HOLD, TARE1, BATCH2, ZERO, PEAK,

PK RST, PRINT, GROSS, START2or STOP2. Then press .

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

15

K _ _ _ USER INPUT3 scrolls across the display and toggles with the current selec-

tion. This controls the function that will be performed when the User 3 input pin

at the rear of the meter (see 4.6) is activated. Referring to the table in Appendix

A, use the and buttons to select: TARE1, BATCH2, ZERO, PEAK, PK RST,

PRINT, GROSS, START2or STOP2. Then press .

L _ _ _ FLASH GROSS scrolls across the display and toggles with the currently

selected setting. Using the and buttons, select NO or YES, and press .

This will cause the display to toggle between the Net/Gross values for 3 seconds each. Toggling

will only occur if the controller has been tared and the Net/Gross values are dierent. The NET

LED indicates which value is being displayed (On: Net, O: Gross). This option will be disabled

if a batch is currently in progress.

1 TARE feature is only available when the Mode is set to NORMAL (see 6.2F).

2 BATCH, START and STOP features are only available when the Mode is set to BATCH (see 6.2F).

6.3 - Calibration

This unit has been calibrated for 0–10,000 counts (2mV/V sensor gain at full scale).

A _ _ _ CALIBRATION TECHNIQUE scrolls across the display and toggles with

SKIP. Press to skip to 6.4, or use the and buttons to select a calibration

method: AUTO, MV/V, ZERO, E_CAL, or CALSET, and press to continue.

¨If you selected AUTO, complete steps 6.3B–F now.

¨If you selected MV/V, complete steps 6.3G–I now.

¨If you selected ZERO, complete step 6.3J now.

¨If you selected E_CAL, complete steps 6.3K–L now.

¨If you selected CALSET, complete steps 6.3M–N now.

¨If you selected SKIP, skip to 6.4 now.

AUTO calibration uses zero and span values to calculate the scale and oset. This is the most

accurate calibration method, but requires known low and high input signals, usually supplied

by test weights. Zero and span calibration procedures are performed separately.

MV/V uses values from the load cell manufacturer’s test certicate.

ZERO allows manual adjustment of the calibrated zero oset.

E_CAL allows the user to view and edit the electronic calibration values (zero oset and scale

factor). These two values are updated when any calibration is performed. Noting these values

and entering them into another instrument will copy the calibration. You may also 'trim' these

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

16

values to alter the current calibration.

CALSET allows the user to select and switch between calibration sets, giving them the option

of saving and restoring a previous calibration.

Auto calibration

B _ _ _ CAL SET X –CALIBRATE ZERO scrolls across the display, where Xis the Cal

Set where the current calibration will be stored (see 6.3M). –CALIBRATE ZERO

toggles with the currently selected option. Use the and buttons to select

YES or NO, and then press .

¨If you selected YES, continue to 6.3C now.

¨If you selected NO, skip to 6.3D now.

C _ _ _ REMOVE WEIGHT – PRESS P TO ACCEPT scrolls across the display and

toggles with the current no-load value. Remove the weight. Use the and

buttons to adjust the no-load value if required, and then press .

D _ _ _ CALIBRATE SPAN scrolls across the display and toggles with the current

selection. Use the and buttons to select YES or NO, and then press .

¨If you selected YES, continue to 6.3E now.

¨If you selected NO, skip to 6.3F now.

E _ _ _ ADD CAL WEIGHT – ENTER DESIRED SPAN – PRESS P TO ACCEPT scrolls

across the display and toggles with the current span value. Apply a calibration

weight to the weigh platform. Then use the and buttons to adjust the

value, and press to accept.

F If Auto calibration was successful, you will be directed out of the calibration

menu to the operational display without viewing any further scrolling messag-

es. (To enter step 6.4, you must select SKIP at 6.3A.)

If calibration fails, _ _ _ CALIBRATION FAILED will scroll across the display and

you will be directed back to the operational display. Check your signal and con-

nections, and then repeat the calibration procedure.

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

17

mV/V calibration

G _ _ _ ENTER TOTAL FULL SCALE WEIGHT OF LOAD CELLS IN COUNTS scrolls

across the display and toggles with the current selection. Using the and

buttons, enter the total full scale weight of the connected load cell(s) in counts,

referring to the load cell manufacturer's test certicate. Then press .

H _ _ _ ENTER MV/V FROM LOAD CELL scrolls across the display and toggles with

the current selection. Using the and buttons, enter the mV/V (or average

mV/V) of the connected load cell(s), and then press .

I _ _ _ SET ZERO NOW? scrolls across the display and toggles with the current

selection. Use the and buttons to select YES or NO, and then press .

Selecting YES sets your zero position when the load cells are powered up and in position.

mV/V calibration is now complete. You will be directed back to the operational

display. (To enter step 6.4, you must select SKIP at 6.3A.)

Zero (oset) calibration

J _ _ _ ADJUST OFFSET scrolls across the display and toggles with the currently

selected zero value. Place a known weight on the weigh platform if required,

and use the and buttons to enter the desired value. Press to accept.

The oset will be automatically calculated to match the desired weight, and the scale factor will

not be altered. (Normally the weight would be removed and the value would be zero.)

Zero calibration is now complete. You will be directed back to the operational

display. (To enter step 6.4, you must select SKIP at 6.3A.)

E_Cal calibration

K _ _ _ E_CAL ZERO OFFSET scrolls across and toggles with the current selection.

Use the and buttons to adjust the zero oset value, and then press .

This is updated aer each calibration to show the internal ZERO OFFSET E Cal value.

L _ _ _ E_CAL SCALE FACTOR scrolls across and toggles with the current selec-

tion. Use the and buttons to adjust the scale factor value, and press .

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

18

This is updated aer each calibration to show the internal SCALE FACTOR E Cal value.

E_Cal calibration is now complete. You will be directed back to the operational

display. (To enter step 6.4, you must select SKIP at 6.3A.)

Cal set selection

M _ _ _ SELECT CAL SET scrolls across and toggles with the current selection. Use

the and buttons to choose either SET 1 or SET 2, and then press .

This feature allows you to save two sets of calibration values on the controller, and to roll back

to a previous calibration, if necessary. The set that you select will be the active calibration set.

N _ _ _ CALIBRATION TECHNIQUE scrolls across the display and toggles with

SKIP. You are now back at 6.3A. Press to skip to 6.4, or use the and

buttons to select a new calibration method, and then press .

6.4 - Zero maintenance

See Section 2.4 for more information on zero maintenance parameters.

A _ _ _ ZERO MAINTENANCE scrolls across the display and toggles with SKIP. Press

to skip to 6.5, or the button and then to ENTER zero maintenance.

B _ _ _ AUTO ZERO scrolls across the display and toggles with the current auto

zero selection. Use the and buttons to select ON or OFF, and press .

¨If you selected ON, continue to 6.4C now.

¨If you selected OFF, skip to 6.4E now.

If AUTO ZERO mode is ON, the controller’s oset will be automatically adjusted so that the

instrument reads zero when it senses that the scale is not loaded (see 2.4).

C _ _ _ CAPTURE BAND scrolls across the display and toggles with the selected

capture band. Adjust this value using the and buttons, and then press .

This is referenced to the current zero value, and is the maximum number of display counts that

the controller will zero within. CAPTURE BAND can be set from 1to 254 counts, and should

always be set to less than the smallest weight to be measured.

PRO-WEI100-MAN-19V01 (0225)Copyright © 2019 Dene Instruments

19

D _ _ _ MOTION BAND scrolls across the display and toggles with the selected

motion band. Adjust this value using the and buttons, and then press .

This provides a rate of change limit setting, to determine the number of counts/second allowed

within the CAPTURE BAND. MOTION BAND can be set from 0to 255 counts. Typical value is

1or 2counts/sec.

E _ _ _ ZERO BAND scrolls across the display and toggles with the selected zero

band. Adjust this value using the and buttons, and then press .

This provides a limit for the number of counts of zero oset allowed to accumulate, relative to

the calibrated zero setting. If the accumulated zero oset becomes greater than this window,

then the controller displays the current loadcell value and does not zero. The suggested limit

for the ZERO BAND is 2% of the calibrated span.

6.5 - Averaging

Your controller has input signal averag-

ing, optimising stable measurement.

If the change in input exceeds the

averaging window value it will not

average, ensuring fast response when

there are large dierences between

readings. (E.g. When product is being

dropped into a bag.)

Input signal in counts

Sampling

Averaging window

in displayed counts

Number

of samples

Input exceeds

averaging window

A _ _ _ AVERAGING PARAMETERS scrolls across and toggles with SKIP. Press

to skip to 6.6, or the button and then to ENTER averaging setup.

B _ _ _ AVE SAMPLES scrolls across the display and toggles with the currently

selected averaging. Using the and buttons, alter the number of input

samples that the controller will average, and then press .

Increasing the number of samples will stabilise measurement, but it will also slow down re-

sponse rates. A typical value is 4.

C _ _ _ AVE WINDOW scrolls across the display and toggles with the currently

selected averaging window value. Using the and buttons, alter the signal

averaging window. Then press .

If your input signal contains large noise spikes, you can increase the size of the averaging win-

dow to ensure that these are still averaged. However, increasing the window size too far will

PRO-WEI100-MAN-19V01 (0225) Copyright © 2019 Dene Instruments

20

reduce the ability of the controller to respond quickly to real changes in input signal. Setting

AVE WINDOW to 0will give continuous averaging as per the selected averaging samples. A

typical value is 10% of your system capacity.

6.6 - Analog output setup

N.B. All new units are calibrated before shipping. Recalibration is only necessary if settings

are wiped or the unit's accuracy requires verication aer a long period of use. e.g. 1 year.

A _ _ _ ANALOG OUTPUT SETUP scrolls across the display and toggles with SKIP.

If your controller does not have analog output installed, (or you do not wish to

congure your analog output now), press to skip to 6.7.

Otherwise, press the button and then to ENTER analog output setup.

B _ _ _ DATA SOURCE FOR ANALOG O/P scrolls across the display and toggles

with the current analog output data source. Use the and buttons to

select an option from: NET/BATCH, or LIVE, and then press .

Note that where NET/BATCH is indicated, the option that will be displayed is controlled by the

weighing mode selected in 6.2F. NORMAL mode = NET, BATCH mode = BATCH.

C _ _ _ LOW SCALE VALUE FOR ANALOG O/P scrolls across the display and tog-

gles with the currently selected low scale display value. Use the and but-

tons to enter your cal low position, and then press .

D _ _ _ HIGH SCALE VALUE FOR ANALOG O/P scrolls across the display and

toggles with the currently selected high scale display value. Use the and

buttons to enter your cal high position, and then press .

To calibrate your analog output, see Section 10.

Factory analog output calibration is precisely set before shipping this instrument,

and should not be adjusted unless advised by the manufacturer.

6.7 - Serial setup

A _ _ _ SERIAL SETUP scrolls across the display and toggles with SKIP. If your

controller does not have a serial port installed, (or you do not wish to congure

your serial options now), please press to skip to 6.8.

Table of contents

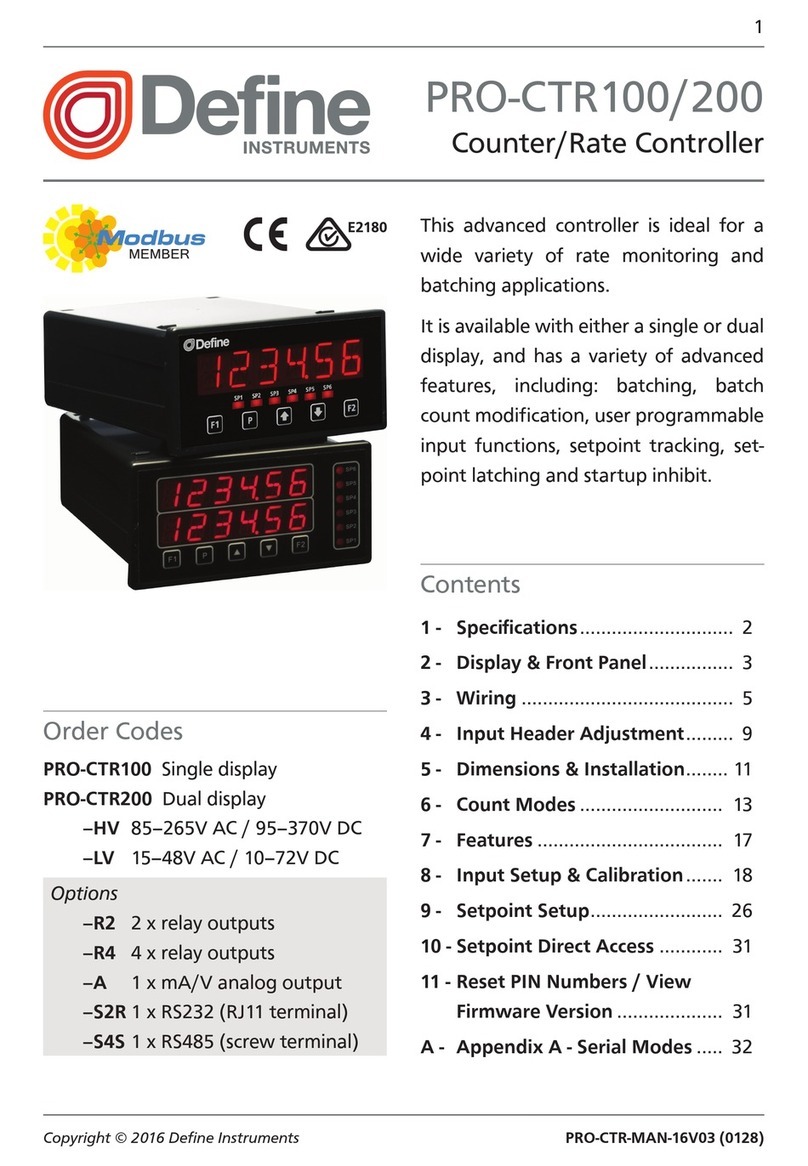

Other Define Instruments Controllers manuals

Popular Controllers manuals by other brands

Larson Electronics

Larson Electronics PTB-1-M-30C-4C instruction manual

Phocos

Phocos CIS user manual

TRIAC

TRIAC 2R2500 Installation & maintenance manual

Phoenix Contact

Phoenix Contact EV Charge Control Basic user manual

Gardena

Gardena Watering Controller 6040 operating instructions

YASKAWA

YASKAWA MP3000 Series Setup manual