Simco-Ion Ioncell User manual

5201128 Rev. D

Ioncell

Ioncell

Standard and In-Line Ionizer

INSTALLATION AND OPERATING INSTRUCTIONS

i

Ioncell 5201128 Rev. D

TABLE OF CONTENTS

1. SAFETY WARNINGS.................................................................................................1

2. DESCRIPTION .........................................................................................................2

3. SPECIFICATIONS .....................................................................................................3

4. INSTALLATION ........................................................................................................4

5. MAINTENANCE........................................................................................................8

6. PARTS AND ACCESSORIES......................................................................................9

9. WARRANTY AND SERVICE ................................................................................... 10

1

Ioncell 5201128 Rev. D

1. SAFETY WARNINGS

PLEASE READ INSTRUCTIONS COMPLETELY BEFORE STARTING

INSTALLATION

ALL INSTALLATION AND TROUBLESHOOTING OPERATIONS MUST

BE PERFORMED BY QUALIFIED TECHNICAL PERSONNEL

This instruction manual uses symbols to identify dangerous situations as follows:

NOTE – Statements identified with NOTE indicate precautions necessary

to avoid potential equipment failure.

CAUTION – Statements identified with CAUTION indicate potential

safety hazards.

ATTENTION – Les déclarations identifiées avec ATTENTION indiquent

des dangers potentiels pour la sécurité.

WARNING – Statements identified with WARNING indicate potential

serious injury hazards.

AVERTISSEMENT – Les déclarations identifiées avec AVERTISSEMENT

indiquent un risque de blessures graves.

NOTE – This equipment must be correctly installed and properly

maintained. Adhere to the following notes for safe installation and operation:

WARNING – Fire Hazard

Keep the unit dry. Do not operate the unit in flammable or explosive

environments.

AVERTISSEMENT – Risque d’incendie

Gardez l’appareil au sec. Ne pas utiliser l’appareil dans des environnements

inflammables ou explosifs.

2

Ioncell 5201128 Rev. D

CAUTION – Electrical Shock Hazard

Turn off power supply before cleaning bar or performing any maintenance

on the system. Electrical installation and repairs must be performed by a

skilled electrical engineer according to the applicable national and local

regulations. The equipment must be properly grounded. Grounding is

required to ensure safe and proper operation and to prevent electrical shocks

upon contact.

ATTENTION – Risque de choc électrique

Coupez l’alimentation électrique avant de nettoyer la barre ou d’effectuer

un entretien sur le système. L’installation électrique et les réparations

doivent être effectuées par un ingénieur électricien qualifié conformément

aux réglementations nationales et locales en vigueur. L’équipement doit être

correctement mis à la terre. La mise à la terre est nécessaire pour assurer un

fonctionnement sûr et approprié et pour éviter les chocs électriques lors du

contact.

CAUTION – Sharp Points

Risk of injury. Keep hands/fingers away.

ATTENTION – Points pointus

Risqué de blessure. Gardez les mains / doigts éloignés.

1. Read Instruction Manual completely before proceeding with installation or

operation. Failure to follow instructions may result in damage to Ioncell ionizer

or power supply.

2. The Ioncell ionizer, when operated with optional power supply, is to be

connected to main electric source with included 3-wire line cord and grounded

plug set. Do not remove electrical ground pin of the plug set.

3. A factory-qualified service technician must perform any required ionizer service

or warranty repairs. Please contact Simco-Ion Customer Service at 215-822-

6401 for information.

2. DESCRIPTION

The Simco-Ion Ioncell is a compact, steady state, bi-polar DC air ionizer designed

for easy installation, and minimal maintenance. It provides powerful ionization

through output tubes up to four feet in length. The single output tube also has the

ability to be split, allowing the Ioncell to service multiple locations from a single

ionization source. Options for Ioncell include:

• Standard: A fan for increased operating range

• In-Line:

– A ring or air knife output applicator for custom applications

– An airflow switch that automatically cuts off power when no airflow is

present, so potential excess ozone production is eliminated

3

Ioncell 5201128 Rev. D

The ionizer can be powered by a universal input, low voltage power supply, or

through a 24 VDC power bus in the host main circuit. Multiple Ioncells can be

linked together from a single power supply, allowing up to 6 units to be daisy-

chained.

Operation of the Ioncell is automatically regulated by built-in proprietary circuitry.

A green light on the face of the ionizer indicates active condition. A red light

will indicate if a fault condition has occurred. Mounting holes for the ionizer are

provided within the integral base of the unit.

The in-line Ioncell is equipped for use with pressurized CDA only (clean dry air).

Ioncell emitter points are general purpose Tungsten.

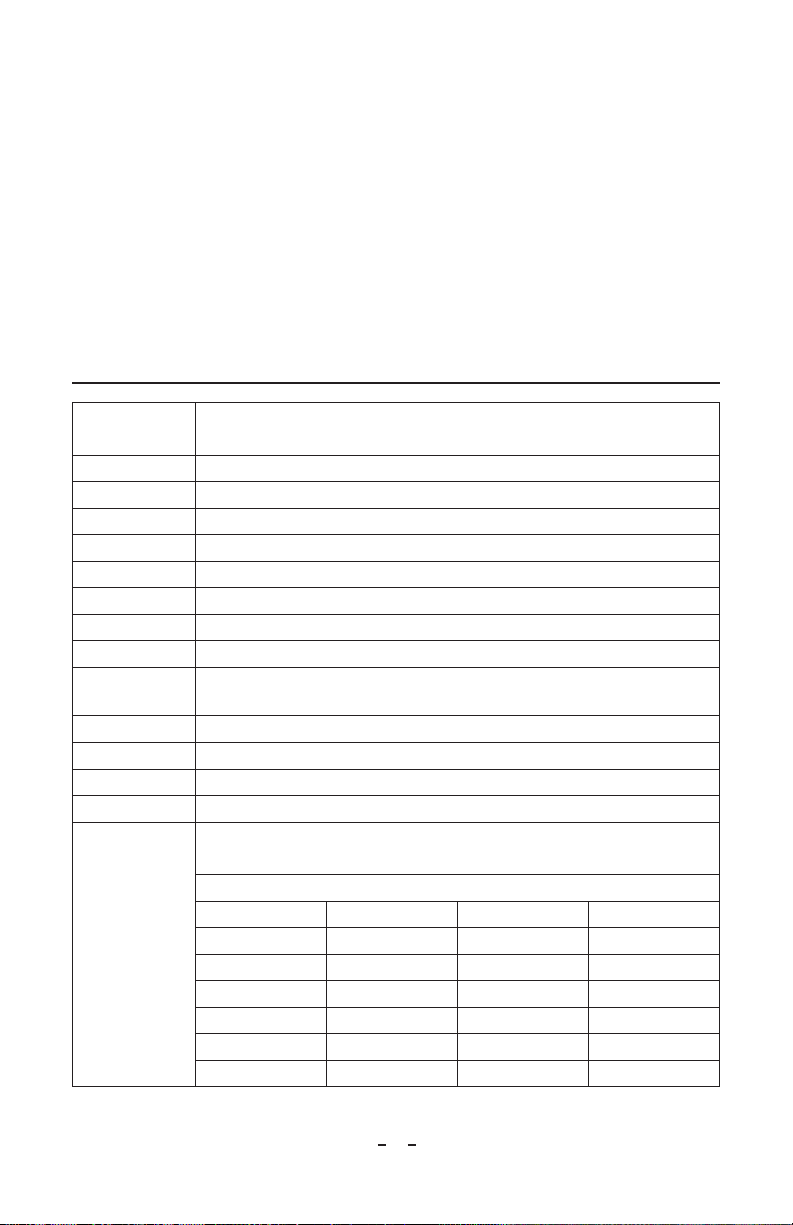

3. SPECIFICATIONS

Input Voltage Power Supply: Universal, 100-240VAC, 50/60 Hz (24VDC, 1.6A output)

Ioncell: 24VDC, 0.1A (0.17A with optional fan)

Output Voltage ±4500 VDC, 5µA, Steady State

Offset Voltage ±50V

Enclosure White Polycarbonate (UL 94V-0 flammability rating)

Alarm Output TTL level alarm output

Indicators Green, POWER ON; Red, FAULT

Mounting Integral mounting flanges accept four (4) #4 or #6 [M3 or M4] screws (not supplied)

Emitter Pins Four (4), Tungsten

Operating Temp 32-122°F [0-50°C]; non-condensing

Dimensions Standard: 1.25”H x 1.3”W x 4.5”L [32 x 33 x 115 mm]

In-Line: 2.5”H x 1.3”W x 4.5”L [64 x 33 x 115 mm]

Weight 5.2 oz [145g]

Gas Input In-Line: 45 psi [3.1 bar] max; clean dry air only

Gas Flow In-Line: 0.8 scfm @ 5 psi to 3.2 scfm @ 45 psi [23 l/m @ 0.34 bar to 92 l/m @ 3.1 bar]

Airflow 5 cfm [0.14 m3/min] with optional fan

Discharge Time

Standard Ioncell: <15 seconds @ 6”[150 mm] to CPM plate 1000-100V

Ioncell with optional fan: <10 seconds @ 12”[300 mm] to CPM plate

In-Line Ioncell with output tube: 1”[25 mm] to CPM plate, 1000-100V

Tube Length 30 psi [2.0 bar] 15 psi [1.0 bar] 5 psi [0.34 bar]

6”[150 mm] 0.5 sec 0.8 sec 1.4 sec

12”[300 mm] 0.8 sec 1.4 sec 2.2 sec

18”[460 mm] 1.0 sec 2.1 sec 3.5 sec

24”[610 mm 1.8 sec 3.2 sec 5.2 sec

36”[910 mm] 6.0 sec 6.8 sec 10 sec

48”[1220 mm] 9.5 sec 13 sec 22 sec

4

Ioncell 5201128 Rev. D

4. INSTALLATION

CAUTION – Sharp Points

Risk of injury. Keep hands/fingers away.

ATTENTION – Points pointus

Risqué de blessure. Gardez les mains / doigts éloignés.

NOTE – Inspect shipping container and contents for visible damage.

Report any damage directly to the carrier before attempting installation of

unit.

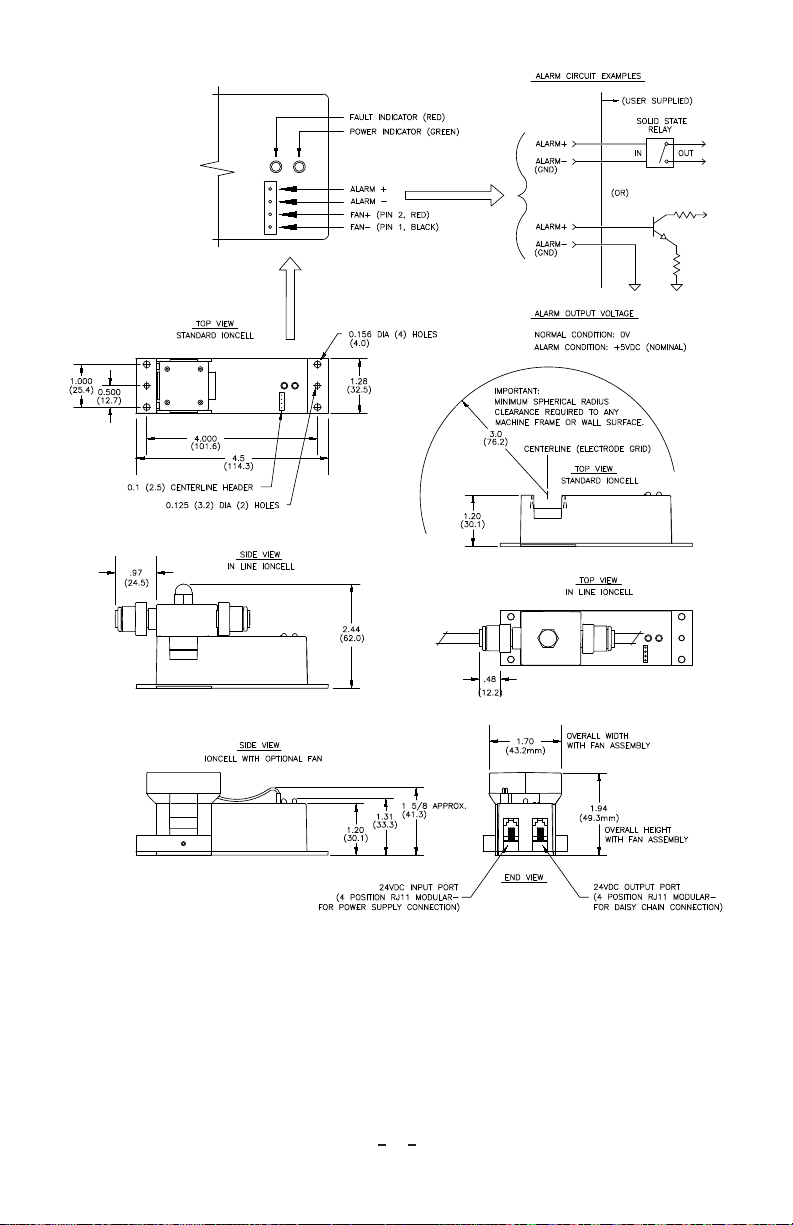

The Ioncell ionizer is designed for fixed position mounting onto a secure equipment

frame or partition surface. The flanged base of the ionizer may be used as a template,

or see Figure 2 for complete dimensional information.

Prepare mounting surface with necessary mounting holes. Secure with #4 or #6 [M3

or M4] screw hardware as required. Mounting hardware is not supplied with unit.

Important mounting location requirement: The center of ionizer’s emitter pin grid

must have a minimum 3” spherical radius clearance to any adjacent equipment

frame or wall surface. A clear line of sight is recommended to the area requiring

static neutralization for best ionizer performance.

CAUTION – This product is intended to be supplied by a Listed AC

Adapter or Power Unit marked “Class 2” or “LPS” and rated output 24

VDC, 1.7A.

ATTENTION – Ce produit est destiné à être alimenté par un adaptateur

de courant alternatif ou transformateur listé “ classe 2 “ ou “ LPS “ et avec

une puissance nominale 24 VDC, 1.7A.

Optional fan assembly mounting and connections: Engage open end of fan assembly

directly around emitter pin grid area of the ionizer, until it snaps into place. Secure

fan assembly by placing fan locking bracket over base of fan assembly and tightening

set screws (do not over tighten). Insert power lead connector of fan assembly into

socket located in the top of ionizer enclosure. The black wire, pin 1 in the connector

must be positioned towards the outside of ionizer enclosure. See Figure 2 for

complete connection diagram.

After the ionizer mounting has been completed, connect power cable between

ionizer and power supply. Secure power supply as necessary. Connect line cord from

power supply to the main electric source. The green light on ionizer will indicate

normal operation.

5

Ioncell 5201128 Rev. D

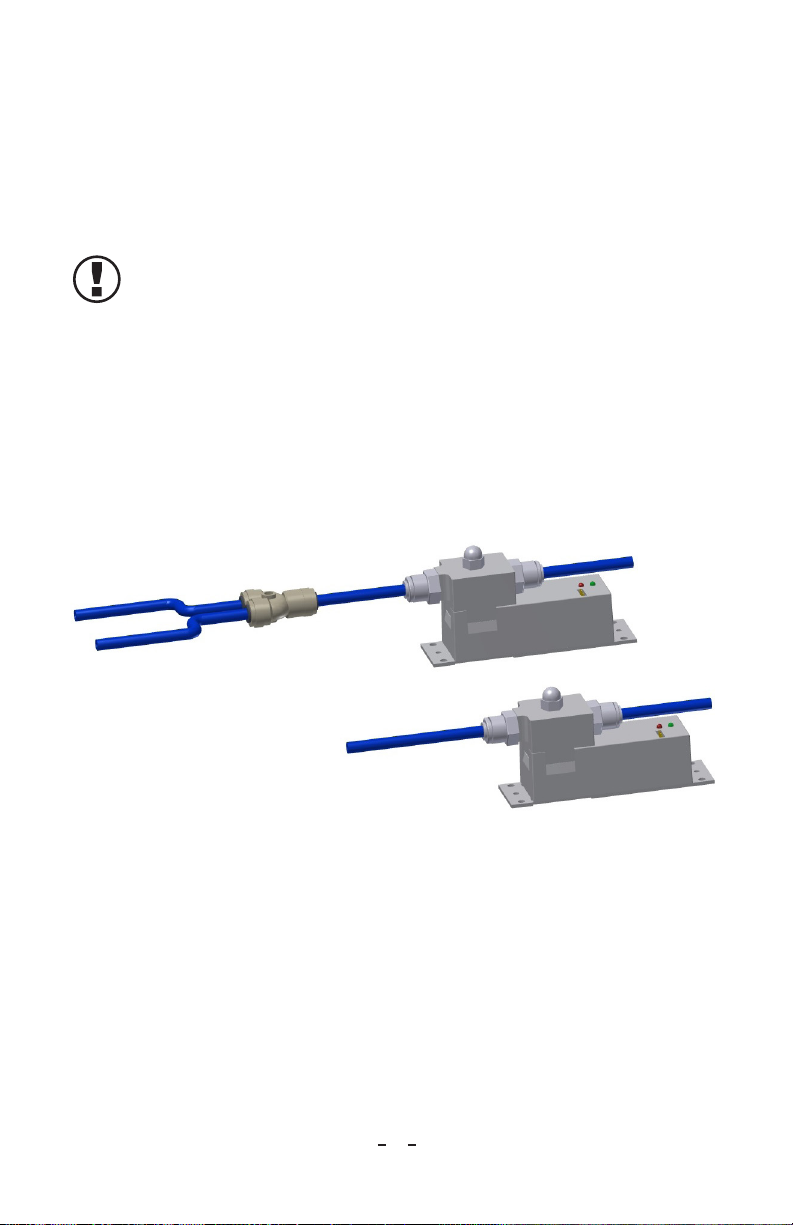

In-line Ioncell connections: An in-line manifold is mounted within the emitter pin

grid area of ionizer. The in-line manifold allows for multi-tube configurations for

locations which have been previously inaccessible for other ionizers. The input and

output connectors both take 1/4” OD tubing. Insert tubing into connector and run

tube to desired location, or, use a 2-way splitter to direct ionization to two different

locations. For optimal performance, use shortest tube lengths possible. Excessive

tube lengths will increase discharge times.

NOTE – Tubing must have the same inside diameter on both sides of the

in-line manifold.

A +5 VDC (TTL level) alarm output is provided for remote monitoring of the

ionizer operating condition. ALARM+ goes high (+5 VDC) on alarm. See Figure

2 for complete connection diagram.

Optional Airflow Switch for In-line Ioncells: The airflow switch replaces the power

cable between the ionizer and power supply. It includes two 1/4” tubing connectors,

labeled “AIR INPUT” for the compressed air supply and “AIR OUTPUT” to be

connected to the ionizer. The In-line Ioncell will switch power to the ionizer off

when compressed air is not being fed to the assembly.

Figure 1. Output Tube Congurations (single and split)

6

Ioncell 5201128 Rev. D

with Optional Fan

In Line Ioncell Module

Standard Ioncell Module

Universal Power Supply

with 6" [150 mm] long cable

and panel mountable RJ-11

modular connector

RJ-11 extension cable

72" [1830mm] long

(included with power supply)

RJ11 extension cable

36" [915 mm] long

(included with Ioncell ionizer)

Line Cord

72" [1830 mm] long

(included with power supply)

Red

Black

Direct Power Bus Cable

72" [1830 mm] long

(units with no power supply)

Customer supplied 24 VDC

Figure 2. Up to 6 (six) Ioncells can be attached to one power supply

7

Ioncell 5201128 Rev. D

Figure 3. Dimensional Drawing

8

Ioncell 5201128 Rev. D

5. MAINTENANCE

The Ioncell ionizer is designed for calibration free operation with a minimum of

maintenance and cleaning. There are no user serviceable parts within the ionizer. No

attempt should be made to disassemble or repair defective products. Please contact

Simco-Ion customer service for information concerning repair or replacement.

NOTE – All corona type ionizers form deposits on the emitter electrodes

during normal service. Typical deposits appear as a white coating upon the

pointed tip region of the electrode. Periodic cleaning of the pointed tips will

maintain the performance and extend the life of the ionizer. Maintenance

frequency will depend on the relative humidity and cleanliness of the

location where the ionizer is operated.

Occasional cleaning of the ionizer housing may be accomplished with a clean cloth

moistened with common glass cleaning solution.

The recommended emitter cleaning procedure is as follows:

1. Turn the ionizer off by disconnecting it from the electrical power source.

2. Simco-Ion recommends using the ITW-TEXWIPE model TX726, Crush Tube

product for cleaning the emitter electrodes. (Follow ITW-TEXWIPE product

instructions) A substitute method consists of a cleanroom swab saturated in a

cleaning solution of isopropyl alcohol and de-ionized water.

3. Prepare the Crush Tube or swab for use. Insert it directly onto the point of the

electrode (CAUTION: SHARP PINS, AVOID CONTACT), rotate slowly,

and withdraw. Repeat this process until all visible deposited material has been

removed.

4. Allow cleaning solution to dry completely before returning the ionizer to

service.

9

Ioncell 5201128 Rev. D

6. PARTS AND ACCESSORIES

Parts Part Number

Standard Ioncell Ionizer Kit with Power Supply, includes items 1, 3 below 4017139

Standard Ioncell Ionizer Kit (no Power Supply), includes items 2, 3 below 4017140

In-line Ioncell Ionizer Kit with Power Supply, includes items 1, 3, 5 below 4015281

In-line Ioncell Ionizer Kit (no Power Supply), includes items 2, 3, 5 below 4015477

Accessories Part Number

Fan Assembly Kit (for Standard Ioncell) 5051983

6” Air Knife Applicator (for In-line Ioncell) 5051678

12” Air Knife Applicator (for In-line Ioncell) 5051679

6” Air Ring Applicator (for In-line Ioncell) 5051680

10” Air Ring Applicator (for In-line Ioncell) 5051681

Airflow Switch (for In-line Ioncell) 5051685

Item Replacement Parts Part Number

1Universal Power Supply with 72” [1830 mm] Line Cord 5051677

2Direct Power Cable, 72” [1830 mm] for user supplied 24VDC 5051688

3Ioncell Interconnect Cable, 36” [915 mm] 4520764

4Ioncell Interconnect Cable, 72” [1830 mm] 4520767

5Tubing and Splitter Kit, for In-line Ioncell 5051683

6Tungsten Electrode Replacement Kit 5051288

10

Ioncell 5201128 Rev. D

9. WARRANTY AND SERVICE

This product has been carefully tested at the factory and is warranted to be free from

any defects in materials or workmanship. Simco Ion will, under this warranty, repair

or replace any equipment which proves, upon our examination, to have become

defective within one year from the date of purchase.

The equipment being returned under warranty should be shipped by the purchaser

to Simco-Ion, 2257 North Penn Road, Hatfield, PA 19440, transportation prepaid

and insured for its replacement cost. Prior to returning any goods for any reason,

contact Simco-Ion Customer Service at 215-822-6401 for a Return Authorization

Number (RMA). This number must accompany all returned items.

This warranty does not apply when the equipment has been tampered with, misused,

improperly installed, altered, has received damage through abuse, carelessness,

accident, connection to improper line voltage, or has been serviced by anyone other

than an authorized factory representative.

The warranty does not apply when Simco-Ion parts and equipment have been

energized by other than the appropriate Simco-Ion power supply or generator,

or when a Simco-Ion power supply or generator has been used to energize other

than Simco-Ion parts and equipment. Simco-Ion makes no warranty, expressed or

implied, nor accepts any obligation, liabilities, or responsibility in connection with

the use of this product other than the repair or replacement of parts stated herein.

Information in this publication supersedes that in all previous published material.

Specifications are subject to change without notice.

Simco-Ion

2257 North Penn Road

Hatfield, PA 19440

(215) 822-6401

(800) 203-3419

www.simco-ion.com

© 2020 Simco-Ion. Printed in the U.S.A.

Table of contents

Other Simco-Ion Air Ionizer manuals