Hardy Instruments Any-Weigh Specification sheet

Any-Weigh™

FLOOR SCALES

OPERATION AND INSTALLATION

MANUAL

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

San Diego, CA 92123-1825

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardyinst.com

Hardy Instruments Document Number: 0596-0280-01 Rev D

Copyright October 2003 Hardy Instruments, Inc. All Rights Reserved. Printed in the U.S.A. (941028)

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned

throughout the world to assist you in your support needs. We also have fac-

tory engineers who will travel to your facility anywhere in the world to help you

solve challenging applications. We're ready to support you with:

•Installation and start-up

•Routine maintenance and certification

•Plant audits and performance measurement

•Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation,

Calibration, Verification or to discuss a Maintenance Agreement please call

800-821-5831 Ext. 1757 or Emergency Service after hours (Standard Hours

6:00 AM to 6:00 PM Pacific Standard Time) and weekends Ext. 1111.

Outside the U.S

Hardy Instruments has built a network of support throughout the globe. For

specific field service options available in your area please contact your local

sales agent or our U.S. factory at +1 858-292-2710, Ext. 1757.

CAUTION:

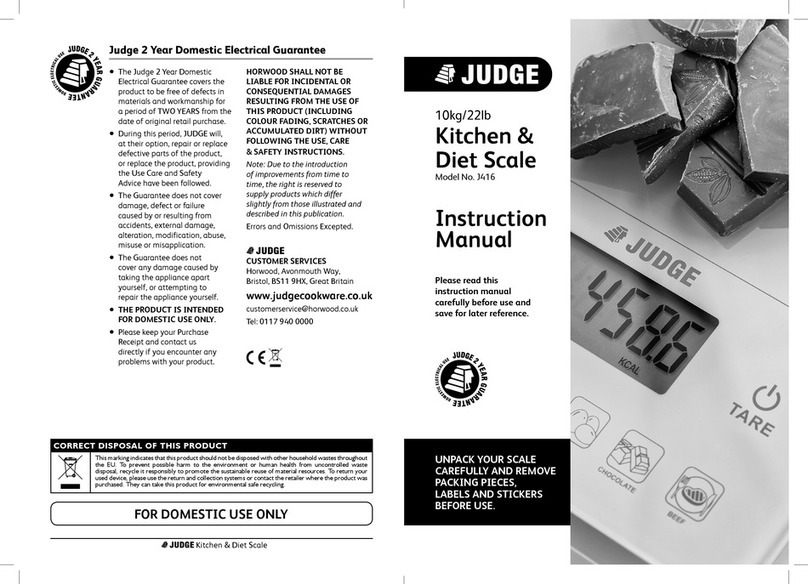

UNPACK WITH CARE

WHEN UNPACKING, DO NOT DISCARD THE PACKING CASE OR ANY

PACKING MATERIAL, UNTIL THE CONTENTS OF THE PACKING CASE

ARE INSPECTED AND CAREFULLY COMPARED WITH THE SHIPPING

DOCUMENTS.

IF ANYTHING IS UNSATISFACTORY, PLEASE NOTIFY HARDY INSTRU-

MENTS IMMEDIATELY BY CALLING, FAXING OR E-MAILING TO:

Hardy Service Center

HARDY INSTRUMENTS, INC.

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

Phone: (800) 821-5831

(858) 278-2900

FAX:(858) 278-6700

E-mail: disupport@hardyinst.com

Web Address: www.hardyinst.com

TO RETURN DEFECTIVE OR DAMAGED PRODUCT(S) CALL HARDY

TECHNICAL SUPPORT FOR A HARDY SERVICE TICKET NUMBER

(HST#). YOUR COMPANY NAME, ADDRESS, TELEPHONE NUMBER,

SERIAL NUMBER OF THE UNIT AND A BRIEF DESCRIPTION OF THE

PROBLEM SHOULD BE READY WHEN CALLING. FOR ALL NON-WAR-

RANTY REPAIRS A PURCHASE ORDER OR CREDIT CARD IS ALSO

REQUIRED.

IN CASE OF DAMAGE DUE TO SHIPPING, NOTIFY THE DELIVERING

CARRIER IMMEDIATELY FOR AN INSPECTION.

Table of Contents

i

Table of Contents

Table of Contents - - - - - - - - - - - - - - - - - - - - - - - - - -i

Table of Illustrations - - - - - - - - - - - - - - - - - - - - - - - -I

SPECIFICATIONS - - - - - - - - - - - - - - - - - - - - - - - - - -1

Platform Material - - - - - - - - - - - - - - - - - - - - - - - - -1

Platform Height- - - - - - - - - - - - - - - - - - - - - - - - - -1

Rated Output - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Excitation- - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Total Error - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Maximum Overload- - - - - - - - - - - - - - - - - - - - - - - -1

Endloading - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Temperature Range - - - - - - - - - - - - - - - - - - - - - - -1

Temperature Effect - - - - - - - - - - - - - - - - - - - - - - - -1

Cable Length - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Materials of Construction - - - - - - - - - - - - - - - - - - - - -1

Steel - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Paint - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Foot Elastomer - - - - - - - - - - - - - - - - - - - - - - - -2

Grade Level - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Anchor Bolt Holds - - - - - - - - - - - - - - - - - - - - - -2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

NEMA Rating- - - - - - - - - - - - - - - - - - - - - - - - - - -2

Test Criteria - - - - - - - - - - - - - - - - - - - - - - - - -2

GENERAL INFORMATION - - - - - - - - - - - - - - - - - - - - - -2

UNPACKING - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3

COMPONENT DESCRIPTIONS - - - - - - - - - - - - - - - - - - -4

SITE PREPARATION- - - - - - - - - - - - - - - - - - - - - - - - -5

Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - -6

FLOOR SCALE INSTALLATION - - - - - - - - - - - - - - - - - - -7

CALIBRATION - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - - -10

C2® Second Generation Calibration - - - - - - - - - - - - - - -11

Test Weight Calibration (Hard Cal) - - - - - - - - - - - - - - - -11

Any-Weigh™ Series Floor Scales

ii

Requirements: - - - - - - - - - - - - - - - - - - - - - - - -11

Material Substitution: - - - - - - - - - - - - - - - - - - - - -12

SCALE VERIFICATION- - - - - - - - - - - - - - - - - - - - - - - -12

MODEL CODE BREAKDOWN - - - - - - - - - - - - - - - - - - - -13

Mild Steel Deck, Painted - - - - - - - - - - - - - - - - - - - - -13

Stainless Steel Deck (304 SS) - - - - - - - - - - - - - - - - - -14

REMOVING SUMMING BOX COVER- - - - - - - - - - - - - - - - -15

Installing the Leveling Feet - - - - - - - - - - - - - - - - - - - -18

INSTALLING A LOAD SENSOR - - - - - - - - - - - - - - - - - - -21

OPTIONAL PIT FRAMES- - - - - - - - - - - - - - - - - - - - - - -25

About Pit Frames - - - - - - - - - - - - - - - - - - - - - - - - -25

OPTIONAL ACCESS RAMPS- - - - - - - - - - - - - - - - - - - - -29

Access Ramp Installation - - - - - - - - - - - - - - - - - - - - -29

OPTIONAL BOLT-DOWN PLATES - - - - - - - - - - - - - - - - - -31

Bolt-Down Plates Installation - - - - - - - - - - - - - - - - - - -32

OPTIONAL BUMPER GUARDS- - - - - - - - - - - - - - - - - - - -33

TROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - -36

INSTRUMENTATION INTERFACE CABLE COLOR CODES - - - - -37

Table of Illustrations

I

Table of Illustrations

TABLE OF ILLUSTRATIONS- - - - - - - - - - - - - - - - - - - - -I

FIG. 1 INSTALLING THE CLOSED EYEBOLTS INTO THE TOP

PLATE - - - - - - - - - - - - - - - - - - - - - - - - - - -4

FIG. 2 SUMMING JUNCTION CARD - - - - - - - - - - - - - - - -5

FIG. 3 DIRECTION WHEN DRIVING HEAVY EQUIPMENT

ON AND OFF THE SCALE - - - - - - - - - - - - - - - -7

FIG. 4 MAXIMUM HEIGHT - - - - - - - - - - - - - - - - - - - - -7

FIG. 5 SPIRIT LEVEL- - - - - - - - - - - - - - - - - - - - - - - -8

FIG. 6 CHECKING PLATFORM LEVEL/SIDE TO SIDE - - - - - - -8

FIG. 7 CHECKING PLATFORM LEVEL/CORNER TO CORNER- - -9

FIG. 8 CHECKING PLATFORM LEVEL/DIAGONALLY - - - - - - -9

FIG. 9 ADJUSTING THE FEET FOR LEVEL - - - - - - - - - - - -10

FIG. 10 SCALE VERIFICATION/POSITION #3 - - - - - - - - - - - -12

FIG. 11 REMOVING THE SUMMING BOX COVER- - - - - - - - - -16

FIG. 12 REMOVING THE SUMMING BOX LID - - - - - - - - - - - -17

FIG. 13 REMOVING THE SUMMING BOX LID - - - - - - - - - - - -18

FIG. 14 INSERTING THE LEVELING FOOT INTO THE

LOAD SENSOR - - - - - - - - - - - - - - - - - - - - -19

FIG. 15 INSIDE VIEW - - - - - - - - - - - - - - - - - - - - - - - -20

FIG. 16 OUTSIDE VIEW - - - - - - - - - - - - - - - - - - - - - - -20

FIG. 17 ALL FOUR FEET INSTALLED - - - - - - - - - - - - - - - -21

FIG. 18 SUMMING CARD - - - - - - - - - - - - - - - - - - - - - -21

FIG. 19 CORD GRIP- - - - - - - - - - - - - - - - - - - - - - - - -23

FIG. 20 REMOVING LOAD SENSOR BOLTS AND FEET- - - - - - -24

FIG. 21 FOUNDATION FOR THE PIT FRAME - - - - - - - - - - - -26

FIG. 22 PIT FRAME DIMENSIONS- - - - - - - - - - - - - - - - - -26

FIG. 23 DRAIN INSTALLATION DIMENSIONS - - - - - - - - - - - -28

FIG. 24 EXCAVATED PIT AND SUPPORT FOR THE PIT FRAME - -28

FIG. 25 RAMP WITH RETAINER PLATES - - - - - - - - - - - - - -30

FIG. 26 INSTALLING ANCHORS FOR RAMP - - - - - - - - - - - -30

FIG. 27 BOLT DOWN PLATES/INSTALLATION - - - - - - - - - - -32

FIG. 28 BUMPER GUARD/GAP REQUIREMENT- - - - - - - - - - -33

FIG. 29 BUMPER GUARD/INSTALLATION- - - - - - - - - - - - - -34

Any-Weigh™ Series Floor Scales

II

Any-Weigh™ Series Floor Scales

1

SPECIFICATIONS

Platform Material 0.25 inch

Platform Height 3.0 inches +.275”

Rated Output 2.0mV/V ±0.1%

Excitation • Recommended 5 Volts DC

•Maximum5VoltsDC

WARNING FOR SCALES FITTED WITH AN INTEGRATED

TECHNICIAN SUMMING CARD, DO NOT

EXCEED 5 VDC EXCITATION. DOING SO MAY

CAUSE PROPERTY DAMAGE. DO NOT USE

WITH THESE INSTRUMENTS: HI 2160, HI

1771 OR ANY INSTRUMENT WITH AN EXCI-

TATION VOLTAGE ABOVE 5 VDC.

Total Error 0.03% of FS Output

Maximum

Overload 150% of the Rated Scale Capacity

Endloading 100% of the Rated Scale Capacity

Temperature

Range • Safe -40º to +80º Degrees C (-40º to +176º

F)

• Compensated -10 to +40 Degrees C (+14º to

104º Degrees F)

Temperature

Effect • On Output - 0.0011% of load/Deg. C

• On Zero - 0.0011% of FSO/Deg C

Cable Length 20 feet (C2 Cable)

NOTE: To purchase C2 Cable contact our local Hardy Instru-

ments Representative or Hardy Instruments Service

Center.

Materials of

Construction

Steel • Mild Steel: Type A36 carbon plate steel (slip

resistance - tread or smooth surface)

Any-Weigh™ Series Floor Scales

2

• Stainless Steel: Type 304 plate steel (slip

resistance - tread or smooth surface)

Paint 100% Acrylic Emulsion (mild steelfloor scale models

only - Stainless Steel scales are not painted)

Foot

Elastomer • Natural Rubber (Standard)

Grade Level In operation, the scale must be firmly and adequately

supported at all four corners to accommodate the

maximum load in your application. The scale must be

installed to within 3º of level.

Accessories Ramps, Pit Frames, Bumper Guards, Lifting Eyebolts,

Bolt Down Plates

Anchor Bolt

Holds 1/2 inch bolts - 9/16” (.5625”) hole, 3.75 inches deep

5/8 inch bolts - 5/8” (.6250”) hole, 4.0 inches deep

Approvals • NTEP Class III Number: 04-087

NEMA Rating Summing Junction Box Enclosure - NEMA 4X Stain-

less Steel

Test Criteria Must exclude at least 65 GPM of wate from 1” inch

nozzle deliverd from a distance not less than 10 ft for

5 minutes.

GENERAL

INFORMATION The Hardy Instruments AnyWeigh™ Series Floor

Scales are designed for applications that require a low

profile weighing surface with high commercial accu-

racy and reliability. The Hardy Floor Scales can be

configured with a complete range of accessories. The

scales can also be configured to fit any floor scale

application.

The typical platform height is three (3) inches. Each

corner can be adjusted an additional .275” (7mm) to

compensate for a non-level floor or pit mounting sur-

face.

The Any-Weigh Floor Scales do not have bearings,

levels or moving parts that can be damaged or wear

Any-Weigh™ Series Floor Scales

3

out. The active elements of the floor scales are four

precision strain gauge load sensors, mounted on all

four corners of the scale platform. The unique Blind

Hole Load Introduction technology allows the foot to

move to compensate for uneven floors. This ensures

that the load forces are always applied to the load sen-

sor at precisely the same point regardless of where the

load is placed on the scale. This ensures you will get

accurate and repeatable weighments.

Each platform load sensor is initially certified for use

in a C2®Second Generation Calibration system.

UNPACKING The Any-Weigh Series Floor Scales are shipped fully

assembled and wired. Inspect the container for any

signs of damage that might occur during shipment.

Since almost all of the Floor Scales are shipped

F.O.B. factory, such damage is normally the responsi-

bility of the carrier and should be reported to them.

Step 1. Remove the banding straps and any ship-

ping restraints.

WARNING DO NOT USE HOOKS OR UNCLOSED EYE-

BOLTS OR ATTEMPT TO LIFT THE SCALE

MANUALLY. FAILURE TO USE THE PROPER

LIFTING TOOLS OR LIFTING METHODS CAN

CAUSE PERSONAL INJURY OR PROPERTY

DAMAGE.

Step 2. Screw 2 closed eyebolts into the threaded

holes on the top plate of the scale. (See

Fig. 1)

• Mild Steel - 1/2 - 13 x 1.5” (Hardy Model

Number HI EB2250-1)

Step 3. Attach a chain, cable or nylon strap to the

eyebolts.

Step 4. Use a forklift or crane with rated lifting

capacity that is equal to or greater than the

total weight of the platform scale to lift the

scale high enough to remove from the

Any-Weigh™ Series Floor Scales

4

crate bottom. See Tables 2 & 3 for ship-

ping weights.

Step 5. Be sure to use all safety precautions when

lifting the platform so that it does not fall

on equipment or personnel. It is highly

recommended that blocks be placed under

the platform before working near the plat-

form scale.

FIG. 1 INSTALLING THE CLOSED EYE-

BOLTS INTO THE TOP PLATE

COMPONENT

DESCRIPTIONS 1. Steel Plate Platform - The platform material is

either low carbon steel plate or 304 stainless steel

plate. The low carbon steel platform cover is

made from a single piece of 1/4" A36 carbon

steel floor plate (skid resistant) or smooth steel

plate. The steel platforms are primed and coated

with a tough weather resistant paint (See Paint

Specifications). The 304 stainless steel platform

is made from a single piece of 1/4" diamond tread

(Conforms to ASTM A793-85) floor plate (skid

resistant) or smooth stainless steel plate with a

bead blast finish.

2. Summing Junction Card Assembly - Accessed

by unfastening the face plate on the center side of

the platform. (See Fig.2) The summing junction

card routes the excitation voltage to each of the

four load sensors and sums the weight signal

Closed Eye Bolts

for Lifting the

Platform Scale

Any-Weigh™ Series Floor Scales

5

back from them. The C2®second generation

electronic calibration is included with your scale.

FIG. 2 SUMMING JUNCTION CARD

3. Load Sensors - The AnyWeigh series scales use

four (4) steel Advantage like load sensors with

hermetic seals. The output of each sensor is 2mV/

V with 5 Volts DC excitation. For more specifica-

tions see the electrical specification section of

this manual.

4. INTEGRATED TECHNICIAN™ (Option) -

(If IT summing card is installed) A built-in sys-

tem diagnostics utility, continuously monitors the

weighing system for possible malfunctions. This

capability also allows the operator to rapidly

troubleshoot a weighing system from the control-

ler or indicator.

5. Leveling Feet - Each AnyWeigh series scale

comes with four (4) 304 stainless steel adjustable

leveling feet. The leveling feet are adjustable to a

maximum of 7mm (.275"). The leveling feet are

attached to each of the load sensors.

SITE PREPARATION • All mounting surfaces for the floor scale

should be level to within 3º, corner to corner,

end to end. Keep in mind that the adjustable

leveling feet have a maximum adjustment of

7mm (.275”).

Any-Weigh™ Series Floor Scales

6

• Before welding anything on the floor scale,

contact Hardy Instruments Service Center

for instructions and precautions.

• Proper drainage must be provided to prevent

the load sensors from standing in water.

Precautions • Do not do any electric welding on or near the

platform scale.

• Do not drop items to be weighed on the

scale. Set them on the platform scale.

• Do not set items on the platform scale that

weigh more than the capacity of the scale.

• Do not store or operate the scale in environ-

ments out of the specified temperature range.

• Do not store other equipment on the scale

even temporarily when it is not used or in

storage.

• Do not allow debris to accumulate on,

around or under the scale.

• Do not set the scale in water or allow water

to accumulate around the scale. Always pro-

vide proper drainage.

• Do not let moisture get on or into any of the

electrical interconnections.

• Do not allow static or other electrical dis-

charges go through the scale.

• Do not leave the screws for the summing

junction box cover plate loose so that the

junction box is not sealed.

• Do not drop the scale when moving or

installing.

• When driving heavy equipment on and off

the scale for weighing purposes, make sure

that you drive onto and off of the platform in

the direction indicated in Figure 3. Also See

Access Ramp Installation Section.

Any-Weigh™ Series Floor Scales

7

FIG. 3 DIRECTION WHEN DRIVING HEAVY

EQUIPMENT ON AND OFF THE SCALE

FLOOR SCALE

INSTALLATION Step 1. Place the platform scale on the operating

location. Make sure that the platform

height is within 3 to 3.275" as measured

from the top of the cover plate to the top of

the floor surface. (See Fig. 4)

NOTE: With the scale in place, the clearance around the edge

of the platform and pit coping should be 1/4” to 3/8”.

FIG. 4 MAXIMUM HEIGHT

Load and unload

heavy equipment

in this direction only!

3.275” (83.1mm)

Any-Weigh™ Series Floor Scales

8

Step 2. Make sure that the platform mounting sur-

face is level to 1/8”.

Step 3. Use a spirit level to check if the platform is

level, side to side, corner to corner and

diagonally. (See Figs. 9, 10, 11, 12)

FIG. 5 SPIRIT LEVEL

FIG. 6 CHECKING PLATFORM LEVEL/SIDE

TO SIDE

Any-Weigh™ Series Floor Scales

9

FIG. 7 CHECKING PLATFORM LEVEL/COR-

NER TO CORNER

FIG. 8 CHECKING PLATFORM LEVEL/DIAG-

ONALLY

Step 4. Adjust each of the leveling feet in the

direction (either up or down), indicated by

the level readings. (See Fig. 9)

• To increase the height rotate the foot counter

clockwise.

• To decrease the height rotate the foot clock-

wise.

Any-Weigh™ Series Floor Scales

10

FIG. 9 ADJUSTING THE FEET FOR LEVEL

Step 5. Place a spirit level on the platform surface

again to check the adjustment for level.

Keep adjusting the legs until the platform

is level and all four leveling feet are firmly

on the floor surface.

Step 6. Check the distance from the top of the

platform to the floor surface at each cor-

ner. All the measurements should be

within 3º of each other and the platform

should be level.

Step 7. If the installation requires bolt down plates

to keep the floor scale in place go to the

Optional Bolt Down Plates Section for

instructions.

CALIBRATION

Pre-Calibration

Procedures Step 1. Open the Junction box cover. (See Fig. 11

for Instructions)

Step 2. Thread the C2® Certified cable through

the grommet on the side of the scale that

houses the junction box.

Foot

Any-Weigh™ Series Floor Scales

11

Step 3. Connect the C2 Certified Summing Card

Interface Cable to the weight instrument.

Color code wires as follows:

• + Excitation Red

•+Sense Blue

• + Signal Green

• - Signal White

•-Sense Brown

• - Excitation Black

•+C2 Grey

•-C2 Violet

Step 4. Use the weight instrument/indicator man-

ual for calibration instructions.

NOTE: To purchase C2®certified cable, contact your local

Hardy Representative or the Hardy Instruments Ser-

vice Center.

C2®Second

Generation

Calibration

Definition - C2®electronically calibrates a scale sys-

tem without the need for test weights. This feature is

in all Hardy weight or rate controllers, and in the

Allen-Bradley weight modules.

Step 1. Refer to the Hardy weight or rate control-

ler manuals or the Allen Bradley module

manual for instructions.

Test Weight

Calibration (Hard

Cal)

Requirements: • Test weight calibration requires the use of

certified class F test weights equal to a mini-

mum of 80% of the rated scale capacity.

• Three weights between 10% and 100% of

the scale capacity should be used to check

the mid range.

• Several low capacity weights equivalent to

one or two instrument divisions are required

to check the systems' sensitivity.

Any-Weigh™ Series Floor Scales

12

Material

Substitution: • When certified test weights are not available

you can use an accurately weighed material

instead.

• The material must be weighed on a second-

ary, calibrated scale and delivered to the site

of the primary floor scale for calibration.

• The secondary calibrated scale should be of

the same accuracy or greater and have a

capacity approximately equal to the primary

floor scale.

SCALE VERIFICATION Step 1. Get a test weight that is equal to 10% of

the full scale capacity.

Step 2. Place the test weight at Position #1 on the

platform. (See Fig. 10)

FIG. 10 SCALE VERIFICATION/POSITION #3

Step 3. Write down the weight for position #1.

Step 4. Place the weight at position #2.

Step 5. Write down the weight for position #2.

Step 6. Place the weight at position #3.

Step 7. Write down the weight for position #3.

Step 8. Place the weight at position #4.

Step 9. Write down the weight for position #4.

Step 10. Check all the readings. If all the readings

are within an acceptable tolerance, no re-

calibration is required.

Position #3

Position #4

Position #2

Position #1

Summing Box

Other manuals for Any-Weigh

1

Table of contents

Other Hardy Instruments Scale manuals