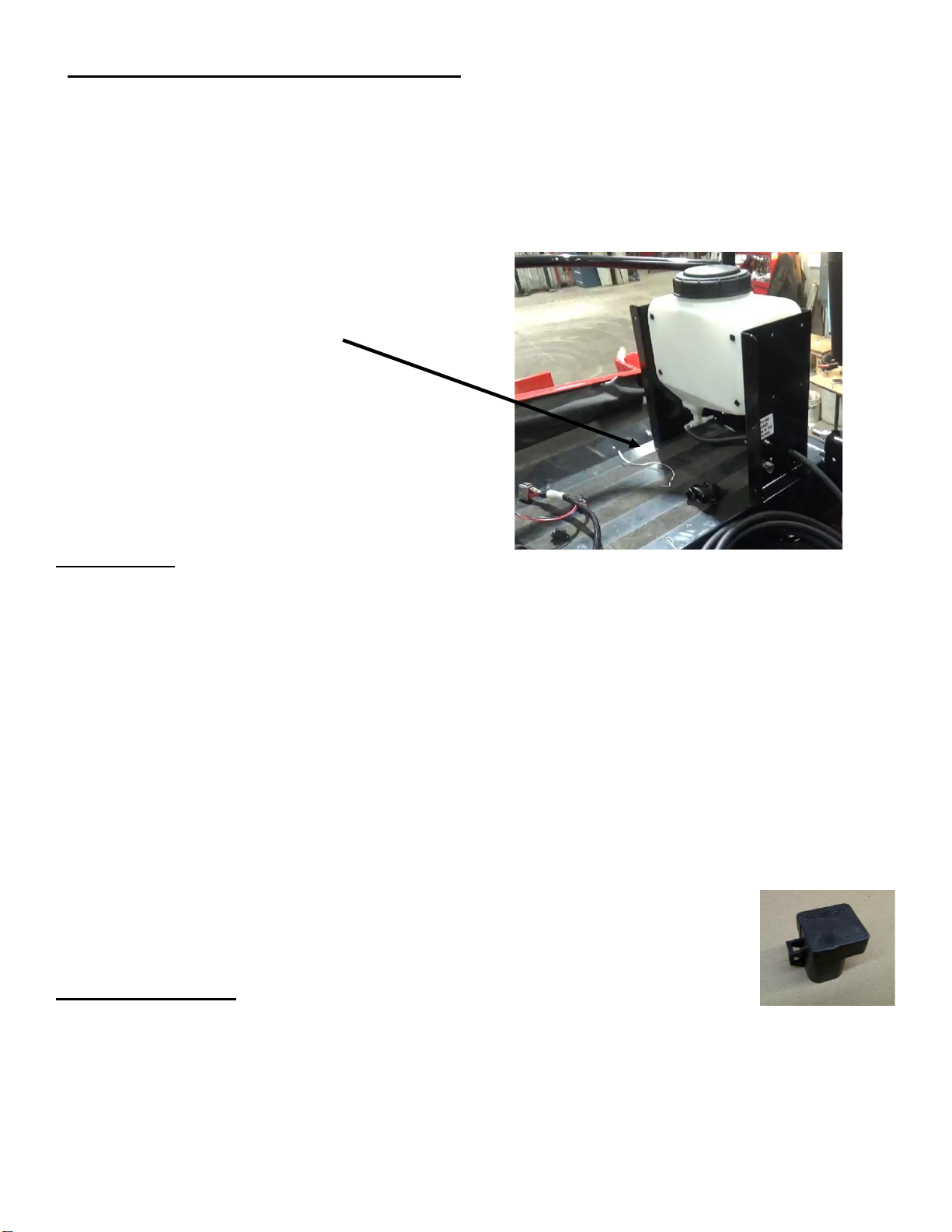

Installation of Dye Sprayer Tank & Plumbing

Installation of Mounting Bracket & Tank –CASE & New Holland Large Squares

Locate the tank and mounting bracket assembly. Looking at Figure 1 decide where a desirable mounting

location will be the most convenient and work the best for the user.

a. Once tank location is decided, mark the mounting holes and drill bit.

b.

System Wiring

Setting up Tractor

1. Connect the red and black eye-loop connectors from 006-765IC Tractor Power/Communication harness

DIRECT to tractor battery. Route 18 pin plug to drawbar of tractor and the other leg of the harness with the 12

Pin and 4 Pin connector into the cab of the tractor.

2. 006-6673 ISO Communication Module (ICM) mounts in the cab of the tractor and connect 006-765IC 12 pin

header harness to it.

3. Connect 006-765CPH key power harness to 4 pin plug on 006-765IC harness near ICM. Securely fasten to

key power outlet in cab of tractor

4. Secure wires with zip ties.

Setting up baler.

1. Route 006-765BN harness from draw bar of baler back toward Balers ECU

2. Remove 006-7303CMS star wheel harness plug from Baler ECU CAN 2 connection and attach 006-765BN

to same connection of 006-7303CMS harness.

3. Remove 006-4640J resistor plug from the 006-7303CMS harness and attach 006-

765VN to same connection of 006-7303CMS. Reattach 006-4640J to port on 006-765VN.

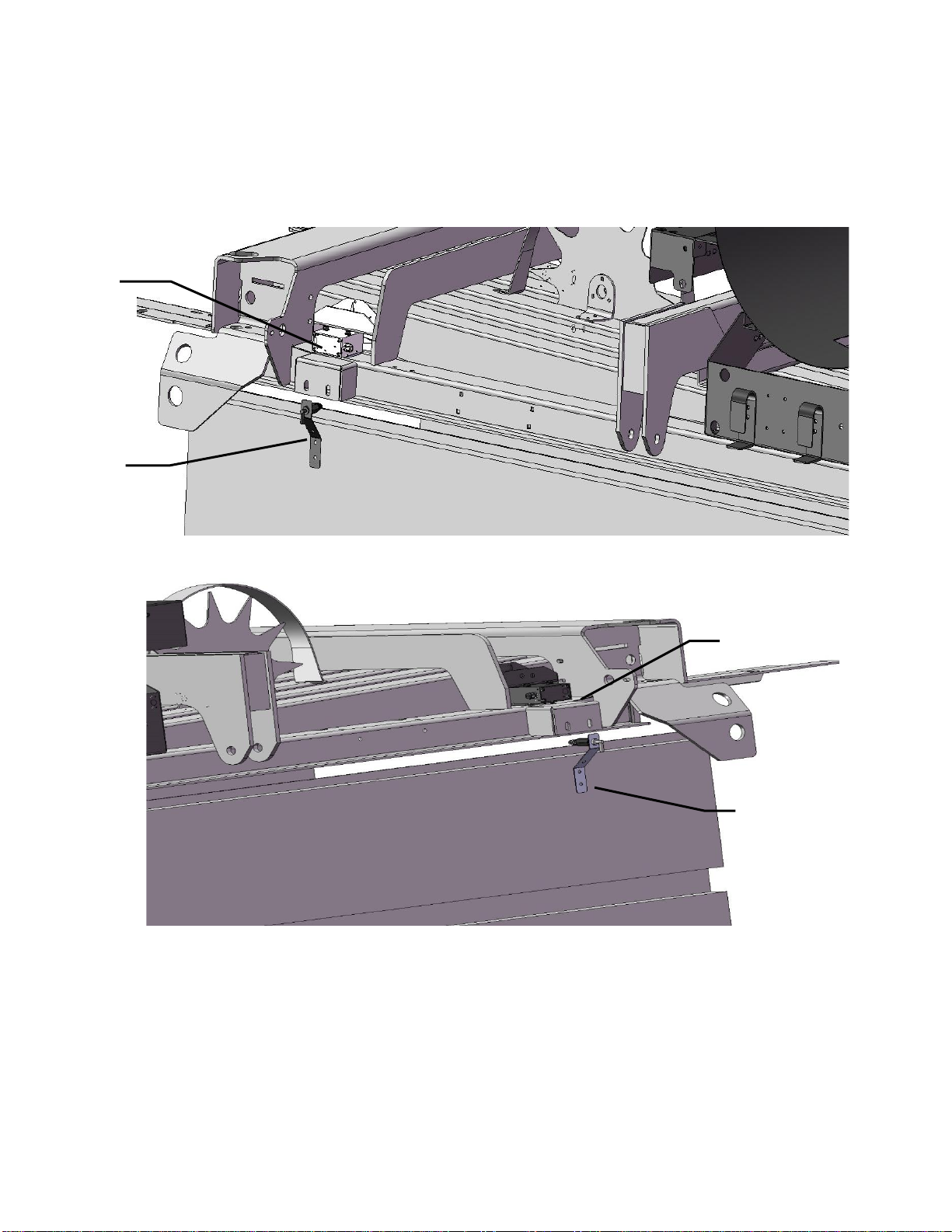

4. Locate the CAN Port 1 on the baler ECU. Remove 6 pin active terminator (X504) from

CAN 1 (Figure 2) and attach active terminator to 006-765VN harness 6 pin plug

5. Attach 006-765VN harness to Baler ECU CAN 1 plug

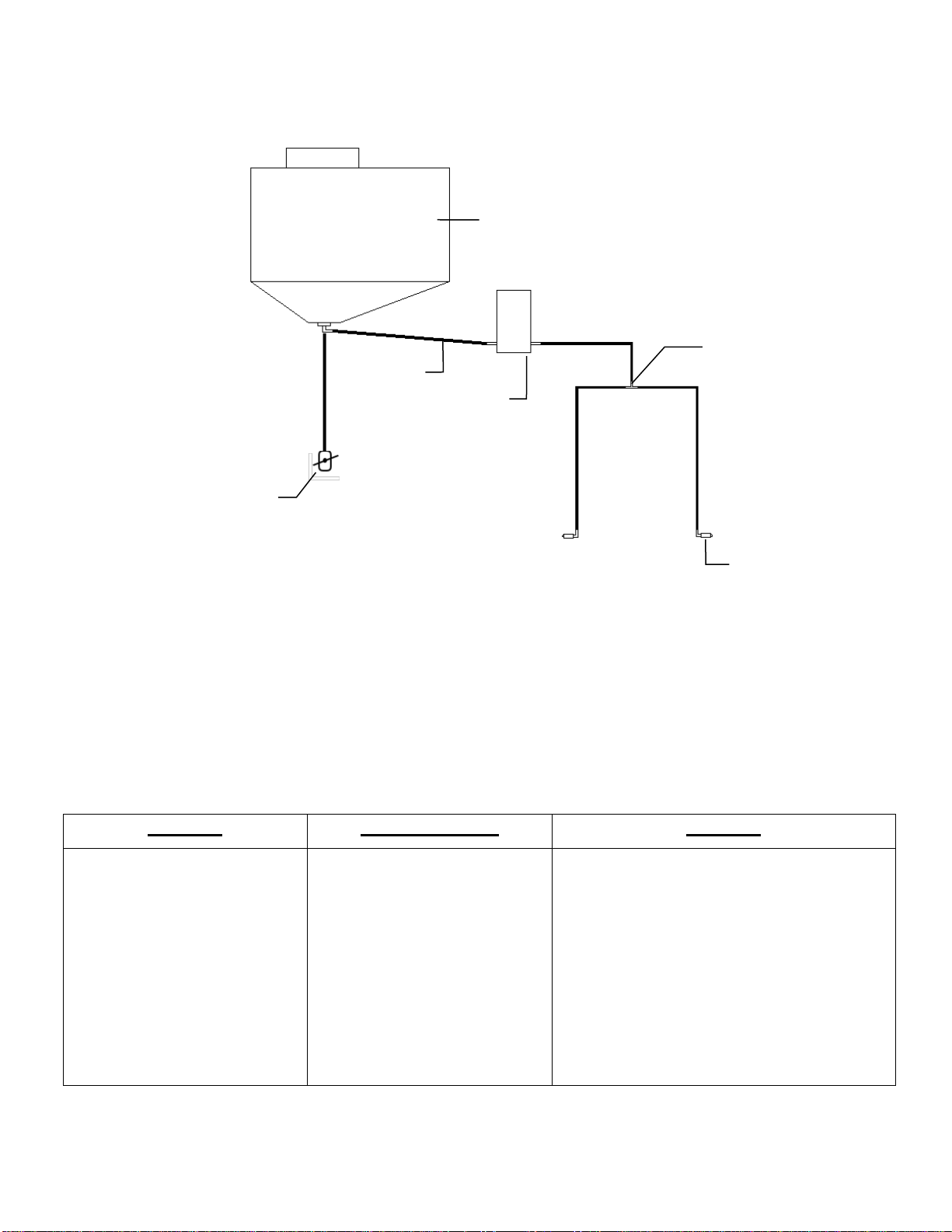

Setting up Dye Marker

1. Locate the wiring harness (006-765IDM3) supplied in the 239 dye Sprayer Marking Kit.

Connect to triangle plug on the metal frame of the dye marker.

2. Route Dye Marking harness (006-765IDM3) to main star wheel harness (006-7303CMS) and attach it to

triangle CAN plug found near star wheels. Secure with zip ties