Hauber 663-Window User manual

Betriebsanleitung

englisch

Doc ID: M001-663-Window Stand: 2021-03-29

Vibration Control

Type 663-Window

•Vibration acceleration (g, peak)

•2 Relay-switching outputs (Adjustable)

•Analogue current output: 4…20 mA

•Frequency range: 10 Hz … 1000 Hz

1 Hz … 1000 Hz

Date of manufacture:

Type description:

Serial no.:

HAUBER-Elektronik GmbH

Operating instructions

Vibration Monitoring Unit

Type 663-Window

Standard

Zone 2 / 22

Zone 1 / 21

663-Window

Version: 2021-03-29

Attention!

Prior to commissioning the product, the instruction manual must be read and un-

derstood.

All rights reserved, including rights to translation.

Subject to modifications.

Please contact the company with any questions:

HAUBER-Elektronik GmbH

Fabrikstraße 6

D-72622 Nürtingen

Germany

Tel.: +49 (0) 7022 / 21750-0

Fax: +49 (0) 7022 / 21750-50

info@hauber-elektronik.de

www.hauber-elektronik.de

HAUBER-Elektronik GmbH

3

1Safety information....................................................................................................................................4

2Instruction Manual Scope ........................................................................................................................5

3Vibration Control Type 663-Window........................................................................................................5

4Intended Use............................................................................................................................................5

5Safety Level .............................................................................................................................................5

6Documents and Certificates.....................................................................................................................6

7Transfer of liability when operating in potentially explosive atmospheres...............................................6

8Fields of application.................................................................................................................................6

9Scope of supply .......................................................................................................................................6

10 Technical data..........................................................................................................................................7

10.1 General data.........................................................................................................................................7

10.2 Electrical data .......................................................................................................................................7

10.3 Typical frequency response..................................................................................................................8

10.4 Mechanical data....................................................................................................................................9

10.5 Housing dimensions..............................................................................................................................9

11 Connections...........................................................................................................................................10

12 Functional Description ...........................................................................................................................11

12.1 Operating Conditions..........................................................................................................................12

12.2 Limit values.........................................................................................................................................12

12.3 Self test...............................................................................................................................................13

13 Assembly and disassembly....................................................................................................................13

13.1 General notes .....................................................................................................................................13

13.2 Fixing the vibration monitoring unit to the mounting surface..............................................................14

13.3 Zone 2 /22 - Fastening Safety Clip / Protective Cover .......................................................................15

13.4 Tamper protection...............................................................................................................................16

14 Installation and Commissioning.............................................................................................................16

15 Grounding Concepts to Avoid Ground Loops........................................................................................16

15.1 Standard Grounding Concept.............................................................................................................17

15.2 Alternative grounding concept............................................................................................................17

16 Maintenance and repair.........................................................................................................................18

16.1 General notes .....................................................................................................................................18

16.2 Troubleshooting Table........................................................................................................................18

17 Coding....................................................................................................................................................19

HAUBER-Elektronik GmbH

4

1 Safety information

1.1 General

The safety instructions are intended to protect people and property from damage and hazards

that could arise as the result of improper use, incorrect operation or other misuse or devices,

especially in explosive areas. Therefore, please read the operating instructions carefully before

working on the product or operating it. The operating instructions must be accessible to operat-

ing personnel at all times.

Please make sure that all documents are present and complete before commissioning or per-

forming other work on the product. If the documents have not all been delivered in full or if fur-

ther copies are necessary, they can also be obtained in other languages.

The product is built according to the latest state of the art. However, hazards to people, machin-

ery and systems can still arise as the result of improper handling, unintended use or operation

and maintenance by persons inadequately trained on the product.

All those who are involved in the installation, operation and maintenance of the product in the

operator’s plant must read and understand the operating instructions.

The product may only be assembled, disassembled, installed and repaired by instructed, suffi-

ciently trained and authorised personnel.

1.2 Symbols used

This symbol indicates an explosion hazard.

This symbol indicates a hazard from electrical current.

This symbol indicates information unrelated to safety.

HAUBER-Elektronik GmbH

5

2 Instruction Manual Scope

The present instruction manual of Vibration Control Type 663-Window is applicable for the mod-

els: Standard, Zone 1 / 21 and Zone 2 / 22.

The functionality of these models is identical. In addition, they have certifications and labellings

allowing their operation in potentially explosive atmospheres. See also Fields of application,

page 6.

3 Vibration Control Type 663-Window

Vibration Control Type 663-Window is used for measuring and monitoring the bearing vibration

of machines as per DIN ISO 10816. It offers the following features:

•Two limit values and two associated delays are seperately adjustable.

•Both relay-switching outputs indicate an exceeding of resp. a fall below the adjusted win-

dowrange. This can be used to genarate an alarm.

•Measurement parameter: The peak value of the vibration acceleration. (1 g = 9.81 m/s²)

•Analogue current output: Interference-free direct current from 4...20 mA, proportional to

the vibration amplitude.

•Cable break on the control cable can be detected by a succeeding evaluation device:

Value of the direct current signal < 3.5 mA.

4 Intended Use

Type 663-Window is used to protect machines and mechanical equipment against undue me-

chanical vibrations. Its use is only allowed within the specifications as per the data sheet, and

exclusively for measuring mechanical vibrations. Main areas of application: Conveyor and

sieving equipment, drying and cooling systems and similar oscillating mechanical plants and

equipment.

5 Safety Level

The hardware, vibration control Type 663-Window, was tested using Exida's FMEDA. The re-

sults of the FMEDA meet the criteria according to SIL2, SIL3 and PL-d.

In determining the safety function, using the safety key figures in accordance with the standards

mentioned under item 4 in the safety manual, the relay contacts of the vibration control Type

663-Window were explicitly evaluated and taken into account. The current output 4...20 mA is

not configured in a safety-relevant manner.

For more information, refer to the safety manual.

HAUBER-Elektronik GmbH

6

6 Documents and Certificates

Please see www.hauber-elektronik.de for the following documents and certificates for Type 663-

Window:

•EC Declaration of Conformity

•Safety manual SIL2

•Safety manual SIL3

•Declaration of conformity ATEX zones 2 and 22, no.: LU 15 ATEX 0131X

•EC-type examination certificate ATEX zones 1 and 21, no.: SNCH 09 ATEX 4380

7 Transfer of liability when operating in potentially explosive atmospheres

The owner of the system is exclusively liable for the appropriate configuration of the electrical

connections with respect to explosion protection regulations and correct commissioning.

If the system is installed by a sub-contractor on behalf of the owner, the system may only be

commissioned after the sub-contractor has issued written confirmation in the form of a certificate

of installation that the system has been installed correctly and professionally in accordance with

the applicable legal regulations.

The operator is obliged to notify the responsible authorities of the initial commissioning of explo-

sion-protected systems or system components and their re-commissioning following extensive

changes or maintenance.

8 Fields of application

Model

Application Fields

Labelling

Standard

Non-explosive atmospheres

Zone 1 / 21

Potentially explosive atmos-

pheres, zone 1 and 21

II 2 G Ex d IIC T4 Gb

II 2 D Ex tb IIIC T120 °C Db

Zone 2 / 22

Potentially explosive atmos-

pheres, zone 2 and 22

II 3 G Ex d nA IIC T4 Gc

II 3 D Ex tc IIIC T120 °C Dc

Tab. 1: Application fields

9 Scope of supply

All versions include:

•Vibration monitoring

•Cylinder head screw with hex socket, M8 x 20 mm

•Spring washers for M8

•Seal label

•Operating instructions

Version Zone 2 / 22 further includes:

•Protective cover for M12 connector

•Safety clip

HAUBER-Elektronik GmbH

7

10 Technical data

10.1 General data

Each sensor has one of the listed measuring and frequency ranges. Further

ranges on request.

Please indicate the measuring and frequency range in your request.

Measuring range:

0 … 4 g

0 … 6 g

0 … 6.4 g

0 … 12 g

Measuring accuracy:

± 5%

Transverse sensitivity:

< 5%

Frequency range:

10 Hz … 1000 Hz (standard)

1 Hz … 1000 Hz

Temperature range:

Ambient temperature:

-30 °C…+60 °C

Measuring head temperature:

-30 °C…+85 °C

Tab. 2: General data

10.2 Electrical data

Output signal:

1 x 4-20 mA (proportional to the measuring range)

Switching contact:

2 x relay contact (pre- and main alarm)

Switching contact switching

load:

1A / 30 V DC

Power supply:

24 V DC ± 10%

Power input (max.):

80 mA

Load/output load (max.):

500 Ω

Fusing:

Microfuse (medium time lag, 160 mA, breaking capacity C)

Automatic:

As soon as the vibration values fall below the limit values, the

potential-free switching contacts automatically re-energize.

Tab. 3: Electrical data

Only unscrew the housing cover if Type 663-Window is disconnected from the mains or

if the atmosphere is non-explosive Otherwise, there is an explosion hazard from spark-

ing when operating ATEX-certified Type 663-Window in potentially explosive atmos-

pheres!

Prior to commissioning Type 663-Window, protect the mains using a microfuse (me-

dium time lag, 160 mA, breaking capacity C)!

HAUBER-Elektronik GmbH

8

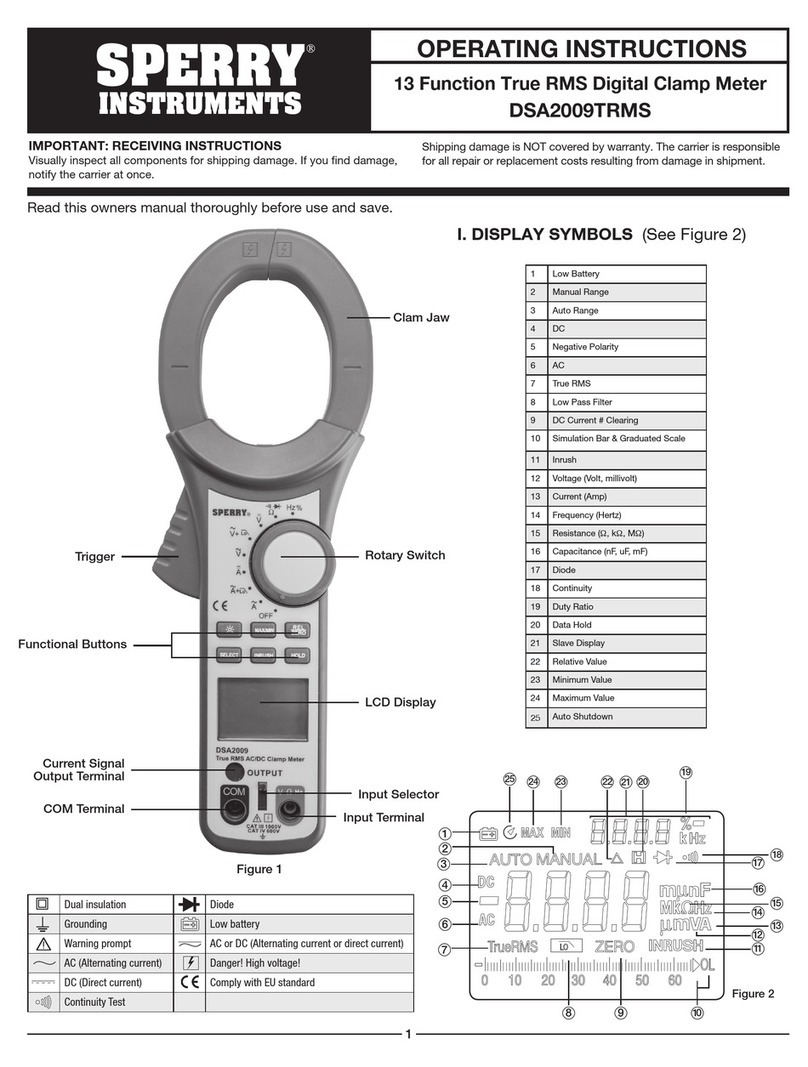

10.3 Typical frequency response

10 Hz–1,000 Hz (standard)

The frequency response is recorded using a reference sensor.

• 4 Hz. . . 1200 Hz acceleration sensor

Fig. 1: Typical frequency response 10 Hz–1000 Hz

1 Frequency in Hz

2 Amplification in dB

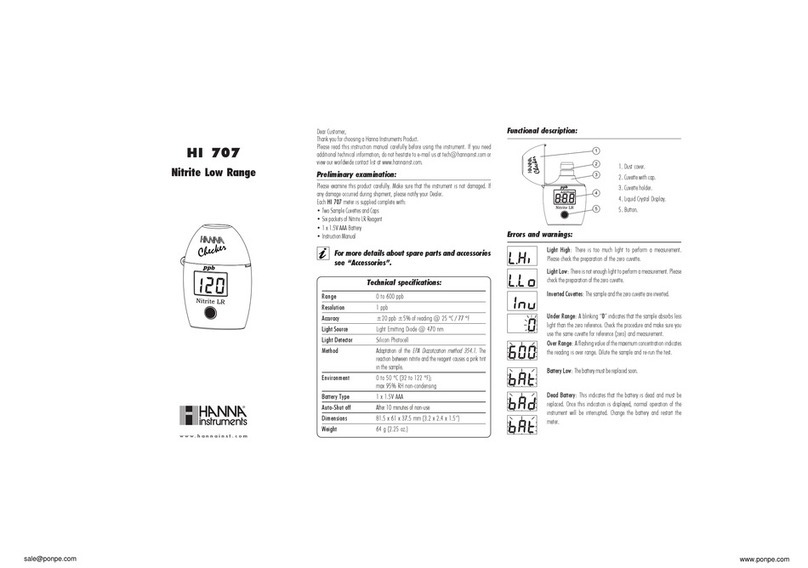

1 Hz–1000 Hz

The frequency response is recorded using two reference sensors.

• 1 Hz. . . 10 Hz laser sensor

• 10 Hz. . . 1200 Hz acceleration sensor

Fig. 2: Typical frequency response 1 Hz–1000 Hz

1 Frequency in Hz

2 Amplification in dB

HAUBER-Elektronik GmbH

9

10.4 Mechanical data

Housing material:

Stainless steel V2A, material no.: 1.4305 (standard)

M12 connector material:

CuZn (brass), nickel plated

Cable gland:

V2A stainless steel

Fastening:

Cylinder head Allen screw M8 x 20 mm

Thread pitch: 1.25 mm (standard)

Mounting:

Housing must be earthed via the M8 fastening

Weight:

approx. 500 g

Protection class:

IP 67

Tab. 4: Mechanical data

10.5 Housing dimensions

Fig. 3: Housing with M12 connector

Fig. 4: Housing with in-

tegrated cable

All measurements

in mm

1 M12 connector

2 Measuring direction

1 Connecting cable

2 Cable gland

3 Measuring direction

HAUBER-Elektronik GmbH

10

11 Connections

Variant:

M12 connector (Standard, Zone 2 / 22)

Pin 1:

24 V DC

Pin 2:

GND

Pin 3:

4 … 20 mA current signal

Pin 4:

Self test (+24 V)

Pin 5:

Relay 1

Pin 6:

Relay 1

Pin 7:

Relay 2

Pin 8:

Relay 2

Variant:

Integrated cable (Zone 1 / 21)

Pin 1:

Weiß

24 V DC

Pin 2:

Braun

GND

Pin 3:

Grün

4 … 20 mA current signal

Pin 4:

Gelb

Self test (+24 V)

Pin 5:

Grau

Relay 1

Pin 6:

Rosa

Relay 1

Pin 7:

Blau

Relay 2

Pin 8:

Rot

Relay 2

Connection plan:

Fig. 5: Connection plan

1 Relay 1

2 Relay 2

3 Evaluation unit (amperemeter, PLC, …)

4 Self-check switch

The connection plan shows the alarm condition and/or the currentless condi-

tion! Relay 1 and 2 are dropped out.

HAUBER-Elektronik GmbH

11

12 Functional Description

Only unscrew the housing cover if Type 663-Window is disconnected from the

mains or if the atmosphere is non-explosive. Otherwise, there is an explosion

hazard from sparking when operating ATEX-certified Type 663-Window in po-

tentially explosive atmospheres!!

Type 663-Window has two limit values, LIM1 and LIM2, with their respective lag times, which

can all be adjusted separately. If the value of the acceleration is below or above an adjustable

window-range, an alarm is generated. The lower limit of the window-range will be adjusted with

LIM1 and the upper limit with LIM2

In addition, Type 663-Window has an analogue current output. This delivers a direct current of

4...20 mA proportional to the vibration acceleration.

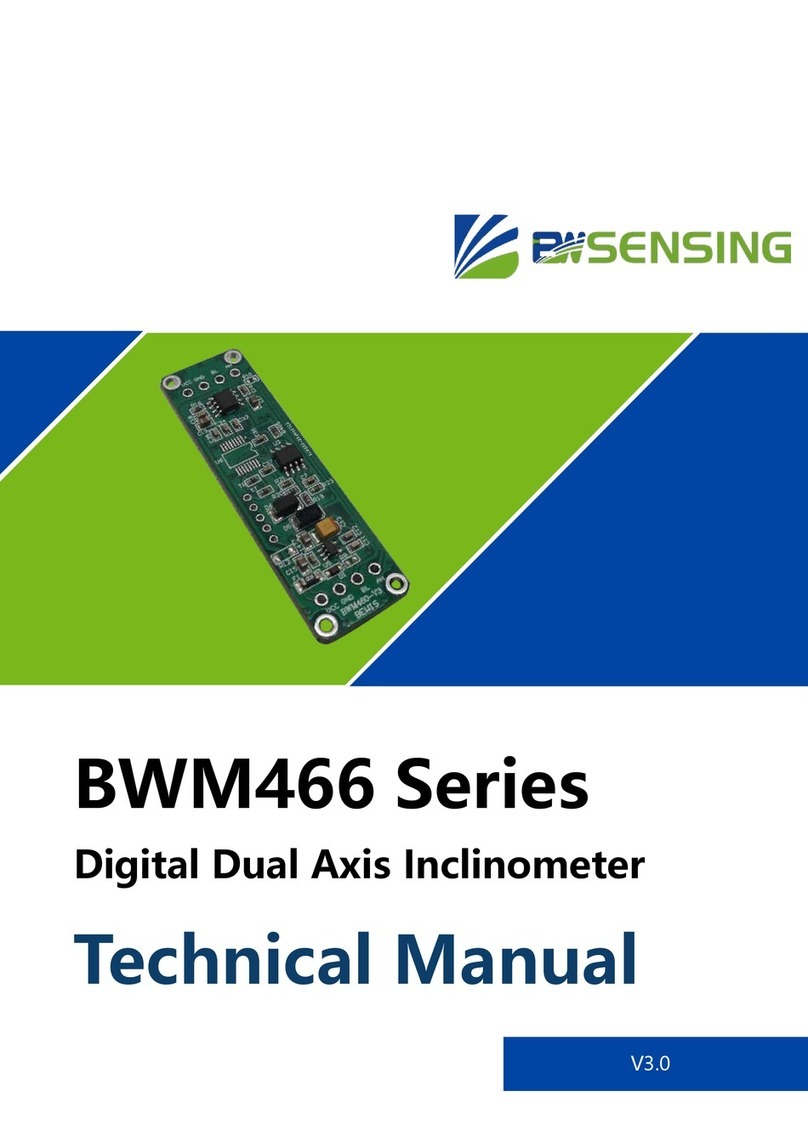

Fig. 6: User Interface Channels LIM1 and LIM2

1 SET Turn-Switch (Limit Value in 15 Steps)

2 TIME-Potentiometer (Lag Time Variably Adjustable, 0...30 sec.)

3 LED Indicators

Fig. 7: Window function

1 Alarm for values below LIM1

2 Window area

3 Alarm for values above LIM2

HAUBER-Elektronik GmbH

12

12.1 Operating Conditions

Operating Condition

Measurement

Relay

LED Indicator

OK

Within Limit Values

Energised

OK

WARNING

Outside of Limit Values,

Lag Time Running

Energised

WARNING + OK

ALARM

Outside of Limit Values,

Lag Time Expired

Dropped out

ALARM

Tab. 5: Operating Conditions

12.2 Limit values

SET Position

Limit values (mm/s)

Measuring range

0 … 4 g

0 … 6 g

0 … 6,4 g

0 … 12 g

0

0

0

0

0

1

0,25

0,375

0,4

0,75

2

0,5

0,75

0,8

1,5

3

0,75

1,125

1,2

2,25

4

1

1,5

1,6

3

5

1,25

1,875

2

3,75

6

1,5

2,25

2,4

4,5

7

1,75

2,625

2,8

5,25

8

2

3

3,2

6

9

2,25

3,375

3,6

6,75

10

2,5

3,75

4

7,5

11

2,75

4,125

4,4

8,25

12

3

4,5

4,8

9

13

3,25

4,875

5,2

9,75

14

3,5

5,25

5,6

10,5

15

3,75

5,625

6

11,25

Tab. 6: Limit values

The SET rotary button has 16 positions, representing the limit value of an alarm. The measur-

ing range of the vibration monitoring unit is divided into 16 linear steps.

In general:

Example: Limit setting

Measuring range:

0 … 6 g

SET rotary button Pos.:

8

Limit value:

3 g

HAUBER-Elektronik GmbH

13

12.3 Self test

The self-test is to verify the correct functioning of the vibration control. Therefore, a test signal is

applied to pin 4 of the control. The test signal simulates a vibration amplitude exceeding the

maximum limit value. This will trigger the control's alarm condition.

Test signal:

a. Direct current, 24 V DC or

b. Square wave signal, 24 V DC / 0.5 Hz

Initial state:

Normal operation

Self-test start:

•Apply the test signal to pin 4.

•The output current signal increases up to ~23 mA.

•After < 35 s, the alarm relays drop out.

If one or both alarm relays fail to drop out, this indicates a fault.

•Remove the test signal.

•After a further < 60 s the output current signal has re-

turned to to 4 mA or its actual value

End self test

Final state:

Normal operation

Duration:

approx. 95 s

Test signal a is only available for production no. 75478 or later.

13 Assembly and disassembly

13.1 General notes

Assembly and disassembly work on and with the monitoring unit may only be performed by an

authorised specialist familiar with the safety regulations governing handling electrical compo-

nents! When using EX-certified monitoring units in potentially explosive atmospheres, the pro-

fessional must also be familiar with the relevant safety regulations!

Before assembly and disassembly disconnect the monitoring unit from the power sup-

ply! Separate plug connections must always be de-energized! If EX-certified monitoring

is operated in a potentially explosive atmosphere, there is otherwise an explosion haz-

ard, due to spark formation!

The monitoring unit housing must be earthed via the fastening - through the

machine earth of the mounting surface or through a separate protective conductor (PE)!

HAUBER-Elektronik GmbH

14

13.2 Fixing the vibration monitoring unit to the mounting surface

Prerequisites

• Mounting surface is clean and flat; i.e. free of

paint, rust, etc.

• Threaded hole in mounting surface:

15 mm, M8

Tools and material

•Hex socket key SW 6, SW 8

•Torque wrench SW 6, SW 8

•Cylinder head screw with hex socket

M8x20

•Spring washers for M8

Work steps and instructions

•Unscrew housing cover from housing

base;

hex socket key SW 8

•Attach monitoring unit using cylinder

head screws and spring washers with 8

Nm on mounting surface;

Torque wrench SW 6

•Screw the housing cover back onto the

housing base and tighten to 5 Nm;

Torque wrench SW 8

Fastening on mounting surface (1)

Tighten housing cover with torque wrench (2)

In order to avoid cold welding of the housing cover to the housing base, the

thread is treated ex-works with an assembly paste for stainless steel connec-

tions.

HAUBER-Elektronik GmbH

15

13.3 Zone 2 /22 - Fastening Safety Clip / Protective Cover

Always operate model Zone-2-22 with the safety clip to avoid accidental disconnection

of the plug connection! Otherwise, there is an explosion hazard from sparking when op-

erating this control in potentially explosive atmospheres!

13.3.1 Fastening Safety Clip

1. Fully insert the connection cable socket into the M12 connector.

(Pay attention to the code cam position!)

2. Tightly fasten the lock nut of the connection cable socket by hand.

3. Mount the safety clip to avoid accidental disconnection of the plug connection:

–Place both shell halves of the safety clip around the plug connection.

–Press both shell halves of the safety clip together by hand until the catch lock en-

gages.

–Place the arrow connected to both shell halves around the cable, then thread it

through the eye on the other end so that the notice sign is legible alongside the ca-

ble.

Fig. 8: Protective Cover

Fig. 9: Fastened Protective Cover

1 Notice sign

13.3.2 Fastening Protective Cover

Fasten the protective cover using the M12 connector after disconnecting the plug connection!

Disassemble the safety clip and fasten the protective cover:

1. Disconnect the control from the mains.

2. Separate both shell halves of the fuse clip using a screw driver.

3. Use the M12 connector to firmly close the protective cover.

Fig. 10: Protective Cover

Fig. 11:Fastened Protective Cover

HAUBER-Elektronik GmbH

16

13.4 Tamper protection

Attach seal labels

The "SEALED" seal label reveals any unauthorised opening of the housing cover.

After installation of the housing cover by the system operator, the seal label shall be attached to

the side above the housing joint.

If any tampering is attempted, the seal label is destroyed and the tampering will be visible to the

system operator

Fig. 12: Seal label

14 Installation and Commissioning

Only authorised experts, who are familiar with the safety instructions for handling electrical com-

ponents are allowed to install or commission this control. For handling ATEX-certified controls

within potentially explosive atmospheres the expert also has to be familiar with the safety in-

structions relevant there.

Ensure the housing cover is properly fastened prior to commissioning (tighten-

ing torque = 5 Nm)! Otherwise, there is an explosion hazard from sparking

when operating ATEX certified Type 663-Window in potentially explosive at-

mospheres!

Prior to commissioning Type 663-Window, protect the mains with a microfuse

(medium time lag, 160 mA, breaking capacity C)!

Protect the connection cable and possible extension cables from electrical in-

fluences or mechanical damage! Ensure to stricly follow local regulations and

directives!

Check the self-test during commissioning.

15 Grounding Concepts to Avoid Ground Loops

Ground loops are among the most frequent problems in measurement setups with sensitive

sensor technology. They arise through unwanted potential differences inside the current circuit

between sensor and evaluation unit. As a countermeasure we recommend our Standard

Grounding Concept or, depending on your application, our Alternative Grounding Concept.

HAUBER-Elektronik GmbH

17

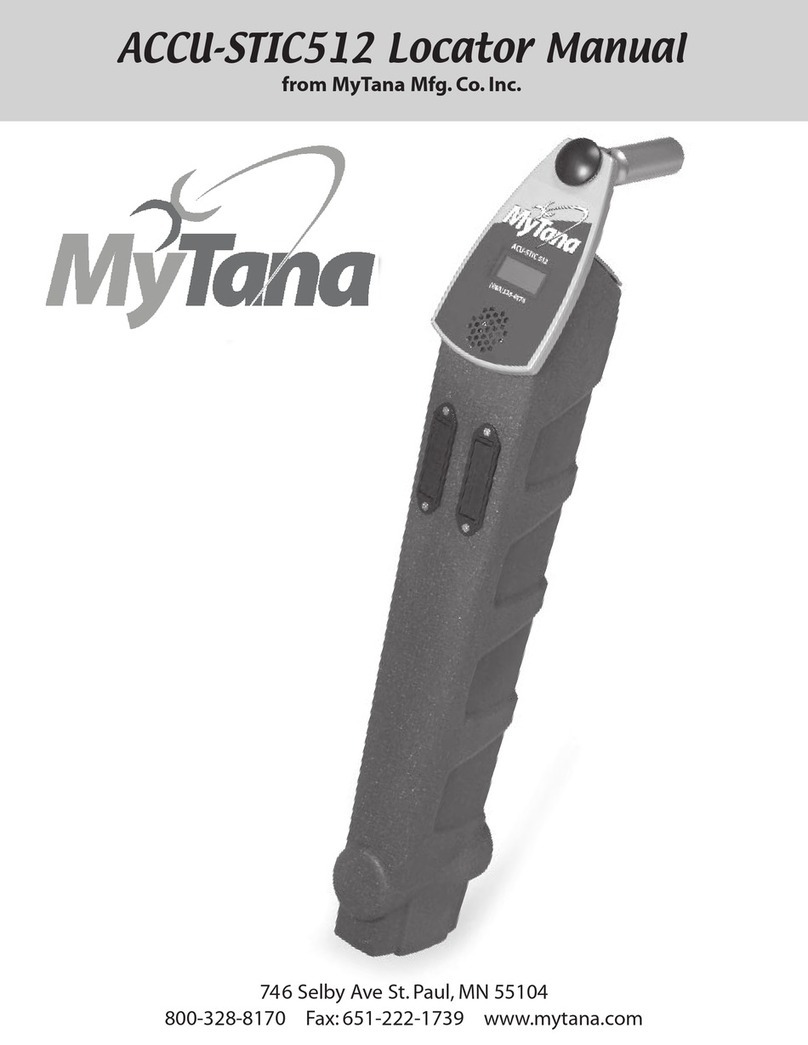

15.1 Standard Grounding Concept

With the standard grounding concept, the sensor cable shield has no connection to the sensor

housing (dashed circle). The sensor housing has the same potential as the machine earth.

Fig. 13: Standard Grounding Concept

1 Machine earth

2 Evaluation unit (measuring instrument, SPS, …)

3 Cable shield

4 Evaluation unit earth potential

5 Optional flexible metal tubing (only available for version with integrated cable)

15.2 Alternative grounding concept

With the alternative earthing concept, the sensor cable shield has a connection to the sensor

housing. The sensor housing uncoupled from the machine earth by means of an EMC adapter

(red). With the alternative earthing concept an electrically secure earth connection is only en-

sured for versions with an M12 connector. For variants with an integrated cable, the alternative

earthing concept cannot be used.

Fig. 14: Alternative grounding concept

1 Machine earth

2 Evaluation unit (measuring instrument, SPS, …)

3 Cable shield

4 Evaluation unit earth potential

5 EMC adapter (Hauber item no. 10473)

In your request, please notify us if you would like to use the alternative earthing

concept. We will then provide you with the appropriate sensor cable and the

EMC adapter.

HAUBER-Elektronik GmbH

18

16 Maintenance and repair

16.1 General notes

Repair and cleaning work on vibration monitoring units may only be performed

by an authorised specialist familiar with the safety regulations governing han-

dling electrical components.

Before repair and cleaning disconnect the monitoring unit from the power sup-

ply! Separate plug connections must always be de-energized!

Immediately replace defective connection cables!

A defective vibration monitoring unit must be completely replaced!

The vibration monitoring unit 663 is maintenance-free!

16.2 Troubleshooting Table

Fault

Cause

Action

No measured

value

(4-20 mA)

No power supply

Check power source and/or supply

Discontinuity in connecting cable

Replace connecting cable

Fuse defective

Replace fuse

Connection has incorrect polarity

Connection of correct pole

Vibration monitoring unit faulty

Replace Vibration Monitoring Unit

Relay doesn't

switch

Wrong limit value set

Set correct limit value

No power supply

Check power source and/or supply

Discontinuity in connection

Replace connecting cable

Fuse defective

Replace fuse

Connection has incorrect polarity

Connection of correct pole

Defective monitoring unit

Replace monitoring unit

Incorrect

Reading

Vibration monitoring unit not

mounted in a friction-locked man-

ner

Mount vibration monitoring unit in a fric-

tion-locked manner

Vibration monitoring unit installed

in wrong place

Install vibration monitoring unit in cor-

rect place

EMC problems

Alternative grounding concept

Tab. 7: Troubleshooting Table

HAUBER-Elektronik GmbH

19

17 Coding

A.

B.

C

D

E.

F

A = HAUBER Type

663 = Monitoring Unit SIL2

4...20 mA ~ g (peak) + free limit values

B = Measuring range

4 = 4 g (peak)

6 = 6 g (peak)

6,4 = 6.4 g (peak)

12 = 12 g (peak)

C = ATEX

0 = no ATEX

1 = ATEX Zone 1 / 21

2 = ATEX Zone 2 / 22

D = Frequency range

0 = 10 … 1000 Hz (Standard)

1 = 1 … 1000 Hz

E = Connection

0 = M12 connector

1 = 2.0 m cable integrated, cable gland nickel-plated brass /

since 01/02/2016 V2A stainless steel and identical to "4”

2 = 5.0 m cable integrated, cable gland nickel-plated brass /

since 01/02/2016 V2A stainless steel and identical to "5”

3 = 10.0 m cable integrated, cable gland nickel-plated brass /

since 01.02.2016 V2A stainless steel and identical to "6”

4 = 2.0 m cable integrated, cable gland V2A stainless steel

5 = 5.0 m cable integrated, cable gland V2A stainless steel

6 = 10.0 m cable integrated, cable gland V2A stainless steel

F = Special design

2 = Standard design

Example:

Type 663.4.000.2

Example:

Type 663.6,4.113.2

Vibration monitoring type 663-Window

Measurement range 4 g (peak)

Frequency range 10...1000 Hz

No ATEX

With M12 plug-in connection

Special design = Window

Vibration monitoring type 663-Window

Measuring range 6.4 g (peak)

Frequency range 1...1000 Hz

ATEX zone 1 / 21

With integrated cable 10.0 m

Special design = Window

This manual suits for next models

1

Table of contents

Other Hauber Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bosch

Bosch BEA 060 Original instructions

Schiltknecht Messtechnik

Schiltknecht Messtechnik MiniAir20 Operating instruction

sauermann

sauermann SI-CA 120 quick start guide

Burkert

Burkert FLOWave S operating instructions

Hach

Hach POCKET COLORIMETER II instruction manual

RS PRO

RS PRO RS-8880 instruction manual