Harnisch+Rieth D-LE 255 S User manual

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

51

/sL

2

L / s

/

D-LE 255 S

10

60

Air

Manual

Auto

MF

m02

1

5

s

4

Operating instructions

Designation of the machine Single/Double-workplace extraction unit

Machine type: D-LE 255 S / D

Machine no.: ...........................

Keep for future reference!

Home address

Harnisch+Rieth

GmbH & Co. KG

Küferstr. 14 - 16

D-73650 Winterbach

Telephone

+49 7181 / 96 78-0

Fax

+49 7181 / 7 31 39

+49 7181 / 96 78-17

E-mail:

http://www.hr-dental.de

Maschinenbau

Werkzeuge

Laborgeräte

Dear customer:

Thank you for the confidence you have placed in us by purchasing the extraction unit D-LE

255 S/D.

To ensure this device provides you with long years of perfect service, please take the time

to carefully read these operating instructions, especially before first use.

Table of contents

1 Safety................................................................................................................................. 3

1.1 Correct use .............................................................................................................. 3

1.2 Possible dangers ................................................................................................... 3

1.3 Approved operators .............................................................................................. 3

1.4 Safety measures at site of operation................................................................ 3

1.5 Marking of safety references contained in these instructions .................. 4

2 Starting up ....................................................................................................................... 4

2.1 Technical data ........................................................................................................ 4

2.2 Unpacking the single/double-workplace extraction unit............................. 5

2.3 Short description of the unit and component identification ...................... 5

2.4 Starting up procedure........................................................................................... 7

2.4.1 Pneumatic structure of tube/hose installation.................................... 7

2.4.2 Structure of the electrical installation ................................................... 9

3 Operation........................................................................................................................ 10

3.1 Checking the filter system................................................................................. 10

3.2 Variants of the dust-generating device automatic detection. .................. 10

3.3 Automatic On-Off / Connection of dust-generating devices .................... 11

3.4 Automatic air volume control ........................................................................... 11

3.5 Automatic shut-off and filter change control Iamp ..................................... 11

3.6 Self test / initialization ........................................................................................ 12

3.7 Notes to monitoring the airflow volume ........................................................ 12

3.8 Setting the extraction unit parameters........................................................... 13

3.8.1 Manual mode (Manual) ............................................................................ 13

3.8.2 Automatic mode (Auto)........................................................................... 13

4 Error messages ............................................................................................................ 14

5 User menu...................................................................................................................... 15

5.1 Changing the user menu settings ................................................................... 16

5.2 Display - Messages and meanings.................................................................. 17

5.2.1 Display messages for "air volume" (l/s) control variant ................ 17

5.2.2 Display messages for "air velocity" (m/s) control variant ............. 18

6 Cleaning / Maintenance .............................................................................................. 20

6.1 Replacing the filter bag ...................................................................................... 20

6.2 Inserting the filter bag ........................................................................................ 20

6.3 Cleaning (replacement) of ultra-fine filter...................................................... 21

7 Electrical fusing............................................................................................................ 22

8 Settings (short summary) and factory setting values ........................................ 23

9 Warranty conditions .................................................................................................... 24

10 EC Declaration of Conformity ................................................................................... 25

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

1 Safety

1.1 Correct use

The single/double-workplace extraction unit D-LE 255 S is used in dental laboratories for extracting

dust (primarily gypsum dust, mineral dust, plastic dust, metal dust, oxide and other ceramic dusts)

produced when working on dust-producing equipment. It should never be used for vacuuming liquids.

If released dust produces also poisonous gases such as methyl methacrylates, appropriate activated

carbon filters must be placed downstream (e.g., D-AK10 from Harniscn & Rieth).

The extraction unit is fitted with a dust grade M filter (<0.1% maximum permeability) pursuant to DIN

EN 60335.

Unauthorised modifications and changes are not permitted for safety reasons.

The operating and maintenance conditions specified in these operating instructions must be ob-

served at all times.

Caution

The unit is not designed as a medical device.

Use on people is not permitted.

1.2 Possible dangers

-Potential sources of ignition or combustible gases, vapours and liquids should not be extracted with

the unit.

-Switch off the unit and disconnect from mains power supply before carrying out maintenance and

cleaning work (pull out the mains plug).

-Particular attention should be paid to ensuring that the filter bag and ultra-fine filter are always in-

stalled correctly and undamaged, as the dust collected poses a health hazard to a certain extent.

-The unit should be disconnected from the mains power supply before accessing built-in electrical

components.

1.3 Approved operators

The operator of the unit should ensure that the operating instructions are accessible to the operating

personnel and have been read and fully understood. Only then should the operator commission the

unit.

1.4 Safety measures at site of operation

Air flowing out of the air outlet should not be hindered in any way.

The distance between the air outlet and the next obstacle (e.g. a wall or furniture) must be at least 10

cm.

The unit should only be operated in cabinets or confined spaces if adequate ventilation is provided.

The permissible ambient temperature must neither fall below 0 °C nor exceed 40°

°°

°C at 50% relative

humidity.

No foreign bodies should be inserted through the ventilation ducts on the unit.

Danger The unit is not suitable for use in rooms where special conditions exist (e.g., corrosive or explo-

sive atmosphere).

Maschinenbau

Werkzeuge

Laborgeräte

1.5 Marking of safety references contained in these instructions

Note Refers to tips and other particularly useful information.

Caution

Refers to particular methods of operation or handling, non-adherence to which can lead to mal-

functioning, damage or other problems.

Danger

Refers to dangerous situations which can Iead to injuries

2 Starting up

2.1 Technical data

40 330

402

542,7

380

L s/

Manual

Auto

3 0

Ls

/

/0 sm

12

MF

Air

60

10

2

D-LE 255 S

51

50

Illustration 1 Extraction unit dimensions

Designation of the machine : Single/double-workplace extraction unit

Machine type: : D-LE 255 S/D

Unit dimensions : Width 420 mm (with power cord strain relief)

:Depth 390 mm (with extraction sockets)

:Height 542 mm

Electrical connection : 200-240 volt (50 Hz)

Over-voltage category: : II

Power consumption : Max. 1,100 watts (blower power)

Electrical fusing : 2x 16 A/T (mains connection)

Airflow :Max. 55 l/s

Sound pressure :52 dB (A) at min. air volume

:64 dB (A) at max. air volume

Ultra-fine filter quality :Dust grade M, DIN EN 60335-2-69

Filter area :1.4 m2

Specific panel filter load :143 m3/m2 x h

Extraction hose connection :50 mm diameter

Dust absorption :Up to approx. 10 kg (dust type dependent)

Weight : About 25 kg

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

2.2 Unpacking the single/double-workplace extraction unit

1. Place the carton on a flat surface.

2. Remove the top packaging material.

3. Push the packaging material away from the unit. Grasp hold of the unit by the lower edge.

4. The unit (weight = approx. 25 kg) should be lifted out of the carton by two persons.

5. Check the accessories:

•Documentation

•Main power cable Item no. 35028

•Ø 50mm extraction hose, 2m long with two Ø 50 mm connectors, Ø 50 mm extraction hose, 2m

long, Item no. 72050 Ø 50 mm connector, Item No. 72050 ....................................................

•See the delivery note for further accessories

2.3 Short description of the unit and component identification

The single/double-workplace extraction unit D-LE 255 S/D has a powerful high-pressure fan which is

fitted with noise suppression. The unit provides two ways to set the airflow rate indicated for

the detection device (extraction mouth):

-Gradually, by means of a pushbutton.

-Continuously, by means of a potentiometer.

In both cases, the airflow rate is automatically controlled. Thus, the airflow volume at the extraction

funnel remains constant regardless of the contamination degree of the filter medium.

It is also equipped with an automatic electronic ignition, an automatic shut-off feature with filter

change indicator, and automatic air volume control. Pneumatic stop valves (accessory) are con-

nected and automatically actuated when the respective dust-generating device is activated, enabling

free airflow at the specified vacuum duct.

The automatic ignition electronics detect a rotating hand-held piece in a fraction of a second and im-

mediately actuate dust extraction. The connected stop valve (accessory) automatically enables the

extraction line immediately. Any commercially-available hand-held pieces can be used for this pur-

pose. The D-LE 255 S/D is also used as an extractor for sand blasting instruments, saws and other

dust-generating devices, electronic detection functioning here in the same manner.

The existing flow control device not only monitors the airflow but also the contamination degree of the

pre-filter and ultra-fine filter. Visual and acoustic indicators are provided to indicate the condition of fil-

ter components, as well as the decrease of the exhausted airflow volume at the extraction funnel be-

low a specified minimum value. If the airflow volume falls below the minimum, all dust-generating de-

vices connected to the extraction unit are shut down.

At specific time intervals but only after switch-on, the extraction unit performs a self-test and clears

the lines.

The extraction unit is designed for mains voltages of 200 - 240 (± 10%) V. That is, the air volume set

by the potentiometer is held constant regardless of line voltage fluctuations.

The dust is collected in a double-ply disposable filter bag with a capacity of up to 10 kg, depending on

the nature of the dust.

The ultra-fine filter has a large surface area and is serially connected to the disposable filter bag, has

a maximum transmittance of <0.1%.

Maschinenbau

Werkzeuge

Laborgeräte

380

51

/s

L

2

L / s

/

D-LE 255 S

10

60

Air Manual

Auto

MF

m02

1

5

s

4

1

2

2

3

1

4

3

7

8

9

21

6

5

13

19

A2

C2

46

A1

C1

12

34 35

Fig. 2: Front and left side view

25

30

32

31

28

26

27

11

15

16

10

17

25

24

23

22

20

12

21

29

33

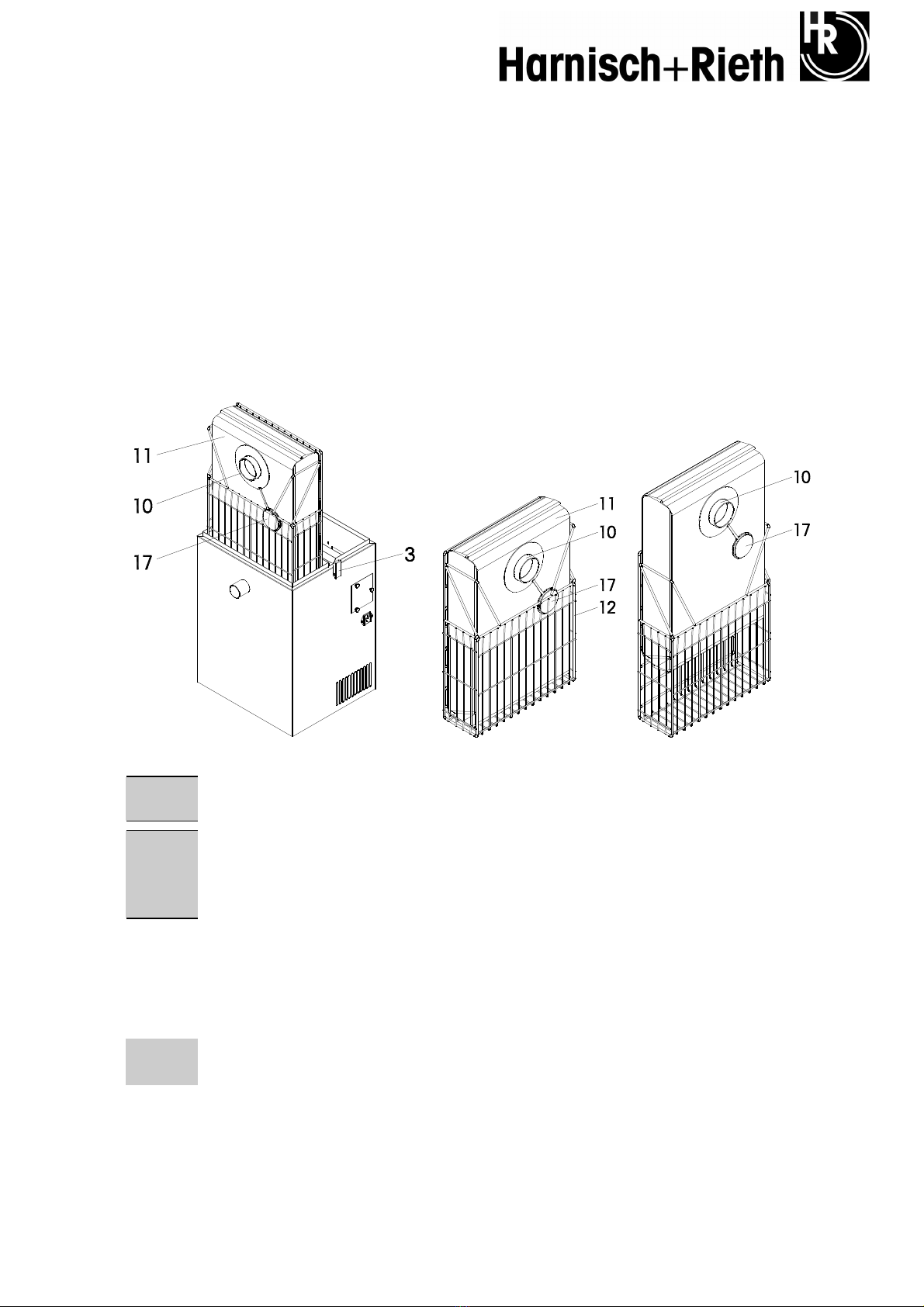

3 Unit cross-section viewed from the left

1Housing

2Cover

32x Quick-action closure

4Panel

5Mounting cover

62x knurled-head screws

7

Socket for automatic stop

valve B1

8Socket f

or automatic stop

valve B2

9

Socket to activate extraction

unit via external voltage 9-

30V DC

13

Connector plug(230 V/50

Hz)

19 Fuse compartment

21 Ball rollers

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

10

Plastic connection for filter bag 24

Sealing surfaces, all-round

11

Filter bag 25

Seal, all-round

12

Mesh basket 26

Extraction channel

15

Ø 63 mm-nozzle (inside) 27

Extraction chamber

16

Ø 50 mm nozzle (outside) 28

2x M6 nuts

17

Closure cover for filter bag 29

Slotted retaining strips

20

Pre-filter 30

Electric cabinet

22

9x screws for floor space 31

Ultra-fine filter

23

Vacuum motor (fan) 32

Ultra-fine filter chamber

33

Main control board

2.4 Starting up procedure

-Check the filter system (see Section "3.1 Checking the filter system").

2.4.1 Pneumatic structure of tube/hose installation

(See Fig. 4, page 7)

1. Establish a hose/tube connection to the dust-generating devices (select a hose length which is a

short as possible, maximum length approx. 2 m for each device), see Fig. 4, page 7.

2. The hose/tube installation can be connected to 50 mm nozzles (16) (Fig. 3, page 5) of the exhaust air

fitting.

3. Connect the automatic pneumatic stop valve to the compressed air supply (pneumatic connection

(41), see Fig.5, Page 8).

Note All devices and installation components can be connected to the unit with flexible hoses or rigid

plastic tubes (see following examples).

Maschinenbau

Werkzeuge

Laborgeräte

1

12a

10a

2

12a

1

0

a

37

37

1a 3a

6a3a

3a

7a7a

4a2a

4a

11a

11a

Absaugung

3a

5a

9a

9a

1

2

Absaugung

Ø

50

Y-Stück: Ø 50 / Ø 50

Fig. 4 Laying tubing to devices over long distances

1a

90 °angle piece Ø 50 7a Y-piece connection fitting Ø 50

2a

Angle connection fitting Ø 50 9a Reducer Ø 50 / Ø 45 / Ø 40

3a

PVC hose fitting Ø 50 10a

PVC hose fitting Ø 50 / Ø 45 / Ø 40

4a

Hose/Tube Ø 50 11a

Hose/Tube Ø 50 / Ø 45 / Ø 40

5a

Y-piece Ø 50 12a

PVC hose fitting Ø 50 / Ø 45 / Ø 40

6a

Y-piece connection fitting Ø 50 37 Automatic pneumatic stop valve

1

Dust-generating device no. 1 33 Main board, see Fig. 2

2

Dust-generating device no. 1

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

2.4.2 Structure of the electrical installation

1. Connect the dust-generating device mains power cable to socket A1 and A2 (see Fig. 5, Page 8).

2. Connect the stop valve connection cable to socket B1 and B2. Turn the

outer sleeve (39) of the connector (38) to the right to lock the connector in socket B1 and

B2 (bayonet lock).

3. Establish a connection to the mains power supply (230V/50Hz) with the mains cable provided (socket

(13)).

L/

D-LE 255 S

2

Air

60

MF

2

/m

0s

1

30

51

s

L s/

Auto

Manual

10

B1

B2

2

1

2

1

2

1

39 40 41 37

38

47

3

4

3

5

C2

C1

D

A1

A2

13

19

9

23

22

Fig.5 Unit and electrical connections

9Socket to activate extraction unit

via external voltage 9-30V DC

39 Outer connector sleeve with bayonet lock

13 Mains socket 230V/50Hz 40 Solenoid valve

19 Main fuses (2x 16 A / T) 41 Pneumatic connection

16 Connection fittings Ø 50 mm (Fig. 3, Page 5) 47 Pressure reducing valve

37 Automatic pneumatic stop valve A1 1x socket for dust-generating devices 230 V

38 Connector with cable and solenoid valve socket A2 1x socket for dust-generating devices 230 V

B1

Stop valve socket no. 1, 230 V, AC B2 Stop valve socket No. 2, 230 V, AC

C1

1x socket for special control cable to

activate the exhaust air fitting.

C2 1x socket for

special control cable to activate

the exhaust air fitting.

1Stop valve No. 1 2Stop valve No. 2

DSpecial connection (e.g., milling unit)

4. Activate the main switch (34) (control lamp (35) illuminates green).

5. The "Auto" (22) or "Manual" button (23) illuminates green (the last operated button illuminates).

6. After pressing the "Manual" button (23) (illuminates green), the extraction unit enters continu-

ous operation mode.

Maschinenbau

Werkzeuge

Laborgeräte

/sL

s5

0

3

L1

/ s

20m

Auto

MF

Manual

10

60

Air

D-LE 255 S

/

12

35

37

38

39

40

22

23

4

6

4

2

4

1

4

4

4

3

4

5

36

34

Fig. 6 Panel with control elements

34 Main switch 37 "Ready" control lamp

35 Main switch control lamp (green) 38 "Service" control lamp

36 Air volume controller (potentiometer) 39 "Filter change" control lamp for ultra-fine filter

40 "Filter change" control lamp for pre-filter

3 Operation

3.1 Checking the filter system

(See Fig. 2 and 3, Page 5)

Caution The single/double-workplace extraction unit D-LE 255 S/D must only be operated with a cor-

rectly fitted, undamaged ultra-fine filter (31) and filter bag (11).

1. Open the 2x quick-action closures (3) and remove cover (2).

2. Ensure that the ultra-fine filter (31) is not damaged and is pressed tightly against the retaining

strips (29) on the seal surfaces (24).

3. The two M6 nuts (28) should be tightened firmly and evenly.

4. The assembly cover (5) must be screwed tight with two knurled-head screws (6).

5. The filter bag (11) should be undamaged when inserted in the wire basket (16), see Fig.17, Page

19.

6. The plastic connector (10) must sit tightly on the connection fitting (15).

7. Clamp the cover (2) firmly with the aid of the two quick-action closures (3)

3.2 Variants of the dust-generating device automatic detection.

(See Figure 5 and 6, Page 8 and 9)

1. Extraction unit activation via sockets A1 and A2.

a) Connect the dust-generating device(s) to socket A1 and/or A2.

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

b) Press and hold the "m" button (45) for 5 sec. Ensure that any connected dust-generating de-

vices are in standby mode.

c) Measurements are performed every 10 seconds (shown on display). After completing the

measurements, the extraction unit is ready for operation.

2. Activation of the extraction unit via special control cable (potential-free contacts).

a) Connect the dust-generation device to socket C1 and/or C2 of the extraction unit by means of

a special control cable. The cable (option) can be provided by H+R.

3. Activation of the extraction unit via socket 9.

a) The extraction unit will be activated by applying a 9-30V DC voltage to socket 9.

3.3 Automatic On-Off / Connection of dust-generating devices

The extraction unit is equipped with an electronic On-Off actuator, which reacts to most hand-held

pieces and other dust-generating laboratory devices.

Caution The power input (power consumption) of devices to be connected should not exceed 900 Watt

per socket A (A1, A2). The overall power input value of all connected devices should, in total,

not exceed1800 W.

1. Connect the dust-generating devices to sockets A1 and A2 (230 V, AC).

2. Connect the automatic stop valves accordingly to sockets B1 and B2 (230 V, AC).

3. The "Auto" button illuminates green after the unit is switched on (main switch (34) ON) (see Fig.

6, Page 9).

Note Please contact our H+R Customer Service Dept. (tel.: +7181/9678-0) if devices other than those

we have intended are to be connected.

The extraction unit starts automatically as soon as a connected dust-generating device is acti-

vated. The unit stops after a delay of approx. 8 seconds if all connected devices are deacti-

vated.

It is possible to adapt the unit individually if it does not react to a particular dust-

generating device. Please contact the H+R Customer Service Dept. to that end.

3.4 Automatic air volume control

The air volume is increased or decreased to suit the number of dust-generating devices in operation

and is independent of the filter contamination degree. The set air volume is then maintained at a con-

stant level by electronic control until the automatic shut-off feature is triggered. The air volume can be

altered by pressing button (43) (to reduce the volume) or button (42) (to increase the volume), see

Fig.6, Page 9.

3.5 Automatic shut-off and filter change control Iamp

(See Fig.6, Page 9)

Note An underpressure sensor triggers the automatic shut-off feature and the "filter change" control

Iamp (39 or 40) illuminates as soon as the max. permissible filter bag (11) (see Fig.3, Page

5) filling level is reached. The extraction unit and the connected dust-generating devices are

switched off.

1. The filter bag (11) must be replaced (see Section "6.1 Replacing the filter bag").

Note The extraction unit can be switched on and off again or the filter bag (11) lightly beaten if the

automatic shut-off feature deactivates the unit. The unit can then operate for some time without

Maschinenbau

Werkzeuge

Laborgeräte

changing the filter bag.

2. Open the clamp closure (3) and remove the closure cover (2) to lightly beat the filter bag (11).

Note •The ultra-fine filter should be replaced if the filter change Iamp (39) illuminates after

the automatic shut-off feature is triggered. See Section "6.3 Cleaning (replacement) of the

ultra-fine filter".

•The pre-filter should be replaced if the filter change Iamp (40) illuminates after the auto-

matic shut-off feature is triggered. See Section "6.1 Replacing the filter bag".

3.6 Self test / initialization

(See Fig.6, Page 9)

A self-test is automatically executed (without user intervention) to avoid the clogging of

pipes/connecting hoses and ensure that the prescribed air volume is available at all extraction ducts.

Every time the device is switched on, the software automatically verifies whether the selected initiali-

sation interval has been exceeded. If so (factory setting: 5 hours), the self-test is started immediately

(but only after the unit is re-started).

Note The self-test can also be performed on demand by holding down the "Manual" button; the unit

is switched on via the main switch.

During the initialisation phase, all extraction ducts are individually open and vacuumed at full extrac-

tion power for 10 seconds. In that period, we total vacuum in the ultra-fine filter chamber is measured

and displayed.

If the total vacuum in the ultra-fine filter chambers exceeds the allowable value set in the service

menu, the extraction unit is switched off with a fault display.

Note If, after initialisation, allowable parameter values are not held, this is indicated by a flashing of

all LEDs (2x red, yellow, green), accompanied by a periodic beep.

I n i t i a l i s i e r u n g

0 2 9 9 8

1

2

A) Test of channel no. 1.

The pressure drop is displayed con-

tinuously

I n i t i a l i s i e r u n g

0 3 0 0 4 0 K

20155

1

2

B) Test of channel no.2

Pressure loss in channel

no. 1 does not exceed the allowable

value thus the display shows "OK".

Channel No. 1 remains open.

I n i t i a l i s i e r u n g

0 3 0 0 4 0 K

2 0 1 5 5 F e h l e r

1

2

C) End of the self-test

Extraction unit is turned off as a

result of an error.

Pressure loss in channel

no. 2 exceeds the allowable value thus

"Error" is displayed.

Fig. 7 Self-test procedure

3.7 Notes to monitoring the airflow volume

A warning is issued 10 seconds after the airflow volume falls below the setpoint by 5%.

In this case, the yellow service LED (38) and both red filter change LEDs (39 and 40) flash and

the buzzer sounds intermittently.

Caution If the air flow volume falls below the setpoint for over 60 seconds, the extraction unit is

switched off (see Error No. 4 in the "Error messages" table on page 13)

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

Note Every time you switch on the extraction unit, the airflow volume control remains off

for approximately 30 seconds

3.8 Setting the extraction unit parameters

The extraction unit can be operated under two sets of rules:

-Control variant "Air volume"(L/s)

-Control variant "Air speed" (m/s)

Users can toggle between modes by pressing and holding the "Air "(41) button for five seconds.

Furthermore, the extraction unit can operate in two modes:

•Automatic mode "Auto"

•Manual mode "Manual"

3.8.1 Manual mode (Manual)

In manual mode, the extraction unit can only be operated under the "air volume" (L/s) control variant.

In this mode, all available extraction channels are open.

Note Any unnecessary channels can be disabled via the user menu.

sL /

Manual

Auto

/s

L

0

3

/ s

0m

2

1

MF

10

60

Air

2

D-LE 255 S

15

20

3

5

37

38

39

40

22

23

46

42

41

44

43

45

3

6

23a

41a

Fig.8 Panel in manual mode

After pressing the "Manual" button, the LED (23a) illuminates green. Thus, the extraction unit is put

into operation immediately. In manual mode, the "Air" (41a) button LED illuminates as the extraction

unit necessarily adopts the "air volume" (l/s) control variant.

Set the desired air volume with the controller (36). The set air volume is shown on the display. Air

volume is automatically regulated and remains constant regardless of the filter contamination degree.

Note The controller (36) can be used to set the air volume of the fan from 10 l/s up to its maximum

value.

3.8.2 Automatic mode (Auto)

In automatic mode, the extraction unit can be operated under two control variants: "Air volume" (l/

s) and "Air speed" (m/s)

Maschinenbau

Werkzeuge

Laborgeräte

sL /

Manual

Auto

/sL

0

3

m/ s

0

2

1

MF

10

60

Air

2

D-LE 255 S

15

20 35

37

38

40

22

23

46

42

41

44

43

45

36

23a

41a

22a

39

Fig. 9 Panel in automatic mode

The LED (22a) illuminates green after pressing the "Auto" button (22). In this mode, the extraction

unit is only switched on as the connected external dust-generating device is activated. In automatic

mode, the "Air" (41a) button LED will only illuminate if the "Air volume" (l/s) control variant

is selected. The "Air" (41a) button LED dims if the control variant "Air speed" (m/s) is selected.

Note Users can toggle between control variants, i.e. "Air volume" (l / s) or "Air speed" (M / s) , at

will by pressing and holding the "Air" (41) button for 5 seconds.

The total airflow volume (setpoint) in all detection points (extraction funnels) is calculated as the

product of the set airflow volume (l/s control variant) and air speed (m/s control variant) by the num-

ber of open extraction channels.

Extraction channels are automatically opened or closed via the operating dust-generating de-

vice by means of downstream stop valves.

Note Use the buttons "+" and "-" or the "User menu" to regulate the l/s air basis from 10 l/s to 55 l/s.

4 Error messages

Error

number Error type

LED (37)

Opera-

tion

LED (38)

Service

LED (40)

Pre-filter

LED (39)

Ultra-

fine filter

Buzzer

1. Replace pre-filter

2. Replace ultra-fine filter

3. Excessive total vacuum

(In the ultra-fine filter cham-

ber)

4.

Minimum airflow volume is

below (by> 5%)

A warning

signal is issued

after 10 sec.

The extraction unit

is switched off after

one minute.

5. Offset pressure sensors NIO

6. Value of the airflow sensor

NIO

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

7. Interruption in electrical cir-

cuit of the motor

Fault on the phase-angle control (overcur-

rent or no zero crossings)

8. Error communicating with

phase-angle control

9. Error in EEPROM memory

10. Error during initialisation

The extraction

unit is switched off.

After correcting the

error, switch on and

reset the extraction

unit.

11.

The desired level air-

flow volume exceeds max.

air volume value of the

blower, for example, by con-

necting an additional chan-

nel.

1

1m/ s

3 0

L / s

3 5 L / s

12

Example: Air volume for extraction channel

(1st workplace) is set to 35 l/s. After activating

the 2nd extraction channel (2nd workplace), air

volume demands stands at 70 l/s. This ex-

ceeds the fan power by 15 l/s In this case, the

extraction channel 2 is disabled immediately

and shown in black on the display after 10

seconds.

Beep sounds and

display shows

this message: In-

sufficient air vol-

ume for additional

channel. The addi-

tional extraction

channel is shown

black on the display

after 10 seconds.

The extraction

channel and socket

A1 and A2 are im-

mediately blocked

or de-energized.

- No signal,- Continuous signal, - Periodic Signal

(with LEDs and buzzer)

5 User menu

(See Fig.6 Page 9)

The user menu allows adjusting the operating parameters and areas of the extraction unit.

Note The user menu is activated by pressing and holding the "MF" (46) button for 5 seconds.

The user menu is exited by pressing the "MF" (46) button.

User menu settings

Parameter name Area/Range Delivery value

1.

Air basis (l/s) 10 to 60 L/s in 5l increments 20 l/s

2.

Current threshold 1 0 to 255 215

3.

Current threshold 2 0 to 255 215

4.

Extraction channel 1 / Enable or

disable

or X

5.

Extraction channel 2 / Enable or

disable

or X

Maschinenbau

Werkzeuge

Laborgeräte

6.

Hose/tube diameter 1 40, 45, 50, 60 mm 40 mm

7.

Hose/tube diameter 2 40, 45, 50, 60 mm 40 mm

8.

Air basis (m / s) 15 to 50 m/s 20 m/s

9.

Language De, En, Fr, Es De

10.

Sensitivity 255 100

A n we n d e r me n ü

L u f t b a s i s ( L / s ) : 2 0 L / s

F r e i g a b e 1 :

R o h r 1 : 4 0 mm

L u f t b a s i s ( m/ s ) : 2 0 m/ s

E mp f . 1 : ( 1 5 3 ) . 1 0 0

A b s t a n d l i n k s 1 : 0 4 0

S p r a c h e D e

A) User menu

The user menu of the single-

workplace extraction unit consists

of only one page.

A n w e n d e r me n ü 1 / 2

L u f t b a s i s ( L / s ) : 2 0 L / s

F r e i g a b e 1 :

F r e i g a b e 2 :

R o h r 1 : 4 0 mm

R o h r 2 : 4 5 mm

L u f t b a s i s ( m/ s ) : 2 0 m/ s

E mp f . 1 : ( 1 5 3 ) . 1 0 0

A) User menu Page 1

A n w e n d e r me n ü 2 / 2

A b s t a n d l i n k s 1 : 0 4 0

E mp f . 2 : ( 0 4 4 ) 2 0 0

A b s t a n d l i n k s 2 : 0 4 0

S p r a c h e D e

B) User menu Page 2

The user menu of the double-

workspace extraction unit consists

of two pages.

Fig. 10 User menu - original illustration

5.1 Changing the user menu settings

MF

45

42

46

44

43

Fig. 11 User menu operation keys

•Use the keys "m"(45) and "l"(44) to position the cursor on the setting you wish to change.

•Use the keys "+" (42) or "" (43) to change the value as required.

-Air basis (l/s): Desired airflow volume in an extraction channel.

-Enable 1 (2): Enable extraction channel 1, 2, or both. Symbols: "

"Means Enable, "X" means

disable.

-Tube 1 (2): The diameter of the connected hoses (tubes) will be provided to the dust-generating

device.

-Air basis (m / s): Desired airflow speed in a tube.

-Recommended 1 (2): Response threshold for extraction unit. The response threshold should be

set above the value displayed in parentheses before. All connected dust-generating devices

must be in standby mode to define the response threshold correctly.

The point displayed between the value in parentheses and the respond threshold indicates that the

start-up signal was issued to the extraction unit.

-Distance to the left: The parameter is possibly redefined after consultation with H+R.

-Language: It is possible to display messages in German, English, French and Spanish.

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

5.2 Display - Messages and meanings

5.2.1 Display messages for "air volume" (l/s) control variant

2 2 m/ s L / s

4 0

2 0

L / s

12

A) Two air channels are open (i.e.,

two stop valves are open)

1 1 m/ s

2 0 L / s

2 0 L / s

12

B) Only one channel is open (i.e.,

only one stop valve is open the

second stop valve is closed)

m/ s

1 1

2 0

L / s

2 0 L / s

12

C) A channel is open (i.e., a stop

valve is open and the second

is disabled in the user menu)

Fig. 12Display messages in "air volume" (l/s) control variant

m/ s

1 1

2 0

L / s

2 0 L / s

12

D1

D2

D3

D4

D5

D6

D7

D8

D10

D9

Fig. 13 Display message components in "air volume" (l/s) control variant

D

1.

Reference air speed in tube ID Ø48mm

(Extraction unit ID of the extraction fitting) ------------

D

2.

Air channel No. 1 is enabled The arrow indicates that the connected dust-generating

device is detected and the extraction unit is opera-

tional. Simultaneously, the stop valve enables the air-

flow.

D

3.

Airflow volume in all tubes or hoses (to-

tal) l/s

Displays the total airflow volume currently being pro-

duced by the blower. If two extraction funnels are ac-

tive, the air volume will increase to 40 l/s (for 20 L/s air

basis, see message D5).

D

4.

Air channel No. 2 is disabled Disabling an air channel is possible only from the user

menu.

D

5.

Air basis (l/s) The air volume required for an extraction funnel is set

in the user menu, e.g. to 20 l/s If two extraction funnels

are simultaneously active, the air volume will increase

to 40 l/s, see message D3.

D

6.

Ultra-fine filter contamination degree Allows a visual assessment of the ultra-fine filter con-

tamination.

D

7.

Pre-filter contamination degree Allows a visual assessment of the pre-filter contamina-

tion.

D

8.

Symbol for pre-filter ------------

D

9.

Symbol for ultra-fine filter ------------

D

10.

Channel number It is possible to connect two workplaces and, thus, two

Maschinenbau

Werkzeuge

Laborgeräte

air channels, channel 1 and channel 2.

5.2.2 Display messages for "air velocity" (m/s) control variant

/4 0

2 0

m/ s

2 0 m/ s

/

/

0

12

A) Two Ø40 air channels are open

(two stop valves are open). If Ø50

is selected in the second chan-

nel, the airflow is increased as if

both channels had a Ø50 diame-

ter to maintain 20 m/s in each

channel. The display shows Ø50.

//

/

0 4 0

2 0

m/ s

2 0 m/ s

2

1

B) Only one Ø40 channel is open

(only one stop valve is open the

second stop valve is closed)

4 0

//

/

0

2 0

m/ s

2 0 m/ s

2

1

C) A channel is open (only

one stop valve is open, the sec-

ond is disabled in the user menu)

Fig. 14 Display messages for "air velocity" (m/s) control variant

//

/

0 4 0

2 0

m/ s

2 0 m/ s

2

1

D11

D2

D12

D13 D14

D6

D7

D8

D10

D9

Fig. 15 Display message components for "air velocity" (m/s) control variant

D

2Air channel No. 1 is active (i.e. there is

airflow in the extraction tube).

The arrow indicates that the connected dust-generating

device is detected and the extraction unit is opera-

tional. Simultaneously, the stop valve has enabled the

airflow.

D

6Ultra-fine filter contamination degree. Allows a visual assessment of the ultra-fine filter con-

tamination.

D

7Pre-filter contamination degree (filter

bags).

Allows a visual assessment of the pre-filter contamina-

tion.

D

8Symbol for pre-filter (filter bags). -------------

D

9Symbol for ultra-fine filter. -------------

D

10 Channel number It is possible to connect two workplaces. Thus, two air

channels, channel 1 and channel 2.

D

11 Diameter of the connected extraction

tube (connecting tube ID Ø40mm)

The tube diameter is defined in the user menu.

D

12 Measured air speed in a single tube. Indicates the actual air speed per tube. It corresponds to

the air basis (m/s) as per configuration.

D

13 Extraction tube without airflow In this case, the stop valve is closed (the dust-

generating equipment has not been activated).

D

14 Air basis (m/s) The desired air velocity in the extraction tube (m/s) is

Maschinenbau

Werkzeuge

Laborgeräte

2 D-LE 255 S/D - 18.07.14 / Vers.: 1

set in the user menu.

Maschinenbau

Werkzeuge

Laborgeräte

6 Cleaning / Maintenance

6.1 Replacing the filter bag

(See Figure 2 and 3 on Page 4 and Page 5)

1. Open the 2x quick-action closures (3) and remove cover (2).

2. Push away the plastic connector (10) from the nozzle (15) with both hands,

3. Close the filter bag (11) with attached plastic cover (17).

4. Take the filter bag (11) in the wire basket (12) to the disposal point.

Fig. 16 Removing the filter bag

Caution The disposable filter bag should never be emptied and reused as, apart from health considera-

tions, this will lead to malfunctions.

Caution Compressed air should not be used to remove any dust present in the filter

chamber (20).

No foreign objects should reach the extraction channel (26) as otherwise the extraction motor can

be damaged.

5. Insert a new filter bag and check the filter system, see section 4.2.

6.2 Inserting the filter bag

(See Fig. 2 and 3, Page 5)

Note Disposable - Paper filter bag Item No. 42 015

Disposable - Fleece filter bag Item No. 42 303

1. Fold the new filter bag (11) and place it in the wire basket (12) as shown in Figure 17.

Other manuals for D-LE 255 S

1

This manual suits for next models

1

Table of contents

Other Harnisch+Rieth Dental Equipment manuals