Hauber 663 User manual

Vibration Control

Type 663

English

Manual

¨Vibration Velocity (

¨2 Relay-Switching Outputs

(Adjustable)

¨Analogue Current Output: 4...20 mA

¨Frequency Range: 10 Hz...1000 Hz

mm/s, rms)

1 Hz...1000 Hz

* The hardware, the vibration control Type 663, was tested using Exida's FMEDA. The results of the FMEDA

meet the criteria according to SIL2, SIL3 and PL-d.

** In determining the safety function, using the safety key figures in accordance with the standards mentioned

under item 4 in the safety manual, the relay contacts of the vibration control Type 663 were explicitly evaluated

and taken into account. The current output 4...20 mAis not configured in a safety-relevant manner.

*

**

Attention!

Before commissioning the product, you must have read and understood

the instruction manual in its entirety!

HAUBER-Elektronik GmbH

Instruction Manual

Issue: 01/02/2016

Vibration Control Type 663

Standard

Zone-1-21

Zone-2-22

1 Safety Information .................................................................................4

2 Instruction Manual Scope ......................................................................5

3 Vibration Control Type 663....................................................................5

4 Intended Use .........................................................................................5

5 Safety Level...........................................................................................5

6 Documents and Certificates ..................................................................5

7 Responsibility for Safe Operation / Disclaimer ......................................6

8 Fields of Application ..............................................................................6

9 Scope of Delivery ..................................................................................6

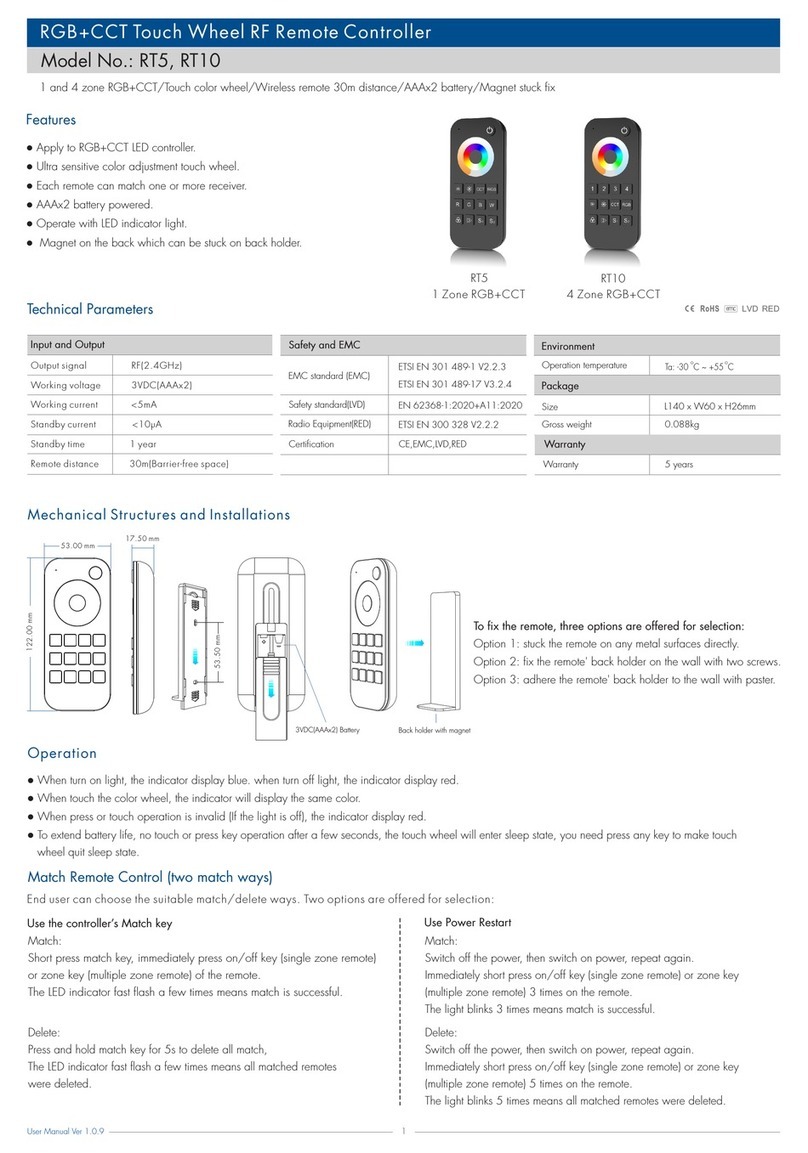

10 Electrical Data .....................................................................................7

11 Mechanical Data..................................................................................9

12 Connections.......................................................................................10

13 Functional Description .......................................................................11

14 Limit Value Adjustment......................................................................12

15 Self-Test ............................................................................................12

16 Mounting and Dismounting................................................................13

16.1 Fastening on the Mounting Surface.............................................13

16.2 Zone-2-22—Fastening Safety Clip / Protective Cover.................14

16.3 Anti-tamper protection .................................................................15

17 Installation and Commissioning.........................................................15

18 Maintenance and Repairs..................................................................16

19 Grounding Concepts to Avoid Ground Loops ....................................17

20 Order code.........................................................................................18

HAUBER-Elektronik GmbH

3

Contents

Standard, Zone-1-21, Zone-2-22

HAUBER-Elektronik GmbH

1 Safety Information

General Information

The safety instructions serve to protect persons and objects from damage and danger that may

arise from misuse, incorrect operation, or other incorrect handling of devices, especially in

potentially explosive atmospheres. Therefore, read the instruction manual carefully, before

working with or commissioning the product. Ensure that the instruction manual is accessible to

the operating personnel at all times.

Before commissioning or otherwise working with the product please check wether all the

documents are available in their entirety. If some documents are missing or if further copies are

required, they can be obtained in different languages.

This is a state-of-the-art product. Nevertheless there are a number of residual risks. This means

that incorrect handling, misuse, or operation and maintenance by insufficiently trained personnel

may cause hazards in the product which may themselves lead to bodily, machine, or system

hazards. Everyone at the operating company, who is concerned with installing, operating, or

maintaining the product, has to have read and understood the instruction manual.

Only instructed, sufficiently trained and authorised personnel are allowed to mount, dismount,

install, or repair this product.

This symbol indicates an explosion hazard.

Symbols Used

This symbol indicates an electrical hazard.

This symbol indicates (non-safety relevant) information.

4

HAUBER-Elektronik GmbH

5

2 Instruction Manual Scope

The present instruction manual of Vibration Control Type 663 is applicable for the models:

Standard, Zone-1-21 and Zone-2-22.

The functionality of these models is identical. In addition, they have certifications and labellings

allowing their operation in potentially explosive atmospheres. (see Sect. 7, Operation Areas).

3 Vibration Control Type 663

5 Safety Level

The hardware, vibration control Type 663, was tested using Exida's FMEDA. The results of the

FMEDA meet the criteria according to SIL2, SIL3 and PL-d.

For more information, refer to the safety manual.

4 Intended Use

Type 663 is used to protect machines and mechanical equipment against undue mechanical

vibrations. Its use is only allowed within the specifications as per the data sheet, and exclusively

for measuring mechanical vibrations. Main areas of application: Industrial fans, ventilators,

blowers, electric motors, pumps, centrifuges, seperators, generators, turbines, and similar

oscillation mechanical equipment.

?EC Declaration of Conformity

?Safety manual SIL2

?Safety manual SIL3

?Declaration of conformity ATEX zones 2 und 22, no.: LU 15 ATEX 0131X

?EC-type examination certificate ATEX zones 1 und 21, no.: SNCH 09 ATEX 4380

6 Documents and Certificates

Vibration Control Type 663 is used for measuring and monitoring the bearing vibration of

machines as per DIN ISO 10816. It offers the following features:

• Two limit values and two associated delays are seperately adjustable.

• The two relay outputs signal if the adjusted limit values are exceeded.

This can be used to generate a pre- and a main alarm.

• Measurement parameter: The root mean square (rms) of the vibration velocity (mm/s).

• Analogue current output: Interference-free direct current from 4...20 mA, proportional to the

vibration amplitude.

• Cable break on the control cable can be detected by a donwstream evaluation unit:

Value of the direct current signal < 3.5 mA.

In determining the safety function, using the safety key figures in accordance with the standards

mentioned under item 4 in the safety manual, the relay contacts of the vibration control Type 663

were explicitly evaluated and taken into account. The current output 4...20 mA is not configured in

a safety-relevant manner.

Available Supplies:

• Allocable Mating Connector, for Assem bly, M12, 8-Pin

• Connection Cable, M12 Socket, 8-Pin, 0.25 mm2,

L= 2 m, 5 m or 10 m

• EMC Adapter

• Vibration Control Type 663

• Allen Screw, M8 x 20 mm

• Spring Washer, M8

• Instruction Manual

Standard

• Vibration Control Type 663

• Protective Cover for M12 Connector

• Safety Clip

• Allen Screw, M8 x 20 mm

• Spring Washer, M8

• Instruction Manual

• Vibration Control Type 663,

Integrated Cable, L= 2, 5, 10, 25 m or on request

• Allen Screw, M8 x 20 mm

• Spring Washer, M8

• Instruction Manual

Zone-2-22

Zone-1-21

9 Scope of Delivery

8 Fields of Application

6

HAUBER-Elektronik GmbH

The correct layout of the electrical connections with regard to explosion protection directions and

correct commissioning is the sole responsibility of the system owner.

If the owner commissions a subcontractor to build the system, the system cannot be

commissioned unless the subcontractor has submitted an installation certificate as prove of the

correct nature of the installation, in accordance with applicable regulations.

The owner must inform the relevant authorities about initial commissioning of explosion-protected

systems or system parts as well as about re-commissioning following major modifications or

maintenance work

7 Responsibility for Safe Operation / Disclaimer

Model Application Fields Labelling

II 2 G Ex d IIC T4 Gb

II 2 D Ex tb IIIC T120 °C Db

II 3 G Ex d nA IIC T4 Gc

II 3 D Ex tc IIIC T120 °C Dc

Non-explosive

atmospheres

Standard

Potentially explosive

atmospheres, zones 1

and 21

Potentially explosive

atmospheres, zones 2

and 22

Zone-1-21

Zone-2-22

*

*

*

* The hardware, i.e., vibration control Type 663, was tested using Exida's FMEDA. The results of the

FMEDAmeet the criteria according to SIL2, SIL3 and PL-d

HAUBER-Elektronik GmbH

7

10 Electrical Data

Only unscrew the housing cover if Type 663 is disconnected from the mains or if the

atmosphere is non-explosive Otherwise, there is an explosion hazard from sparking when

operating ATEX-certified Type 663 in potentially explosive atmospheres!

8

16

32

64

128

256

10 Hz...1000 Hz

1 Hz ...1000 Hz

Prior to commissioning protect the mains using a microfuse

160 mA, breaking capacity C)!

Type 663, (medium time lag

Measuring ranges: 0... mm/s

0... mm/s

0... mm/s

0... mm/s

0... mm/s

0... mm/s

Measuring accuracy: ±5%

Transverse sensitivity: < 5 %

Frequency range: (standard)

(optionally)

Output signals: 1 x 4...20 mA

2 x relay contact ( pre- and main alarm)

Relay switching load: 1A / 30V DC

Voltage supply: 24V DC ±10%

Power input (max.): 80 mA

Ambient temperature: -30°C...+60°C

Operating temperature range: -30°C...+85°C (meas. head temp. at fastening)

Burden/load (max.): 500 Ù

The burden comprises the resistance of the evaluation

unit, the specific line resistance, and the transition

resistances.

Fusing: Microfuse (medium time lag, 160 mA, breaking capacity

C)

Automatically: As soon as the vibration values fall below the limit

values, the relays automatically re-energise

•

Each Type 663 has

one of the listed

measuring ranges.

•

Further measuring

ranges on request.

•

Please indicate the

measuring range in

your order.

HAUBER-Elektronik GmbH

Arbeitsbereich interner Sensorbaustein

0

20

40

60

80

100

120

140

160

180

200

0 100 200 300 400 500 600 700 800 900 1000

Frequenz (Hz)

Schwinggeschwindigkeit (mm/s)

Operating Range

Operating Range of Vibration Control Type 663

Reading example:

Frequency Max. measurable

(Hz) vibration velocity

100 160

400 40

1000 18

The operating range is independent of the measuring range. The diagram shows that the

vibration velocity amplitude decreases as the frequency increases.

Vibration Velocity (mm/s)

Frequency (Hz)

Frequency Response 10 Hz...1000 Hz

-40

-35

-30

-25

-20

-15

-10

-5

0

5

1 10 100 1000 10000 Hz

dB

Frequency Response 1 Hz...1000 Hz

-40

-35

-30

-25

-20

-15

-10

-5

0

5

0,1 1,0 10,0 100,0 1000,0 10000,0 Hz

dB

8

Housing material: V2A stainless steel; material no.: 1.4305

M12 connector material: CuZn (brass), nickel plated

Cable gland: V2A stainless steel

Fastening: Allen screw, M8 x 20 mm,

Thread pitch: 1.25 mm

Weight: approx. 500 g

IP code: IP 67

Mounting: Ground housing using M8

fastening (see Sect.16).

HAUBER-Elektronik GmbH

9

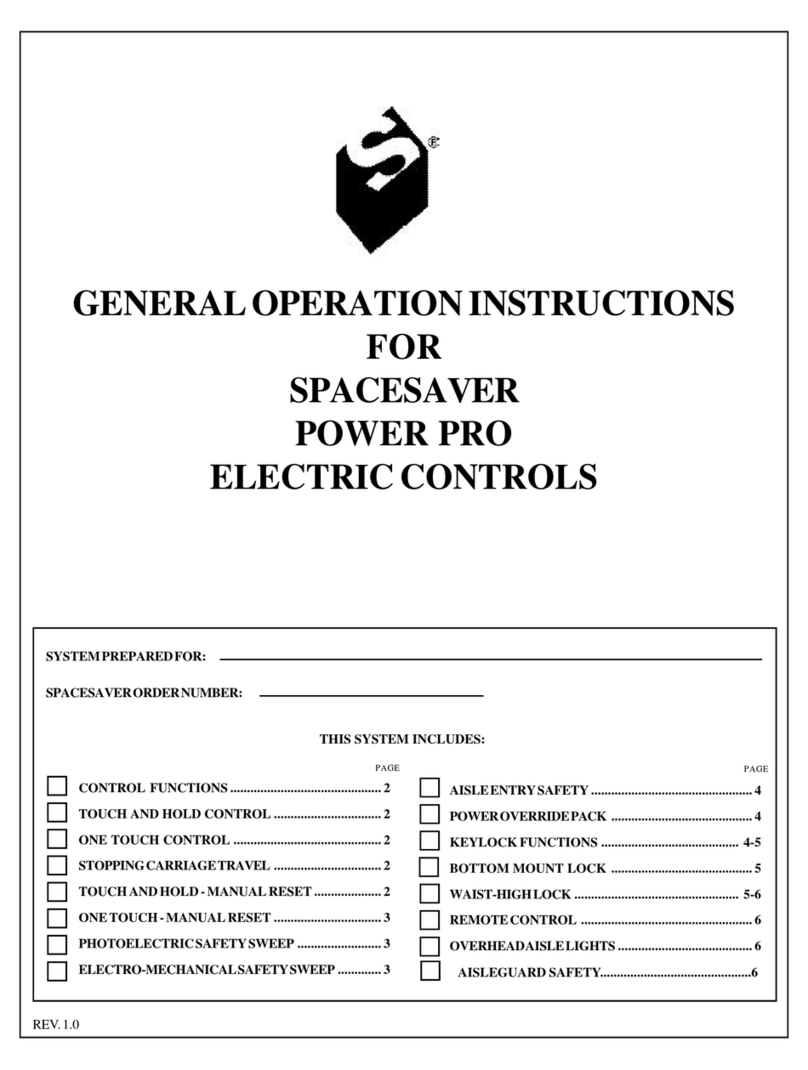

11 Mechanical Data

Housing Dimensions and Direction of Measurement

Standard, Zone-2-22 Zone-1-21

Note: Direction of measurement = direction of fastening

30

M12

Connector

Connection Cable

Direction of

Measurement

Cable Gland

Direction of

Measurement

Measures in mm.

Housing Dimensions and Direction of

Measurement: Standard, Zone-2-22

Housing Dimensions and Direction of

Measurement: Zone-1-21

HAUBER-Elektronik GmbH

10

Connection Plan for All 3 Models

12 Connections

Note: The connection plan shows the alarm condition and/or the currentless condition! Relay 1

and 2 are dropped out (see p. 11 for more information on operating conditions).

Connection Cable Socket

(Supplies)

M12 Connector

2

3

4

78

5

6

1

M12 Connector, 8-pin.

See connection plan for pin allocation.

Connection cable socket M12, 8-pin,

0.25 mm². See connection plan for pin allocation.

Standard, Zone-2-22 Zone-1-21

Connection Cable

PUR sheathed cable, Ø: approx. 6.5 mm,

8 -pin 0.25 mm².

See connection plan for pin allocation.

Evaluation

Unit

Type 663

Pin 1: white

Pin 2: brown

Pin 3: green

Pin 4: yellow

Pin 5: grey

Self-Check

switch

Relay 2

Relay 1

Evaluation of the 4...20 mA

current signal using an ammeter

or PLC

Pin 6: pink

Pin 7: blue

Pin 8: red

1

2

3

4

5

6

7

8

WH

BN

GN

YE

GY

PK

BU

RD

ALARM

WARNING

OK

HAUBER-Elektronik GmbH

13 Functional Description

Type 663 has two limit values, LIM1 and LIM2, with their respective lag times, which can all be

adjusted separately.

Relay outputs 1 and 2 signal if the adjusted limit value has been exceeded by dropping out the

respective relay contact. If the limit value is then undercut, relay outputs 1 and 2 will also signal

this by automatically re-energising.

In addition, Type 663 has an analogue current output. This delivers a direct current

of 4...20 mA proportional to the vibration amplitude.

User Interface Channels LIM1 and LIM2—Controls and LED Indicators

Operating Conditions Channels LIM1 and LIM2

SET Turn-Switch

Limit Value in 15 Steps

(Table: Limit Value, page 12)

TIME Potentiometer

Lag Time Variably

Adjustable, 0...30 sec.

—red

—yellow

—green

Operating Condition Measurement Relay LED Indicator

OK <= Limit Value Energised OK

WARNING > Limit Value,

Lag Time Running Energised WARNING+OK

ALARM > Limit Value,

Lag Time Expired Dropped Out ALARM

Only unscrew the housing cover if Type 663 is disconnected from the mains or if the

atmosphere is non-explosive. Otherwise, there is an explosion hazard from sparking when

operating ATEX-certified Type 663 in potentially explosive stmospheres!

11

Measuring range e.g.:

Set turn-switch pos.:

Limit value:

HAUBER-Elektronik GmbH

12

15 Self-Test

Example: Limit value adjustment

14 Limit Value Adjustment

0...32 mm/s

16 mm/s

8

0000000

10.5 1 2 4 8 16

21 2 4 8 16 32

31.5 3 6 12 24 48

42 4 8 16 32 64

52.5 5 10 20 40 80

63 6 12 24 48 96

73.5 7 14 28 56 112

84 8 16 32 64 128

94.5 9 18 36 72 144

10 5 10 20 40 80 160

11 5.5 11 22 44 88 176

12 6 12 24 48 96 192

13 6.5 13 26 52 104 208

14 7 14 28 56 112 224

15 7.5 15 30 60 120 240

SET

Turn-Switch

Position

Limit Value

Range

0…8 mm/s

Range

0…16 mm/s

Range

0…32 mm/s

Range

0…64 mm/s

Range

0…128 mm/s

Range

0…256 mm/s

The self-test is to verify the correct functioning of the vibration control. Therefore, a test signal

is applied to pin 4 of the control. The test signal simulates a vibration amplitude exceeding the

maximum limit value. This will trigger the control's alarm condition.

Test signal: a. Direct current, 24 V DC or

b. Square wave signal, 24 V DC / 0.5 Hz

Initial state: Normal operation

Self-test start: • Apply the test signal to pin 4.

àThe output current signal increases up to ~23 mA.

àAfter < 35 s, the alarm relays drop out.

If one or both alarm relays fail to drop out, this

indicates a fault.

• Remove the test signal.

àAfter a further < 60 s the output current signal has

returned to to 4 mA or its actual value.

End self-test.

Final state: Normal operation

Duration: approx. 95 s

• Test signal a is only available for production no. 75478 or later.

HAUBER-Elektronik GmbH

16 Mounting and Dismounting

Only authorised experts, who are familiar with the safety instructions for handling electrical

components, are allowed to perform mounting or dismounting work on or using this control. For

handling ATEX-certified controls within potentially explosive atmospheres the expert also has to be

familiar with the safety instructions relevant there.

Requirements

?Mounting surface clean and flat,

i.e. free from paint, rust, etc.

?Threaded hole on the mounting

surface:

Depth: 15 mm

Thread: M8

Unscrew housing cover from housing

base.

?Allen key, SW8

Use Allen screw and spring

washer to friction-lock the control

on the mounting surface.

?Allen key, SW6

Slightly fasten housing cover to housing

base by hand.

(Avoid jamming the thread!)

Tighten housing cover using a tightening

torque = 5 Nm.

?Torque wrench SW8

Workflow

1.

2.

3.

?Allen key, SW6, SW8

?Torque wrench SW8

?Allen screw M8x20

?Spring washer for M8

Tools and materials

Note: To prevent any cold-welding between housing cover and housing base, the control is

delivered with a fitting lubricant for stainless steel connections applied to its thread.

Before mounting or dismounting, disconnect the control from the mains! Ensure that

disconnected plug connections are always de-energised! Otherwise, there is an explosion

hazard from sparking when operating ATEX-certified Type 663 in potentially explosive

atmospheres!

Ground the control housing via the fastening, i.e. the machine earth or a seperate earth

conductor (PE)!

16.1 Fastening on the Mounting Surface

Fastening on the mounting surface

Mounting Surface

zu

5 Nm

Tightening housing cover using a torque wrench

13

HAUBER-Elektronik GmbH

Shell Half Arrow and Eye

Sign

Fastened Safety Clip

Protective Cover Fastened Protective Cover

Safety Clip

Fully insert the connection cable socket into the M12 connector.

(Pay attention to the code cam position!)

16.2 Zone-2-22—Fastening Safety Clip / Protective Cover

1. Disconnect th control from the mains.

2. Separate both shell halves of the fuse clip using a screw driver.

3. Use the M12 connector to firmly close the protective cover.

1.

2.

3.

Tightly fasten the lock-nut of the connection cable socket by hand.

Mount the safety clip to avoid accidental disconnection of the plug connection:

1. Place both shell halves of the safety clip around the plug connection.

2. Press both shell halves of the safety clip together by hand until the

catch lock engages.

3. Place the arrow connected to both shell halves around the cable, then thread

it through the eye on the other end so that the notice sign is legible

alongside the cable.

Fastening Protective Cover

Fastening Safety Clip

Disassemble the safety clip and fasten the protective cover:

Always operate model Zone-2-22 with the safety clip to avoid accidental disconnection of

the plug connection! Otherwise, there is an explosion hazard from sparking when operating

this control in potentially explosive atmospheres!

Fasten the protective cover using the M12 connector after disconnecting the plug connection!

14

HAUBER-Elektronik GmbH

15

17 Installation and Commissioning

Only authorised experts, who are familiar with the safety instructions for handling electrical

components, are allowed to install or commission this control. For handling ATEX-certified controls

within potentially explosive atmospheres the expert also has to be familiar with the safety

instructions relevant there.

Ensure the housing cover is properly fastened prior to commissioning (tightening torque =

5 Nm)! Otherwise, there is an explosion hazard from sparking when operating ATEX-

certified Type 663 in potentially explosive atmospheres!

Prior to commissioning Type 663, protect the mains with a microfuse (medium time lag,

160 mA, breaking capacity C)!

Protect the connection cable and possible extension cables from electrical influences or

mechanical damage! Ensure to stricly follow local regulations and directives!

Check the self-test during commissioning.

The "SEALED" seal label indicates that it is not permissible to open the casing

cover.

After the system operator has assembled the casing cover, the seal label is attached

to the side so that it covers the casing parting line.

Any attempt to tamper with the casing will destroy the label and makes the

attempted tampering visible to the system operator.

16.3 Anti-tamper protection

Attaching the seal label

Seal label

Attaching the seal label

HAUBER-Elektronik GmbH

16

18 Maintenance and Repairs

Note: Type 663 and its models are maintenance free!

Error Table

Only authorised experts, who are familiar with the safety instructions for handling electrical

components, are allowed to repair this control. For handling ATEX-certified controls within

potentially explosive atmospheres the expert also has to be familiar with the safety instructions

relevant there.

Disconnect Type 663 from the mains prior to performing repair or cleaning work! Ensure

that disconnected plug connections are always de-energised! Otherwise, there is an

explosion hazard from sparking when operating ATEX-certified Type 663 in potentially

explosive atmospheres!

Immediately replace defective connection cables!

from sparking when operating ATEX-certified Type 663 in potentially explosive

atmospheres!

Otherwise, there is an explosion hazard

If the control is defective, replace it in its entirety!

Error Cause Countermeasure

No measured value (4...20 mA)No power supply Check power supply and/or connection cable

Connection cable interrupted Replace connection cable

Defective fuse Replace fuse

Wrong connection cable polarity Correct connection cable polarity

Defective control Replace control

Relay fails to switch Limit value incorrectly adjusted Correctly adjust limit value

No power s upply Check power supply and/or connection cable

Connection cable interrupted Replace connection cable

Defective fuse Replace fuse

Wrong connection cable polarity Correct connection cable polarity

Defective control Replace control

Incorrect reading Control m ounting not friction-locked Friction-lock control

Control m ounting at wrong position Mount control at correct pos ition

EMC is s ues See Sect. 19, Grounding Concepts

HAUBER-Elektronik GmbH

17

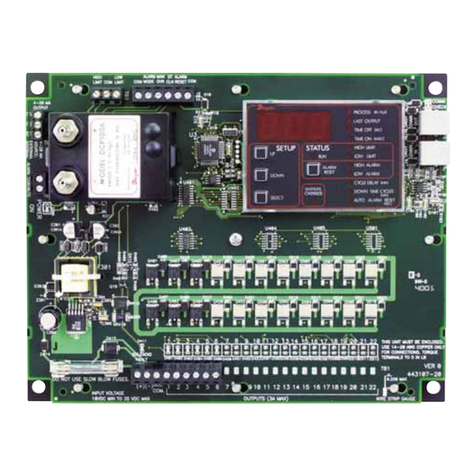

19 Grounding Concepts to Avoid Ground Loops

Ground loops are among the most frequent problems in measurement setups with sensitive

sensor technology. They arise through unwanted potential differences inside the current circuit

between sensor and evaluation unit. As a countermeasure we recommend our Standard

Grounding Concept or, depending on your application, our Alternative Grounding Concept.

Alternative Grounding Concept

In the Alternative Grounding Concept the shield of the sensor cable is connected to the

sensor housing (dotted circle). The sensor housing is uncoupled from the machine ground via

an EMC adapter (black).

Machine Evaluation Unit

+24V / 4...20mA

Sensor Cable

Machine

+24V / 4...20mA

Sensor Cable

Evaluation

e.g. Ammeter,

PLC

Unit:

Standard Grounding Concept

In the Standard Grounding Concept the shield of the sensor cable is not connected to the sensor

housing (dotted circle). The potential applied to the sensor housing and the machine ground is

identical.

Maschine Ground

Maschine Ground

Sensor

Housing

EMC Adapter

Please indicate in your order if you wish to use the Alternative Grounding Concept.

We will then offer you the respective sensor cable and EMC adapter.

Evaluation Unit

Evaluation

e.g. Ammeter,

PLC

Unit:

Shield

Shield

Sensor

Housing

.F

.

B

..

663 = Monitoring SIL2

4...20 mA ~ mm/s rms + free limit values

32 = 32 mm/s rms

64 = 64 mm/s rms

128 = 128 mm/s rms

8 = 8 mm/s rms

16 = 16 mm/s rms

No

1 = ATEX zone 1/21

2 = ATEX zone 2/22

0 = ATEX

0 = 10...1000 Hz

1 = 1...1000 Hz

Standard design0 =

connector

1 = 2,0 m integrated cable

2 = 5,0 m integrated cable

3 = 10,0 m integrated cable

0 = M12

Example:

Type 663.16.000.0

Vibration monitoring type 663

Measurement range 16 mm/s rms

Frequency range 10...1000 Hz

No ATEX

With M12 plug-in connection

No special design = Standard

C D E

A

20 Order code

HAUBER-Elektronik GmbH

18

A = HAUBER type

B = Measurement range

C = ATEX

D = Frequency range

E = Connector/cable

F = Special design

Example:

Type 663.64.113.0

Vibration monitoring type 663

Measuring range 64 mm/s rms

Frequency range 1...1000 Hz

ATEX zone 1/21

With integrated cable 10.0 m

No special design = Standard

Other manuals for 663

1

Table of contents

Popular Controllers manuals by other brands

Airwell

Airwell AHU V2-7ACELH040 Operation & installation manual

Trinamic

Trinamic TMCM-1141 Hardware manual

Smartbitt

Smartbitt SBAVR1202S user manual

Dwyer Instruments

Dwyer Instruments DCT1010DC Installation and operating instructions

dji

dji Phantom 2 Vision + user manual

Giacomini

Giacomini K275Y013 manual