Hanwei BS03 User manual

BS03

Fixed gas detector

Operation manual

Read this manual carefully before using the device

Ver:HWWM160617CG

Safety information

1. Before using the device, please first carefully read and follow the

following information to operate the device:

2. Please don't use the defective detector. Before using, please check if

there is crack or spare part missing. If yes, please contact the seller.

3. In order to keep the accuracy, please calibrate it once before the first

time using.

4. Working voltage of the detector is DC18V to DC30V and recommended

voltage is DC24V. The voltage exceeding DC30V will damage the

detector.

5. Before using, please make sure the housing is fixed.

6. There should be no speedy gas flow on the installation place. Otherwise,

it will influence the detection result.

7. Please don't expose the device to the gas which concentration is

exceeding the range. Otherwise, it will influence the accuracy and

shorten the sensor life.

8. Please don't paint the sensor parts or detector.

9. Only sensor spare parts which are specified for BS03 are allowed to be

used.

10. It's suggested calibrate the sensor once every 6 months.

11. In order to avoid damage human beings, please operate it when power

off. Before opening the cover, make sure there is no mixture gas of

combustible gas and air. Otherwise, it will possibly cause fire or

explosion.

12. Please avoid water or dust to come into the housing.

13. Please don't expose the device to the environment which has electric

shock, strong magnetic field or serious continuous mechanic shocking.

14. When no using, please take out the battery from the remote controller.

15. Installation must abide by the national and local regulations.

16. It's forbidden to disassembly, adjust or repair the device without

permission.

17. All the operation inside the device must be carried by professional

persons.

Table of content

1. BRIEF INTRODUCTION........................................................................... 1

2. MAIN TECHNICAL SPECIFICATION.......................................................... 1

3. STRUCTURE........................................................................................... 2

4. INSTALLATION ....................................................................................... 3

4.1 INSTALLATION POSITION .............................................................................3

4.2 DIMENSIONS............................................................................................4

4.3 INSTALLATION METHODS.............................................................................4

5. WIRE CONNECTION............................................................................... 6

6. OPERATION........................................................................................... 8

6.1LOW ALARM SETTING.................................................................................9

6.2HIGH ALARM SETTING ................................................................................9

6.3ZERO TRANSLATION ...................................................................................9

6.4SINGLE POINT CALIBRATION.......................................................................10

6.5 ADDRESS CODE SETTING ...........................................................................10

7. SENSOR REPLACEMENT ...................................................................... 11

8. TROUBLE SHOOTING GUIDANCE ......................................................... 13

BS03 fixed gas detector operation manual

1

1. Brief introduction

BS03 fixed gas detector, adopting high-quality catalytic gas sensor and

SMD arts and crafts, has advantages of good reproducibility, disturbing-proof

against temperature and humidity, long life-span and easy operation.

The signal output of BS03 is standard 4-20mA. It is widely used in

refineries, chemical plant, LPG station, gas boiler, and Spray-Paints etc where

gas leakage easily.

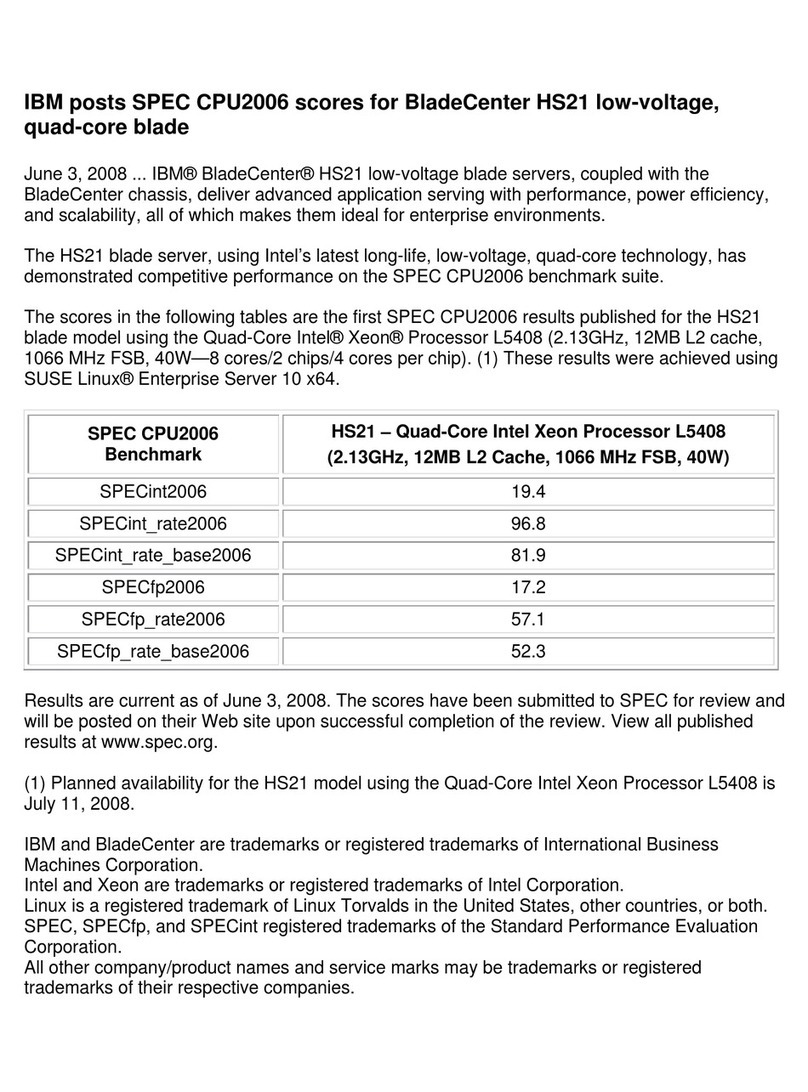

2. Main technical specification

Gas

Range

Resolution

Calibrating gas flow

LEL

0-100%LEL

1%LEL

500±50ml/min

CH4,

C3H8

0-100%LEL

1%LEL

500±50ml/min

CH4

0-5%VOL

0.1%VOL

500±50ml/min

CO

0-1000PPM

1PPM

200ml/min

H2S

0-100PPM

1PPM

200ml/min

NH3

0-100PPM

1PPM

500±50ml/min

CL2

0-20PPM

0.1PPM

1000±50ml/min

H2

0-100%LEL

1%LEL

500±50ml/min

O2

0-30%VOL

0.1%VOL

300±50ml/min

H2

0-1000PPM

1PPM

200ml/min

SO2

0-50PPM

0-20PPM

1PPM

600±50ml/min

CO2

0-6000PPM

0-5000PPM

1PPM

500±50ml/min

NO

0-1000PPM

1PPM

200ml/min

NO2

0-20PPM

0-50PPM

0.1PPM

1000±50ml/min

HCN

0-100PPM

1PPM

200ml/min

Sensor type: Catalytic, electrochemical or NDIR gas sensor

Gas sampling: Natural diffusion

Power supply: DC24V±25%

Power consumption: ≤3W

BS03 fixed gas detector operation manual

2

Working method: Continuous monitoring

Accuracy: ≤±5%F.S.

Indication method: 4-digit LED light

Condition display: 3 LED lights indicate fault alarm, L-alarm and H-alarm

Operation: Infrared remote control

Response time: ≤30s (LEL) / ≤60s (toxic gas)

Working temperature: -40℃~70℃(LEL) / -20℃~50℃(toxic)

Working humidity: <95%RH

Explosion-proof: Ex dⅡCT6

Protection: IP65

Pressure Limit: 86-106kPa

Signal output: 4~20mA or RS485, 2 relay output

Install screw thread: G3/4"

Cable dimension: ≥1.5mm2×3

Transmission distance: ≤1000m

Dimensions: l×b×h, 210×200×105mm

Weight: about 2100g

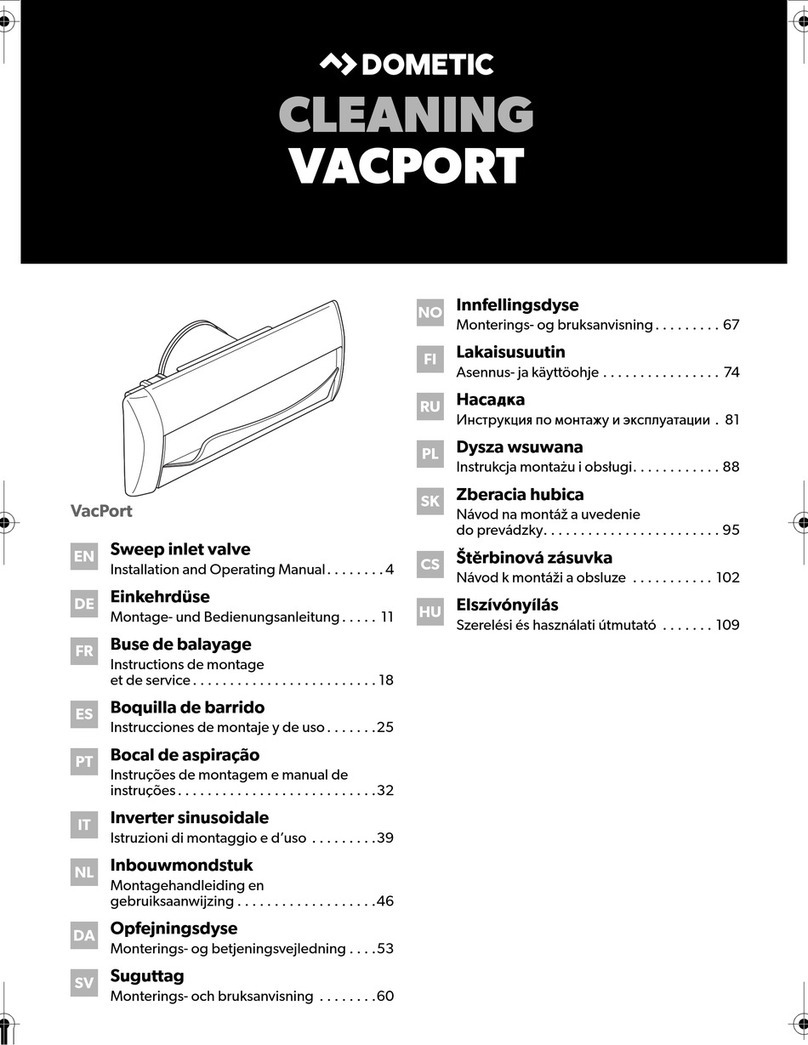

3. Structure

BS03 fixed gas detector operation manual

3

4. Installation

4.1 Installation position

1) For petrol gas, oil gas and alcohol gas etc. which is heavier than the air,

the position is 0.3m-0.6m higher than the ground.

2) For natural gas, CH4 etc which is lighter than the air, the position is

0.5m-2m higher than the gas source. Gas density more than

0.97kg/CBM, then it's heavier. Gas density less than 0.97kg/CBM, then

it's lighter.

3) The position should be far away from shocking, shattering, strong

electromagnetic interference. Around the position, there should be at

least 0.3m empty place.

4) The position should be within 1m around the possible gas leakage area,

such as valve, pipe connection point, gas outlet place. Please try to

install it nearer to the above places, but avoid influencing the working of

the other equipment. Please avoid the environment of high temperature

and humidity. Also please keep it from water swashing, oil and

mechanical damage. Please also consider the convenience of

maintenance and calibration.

5) For large scale detection, we suggest install 1pc every 10-12 square

meters, so as to get the best detection result.

No.

Name

No.

Name

1

Protection cover

9

Pipe connector

2

Decoration

10

Display screen

3

Lower shell

11

Wire connection hole

4

Upper shell

12

H-alarm LED

5

Wire connection hole

13

L-alarm LED

6

Pipe joint

14

Fault / Power LED

7

Remote control receiving

window

15

Ground nut

8

Fixing hole

BS03 fixed gas detector operation manual

4

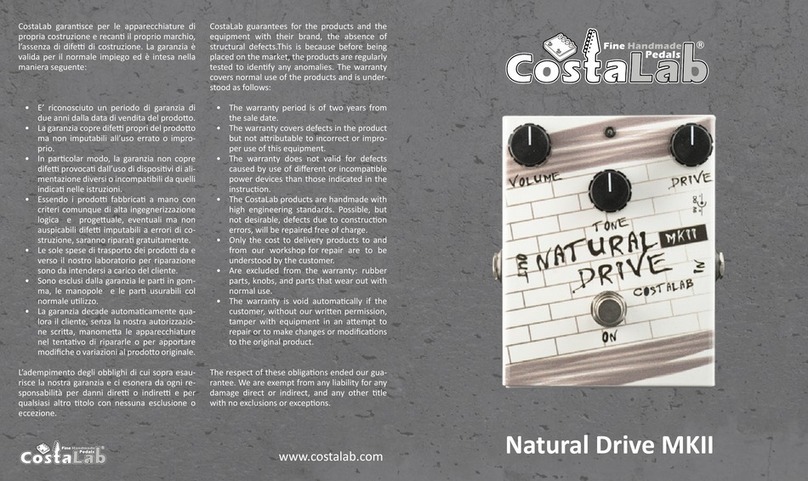

4.2 Dimensions

4.3 Installation methods

Note: Fix the detector with sensor head downwards!

According to the installation place, you can fix the detector onto the wall or to

the gas pipes. Please follow the details as below:

Method 1(thread butted type fixing method): If there are transverse

or vertical siphon with G3/4 Screw thread in installed places, please

connect the two terminals of the detector to the gas pipes. Then connect

and screw down the pipe screw thread nut and fix it tightly.

BS03 fixed gas detector operation manual

5

Method 2: If the user needs to install the detector onto the wall, please

choose an appropriate place on the wall according to the detector

dimensions. Then fix the detector by using 3 pieces of M6×70 bulge

bolts in the corresponding installed holes.

BS03 fixed gas detector operation manual

6

Method 3: If there is 1" to 2″(diameter) pipe, the user can use 2 U-type

bolts to fix the hanging plate on the pipe, and then fix the detector onto

the plate. Or, the user can first fix the detector onto the plate and then fix

the plate on the pipe.

5. Wire connection

Note: Electricity power must be cut off before wire connection.

Wire connecting steps:

1) Screw down the cover in counter-clockwise way. Then use a cross-type

screw to screw down the 3 bolts and take off the display PCB.

2) Screw down the pipe connector in counter-clockwise way. Take out the

explosion-proof pad. In turns, put 3-line wire to the internal of the

enclosure through the pipe connector, compaction circle, air-proof

closing plug and the wire connection hole. According to the

explosion-proof requirement, please don't take out the explosion-proof

closing plug from the unused wire connection holes. Please don't throw

away any part inside the enclosure or the PCB.

3) All the wires should be connected to the terminals. The terminal

instruction is as follows:

BS03 fixed gas detector operation manual

7

A. If the output signal is 4-20mA signal, then the terminal definitions are as

below:

NO.

mark

function

spec

1

L-Alarm

Low alarm output

Switching value

2

L-Alarm

Low alarm output

3

24V

Power input

DC24V±25%

4

GND

Power input

5

Iout

Current ouput

4~20mA

6

NC

—

—

7

H-Alarm

High alarm output

Switching value

8

H-Alarm

High alarm output

9

24V

Power input

DC24V±25%

10

GND

Power input

11

Iout

Current output

4~20mA

12

NC

—

—

BS03 fixed gas detector operation manual

8

B. If the output signal is RS485 signal, then the terminal definitions are as

below:

4) After the correct wire connection, take out the useless wire from the

enclosure. Then tighten the compaction circle, rubber air-proof circle and

wire. Explosion-proof soft tube can also be connected with the device directly.

Note: The size of the connection wire between the controller and detector

should not be less than 6mm, and the distance should be note more than

1000m.

5) After checking all the connection well, install the display PCB and the

front cover. Make sure O-type circle is put on and connected with the cover

tightly.

6. Operation

On the remote controller, there are totally five buttons as follows: “Setup”,

“Confirm”, “Cancel”, “+” and “-”.

Warning: It's forbidden to replace the batteries for the remote control in

working area.

Note: “Setup”, “Confirm” and “Cancel” are single-spring buttons. These

buttons can only be triggered once even if you press them continuously, and

the interval between two springs should not be less than 1 second. “+” and “-”

are continuous-spring buttons and can be triggered by continuous pressing.

Setting can only be affected after pressing “Confirm”. After setting, press

“Cancel” to return to the normal mode. Effective setting can be kept till the

next setup, even if without power.

NO.

mark

function

spec

1

L-Alarm

Low alarm output

Switching value

2

L-Alarm

Low alarm output

3

24V

Power input

DC24V±25%

4

GND

Power input

5

A

Data communication

RS485A

6

B

Data communication

RS485B

7

H-Alarm

High alarm output

Switching value

8

H-Alarm

High alarm output

9

24V

Power input

DC24V±25%

10

GND

Power input

11

A

Data communication

RS485A

12

B

Data communication

RS485B

BS03 fixed gas detector operation manual

9

Display in different status:

1) Normal status: Display the detecting result of the gas concentration

2) Sensor fault status: Screen display “E-02”; yellow LED is on.

3) High concentration protection status(only available for LEL type):

Screen display “100”, 3 LED lights are all on, electrical current output

21.3mA.

4) Low alarm status: red L-ALARM LED light is on

5) High alarm: red L-ALARM LED light and red H-ALARM LED lights

are on.

6) Low alarm setting: “F--1”

7) High alarm setting: “F--2”

8) Zero calibration: “F--3”

9) Single point calibration: “F--4”

10) Factory setting: “F--5”(Unavailable to the customers).

6.1 Low alarm setting

In normal status, press “Setup” once and it displays “F-1”. Press

“Confirm”, it displays the default low alarm. This figure can be adjusted by

pressing “+” or “-”. After setting completed, press “Confirm” to save the

setting. The setting will be effective immediately after exit. The screen will

display “F-1”. You can press “setup” to make the other settings or press

“Cancel” to exit to return to the normal status.

6.2 High alarm setting

In normal status, press “Setup” twice and it displays “F-2”. Then press

“Confirm”, it displays the default high alarm. This figure can be adjusted by

pressing “+” or “-”. After setting completed, press “Confirm” to save the

setting. The setting will be effective immediately after exit. Then the screen

will display “F-2”. User can press “setup” to make the other settings or press

“Cancel” to return to the normal status.

6.3 Zero translation

After the detector have been used for a long time, or the detector was

put in a new type environment, it may not display “0”in clean air, this

phenomenon is called “zero drift”, zero drift is normally caused by big

change of temperature or humidity, and this phenomenon can be corrected

by zero translation.

Zero translation can do simple correction for gas detector, but

comparing with calibration, it cannot correct the sensitivity deviation after

long time use. So in principle, please do zero translation for correction only

when calibration is not convenient to do, and proceed zero calibration every

half year even zero translation have been made.

Zero translation method: after the detector works more than 20 minutes,

BS03 fixed gas detector operation manual

10

put it into clean air (zero translation can not be done when there is other gas

in the environment, if the detecting gas is O2 or CO2, zero translation must

be done in pure N2 gas environment), in normal working status, press

“Setup” three times, screen will display “F-3”, then press “Confirm”, it

displays “XXXX” (The A/D value of the present zero point). After this figure

on the screen is steady, press “Confirm” to remember this figure to complete

zero translation. The translation will be effective immediately after exit.

Then the screen displays “F-3”. The user can press “setup” to make other

setting or press “Cancel” to return to the normal status.

6.4 Single point calibration

Detector’s calibration must be operated by professional engineers and

using standard gas, it is forbidden to calibrate the detector privately. In order

to keep the detector’s accuracy, we suggest calibrate the detector at least

once every half year.

Calibration method: After the detector has been working for more

than 20 minutes, input standard gas (gas concentration is half of the

detector’s detecting range) into the detector. Then press “Setup” four times in

normal working status, the screen will show “F-4”, then press “Confirm” and

it will display the default calibration point. Press “+” or “-”to change the

calibration point to be same with the input gas concentration level, then

press “Confirm” to remember this figure, it will display “XXXX” (The A/D

value of the present gas environment). After the A/D value on the screen is

steady, press “Confirm” to remember this figure for calibration. The

calibration operation will go into effect immediately after exit. After then the

screen will display “F-4”. The user can press “setup” to make other settings or

press “Cancel” to return to the normal status.

Note: Please don't carry the above calibration when the detector is

working or there is no standard calibration gas.

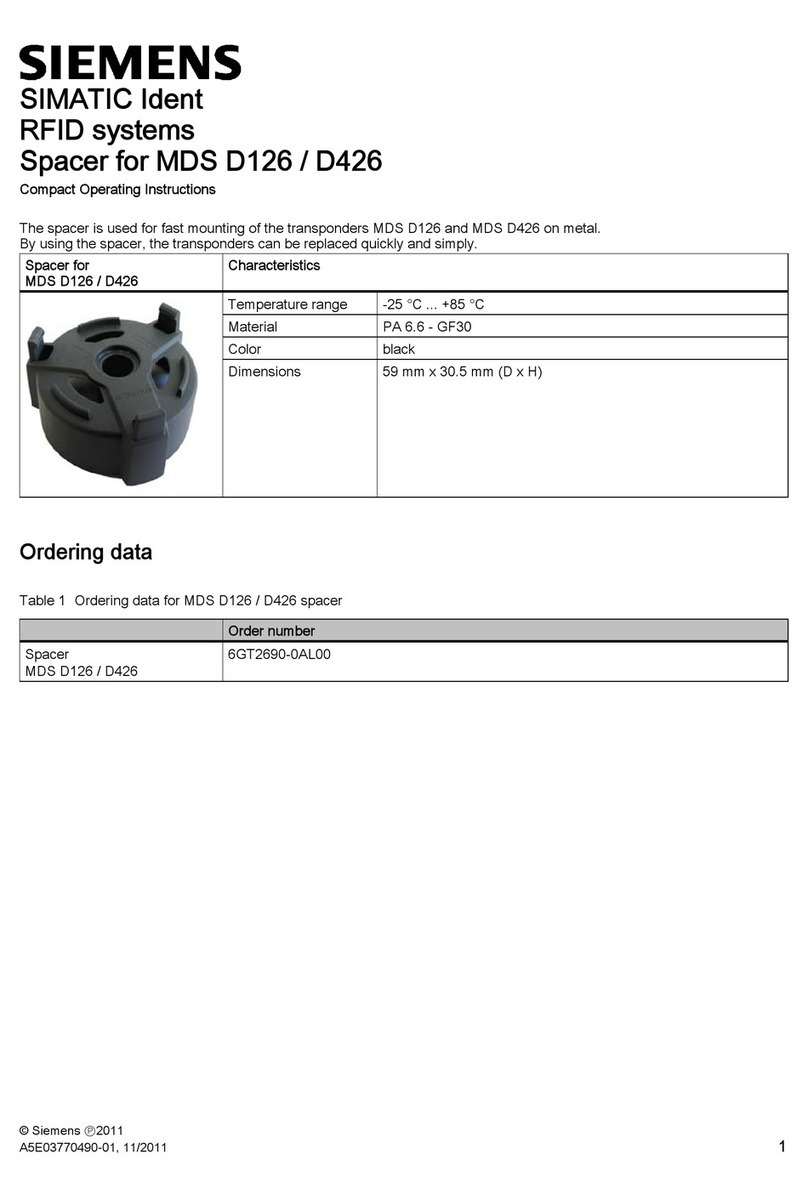

6.5 Address code setting

If the detector’s output signal is RS485 signal, the detector’s address

code can be set as the following:

Address code switching locate inside the detector, you must cut off the

power and open the cover only then you set the switching.

The address code is set by the dial switch from second switch to the

eighth switch, and they are calculated by binary method, right side are low

bit, left side are high bit. Switch at up position “ON”means 1, at low

position “OFF”means 0. From right to left, every switch means in turn 1 、

2、4 、8 、16 、32 、64. Calculating formula: ADD=

X2×64+X3×32+X4×16+X5×8+X6×4+X7×2+X8×1. (X2 to X8 only can be

BS03 fixed gas detector operation manual

11

“0”or “1”).

For example: from low bit to high bit, second switch and fourth are at

up position “ON”, then X7=X5=1, other bits are all 0, so the address code

shall be calculated as: ADD=0×64+0×32+0×16+1×8+0×4+1×2+0×1=10

You can find the address code settings at the last pages of this manual.

The first code switch only can be used during maintenance operation,

but it must be at “ON”position normally. To same one controller, there

cannot be more than one detectors which are set at same address code.

7. Sensor replacement

In normal working environment, catalytic sensor’s using life is 3 years,

electrochemical sensor’s using life is 2 years. When the sensor life is overdue,

the detection result may be not accurate.

To replace the sensor, please first cut off the power but it won’t be necessary

to open the detector’s housing, only need to open the sensor assembly.

1. Take off the calibration cover in anti-clockwise.

2. Pull out the decoration part downwards.

3. Screw off the top thread from the sensor protection cover.

4. Take off the protection cover in counter-clockwise.

5. Take out the old sensor.

6. Install new sensor, make sure the electric contact match to each contact

positioning hole.

7. Then install in turns protection cover, top thread, decoration part and

calibration cap.

8. Power on the detector and calibrate the detector.

BS03 fixed gas detector operation manual

12

BS03 fixed gas detector operation manual

13

8. Trouble shooting guidance

Problems

Possible reason

solution

NO response to gas

Sensor damage

Replace sensor

Electrical fault

Contact with seller

Abnormal

connection with

controller

Wiring fault

Check the wiring

Electrical fault

Contact with seller

E-01

Calibration fault

recalibrating

E-02

Wiring fault, connection fault or

sensor fault

Reconnect the wire or

replace sensor

E-04

Sensor drift

Replace sensor

E-06

System’s parameter fault

Reload system parameter

Attachment 1

Address code settings

Table of contents

Popular Other manuals by other brands

aquaHabitats

aquaHabitats MicroHabitat 30 Instructions for use

Siemens

Siemens MDS D126 Compact operating instructions

Air Water Life

Air Water Life Aqua-Ionizer Deluxe 9.0 owner's manual

STEIN

STEIN EMBRACE FRAMELESS HINGED DOOR - TILE installation instructions

Enerwave

Enerwave ZWN-RSM1S installation instructions

Daewoo

Daewoo DVT-21F1LA Service manual

Towing Products

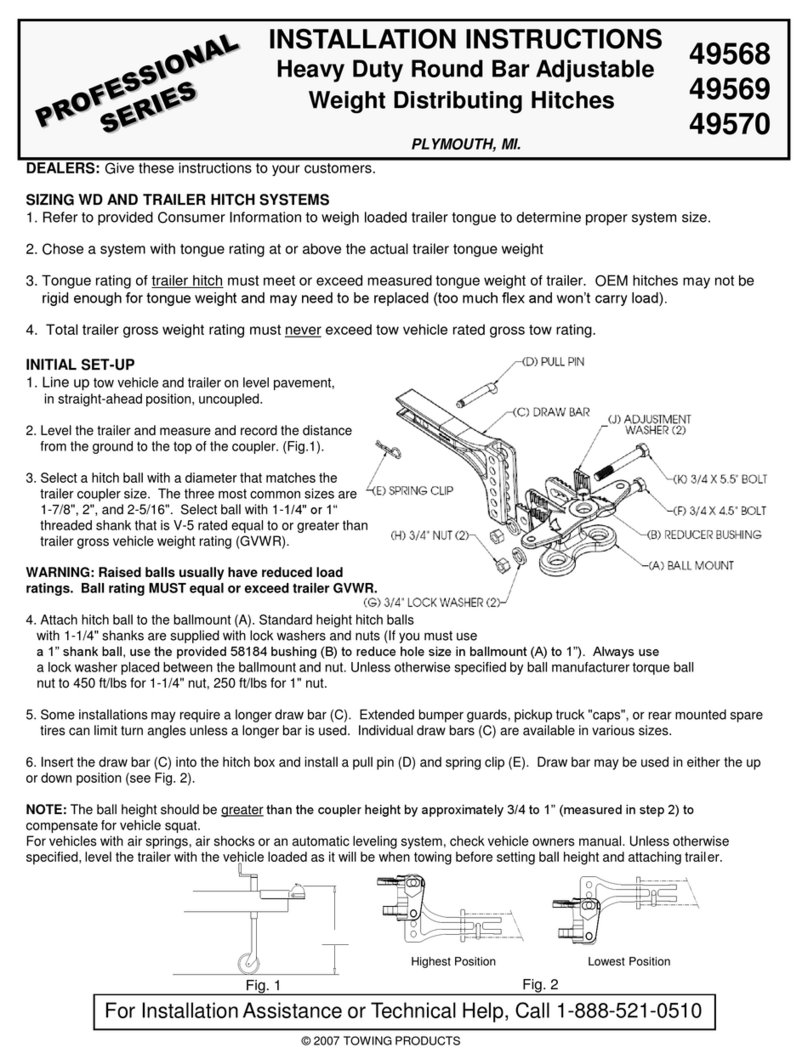

Towing Products 49568 installation instructions

Task Force Tips

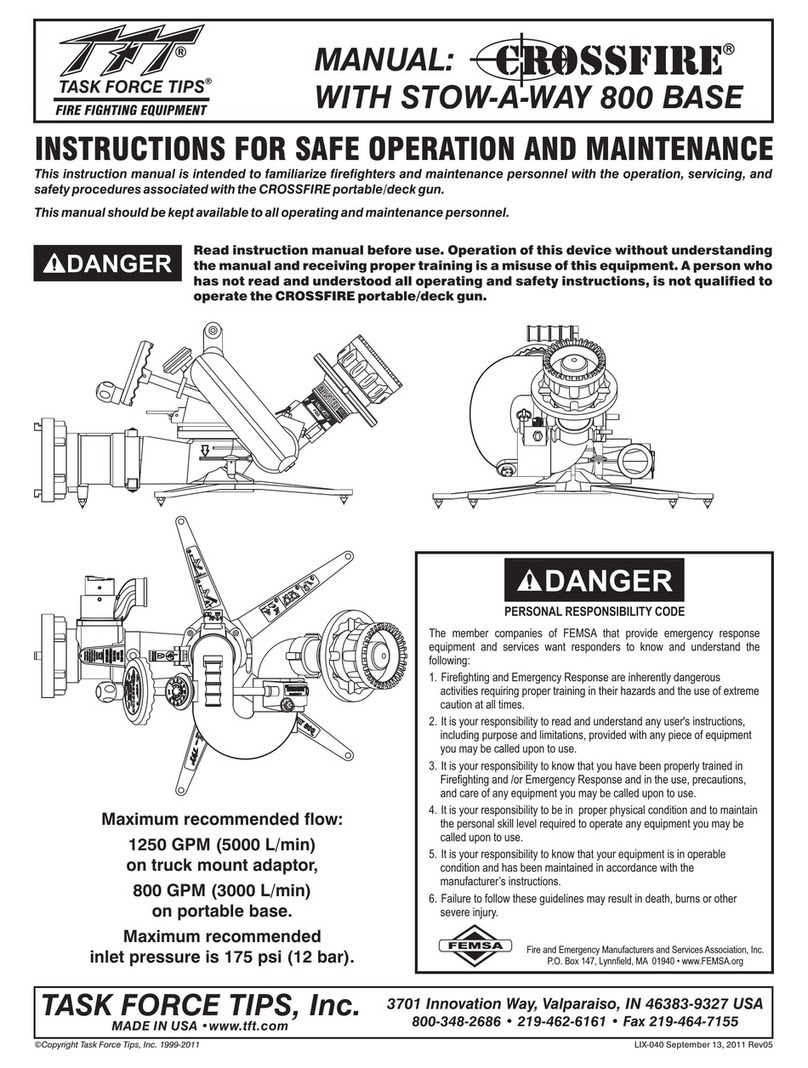

Task Force Tips CROSSFIRE INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Alemlube

Alemlube WP1290 Owner technical manual

QA1

QA1 52888 installation instructions

Wallenstein

Wallenstein BXM Series manual

PERCo

PERCo WHD-16 Installation and operation manual