hatch A50B User manual

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

HATCH GROUP INC.

Pressure Steam Sterilizer

Autoclave A50B 3L Operation Manual V1.0

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

2

Catalogue

Catalogue.............................................................................................................................................................................2

Scope of Use........................................................................................................................................................................3

User Guide...........................................................................................................................................................................3

1. Brief introduction............................................................................................................................................................7

2. Specifications..................................................................................................................................................................9

3. Installation.....................................................................................................................................................................11

4. Adjusting.......................................................................................................................................................................15

5. Introduction of preset programs ....................................................................................................................................15

6. User interface description..............................................................................................................................................17

7. Instructions of operation................................................................................................................................................23

8. Errors list.......................................................................................................................................................................28

9. Maintenance..................................................................................................................................................................31

10. Quality assurance ........................................................................................................................................................37

11. Accessories..................................................................................................................................................................37

12. appendix......................................................................................................................................................................38

Appendix 1 : Inspection items and results.........................................................................................................................38

Appendix 2: Print record sample and instructions.............................................................................................................38

Appendix 3:Explanation of each stage...........................................................................................................................39

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

3

Scope of Use

This manual is applicable to the tabletop pressure steam sterilizers.

Model:A50B

Please read this manual carefully before use to ensure that the equipment is safe and reliable for your

service!

Please keep this manual during the life of the equipment. If the manufacturer has any necessary

updates, ensure that all updates received are kept as attachments with this manual.

When the place of use or the unit of use of the equipment changes, the manual must be transferred or

handed over as part of the whole equipment.

Please read this manual carefully before using the equipment,be familiar with the

operati

on and safety instructions of the equipment. Do not use instruction that is not from the

manufacturer for reference.

We reserve the right to change the design without prior notice.The information contained in this

manual is current at the time of publication.

User Guide

For safe and reliable use of the equipment, please be sure to pay attention to these instructions.

Safety Caution:

The machine is equipped with some necessary safety measures, in order to avoid causing harm, it is

strictly prohibited to terminate or destroy these safety measures.

Important Notice

Please read this instruction carefully before use.

The equipment must be operated and maintained by professional personnel who must have received

good training.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

4

For normal operation of the equipment, please keep the equipment clean, do not rinse or water the

equipment;

The maintenance of the equipment must be carried out by the personnel authorized by the

manufacturer, who have passed the corresponding training of the manufacturer;

Equipment accessories or attachments can only be obtained from the manufacturer, otherwise the safe

and effective operation of the equipment cannot be guaranteed.

Emergency handling:

If an emergency is found, it shall be handled as follows:

⚫Turn off the power switch; ⚫

Unplug.

Product responsibilities:

Without the written permission of the manufacturer, it shall not be modified or used beyond the scope.

The manufacturer shall not be liable for any damage caused thereby.

Symbol description:

Special attention should be paid to the danger, warning and attention in this manual

:

Indicates potential hazard to personnel and equipment and must be strictly observed.

:

Indicates potential hazard to personnel and must be strictly observed.

:

The potential harm to the equipment must be taken seriously.

Protective grounding of TypeⅠequipment

Watch for burns on hot surfaces

Refer to manual

Face up

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

5

No rolling

Stack cannot exceed 2 layers

Temperature range 5℃~40℃

Relative humidity is no greater than 80%

keep dry

Safety Notices:

This sterilizer is only suitable to sterilize moisture- and heat-resistant medical devices, not okay

for oils and powders, such as petroleum jelly and agar.

This sterilizer cannot be used for sterilization of liquids or liquids sealed with closed containers

(especially glassware), which may cause the containers to burst, endangering the safety of

persons and equipment.

Chloride ion is an important factor causing corrosion of stainless steel. If you use this sterilizer

to sterilize items which contains chloride ions, you must rinse the sterilization chamber with

clean water after each cycle to prevent the deposited chloride ions from corroding the pot and

extending the service life of the equipment.

When you see the symbol anywhere on the device, it means that the surface temperature

is high, avoid touching to avoid burns.

This equipment complies with the emission and immunity requirements of Class A equipment

specified in GB / T 18268. It may cause interference when used in home or similar environment,

and protective measures are required.

It is recommended to evaluate the electromagnetic environment before using the equipment. It

is forbidden to use this device near strong radiation sources (such as unshielded radio frequency

sources), otherwise it may interfere with the normal operation of the device.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

6

When an unexpected situation occurs during the use of the product, if the device alarms or other

abnormal conditions occur,please immediately cut off the power supply ofthe device, and check

and correct according to the "abnormal conditions" chapter of the manual.

Necessary monitoring shall be carried out in accordance with relevant national and regional

regulations. After putting the monitoring substance (such as chemical indicator or biological

indicator) into the equipment, run the corresponding program to monitor the sterilization effect,

and judge according to the result. If it fails, find the cause or contact the manufacturer.

A three-hole socket (220 ±22VAC / 16A / 50Hz) must be used to ensure that the socket is reliably

grounded. Do not place the device where it is difficult to disconnect the power.

Do not use other power supplies with different voltages or frequencies.

Do not touch the plug and socket with wet hands.

Do not damage, modify, pull, excessively bend or twist the power cord, and do not place heavy

objects on the power cord.

Please do not place the sterilizer on an unstable workbench, such as a shaking table, a sloping

surface or a place where it will vibrate.

Do not block or cover the sterilizer door, vents or heat dissipation windows.

Please do not place anything on the sterilizer.

If the sterilizer is not used for a long time due to various reasons, the power cord plug should be

disconnected from the power supply and placed in a dry and cool place.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

7

1. Brief introduction

LF series high-pressure steam sterilizer is specially designed and manufactured by for clinics, hospital

departments, laboratories and other occasions requiring frequent sterilization.Used by a physician or

professional.The sterilizer uses microprocessor intelligent control, man-machine interface, easy to

operate, safe and reliable. The parameters and states in the process of operation are displayed

dynamically by the LCD screen. Automatic fault diagnosis, over temperature, over pressure automatic

protection, ensure the effectiveness of sterilization and disinfection.

1.1 Product categories:

The product is classified as class I type B equipment according to electrical safety;

The product is classified as type B equipment according to YY/T 0646 "small steam sterilizer -

automatic control" standard.

This product is classified as class A equipment according to the electromagnetic compatibility GB/T

18268 standard.

1.2 Product structure:

This product mainly consists of sterilization chamber, sterilization chamber door and seal ring, steam

generator, condenser and fan, vacuum pump, water pump, solenoid valve, sensor, heating ring,

bacteria filter, piping system, power supply, control system, accessories (tray, tray rack, tray handle).

1.3 Range of application

It is used for sterilizing medical instruments which are resistant to heat and humidity.

Don't sterilize the liquid! And ensure that the sterilized equipment can withstand heat and

humidity.

1.4 Sterilization principle, main sterilization factors and strength

1.4.1 Sterilization principle

This equipment is suitable for the vacuum pump to exclude the cold air in the sterilizing room,

take saturated steam as the sterilizing factor, and use the characteristics of high latent heat and high

penetrability of saturated steam to sterilize the equipment.

1.4.2 Sterilization factor and strength

1)sterilization factor and strength of the sterilization procedure at 134℃: the temperature of

saturated water vapor is between 134℃and 137℃, and the temperature difference between each

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

8

point in the sterilization chamber at the same time is no more than 2℃, and the maintenance time is

4min;

2)sterilization factor and strength of the sterilization process at 121℃: the temperature of

saturated water vapor is between 121℃and 124℃, and the temperature difference between each

point in the sterilization chamber at the same time is no more than 2℃, and the maintenance time is

20min.

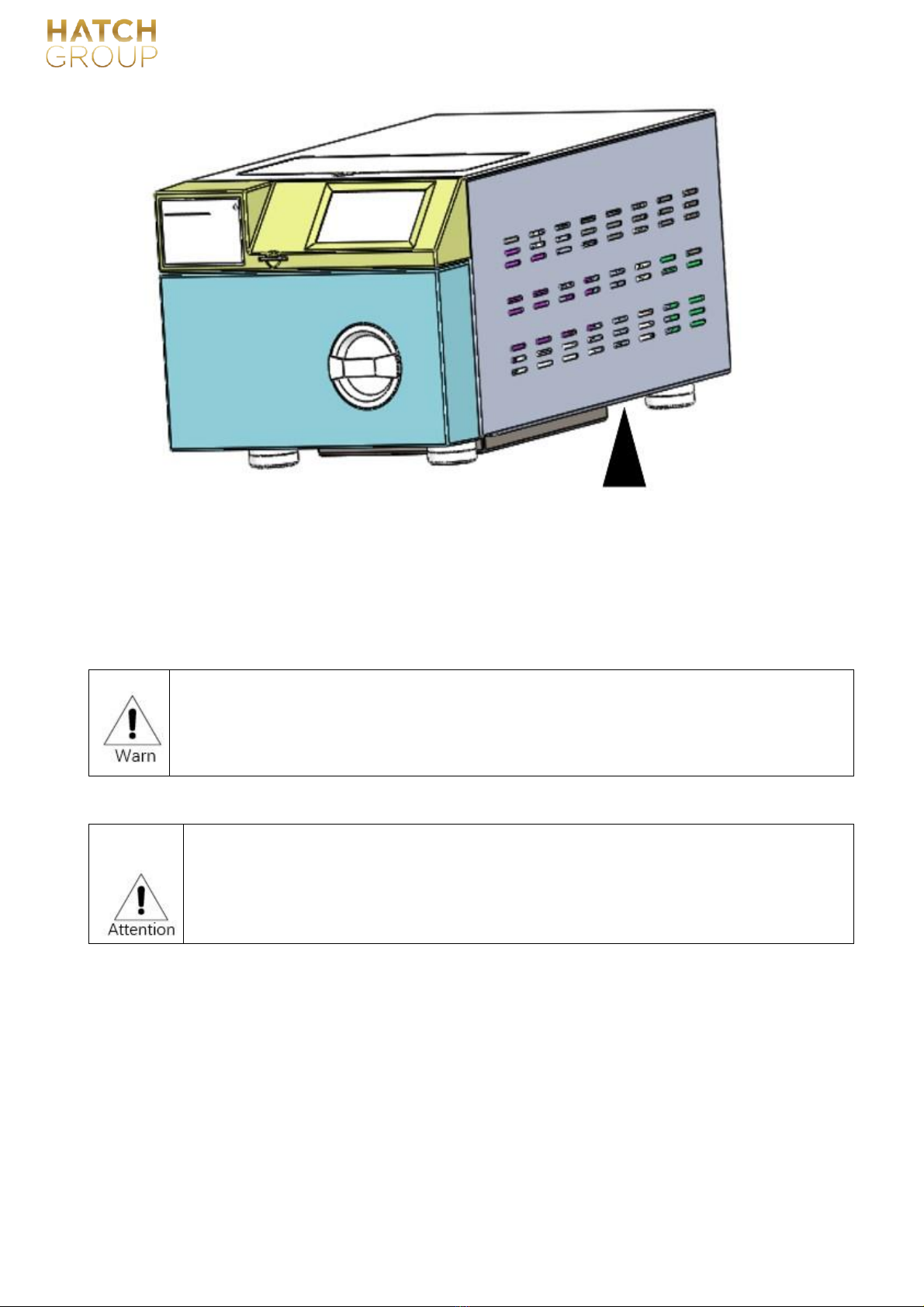

1.5 Visual section of the device

1

Touch Screen

7

Socket

13

Switch sensor

2

Handle

8

Ventage

14

Door locker

3

Printer

9

Outlet of waste water tank

15

Outlet of waste water tank

4

Clean water tank

10

Outlet of clean water tank

16

Door seal

5

Power switch

11

Safety valve

17

Button battery housing

6

Fuse

12

SD card port

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

9

2. Specifications

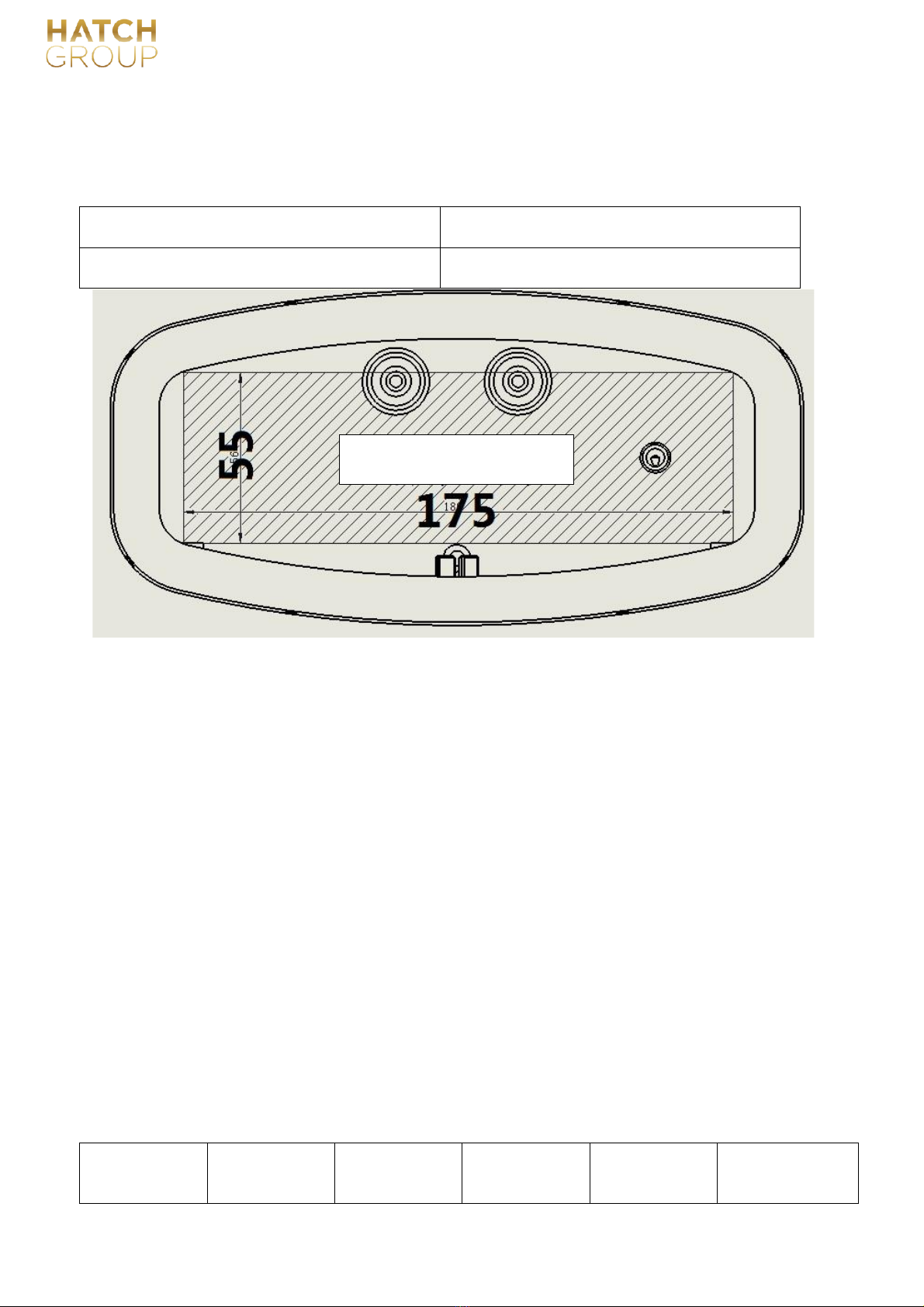

2.1 Chamber specification:

Available space size:

Model No.

Dimensions(DN * Length mm)

A50B

L=175, H=55, D=280

2.2 Parameter of Chamber:Design

pressure: -0.1/0.27MPa;

Design temperature:140℃

2.3 Parameter of autoclave:

Max working temperature:137℃

Max working pressure:0.24MPa

Safety valve set-pressure:0.24MPa;Safety valve open-pressure:0.24MPa~0.26MPa

Capacity of clean water tank:1L

Capacity of waste water tank:0.8L

Power input:220V±22V, 50Hz,2900VA

Life span:5 年

2.4 Environmental requirements for use: Environment

temperature: 5℃~40℃;

Relative humidity: ≤85%;

Ambient atmospheric pressure: 80kPa~106kPa;

Water usage requirements as shown in the table below:

Evaporation

residue

Silica

Iron

Cadmium

Lead

Other heavy

metals

Space available

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

10

≤10mg/L

≤1mg/L

≤0.2mg/L

≤0.005mg/L

≤0.05mg/L

≤0.1mg/L

Chloride

Phosphate

Conductivity

PH value

Conductivity

hardness

≤2mg/L

≤0.5mg/L

≤15uS/cm

5~7.5

Colorless clean

without

precipitation

≤0.02mmol/L

2.5 Transportation and storage conditions:

Ambient temperature: 5 ~ 40 ℃

Relative humidity: ≤80%

No corrosive gas

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

11

3. Installation

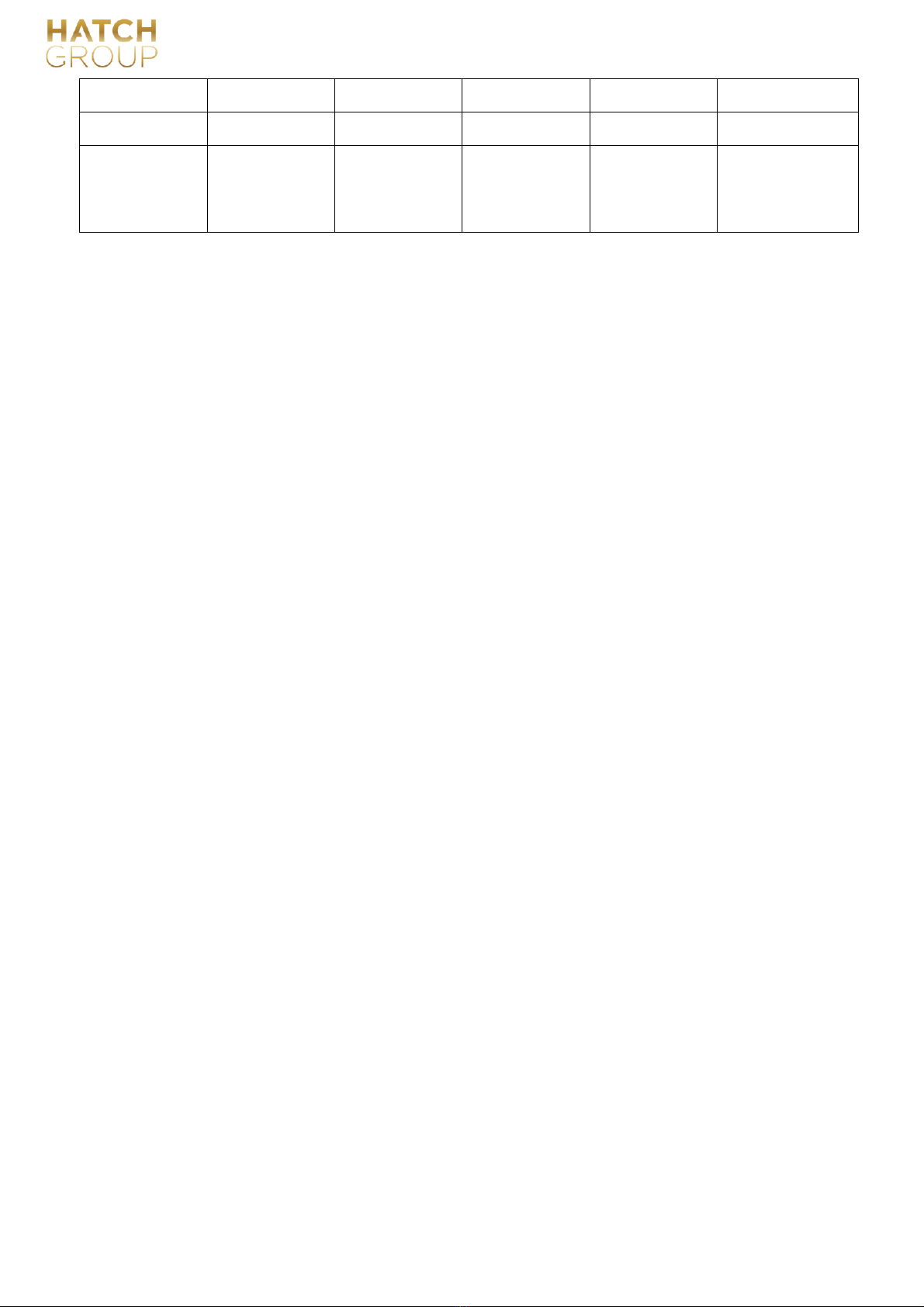

3.1 Product dimensions and weight

The external dimensions of A50B equipment are as follows (unit: mm),

Equipment weight:

Model

Gross weight (kg)

Net weight (9kg)

A50B

24

20

3.2 Installation requirement

In order to ensure the safe and reliable work of the equipment, please check whether it meets the

requirements according to the following clauses.

3.2.1 Power requirements: AC220V 50Hz unidirectional power supply, voltage fluctuation does

not exceed ± 10%, power> = 3.5kVA;

3.2.2 Environmental requirements: This equipment is required to be installed in a clean, dry,

well-ventilated indoor environment with small temperature difference. For temperature, humidity and

ambient atmospheric pressure requirements, see chapter 2.4.

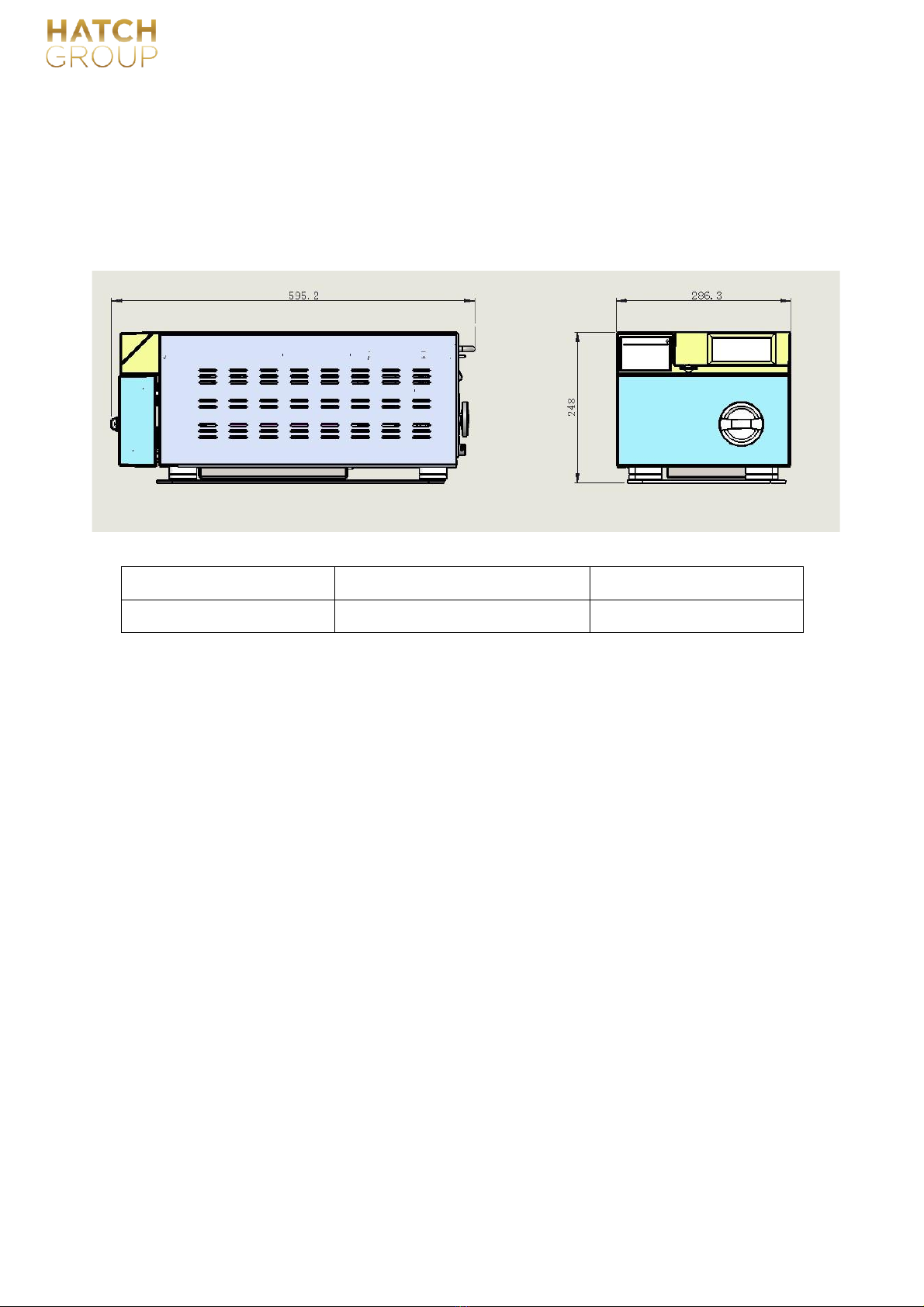

3.3.3 Installation space requirements: at least meet the minimum size requirements of the

following figure, see below.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

12

Minimum width of table L1

Left side to wall L2

Minimum Height

55mm

≥100mm

0.7m

3.3.4 Installation table requirements: The installation table is strong enough to bear the weight

of the device and the sterilized object. The table can withstand at least 40kpa pressure.

Do not install the device in a closed cabinet; make sure that the shelf or table on which

the sterilizer is placed is strong enough; do not block the vent of the sterilizer.

3.3 Handling of packaged products

To ensure safe handling, please use a cart and similar tools to move the device. If there are no carts

or similar tools, at least two people are required to carry them in the front and back of the packing

box.

When handling by people, please pay special attention to avoid danger.

3.4 Unbox

After disconnecting the packing tape on the package with scissors, use a flat-blade screwdriver to

open the lock at the bottom of the box, remove the packaging cover, and finally remove the plastic

bag.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

13

3.5 Lift the device onto the installation surface

The device can be placed by one person, after the device is lifted between the front and rear

feet of the product, it is placed on the workbench. Please note the following when handling:

It is strictly forbidden to lift the door during transportation to avoid damage to the

device;

Do not lift the foot pads of the device during handling to avoid personal injury;

Do not roll-proof when transporting, put the device on its side or upside down;

The recommended location for equipment handling is as follows:

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

14

3.6 Feet adjustment

The height of the feet has been adjusted when the equipment leaves the factory. If the installation

surface is flat, no adjustment is needed; if the surface is uneven, the feet of the sterilizer should be

adjusted to make the sterilizer roughly flat.

3.7 Insert the power plug into the socket.

Make sure that the equipment is reliably grounded.

3.8 Other considerations

After the device has been transported and stored in an environment below 2 ° C. The

equipment must be placed in an environment with a temperature not lower than 5 ° C for

2 hours before operation. This kind of situation usually occurs in winter, and the freezing

of water in the equipment pipeline may cause equipment failure.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

15

4. Adjusting

To ensure the normal use of the sterilizer, the sterilizer cannot be delivered for use until the adjusting

work is successfully completed. The specific debugging steps are as follows:

4.1 Atmospheric pressure resetting

After the device is installed in the first time or moved, the atmospheric pressure needs to be reset.

Otherwise, the door may not open (E10, E11).

Steps for resetting the atmospheric pressure:

Open the door, turn off the power, wait for 20s, turn on the power, wait for 1 minute.

4.2 Date and time setting

Check the date and time are correct, if not correct, make adjustment, see chapter 6.1.4.2 The date

and time have been set when the device leaves the factory, usually no adjustment is required。

4.3 Leak test

The leak test is done to ensure the tightness of the sterilization chamber and its pipelines to ensure

that the cold air in the sterilization chamber is eliminated. This device comes with a leak test program,

the program is "vacuum test". Run this program in the cold state. After the test, the device will display

the test results. Can only be used after passing this test

The test results may be inaccurate when the sterilization chamber is hot, and must be

tested when the sterilization chamber is cold.

4.4 Sterilization parameter confirmation

Use chemical indicator test for preliminary sterilization parameter confirmation

This test requires a B-D test package or PCD test device

Put the B-D test package or PCD test device in the sterilization room, and place it on the lower

floor near the door. Run the B-D test program. After the program is completed, remove the test

package and observe the indicator paper. The indicator paper changes color evenly to the required

color to be qualified.

5. Introduction of preset programs

5.1 Parameters of preset programs

Program

Sterilization

temperature

(℃))

Holding time

(Min)

Pre-vacuum

times

Drying time

(Min)

Remarks

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

16

5.2 Introduction to the load of each program

5.2.1 Load type corresponding to each program

134℃ universal

quick

Non-wrapped load or wrapped solid, fabric and cavity load, Paper-plastic packaging or

double-layer packaging may not dry, should be used immediately after sterilization

Universal

Non-wrapped load or wrapped solid, fabric and cavity load

134℃ solid

Solid load without package, should be used immediately after sterilization

B-D/Helix test

B-D test device or PCD test device

Vacuum test

Without any loading

Drying

Dry the load when it is not dry after sterilization

5.2.2 Applicable maximum load table

Model

Maximum weight of instruments

Maximum weight of fabric loads

A50B

2.2kg

0.5kg /package

5.3 Maximum working time and maximum water consumption when each program is at maximum

load

Model

Loading

kg

134℃

quick

Universal

134℃ Universal

121℃ Universal

134℃ Solid

Longes

t time

min

Min

water

consump

tion

mL

Longest

time

min

Min

water

consump

tion

mL

Longest

time min

Min

water

consump

tion

mL

Longest

time

min

Min

water

consump

tion

mL

134

℃

universal quick

134

Preset

4

3

4

℃

134

universal

Preset

134

3

6

4

4

134

℃ solid

134

1

2

121

℃

universal

121

Preset

8

3

4

B-D/Helix test

134

3.5

3

4

Test program

Vacuum test

Vacuum to -80kPa

,

holding 15min

Test program

Drying

5

min

Preset drying

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

17

LFSS0

3AA

2.2kg

20

280

24

300

38

380

18

240

6. User interface description

This device uses a 4.3-inch touch screen as a human-computer interaction interface.

6.1 Menu page introduction

Introduction of general keys:

: Display the current date

:Back to the previous interface;and time.

:Save Settings;: Show the current number of cycles;

6.1.2 Home Page : Display the current temperature

in the sterilization chamber;

: Display the current

pressure in

: Shows the quality of

the water

: Shortcut key, the

default is the

last run program, the

user can directly click

here to

:Click here to have

more options:

including program

menu, setting menu,

service

:Programs

for user to select;

:Settings for user to choose;

6.1.2

More Options

the sterilization chamber;

in the tank;

start this program;

menu and recording menu.

dealer;

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

18

:Service Menu, for manufacturer or

:for user, the check the latest 20

cycles, also available to print

6.1.3 Programs (totally 7)

4 sterilization programs:134℃ unniversal,134℃ universal quick,134℃ solid,121℃ universal;1

dry program:dry

2 test programs:Vacuum test, to check the leakage of machine;

B-D/helix test, to check the effectiveness of program;

Remarks: For preset parameters of each program, corresponding load information and other information, please refer to

Chapter 5 of this manual.

6.1.4 Settings

Press

the corresponding button to select the desired language.

6.1.4.1

:

to select languages:

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

19

6.1.4.2 :Used to set the date and time, after entering the page is as below:

The left picture shows that the current time is

13:11pm, Mar 30th 2020

YY:year

MM:month DD:day

hh: hour

mm:min

6.1.4.3 :Setting units for temperature and

pressure, the page after entering is like below:

The current unit is indicated in yellow font. Select the

corresponding unit and press OK to change the unit accordingly.

6.1.4.4 :The user sets whether the power-on preheating function is turned on or off. After entering, the

page is like this:

When set to "On": The equipment will start to warm

up and keep warm after being powered on, in order

to shorten the sterilization cycle time;

When set to "off": the device will not preheat after

power on, the device will only start to preheat after

the program is running,

the entire sterilization cycle time will be 5-7

minutes longer than the "on"

It is recommended to set this setting to "On".

When this setting is turned on,

special care should be taken not to touch the sterilization

chamber when the door is open to avoid burns.

No.:GC-JS-21 Version: 01/00 Effective date:2020-03-30

20

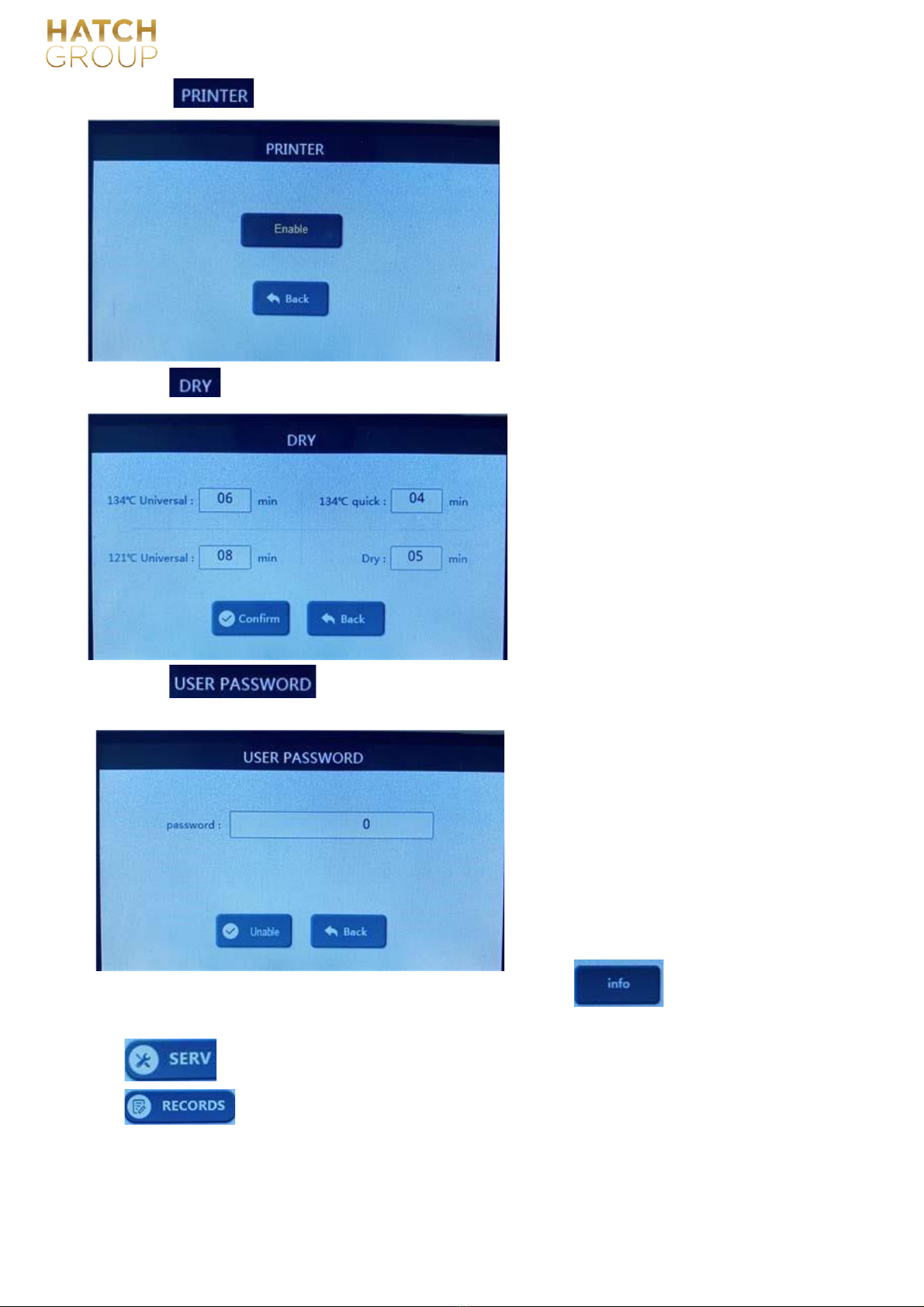

:The user sets whether to print records or not, and the

page after entering is like this:

On: printer prints records, SD card stores records;

Off: printer does not print records, SD card stores

records;

6.1.4.6 :The user can change or set the drying time of 4 programs.:

Adjustment range: 0 ~ 60 minutes.

Drying time of 134 ℃solid program is not

adjustable

If the user finds that the drying effect after

sterilization is not good, the user can increase

the drying time of the

corresponding program here.

The drying time can be changed according to the

time display.

6.1.4.7 :The user can set whether to enter with a password when starting up, and set the

entry password:

Press the "Enable" button to set whether this

function is enabled:

Enable: This function is turned on, and you

need to enter the password when you turn on

the computer to enter.

Not enabled: This function isnot turned on, and

it is directly entered when starting up.

Press the password display to change the

password.

6.1.4.8 :Enter here to view the

information of this device

6.1.5 Users cannot enter, only the manufacturer or the manufacturer's representative. Password required.

6.1.6 The user can enter to view and make up the sterilization record for nearly 20 times, see

7.12 for details.

6.1.7 To-be-run page and running interface

6.1.7.1 After the program is selected, enter the interface to be run, the interface is as follows

6.1.4.5

Table of contents

Popular Steriliser manuals by other brands

Market Forge Industries

Market Forge Industries STM-ED owner's manual

Air Cleaner

Air Cleaner profiSteril 100 user manual

Smeg

Smeg DRY50V instruction manual

Elecro Engineering

Elecro Engineering H.R.UV-C SPA-PRO Installation and operating manual

Gorenje

Gorenje K10BY instruction manual

Memmert

Memmert SM 200 operating instructions