3

Introduction

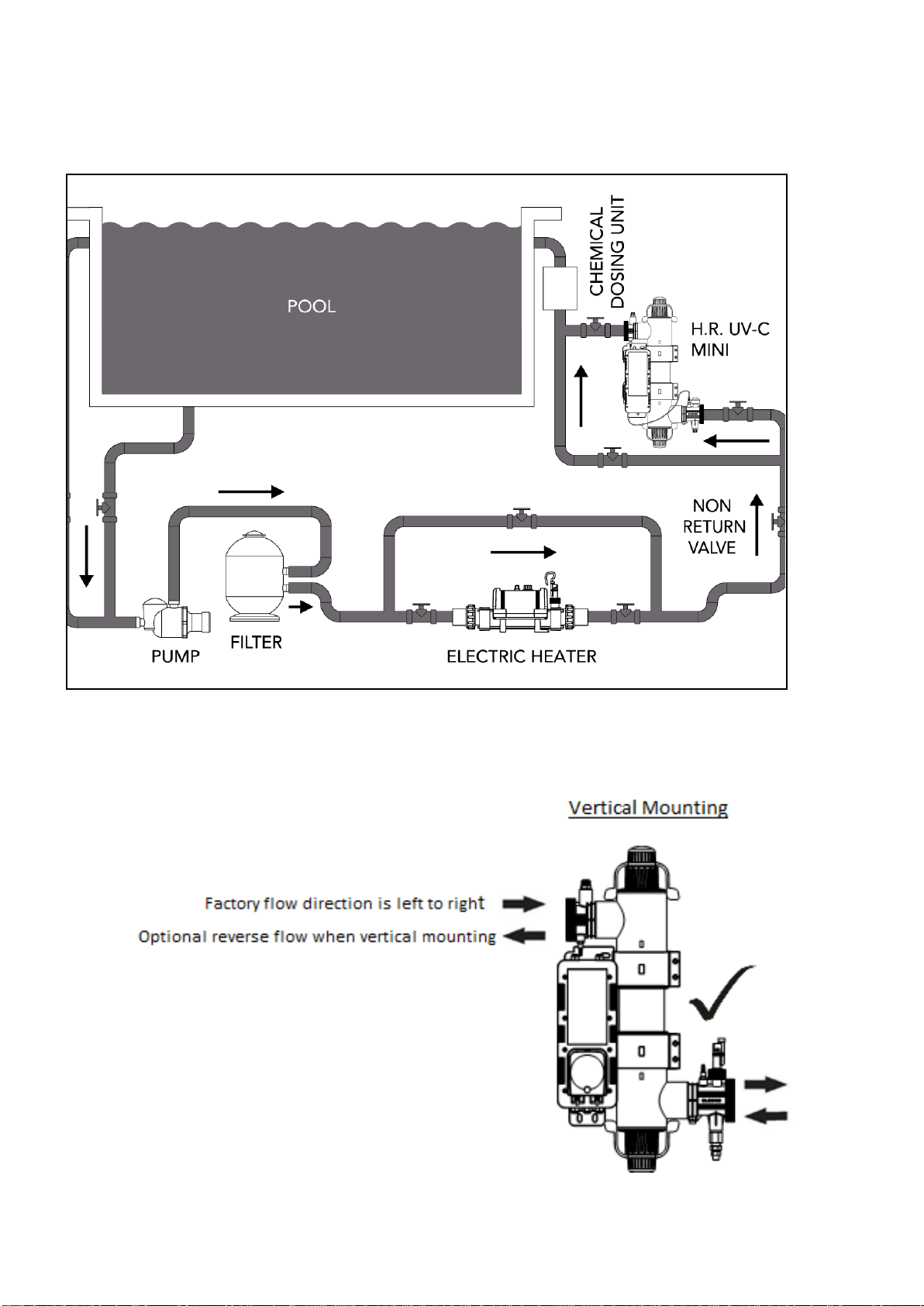

Thank you for purchasing the H.R.UV-C SPA pool sanitising system, the latest in high reflection UV

technology, manufactured to the highest standards in England.

To ensure years of trouble-free service, please read and follow these instructions for proper installation,

maintenance and use. Incorrect installation will affect your warranty.

Please retain this manual for future reference.

1. IMPORTANT SAFETY INSTRUCTIONS

WARNINGS:

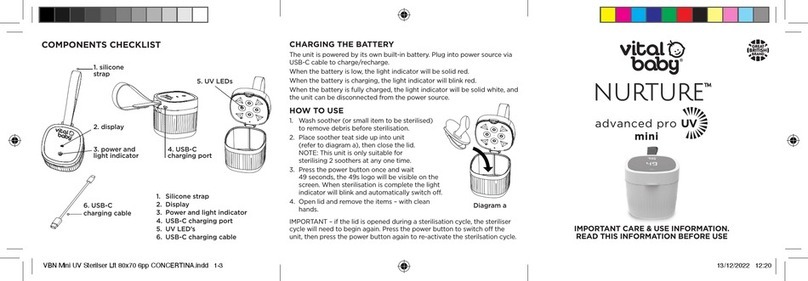

•Read the maintenance instructions before opening the appliance.

•Do not operate the ultraviolet-C emitter when it is removed from the appliance enclosure.

•Unintended use of the appliance or damage to the housing may result in the escape of

dangerous ultraviolet-C radiation. ultraviolet-C radiation may, even in little doses, cause

harm to the eyes and skin.

•This unit must be earthed.

•Power must be supplied through a Residual Current Device (RCD) with a rated residual

operating current not exceeding 30mA

•Do not run this unit dry

•Do not cover this unit

•The unit must not be submerged in water

•Carefully examine the unit after installation. It should not be powered on if there is water

on any parts not intended to be wet

•If the unit shows any sign of water leakage immediately disconnect power supply

•If the quartz sleeve is cracked, replace it immediately

•To avoid injuries young children should never be allowed near UV sanitizer

•Failure to disconnect the power from the UV sterilizer and pump before servicing or

maintenance could result in personal injury or property damage.

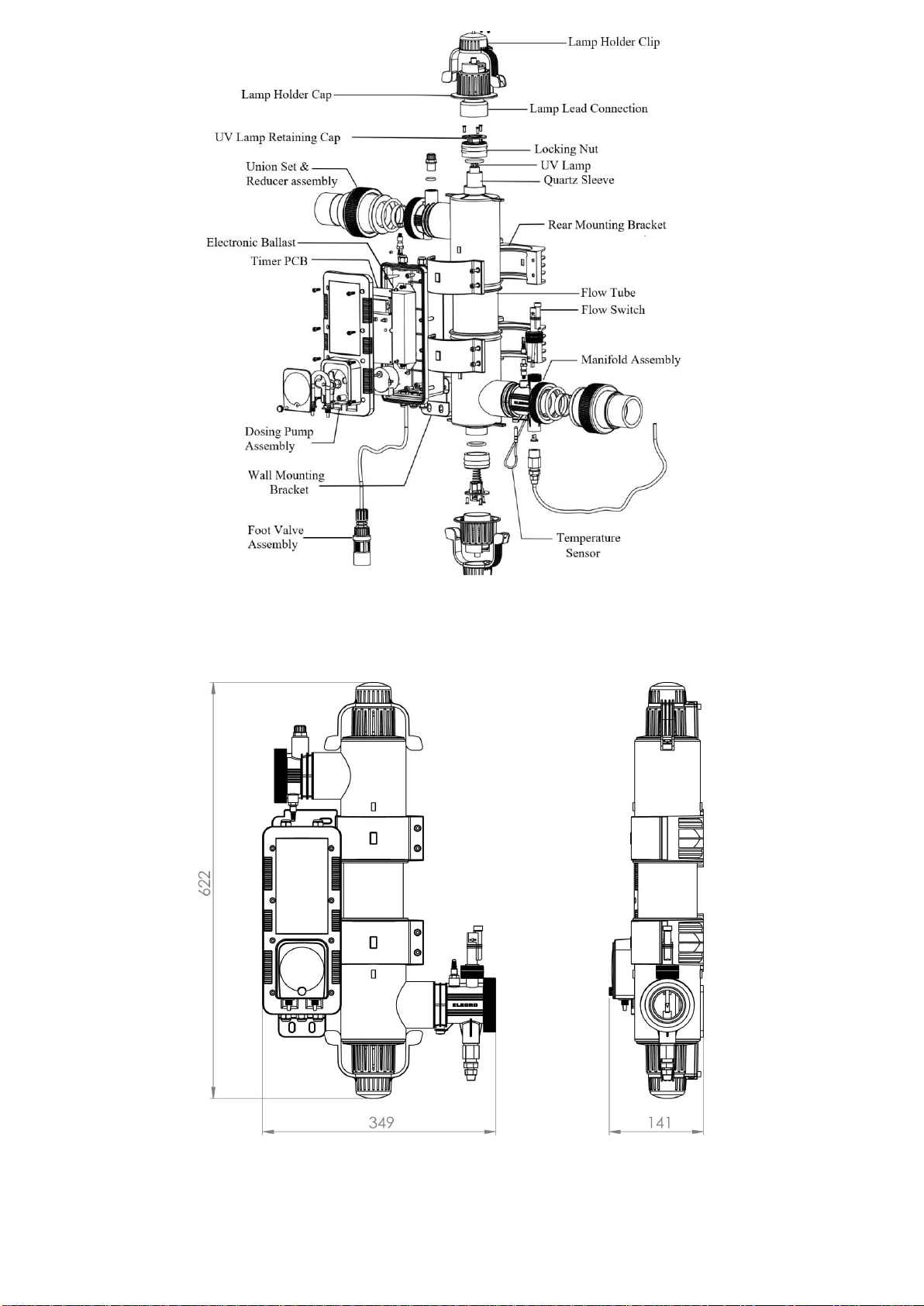

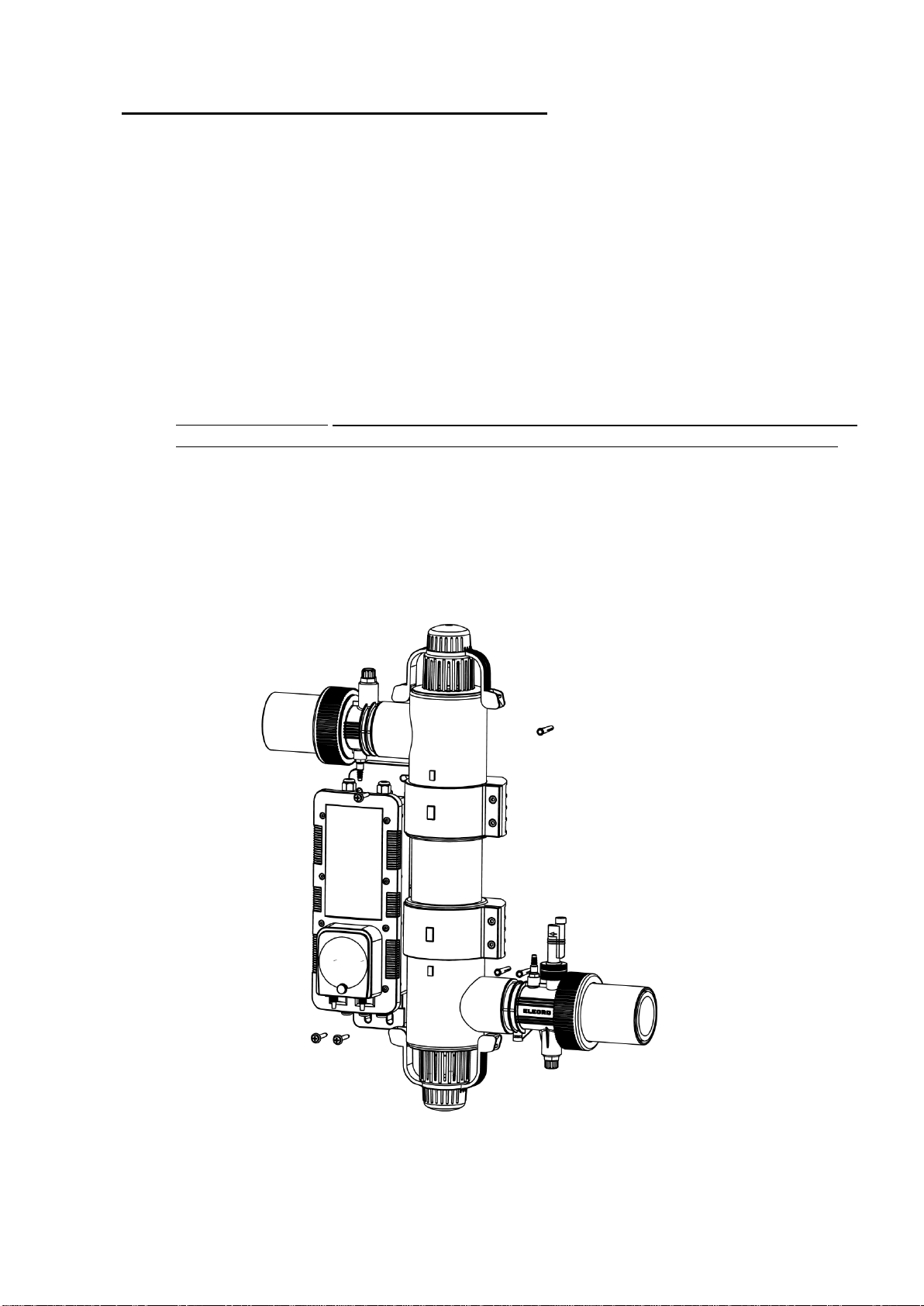

2. PRODUCT OVERVIEW

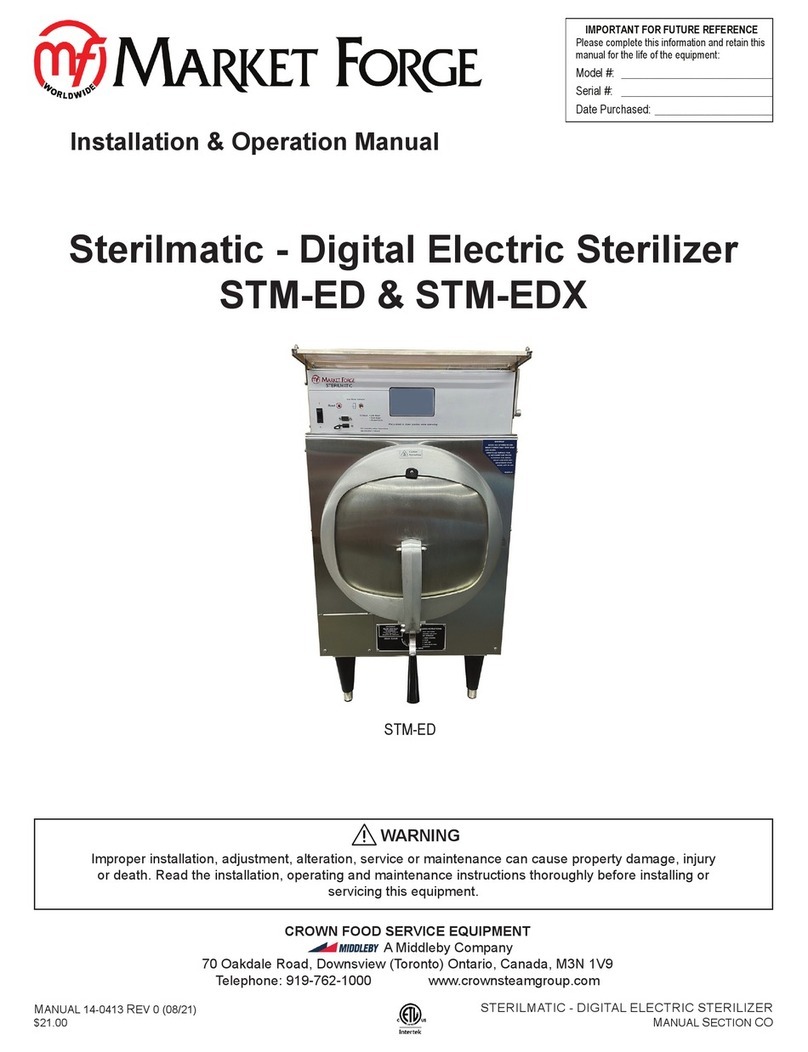

The H.R.UV-C SPA is available in 30W single tube format, supplied complete with flow switch and

either an analogue lamp life indicator and reset switch, or digital lamp life countdown with intelligent

dosing pump.