DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Website: Desco.com

TB-2016 Page 2 of 5 © 2012 DESCO INDUSTRIES, INC.

Employee Owned

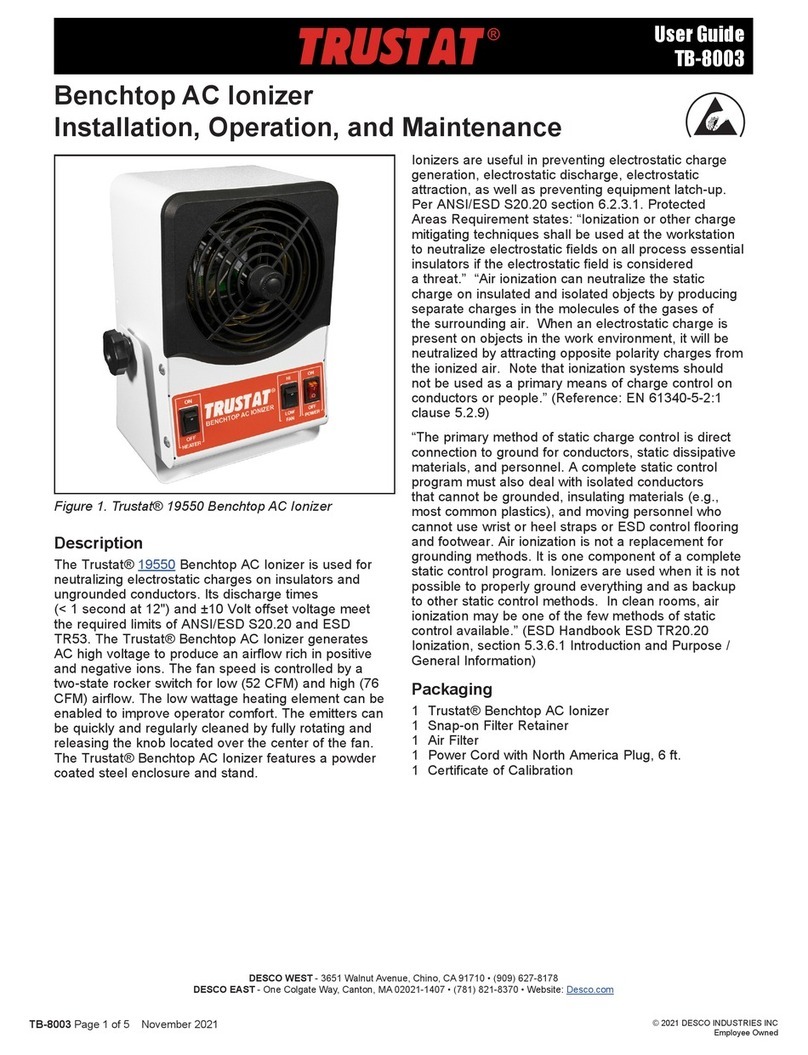

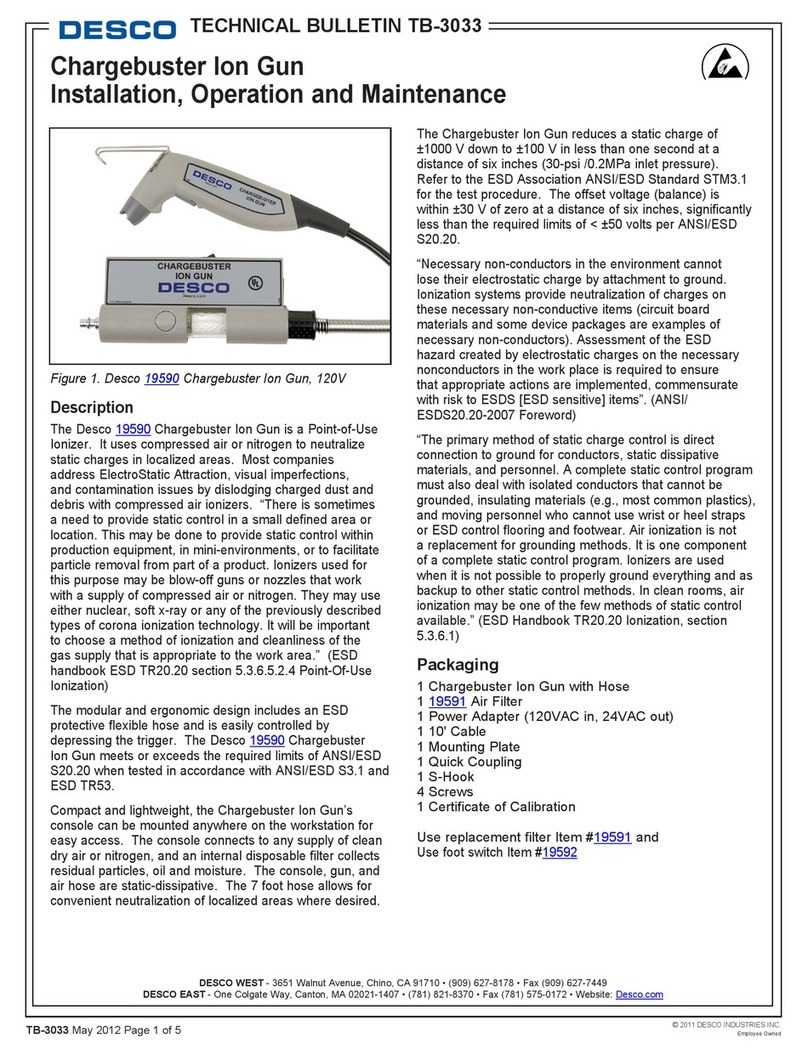

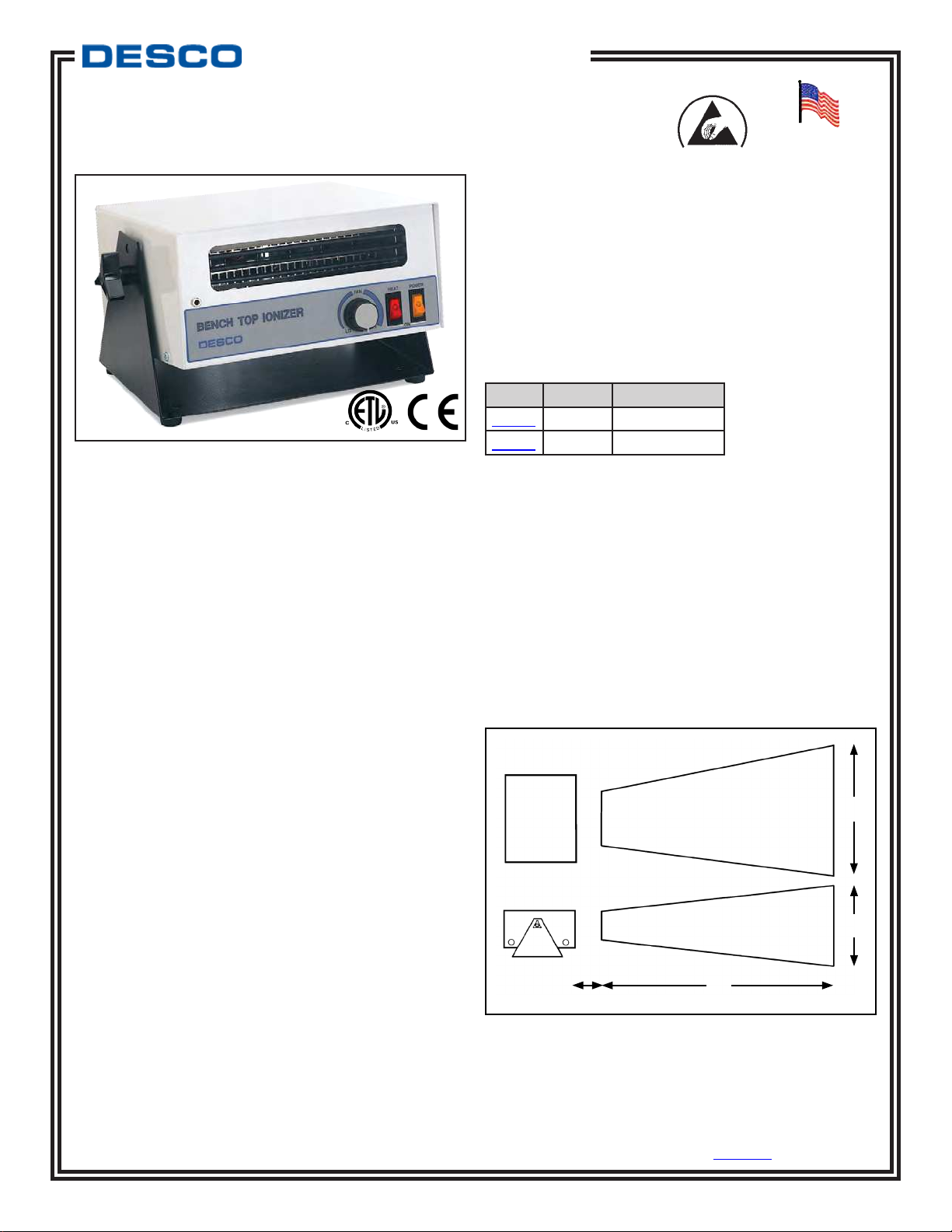

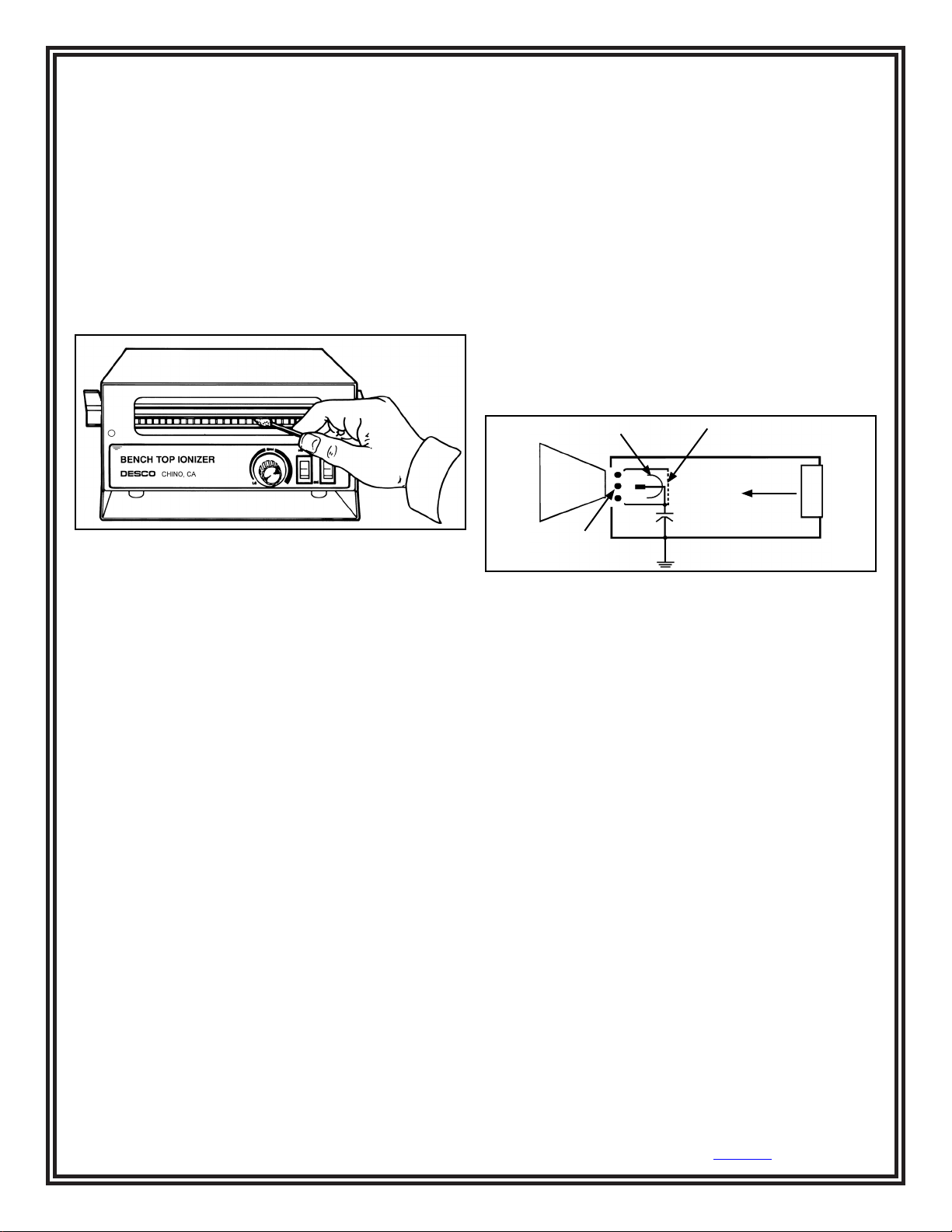

Mount the unit in the desired position. You can bolt the

stand to a wall or under a shelf as desired. For best results,

the unit should be mounted so that no obstructions exist

between the output area and the area to be neutralized.

of the technical requirements that are incorporated into

the ESD program plan.” And section 6.1.3.2. Compliance

Verification Plan Guidance states: “In addition to internal

audits, external audits (Organization and supplier of ESDS

items) should be performed to ensure compliance with

planned requirements. Verifications should include routine

checks of the Technical Requirements in the Plan. The

frequency of verification checks should be based on the

control item usage, its durability and associated risk of

failure.”

Under normal conditions, the ionizer will attract and

accumulate dirt and dust (especially on the emitter

electrodes). To maintain optimum performance, cleaning

must be performed on a regular basis. The electrodes

should be cleaned at least as often as indicated in the next

section. However, more frequent cleaning may be required if

used in environments with more contaminants.

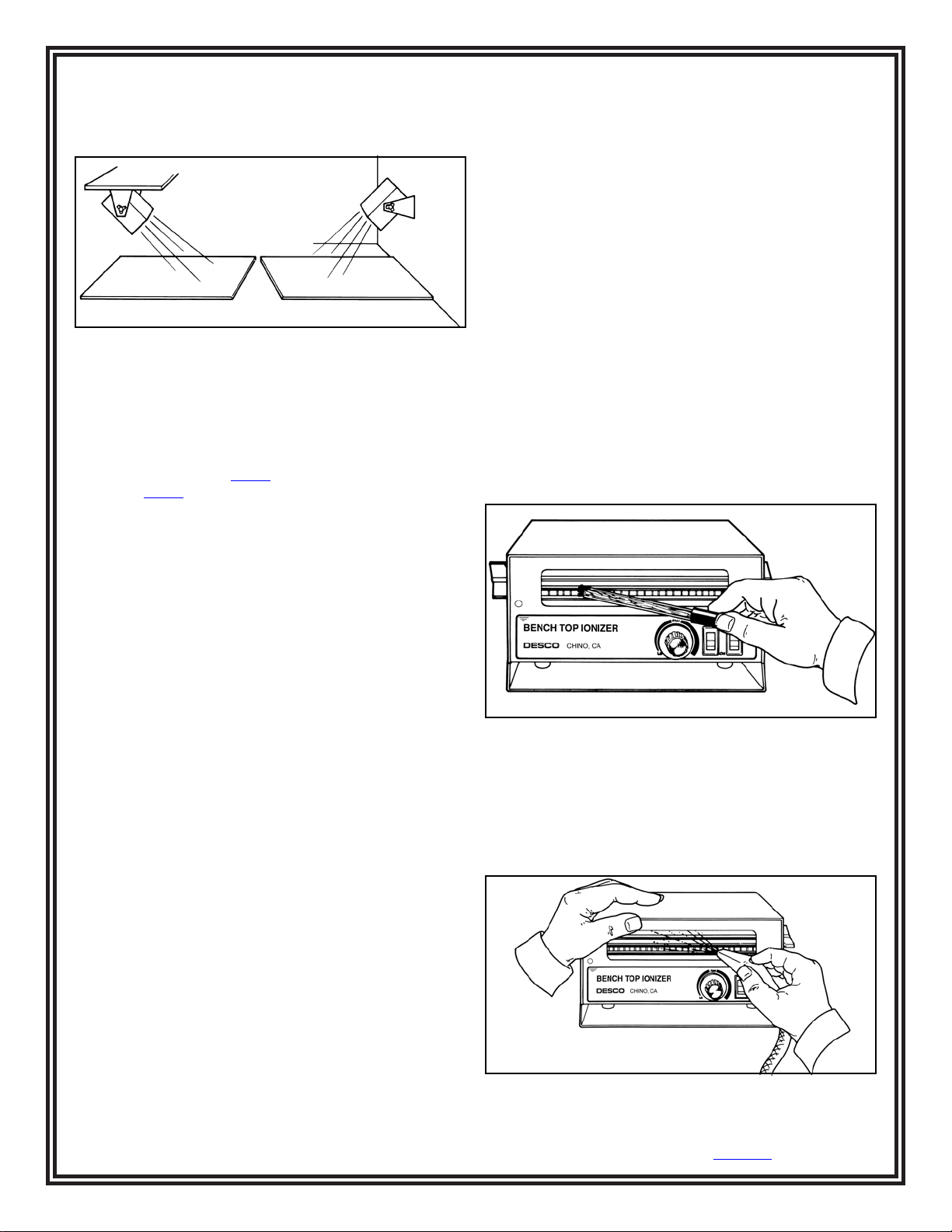

METHOD 1 (Every 6 months)

The Bench Top Blower Ionizer comes with an easy-cleaning

brush which should be stored in a convenient location.

Disconnect power to the ionizer. Then slide the brush

through the grill and across the electrodes several times to

remove the dirt and dust.

Figure 3. Wall or shelf mounting of the ionizer

Set both front panel rocker switches in the “off” position.

Connect the IEC plug into the connector on the back panel

of the ionizer, press firmly to ensure that the cord is properly

attached. Install the power cord into a properly grounded

outlet. The ionizer must be grounded for proper operation.

Desco recommends the 19219 Ground Hub Continuous

Monitor or 98130 AC Outlet Analyzer to check the ground.

Operation

Turn on the power switch and adjust fan speed for the

desired air flow. Higher air flow will result in a faster

neutralization rate.

Aim the unit so that the maximum airflow is directed at the

items or area to be neutralized.

The left rocker switch turns on a heater which will raise the

temperature of the output air to about 10°F above ambient.

The heater is only to offset the chill factor of the moving air.

It is not intended to warm the workstation.

If the ionizer is used in a manner not specified by the

manufacturer, the protection provided by the ionizer may be

impaired.

Maintenance

“As with all ionizers, periodic maintenance will be needed

to provide optimum performance.” (Reference: IEC

61340-5-2:1 paragraph 5.2.9).

The frequency of monitoring ionizers really depends on how

and where they are used. Since the majority of them use a

fan to transport the ions to the working area, the cleanliness

of the air directly affects their performance over time and how

often the emitters should be cleaned.

EIA-625 recommends checking ionizers every 6 months, but

this may not be suitable for many programs particularly since

an out-of-balance may exist for months before it is checked

again. ANSI/ESD S20.20 section 6.1.3.1 Compliance

Verification Plan Requirement states: “Test equipment shall

be selected to make measurements of appropriate properties

Figure 4. Cleaning the electrodes (method 1)

METHOD 2 (Annually)

To remove heavier accumulations of dirt and dust, use clean,

compressed air. Disconnect power to the ionizer. With

one hand firmly on top of the ionizer, aim com pressed air

through the front grill, directly at the pins. A few passes back

and forth with the nozzle is sufficient.

Figure 5. Cleaning the electrodes (method 2)