Micropilot M FMR 230 with HART/4...20 mA Identification

Endress + Hauser 7

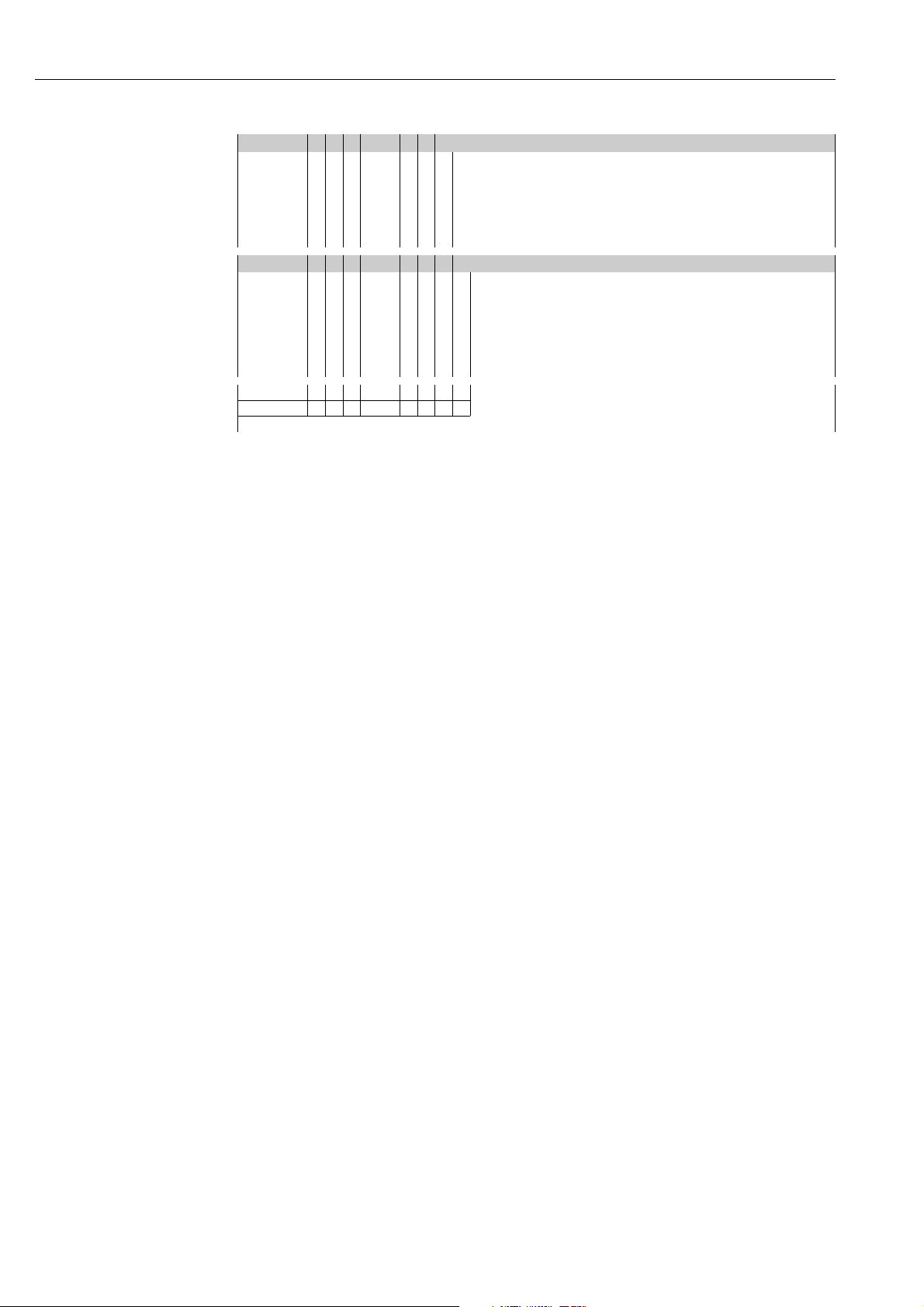

Ordering structure Micropilot M FMR 230 (continued)

30 Type of antenna, sealing, temperature

Type Sealing Temperature range

V Standard Viton/FKM -20 °C…200 °C / -4 °F…+392 °F

E Standard EPDM -40 °C…150 °C / -40 °F…+302 °F

K Standard Kalrez 0 °C…200 °C / 32 °F…+392 °F

L Extended temperature Graphit -60 °C…280 °C / -76 °F…+536 °F

M High temperature Graphit -60 °C…400 °C / -76 °F…+752 °F

H Enamel antenna PTFE -40 °C…200 °C / -40 °F…+392 °F

Y Special version

40 Process connection, material

Flange Dia/Pressure Standard Material

CMJ DN80 PN16 EN 1092-1, B11) 316L

CNJ DN80 PN40 EN 1092-1, B11) 316L

CQJ DN100 PN16 EN 1092-1, B11) 316L

CQ5 DN100 PN16 EN 1092-11) Alloy C4 >316Ti

CRJ DN100 PN40 EN 1092-1, B11) 316L

CWJ DN150 PN16 EN 1092-1, B11) 316L

CW5 DN150 PN10/16 EN 1092-11) Alloy C4 >316Ti

EWT DN150 PN16 EN 1092-1, B11) enamelled steel

CXJ DN200 PN16 EN 1092-1, B11) 316L

EXT DN200 PN16 EN 1092-1, B11) enamelled steel

C6J DN250 PN16 EN 1092-1, B11) 316L

C65 DN200 PN16 EN 1092-11) Alloy C4 >316Ti

ALJ 3"/150 lbs ANSI B16.5 316/316L

AMJ 3"/300 lbs ANSI B16.5 316/316L

APJ 4"/150 lbs ANSI B16.5 316/316L

AQJ 4"/300 lbs ANSI B16.5 316/316L

AVJ 6"/150 lbs ANSI B16.5 316/316L

AV5 6"/150 lbs ANSI B16.5 Alloy C4 >316Ti

AVT 6"/150 lbs ANSI B16.5 enamelled steel

A3J 8"/150 lbs ANSI B16.5 316/316L

A35 8"/150 lbs ANSI B16.5 Alloy C4 >316Ti

A3T 8"/150 lbs ANSI B16.5 enamelled steel

A5J 10"/150 lbs ANSI B16.5 316/316L

A55 10"/150 lbs ANSI B16.5 Alloy C4 >316Ti

KA2 10 K 80A JIS B2210 316Ti

KH2 10 K 100A JIS B2210 316Ti

KV2 10 K 150A JIS B2210 316Ti

KD2 10 K 200A JIS B2210 316Ti

K52 10 K 250A JIS B2210 316Ti

1) agreeable to DIN 2527

TL2 3" Tri-clamp ISO 2852 316Ti

YY9 Special version

50 Output and menu based operation

A 4…20 mA HART with VU 331 (4-line alphanumeric display)

B 4…20 mA HART

K 4...20 mA HART, prepared for FHX40, mounting of remote display (accessory)

C PROFIBUS PA with VU 331 (4-line alphanumeric display)

D PROFIBUS PA

L PROFIBUS PA, prepared for FHX40, mounting of remote display (accessory)

E Foundation Fieldbus with VU 331 (4-line alphanumeric display)

F Foundation Fieldbus

M Foundation Fieldbus, prepared for FHX40, mounting of remote display (accessory)

Y Special version

60 Housing

A Aluminium F12-housing, coated, IP65

B 316L F23-housing, IP65/NEMA4x

C Aluminium T12-housing with separate connection compartment, coated, IP65

D Aluminium T12-housing with separate connection compartment, coated, IP65,

overvoltage protection

Y Special version

FMR 230- Product designation (part 2)