4

Introduction

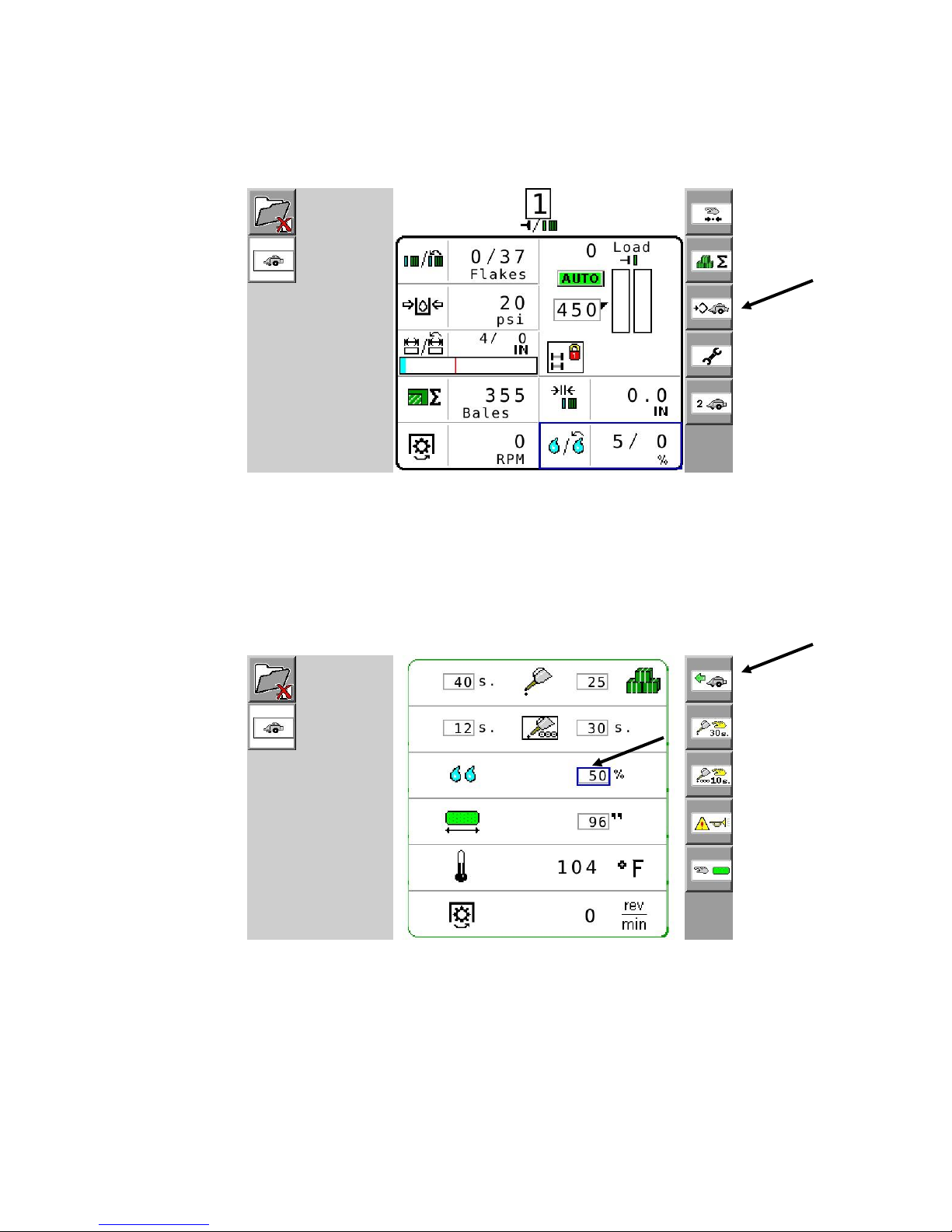

Thank you for purchasing a Harvest Tec Model 600A Moisture Monitor System. This 600A Moisture Monitoring

System has been designed to be operated through the baler’s ISOBUS system and/or an Apple iPad (not

included) using the Hay App. The 600A Moisture Monitoring System offers these advantages:

1. Operation coordinated with baler operation

2. Less cab clutter providing better visibility

3. Ease of use with all information on one screen

4. Records kept together

5. The system is ready for future updates

The 600A Moisture Monitor kit includes the following parts: Dual Channel Processor (DCP), Moisture Sensors,

Harnesses, Bluetooth receiver and Miscellaneous Hardware. For your convenience a parts break down for the

600A Moisture Monitoring System is included in the back of this manual. If you do have questions please bring

this manual into the dealership. They can assist you in ordering the correct replacement parts.

Right and Left sides are determined by facing in the direction of forward travel.

System Requirements

The Baler Processor must have Version 3.3 or higher.

C1000 monitor must have Version 3.0.1 or higher

If equipped with the SBM, the SBM must have Version 4.0 or higher.

*iPad Mini or iPad 3rd Generation (2012) or newer, running the current iOS operating system

or one version previous required for iPad option

Safety

Carefully read all safety signs in this manual and on the moisture sensor kit before use. Keep signs clean and

clear of obstruction to view. Replace missing or damaged safety signs. Replacement signs are available from

your local authorized dealer. See your installation manual under the replacement parts section for the correct

part numbers.

Keep your moisture sensor kit in proper working condition. Unauthorized modifications to the moisture sensor

kit may impair the function and/or safety of the machine.

Carefully read and understand all safety signs before installing or servicing.

Safety Decals

Number 1

Disconnect power before servicing.

Part no. DCL-8003

Number 2

Read and understand the operator’s manual

before using or working around the equipment.

Part no. DCL-8000