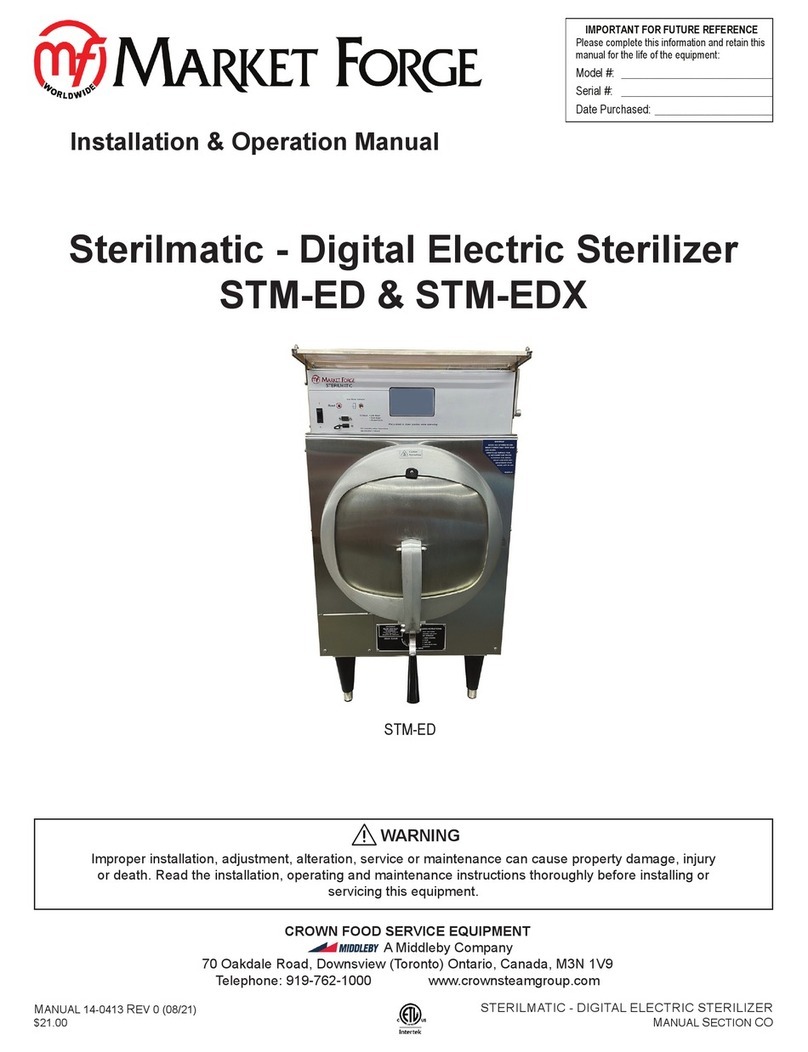

INTRODUCTION

Product Description ..........................................................i

Service Contacts ..............................................................i

SECTION 1 INSTALLATION INSTRUCTIONS

Service & Technical Information Contact..........................1

Operating Environmental Conditions................................1

Intended Use - Sterilization Cycle ....................................1

Installation ........................................................................1

Electrical...........................................................................1

Outside Venting ................................................................1

Water-Cooled Exhaust Condenser...................................1

Tray Supports...................................................................1

Bafe Installation ..............................................................1

Operation Check...............................................................1

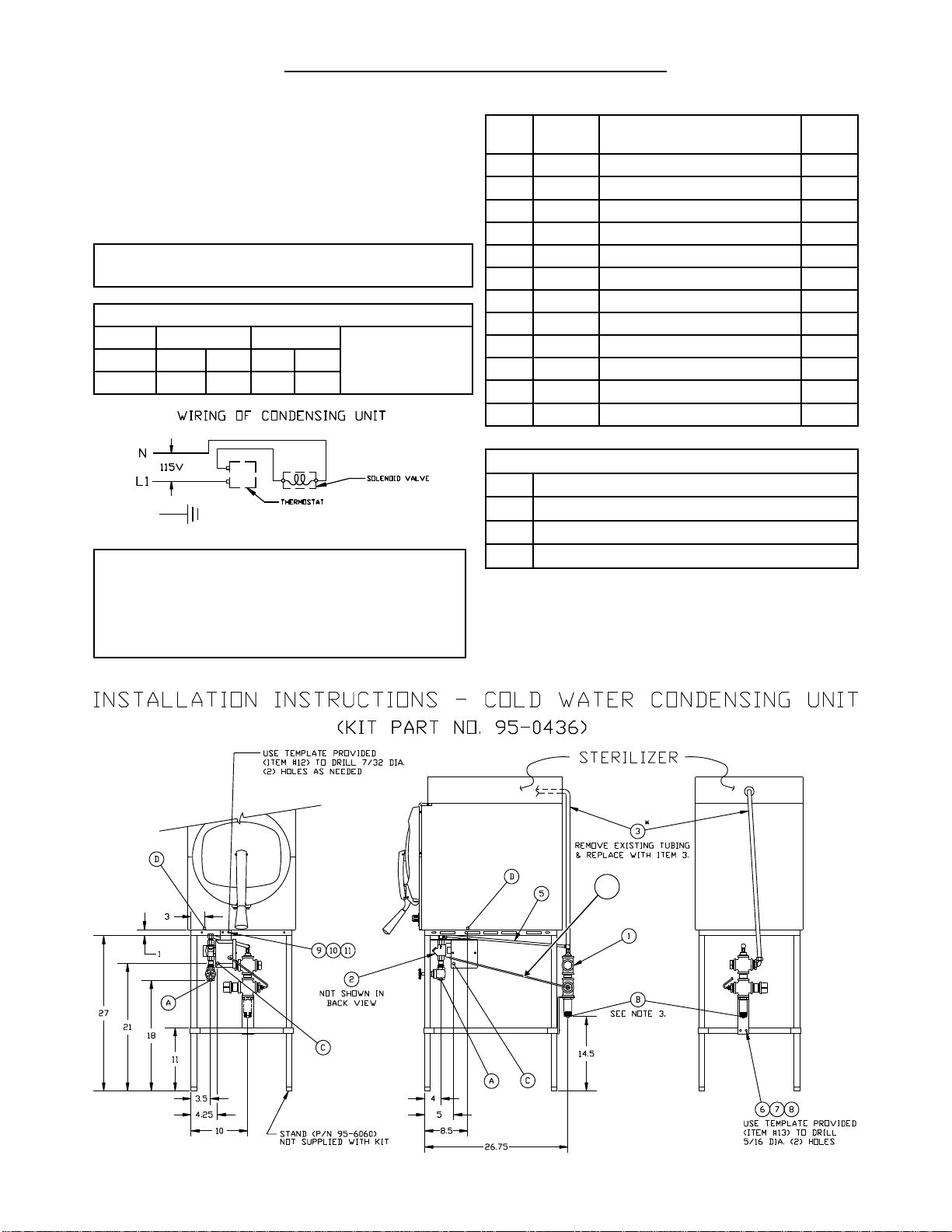

Cold Water Condenser .....................................................2

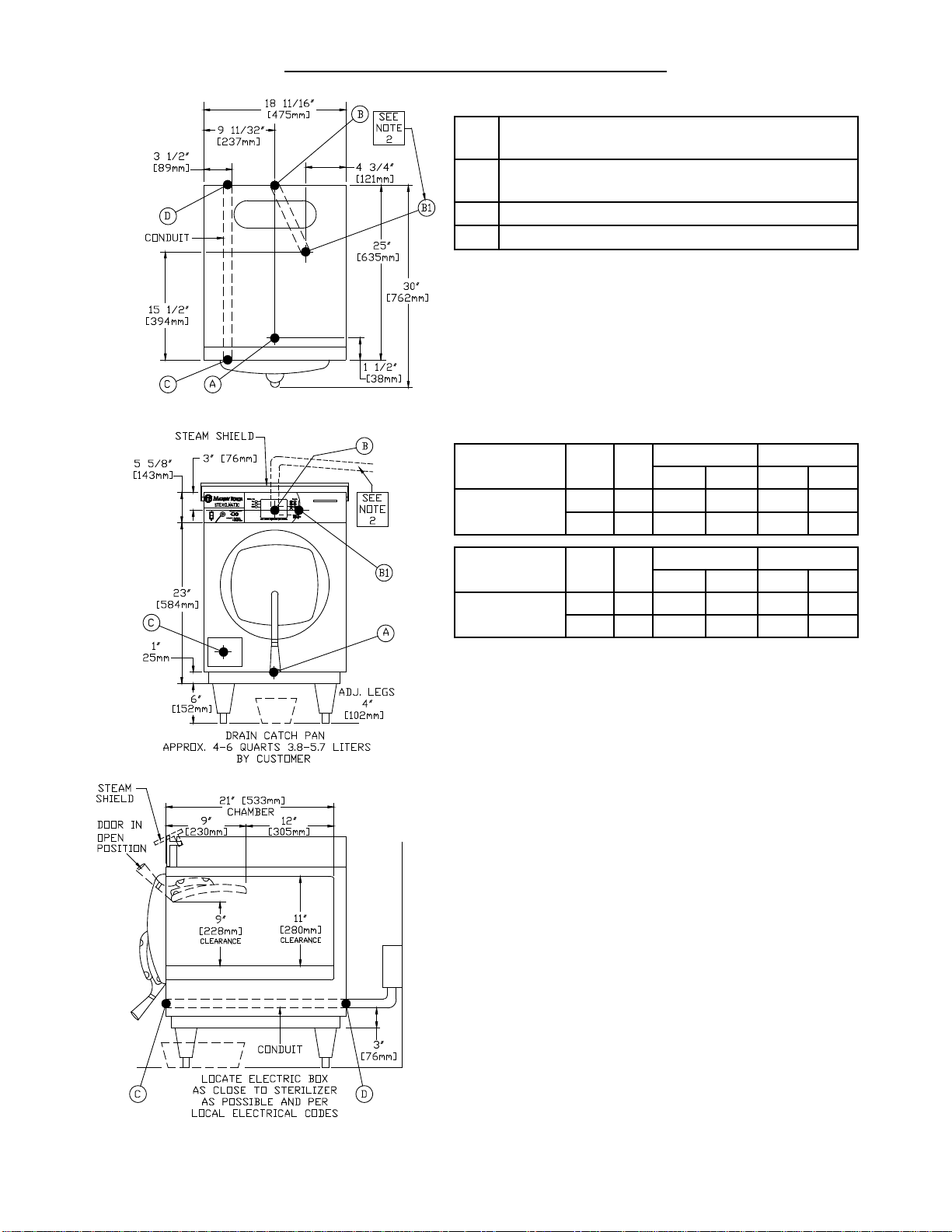

Service Connections.........................................................3

Electrical Requirements....................................................3

Dimensions.......................................................................3

Instructions for Installing Pan Supports & Bafes.............4

Electrical Supply Connections..........................................4

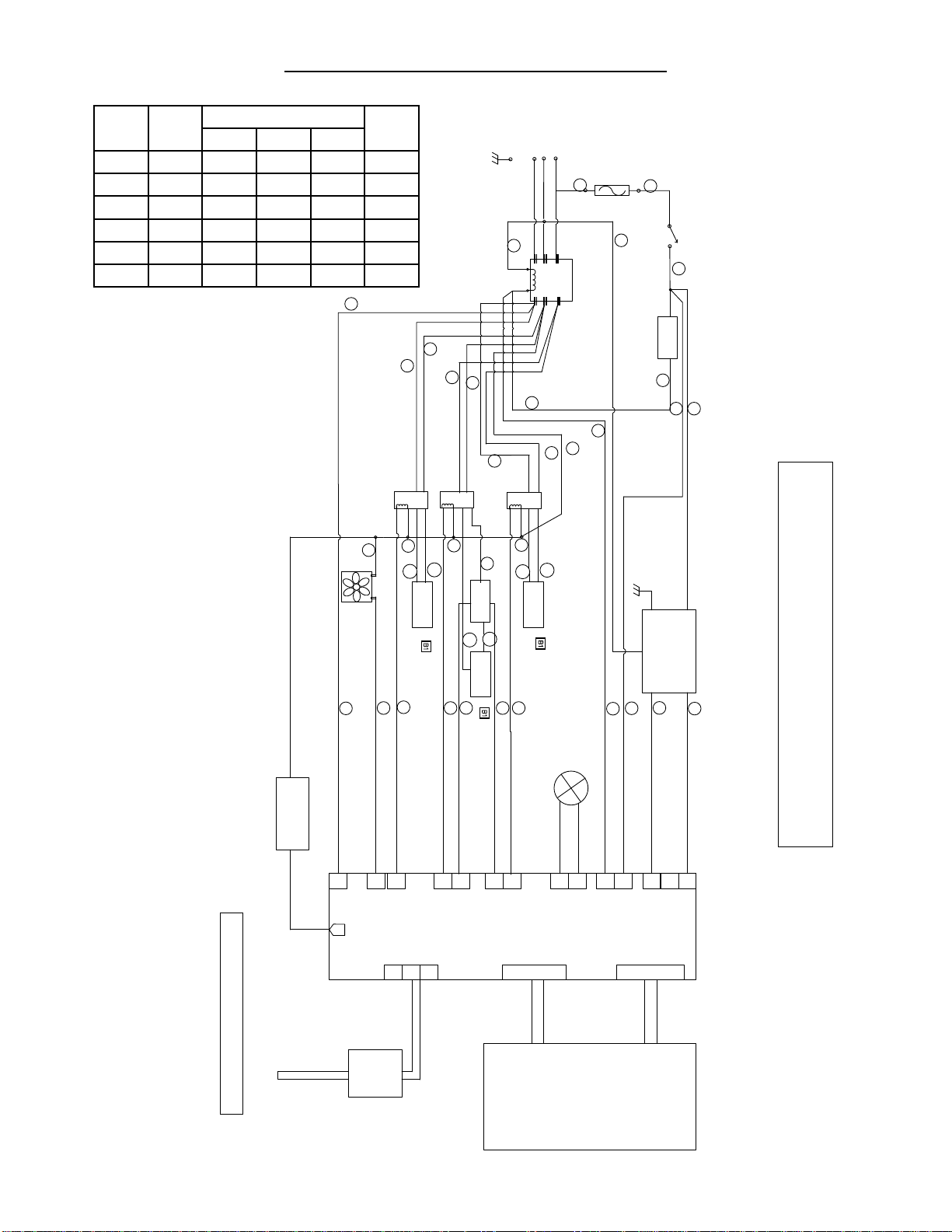

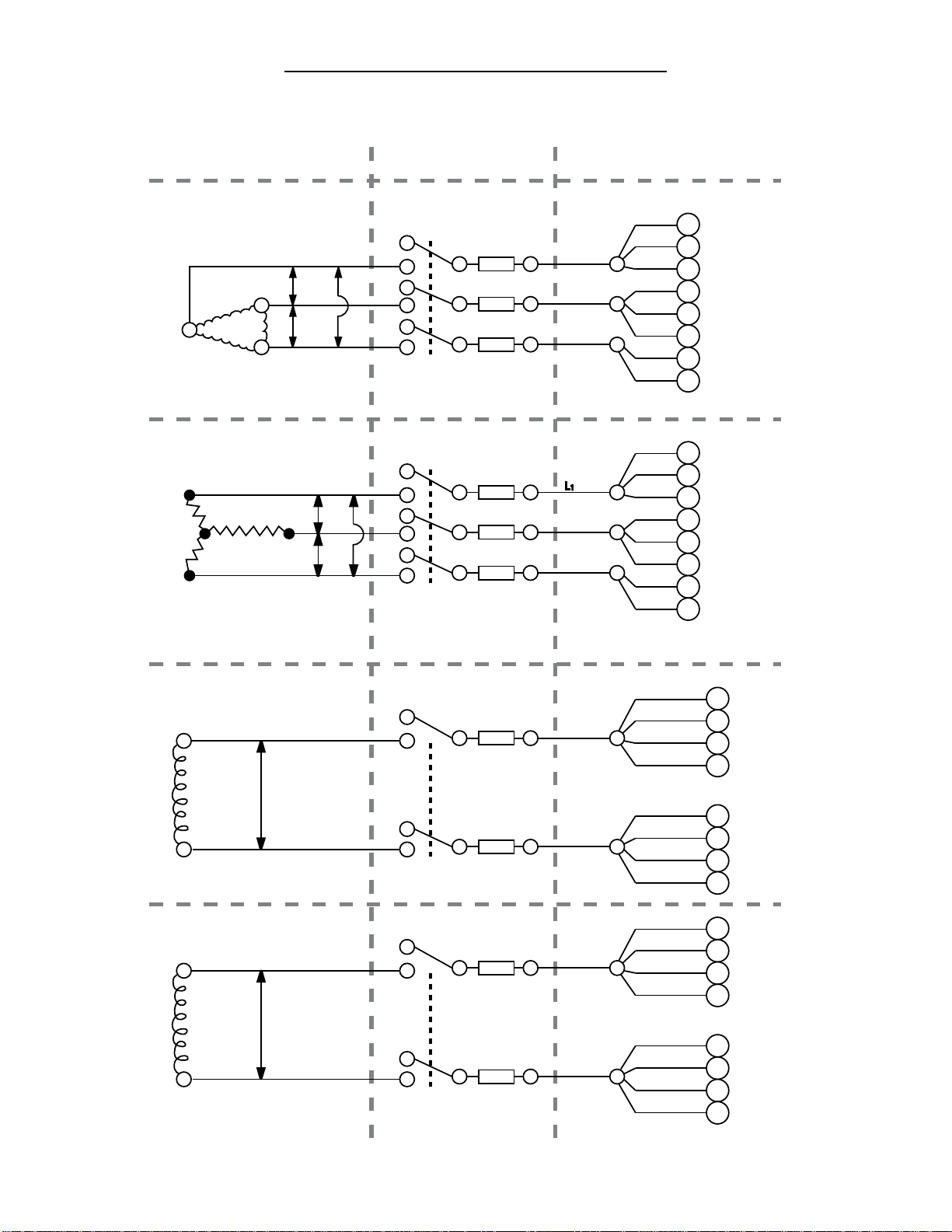

Wiring Diagram - 1 Phase ................................................5

Wiring Diagram - 3 Phase ................................................6

Typical Circuit Connection for STM-ED............................7

SECTION 2 WATER CONDITIONS

Water Conditions ..............................................................9

SECTION 3 OPERATING INSTRUCTIONS

General Operating Instructions.........................................10

Load Sterilizer...................................................................10

Close Door........................................................................10

Determine Correct Sterilization Times..............................10

Sterilization Guide ............................................................10

Minimum Sterilization Times Table ...................................11

CONTROL PANEL

Detailed Operating Instructions ........................................12

Controller Overview..........................................................13

Set Up...............................................................................13

Manual Programing ..........................................................13

Setting Units .....................................................................13

Setting Temperature .........................................................13

Setting Time......................................................................14

Setting Vent Mode ............................................................14

Stopping the Unit..............................................................14

Description of Cycles........................................................14

Preset Keys......................................................................15

Programing Preset Keys...................................................15

Using Preset Keys............................................................15

Printing Data Logger.........................................................15

Print Key...........................................................................16

Printing Previously Run Cycles ........................................16

Printer Paper Cutting........................................................16

Printer paper Changing ....................................................16

Low Water Reset ..............................................................17

Steps to Reset the Unit.....................................................17

Recommended Steps but not Required ...........................17

SECTION 4 MAINTENANCE

Daily Cleaning Procedure.................................................18

SECTION 5 FIELD SERVICE INSTRUCTIONS & ASSEMBLY

Sterilmatic Open Stand.....................................................19

Sterilmatic Open Stand with Condenser...........................19

Parts List for Condenser with Optional Stand...................19

Door Adjustment...............................................................19

Door Assembly .................................................................20

The Door Gasket ..............................................................20

Door Lift Spring.................................................................20

To Remove the Door Assembly ........................................20

The Fulcrum & Drain Assembly........................................21

Roller Assembly................................................................21

Cast-In Heating Elements.................................................22

Low Water Cut-Off Manual Reset.....................................22

Saftey Valve......................................................................22

The Flue ...........................................................................22

Echaust Solenoid Valve....................................................22

SECTION 6 ILLUSTRATED PARTS LIST

Vent Piping .......................................................................23

Electrical Components......................................................24

Sterilizer Assembly ...........................................................25

Pan Supports & Bafe ......................................................26

Door Handle Assembly.....................................................27

SECTION 7 TROUBLE-SHOOTING

Trouble Shooting Guide....................................................29

SECTION 8 APPENDIX

Error Codes ......................................................................30

SECTION 9 WARRANTY INFORMATION

Sterilizer Warranty ............................................................31

Sterilizer Warranty Resistration ........................................32

TABLE OF CONTENTS