HAWE Hydraulik IEP 014-CP User manual

Battery pack type IEP

Assembly instructions

(Translation of the original instructions)

B 6130

02-2022-1.0en

Ident. No.: IEP 014-CP

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorization is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

HAWE Hydraulik cannot provide individual guarantees that the stated circuits or procedures (including in part) are not subject to the

intellectual property rights of third parties.

Printing date / document generated on: 09.03.2022

2/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

Table of Contents

1 About these instructions.................................................................................................................................. 4

1.1 Target audience................................................................................................................................................. 4

1.2 Safety instructions and symbols...........................................................................................................................4

1.3 Applicable documents.........................................................................................................................................6

2 For your safety................................................................................................................................................ 7

2.1 Intended use.....................................................................................................................................................7

2.2 Misuse.............................................................................................................................................................. 7

2.3 Residual risks.................................................................................................................................................... 7

2.4 Duties of the operator........................................................................................................................................8

2.5 Qualification of the personnel............................................................................................................................. 8

2.6 Personal protective equipment.............................................................................................................................9

3 About this product......................................................................................................................................... 10

3.1 Markings..........................................................................................................................................................10

3.2 Structure......................................................................................................................................................... 11

3.3 Functions........................................................................................................................................................ 12

3.4 Control............................................................................................................................................................14

3.5 Connector assignment....................................................................................................................................... 15

3.6 Number of cycles............................................................................................................................................. 15

4 Transport and storage..................................................................................................................................... 16

4.1 Transport equipment......................................................................................................................................... 16

4.2 Scope of delivery............................................................................................................................................. 16

4.3 Checking the delivery........................................................................................................................................17

4.4 Storage........................................................................................................................................................... 17

5 Assembly and installation...............................................................................................................................18

5.1 Electrical connection........................................................................................................................................ 18

6 Start-up......................................................................................................................................................... 20

6.1 Safety devices and performance limitations..........................................................................................................21

7 Operation....................................................................................................................................................... 23

8 Maintenance...................................................................................................................................................25

8.1 Maintenance plan............................................................................................................................................. 26

9 Disassembly and disposal................................................................................................................................27

10 Troubleshooting..............................................................................................................................................29

11 Appendix........................................................................................................................................................35

11.1 General data.................................................................................................................................................... 35

11.2 Weight............................................................................................................................................................ 35

11.3 Electrical data..................................................................................................................................................36

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 3/39

1About these instructions

This manual is part of the product and describes the safe and proper use in all operating phases.

All photos and drawings in this manual show an available product variant. For precise details concerning

the variant you have purchased, please refer to the type plate attached to the product.

Read instructions before use.

Make the manual accessible to operating and maintenance personnel at all times.

Keep this manual for the lifetime of the product.

Only pass on the product to third parties together with this manual.

1.1 Target audience

The target audience of this manual is trained and qualied personnel who are familiar with the installa-

tion, operation and maintenance of machines.

The manual provides relevant information for the machine manufacturer and machine operator as well as

for training courses.

You can request further information on the product at: HAWE Hydraulik SE, Einsteinring 17, 85609

Aschheim/Munich, Germany.

1.2 Safety instructions and symbols

Safety indication In these instructions, the following warning and safety notes are used:

Symbol Meaning

DANGER

Draws your attention to a hazardous situation that can lead directly to

serious injury or death if not avoided.

WARNING

Draws your attention to a hazardous situation that can indirectly lead to

serious injury or death if not avoided.

CAUTION

Draws your attention to a hazardous situation that can indirectly lead to

light to moderate injury if not avoided.

Notice to prevent environmental and material damage.

Information to ensure the correct use of the product.

4/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

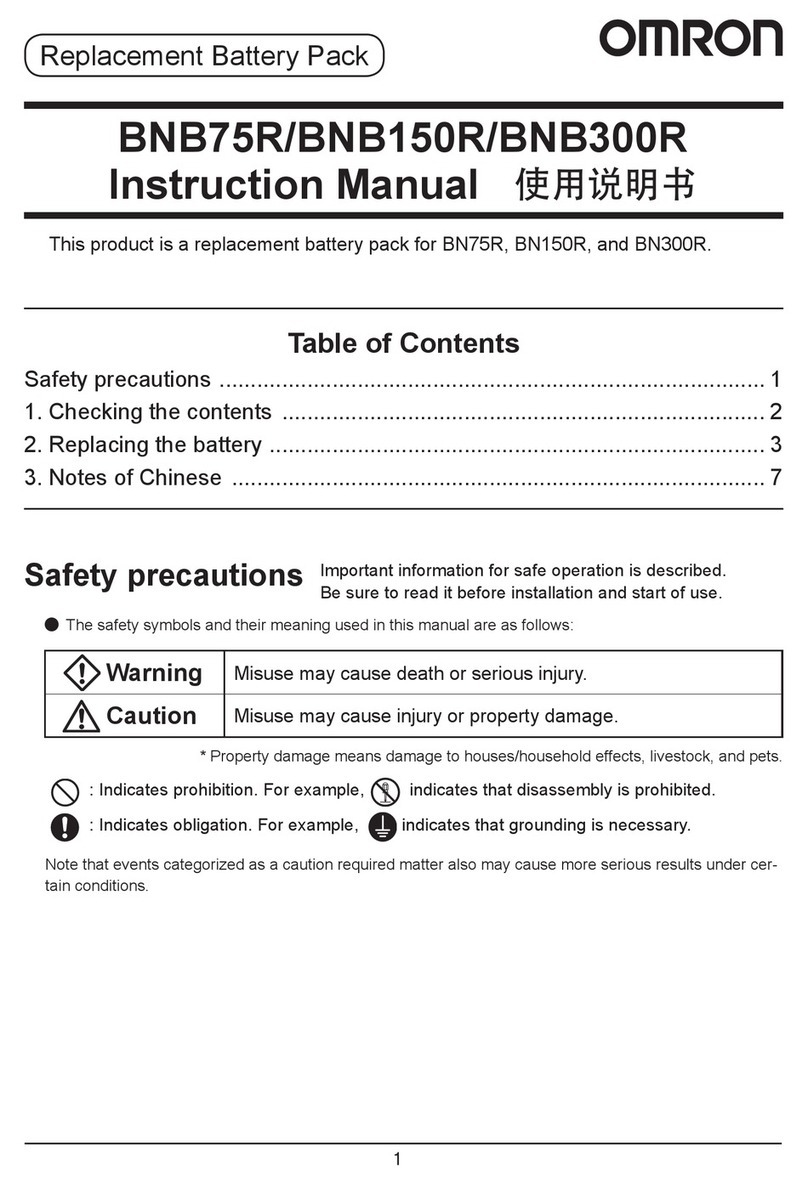

Safety symbols General safety symbol

Draws your attention to additional safety information.

Slipping hazard Dragging hazard from

moving parts

Harmful substances Tripping and falling

hazard

Fire accelerants Falling loads

Burn hazard Crushing hazard

Electrical voltage Suspended loads

No access to persons

with pacemakers and

defibrillators

Mandatory signs Protective equipment

Safety boots

Wear appropriate safety boots to protect your feet against mechanical

hazards

Work gloves

Wear suitable work gloves to protect your hands against chemical and

mechanical hazards.

Safety goggles

Wear safety goggles to protect your eyes against chemical and mechanical

hazards.

Protective clothing

Wear tted clothing without protruding parts.

Follow the safety data sheet of the hydraulic uid.

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 5/39

1.3 Applicable documents

Standards Designation

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

The protective objectives of DIRECTIVE 2014/30/EU are achieved by explicit

application of EN 60204-1, section 4.4.2 Electromagnetic Compatibility

(EMC).

Documents

D 6130 Data sheet battery pack type IEP

6/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

2For your safety

The product is built according to the state of the art and recognized safety regulations.

Nevertheless, there is a risk of personal injury and damage to property if this chapter and the safety

instructions in this manual are not observed.

2.1 Intended use

■The product is a technical work tool and intended for commercial and industrial use only.

■The product may only be operated in accordance with the technical data, operating conditions and

performance limits specied in this manual.

■Only use original accessories and original spare parts approved by the manufacturer.

■Temperature range: Charging: 0 to 40°C

■Temperature range: Discharging: -10 to 45°C

■Suitable for operation up to 2000 m above sea level

■Use of the product in environments with intensive electrostatic elds and where strong electromag-

netic procedures are present, or in the immediate vicinity of parts and parts at high voltages must be

avoided.

■The product satises protection class IP65, exclusively when the main connector is connected or

engaged.

Electronic product

The product must not be commissioned by the machine manufacturer unless the higher-level

machine/system complies with the requirements of the applicable Machinery and EMC Directives.

2.2 Misuse

■Use in other operating modes than specied in the intended use

■Using the product beyond the specied performance limits

■Use of the product in potentially explosive atmospheres and in the presence of highly ammable

substances/media is prohibited.

2.3 Residual risks

WARNING

Danger of death due to explosion or re in the system or the device.

If a lithium-ion battery catches re, the re can spread in an explosive manner, with highly hazardous

potential. This can lead to fumes hazardous to health, to severe injuries or death.

Move away from the device or the re.

Call the re brigade and tell them the incident concerns a lithium-ion battery.

Provide re extinguishers with a high cooling effect.

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 7/39

WARNING

Electrical and magnetic elds

Consumers connected to the battery can generate electrical and magnetic elds. These elds affect the

operation of heart pacemakers and implanted defibrillators.

Wearers of heart pacemakers and implanted defibrillators must maintain a sufcient distance from

magnets.

Wearers of such devices must be warned against approaching too closely to magnets.

Block off the area around the drive system, and provide suitable warning signs on the barriers.

CAUTION

Health hazard due to contact with vapours from damaged batteries.

Poisonous vapours can be released if the battery pack (battery) is damaged. Contact with skin, eyes and

mucous membranes can lead to irritation.

Wear personal protective equipment (safety glasses, gloves, mouth protection).

In the event of contact, thoroughly wash the affected body parts with water.

Call a doctor.

2.4 Duties of the operator

Observe and comply with regulations:

The product must not be commissioned until the complete higher-level machine or system complies

with the provisions, safety regulations and standards relevant in that country for the application.

Observe and apply regulations for accident prevention and environmental protection.

Assess and document the new dangers in the complete system’s manual.

Operate product safely:

Despite safety devices, the product still poses residual risks. Observe the safety instructions in this

manual to reduce health hazards and avoid dangerous situations.

The operating company must ensure the operating conditions (see the technical data) are within the

limits for use of the product.

Keep all instructions / signs on the product in legible condition and observe them.

Instruct personnel:

Regularly train the personnel in all points of these instructions and ensure that they are observed.

Ensure the terms of the industrial safety and operating instructions are observed.

Only use qualied personnel. Due to their training and experience, the qualied personnel must be

able to recognize risks and avoid possible hazards.

2.5 Qualification of the personnel

The activities described in this manual require comprehensive knowledge of the mechanical and electrical

aspects.

For transport and handling of heavy loads, additional knowledge of lifting gear and slings is necessary.

The activities may be performed only by an appropriately qualied person or by a person under

instruction under the supervision of a qualied person.

Other activities described in this manual may be performed only by HAWE or by authorised specialist

companies.

The personnel must have read and understood this manual.

8/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

Trained personnel Personnel instructed comprehensively, by skilled staff on behalf of the owner, in how to perform its

appointed tasks and in how to use the product safely.

Specialist personnel Due to their technical training, knowledge and experience, specialists are able to assess and carry out the

assigned work and can independently recognize possible dangers.

Qualied electrician A person with appropriate professional training, knowledge and experience, so that he/she can recognize

and avoid dangers that can be caused by electricity.

Auditor Persons of a technical inspection body who are authorized to perform testing and monitoring tasks for

pressure equipment and electrical systems.

2.6 Personal protective equipment

Personal protective equipment is designed to prevent and reduce hazards.

In the instructions, safety instructions with mandatory symbols indicate the wearing of special

protective equipment for special activities.

Instruction and supply is carried out by the operator.

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 9/39

3About this product

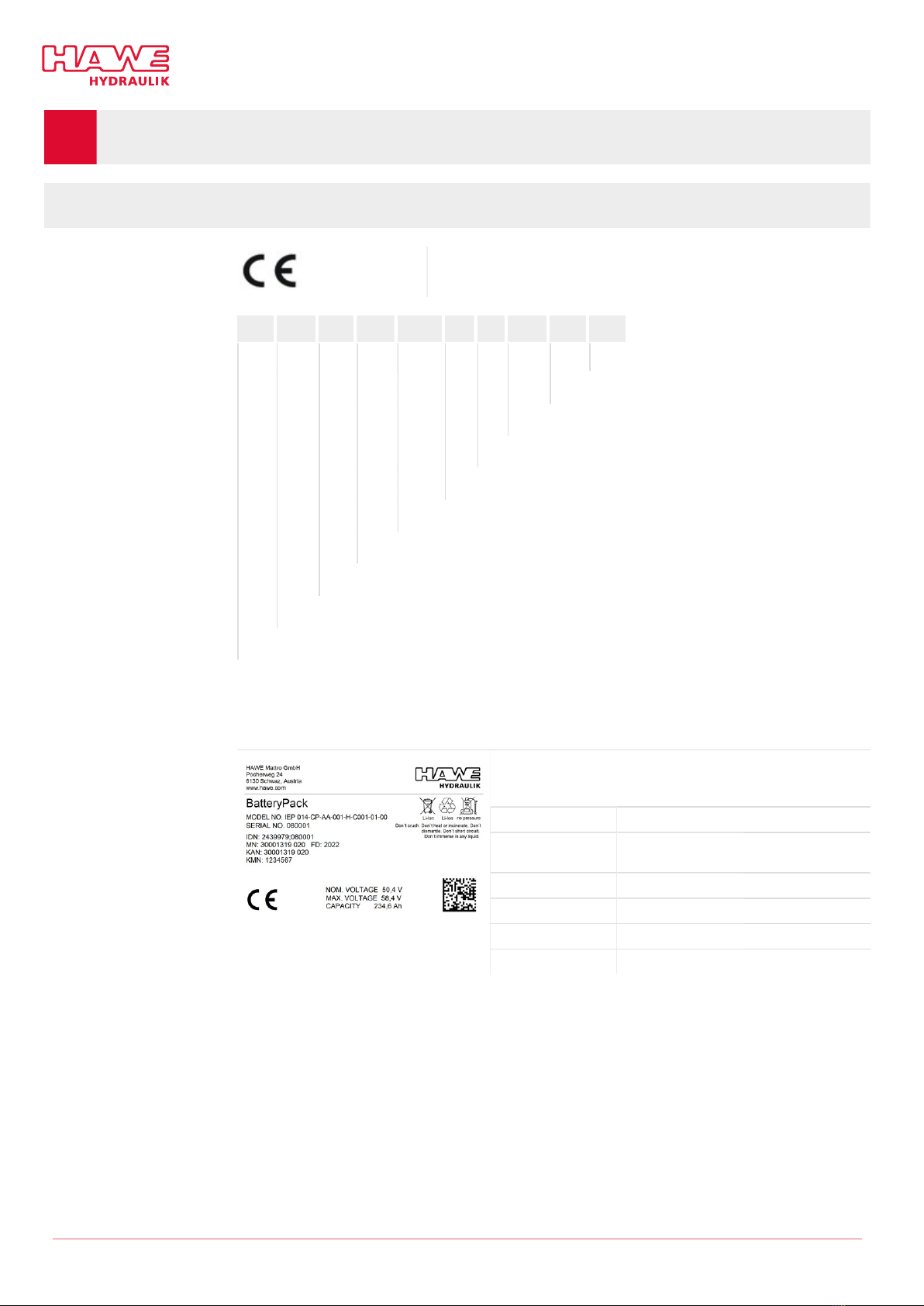

3.1 Markings

Device labelling CE mark

The CE mark can be found on the type plate

Order coding IEP 014 -CP -AA -001 -H -C 001 -01 -00

Mechanical auxiliary functions

Electrical auxiliary functions

BMS parameter set

BMS type

Heat management

Housing type including plug

Cell type

Cell configuration

Cells in series (nominal voltage)

Basic type

Order coding IEP

The order coding can be found on the type plate

Type plate

The type plate with the manufacturer’s contact data carries the

following data on the handle side:

Model No Order coding

Serial No Serial No (also stamped on to the top face

of the front cover)

IDN Identification number

MN Material number

KAN Customer order number

KMN Customer material number

10/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

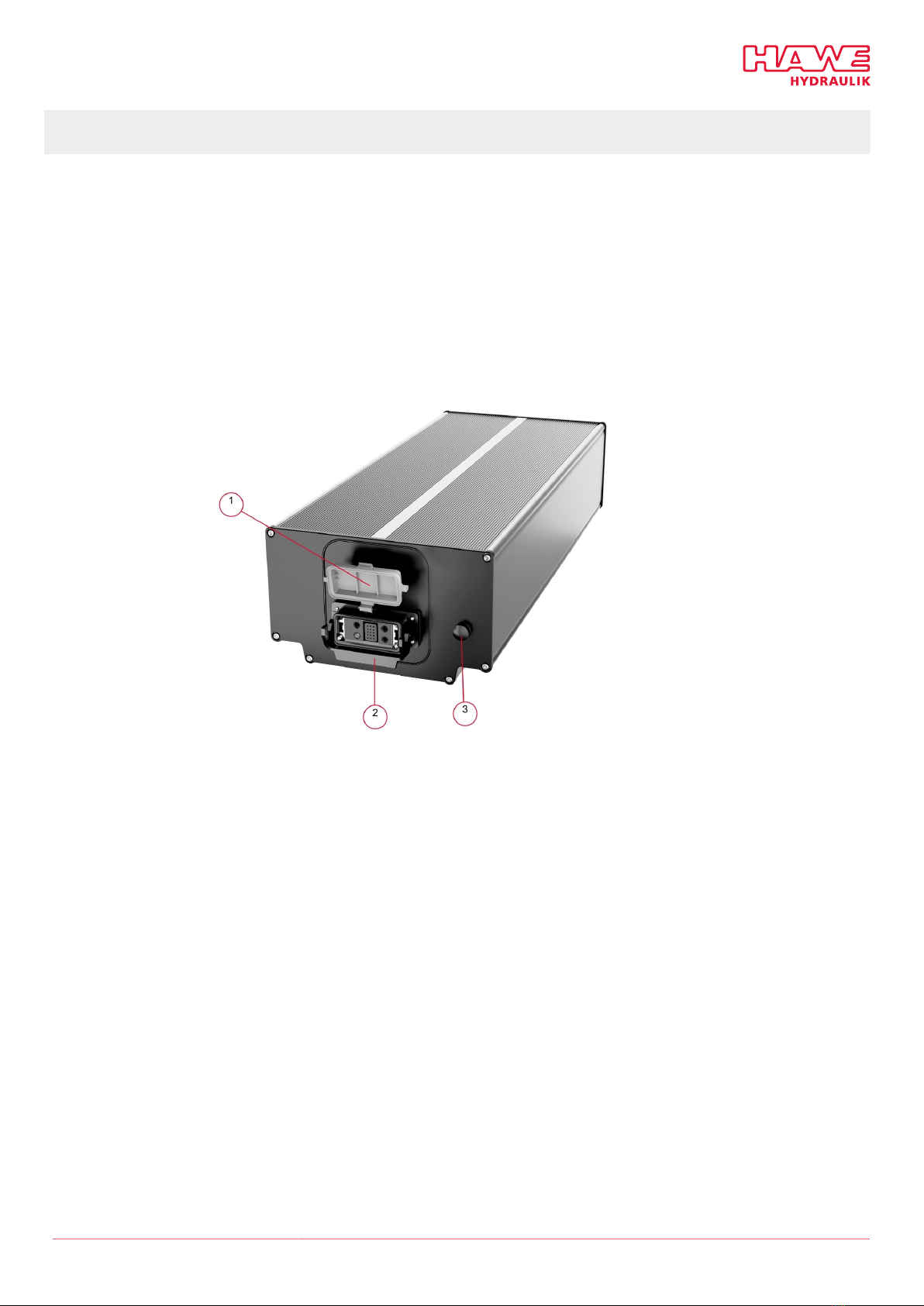

3.2 Structure

The energy pack type IEP consists of linked-up lithium ion cells. The integrated battery management

system (BMS) continuously monitors the battery’s condition. This protects the battery from excessive

charge and deep discharge, excessive or insufficient temperature and excessive current. It performs

balancing and optimises the battery’s service life.

The product is available in the following versions:

■IEP 014-CP

The product satises protection class IP65, exclusively when the main connector is connected or

engaged.

1Cover of the main connector

2Locking clip

3Pressure equalisation membrane

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 11/39

Assemblies of the IEP This block diagram shows the principal assemblies of the battery pack.

1Integral pre-charge

2Relay monitoring

3Current monitoring

4Temperature monitoring

5Integral heater

6Cell balancing

7SOC calculation

8CAN interface

9Short circuit protection (fuse)

10 Lithium-ion cells

11 Inputs

12 Main connector

3.3 Functions

Integrated precharge Precharge: The BAT+ relay is bridged with a 2Ω resistance. This produces current ow charging the

capacitors in the connected consumers, e.g. an inverter. When current ow undershoots the preset

maximum at the end of the precharge phase, the BAT+ relay closes and precharging ends.

Default parameters

■Precharge time: 0.65 s

■Current at end of precharge time: < 2 A

These parameters may be changed without notice during series production or be changed to match

customer requirements.

DAMAGE

■The lower the current at the end of the precharge time, the lower also the wear on the relay contacts.

■No more than 10 precharge operations may be performed or attempted within 10 minutes.

Two factors affect residual current at the end of the precharge time:

1. The connected capacity value. Experience has shown that the precharge facility’s design can handle

the reasonably expectable capacities.

2. Continuous current IDC at the end of the precharge time.

12/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

Typical causes for IDC

■Consumers that are already attempting to supply power during precharging, e.g. DC/DC converters. In

this case, DS/DC converter power-up needs to be delayed so that it does not supply power until after

precharging has nished (e.g. via ‘enable pin’).

■Consumers with significant input capacities feature bleeder resistors (discharge resistors) that ensure

input capacities are discharged when switched off. Their resistances are typically within the low kΩ

range. Parallel circuits with multiple consumers will often result in significantly higher IDC.

Voltage monitoring The integral Battery Management System (BMS) monitors the voltage of the battery pack. If this

detects hazardous over-voltage or under-voltage it switches the pack off and outputs a corresponding

error report. It also switches the pack off if pre-dened or customer-specied charging or discharging

conditions are detected. This is part of normal operation and no error report is output. To avoid undue

wear of the relay contacts, the user must however congure his control system so that switching off

under load does not occur in the regular course of events.

Relay monitoring The status of the HV switch-off (relay) is monitored. This enables detection of any statuses incorrectly

closed (such as relay contacts welded) and statuses incorrectly open (such as a cable break in the relay

supply cable, lack of a vehicle-side safety bridge).

Current monitoring The integral current sensor (Hall sensor) measures the charging currents and discharging currents within

the system. The values are evaluated in the Battery Management System (BMS).

Temperature monitoring There are a total of 4 temperature sensors (NTC 10K) within the housing of the battery pack, these

are distributed uniformly within the installation area. The sensors are evaluated by the BMS. If the

temperatures measured lie outside the permitted limit values, the BMS triggers the opening of the main

contactor, thereby preventing the ow of current into the battery or from it.

Integral heater The battery incorporates an electric heater. When the battery pack is at a low temperature (below 5°C)

this serves to bring the temperature up to a level at which the data sheet species that the cells can be

charged or discharged.

The heater is active in the following modes:

■Drive

■Charge

■Heater request via CAN

As soon as the battery is active (ignition/CAN) the heater is automatically activated by the BMS.

As soon as the lowest temperature that is measured is found to be below 7°C, the heater is switched on.

It remains on until the lowest temperature that is measured reaches 9°C. The heater is also deactivated

if the difference between temperature readings received from the sensors is greater than 9°C.

The heating request via the CAN bus takes no account of the switch-off temperature, so it is the user

who must comply with the above limits. A switch-off is also performed at high differences in tempera-

ture or excess temperature of the overall battery pack. In addition there is a passive switch-off system

fully independent of the electronics. This is triggered if the heater is switched on at a temperature that

is too high. This system is self-resetting, but after its initial activation it changes its characteristics and

becomes "too sensitive".

To restore normal functionality of the heater, there is no other option than servicing the battery pack.

The use of the associated chargers in an under-temperature situation merely compensates the current

consumption of the heater. This allows the battery pack to be "pre-heated” until normal charging can be

performed.

Cell balancing The Battery Management System (BMS) performs passive cell balancing.

SOC calculation The Battery Management System (BMS) has an integral SOC calculation. This allows the charge status of

the battery to be read via the CAN bus.

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 13/39

CAN interface Communication with the BMS is performed via the CAN bus. All the relevant data can be viewed. For

this see the CAN matrix which is provided in a separate document. Where a battery pack is connected in

parallel, we recommend a combination of terminal 15 and the CAN wake-up. This ensures that the CAN

and the BMS can communicate with each other and operate without problems.

3.4 Control

Central control system and

software

The control system for the superordinate machine is handled by the machine manufacturer. The machine

manufacturer must determine the operating modes for safe operation.

All required safety barriers, safety functions and safety controls must be put in place by the

superordinate machine’s manufacturer.

It remains the duty of the superordinate machine’s manufacturer to ensure that the product is

properly used in and approved for the overall system, the customer's environment and the target

market.

Make sure that the superordinate system/machine can perform the following functions and supplement

them in accordance with your own risk assessment:

■The technical data specifications in the data sheets must be complied with.

■Load circuit faults cannot trigger any hazard and can be safely rectied.

■Load circuit power supply failure will not result in danger.

■The battery does not feature integrated insulation monitoring (IMD). Should such be required for

safety engineering reasons or legally, insulation monitoring will need to be implemented in the

superordinate system.

■Observe the technical requirements relating to the IP class, environmental conditions and impact on

EMC:

°It must be possible to galvanically isolate the superordinate machine from the mains by means of a

main switch in order to enable work on live parts.

°Install the device in a well-ventilated room that is not too small, to protect it from overheating.

°Protect the device from moisture and dripping and splashing water.

■It is impossible for people to reach into the electrical circuit’s danger zone.

14/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

3.5 Connector assignment

Connector assignment, voltage range of the start signal and electrical performance data are

detailed in the appendix under "Electrical data", page 36.

1Power module minus

2Signal module

3Power module plus

3.6 Number of cycles

The number of cycles (cycle life performance) is strongly dependent on the loading of the battery

and the conditions (temperature, charging currents and discharge currents) under which it is used. A

partial discharge of the battery reduces the loading and extends its service life, as does a partial charge.

Elevated temperatures and high currents have a negative effect on the cycle life performance.

■IEP 014-CP: Set to 3.98V per cell. This guarantees a higher number of cycles. If desired the charge

cut-off voltage can be raised to 4.20V, which creates a penalty against the achievable number of

cycles.

The following values serve as indications. No more exact conclusion can be reached until the

relevant proles of load, charge and temperature prole can be tested at the battery for the

application in question.

Charge status (V/cell) Discharge cycles available stored energy in %

4,20 300 - 500 100

4,15 400 - 700 90 -95

4,10 600 - 1000 85 -90

4,05 850 - 1500 80 -85

4,00 1200 – 2000 70 -75

3,90 2400 – 4000 60 -65

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 15/39

4Transport and storage

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

CAUTION

Personal injury through tipping or falling load

The product might tip over or fall during transport. This could lead to hands and feet becoming trapped.

Adhere to the symbols on the packaging.

Use permitted transport aids to carefully transport the product as close to the installation location

as possible.

Select transport aids that will allow the maximum load to be transported safely.

Wear safety shoes, work gloves and safety glasses.

4.1 Transport equipment

DAMAGE

Danger for electronic components – electrostatic discharge – material damage

Deliver product in ESD protective packaging.

DAMAGE

Material damage due to mechanical damage

Protect the product against mechanical damage, e.g. by applying suitable padding.

such as foam, covers, cardboard

Only tested and approved aids are permitted for use.

4.2 Scope of delivery

The supply of the completely installed unit corresponds to the order coding listed on the order:

■Battery pack as ordered

■User manual

Optional

■3 kW charger (1-phase / 230 VAC)

■5 kW charger (3-phase / 400 VAC)

■Cables with mating connectors (tailor-made solutions)

■Energy cage (battery housing)

Not included in the scope

of delivery

■Accessories for commissioning

16/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

4.3 Checking the delivery

Unpacking 1. Take out the product.

2. Check that the product is complete and check for transport damage.

Note any transport damage on the transport documents or on the carrier's delivery note.

Take photos of any transport damage and show them to the manufacturer.

3. Dispose of the product packaging correctly in accordance with local regulations.

DAMAGE

Claim immediately for all defects at:

HAWE Mattro GmbH

Pocherweg 24

6130 Schwaz

Tel.: +43 5242 20904-0

Claims for damage can be accepted only if submitted within the applicable claim periods. HAWE cannot

accept liability for later claims.

4.4 Storage

DAMAGE

Property damage from incorrect storage

Incorrect storage can lead to damage. Refer to the technical data.

Store the product and its individual components as follows:

■Do not store outdoors.

■Store in an area that is dry and free of dust.

■Protect against sunlight (UV radiation). (dark)

■Storage temperature 0 to 20°C.

■Humidity (atmospheric humidity 50% or less)

■Protected against splashed water and dripping water.

■Do not store near sources of ignition or heat, aggressive media (e.g. acids, fuels or lubricants) or

ozone-producing sources of light (e.g. fluorescent light sources, mercury-vapour lamps).

■Do not place in the immediate vicinity of sources of heat (such as radiators)

■Place only in areas equipped with re alarms.

■Maintain the required safety clearance from ammable materials (at least 2.5m).

■Ensure the storage area is acceptable to the re brigade ofcer and the insurance company.

■Mark the storage area with appropriate notices.

■Prevent excessive cell voltage (during storage, the SOC of the battery must lie between 35 and 55%.)

■Avoid deep discharge. (Check the voltage and SOC of the battery 1x per month, more often if subject

to rapid discharging.)

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 17/39

5Assembly and installation

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

DAMAGE

Material damage due to mechanical damage

Protect the product from mechanical damage during assembly and installation, e.g. by padding.

5.1 Electrical connection

DANGER

Risk of fatal injury from electric shock

Touching live components directly or indirectly causes injury or death.

Electrical and electronic components must only be replaced and connected by trained specialist

personnel.

Obey all applicable electrical safety rules.

Only connect electric lines to the hydraulic system while the system is de-energized.

DANGER

Risk of injury due to electric shock from the operating capacitor

Burns, serious injuries or death may result if electromagnetic waves lead to functional interference with

the temperature measurement.

Ensure the operating capacitor is discharged to a safe voltage level.

WARNING

Electrical and magnetic elds

Electrical and magnetic elds impair the functionality of cardiac pacemakers and implanted defibrilla-

tors.

People with pacemakers or implanted defibrillators must maintain a sufcient distance from

magnets.

Advise people with pacemakers or implanted defibrillators against approaching magnets.

Cordon off the area around the drive system and afx suitable warning signs to the barriers.

18/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

DAMAGE

Hazard for electronic components – property damage

Electromagnetic waves lead to malfunctions of electrical or electronic equipment.

To prevent electrostatic discharge, do not touch electronic components and contacts.

After switching off the electrical power supply, wait at least 15 minutes for the energy stored in the

capacitors to dissipate.

Do not expose components to moisture and an aggressive environment.

To avoid overheating, always keep ventilation openings (if any) open and allow sufcient air

circulation.

This is to avoid electromagnetic waves leading to functional interference

Twist and shield the conductors.

Route intersections at right angles.

Connect the shield at only one end and close to the control system at ground potential.

Route control cables and power cables separately.

Leave a 10 to 20 cm gap between the control cables and power cables.

Provide separate shields for analogue and digital control lines.

Tool ■Voltage tester to EN 61243-3 of at least measurement category CAT III 600V to the standard ICE

61010-1.

■Always use suitable cables. Refer to DIN VDE 0276-1000 or the equivalent national regulations to

determine the current-carrying capacity of the power cables.

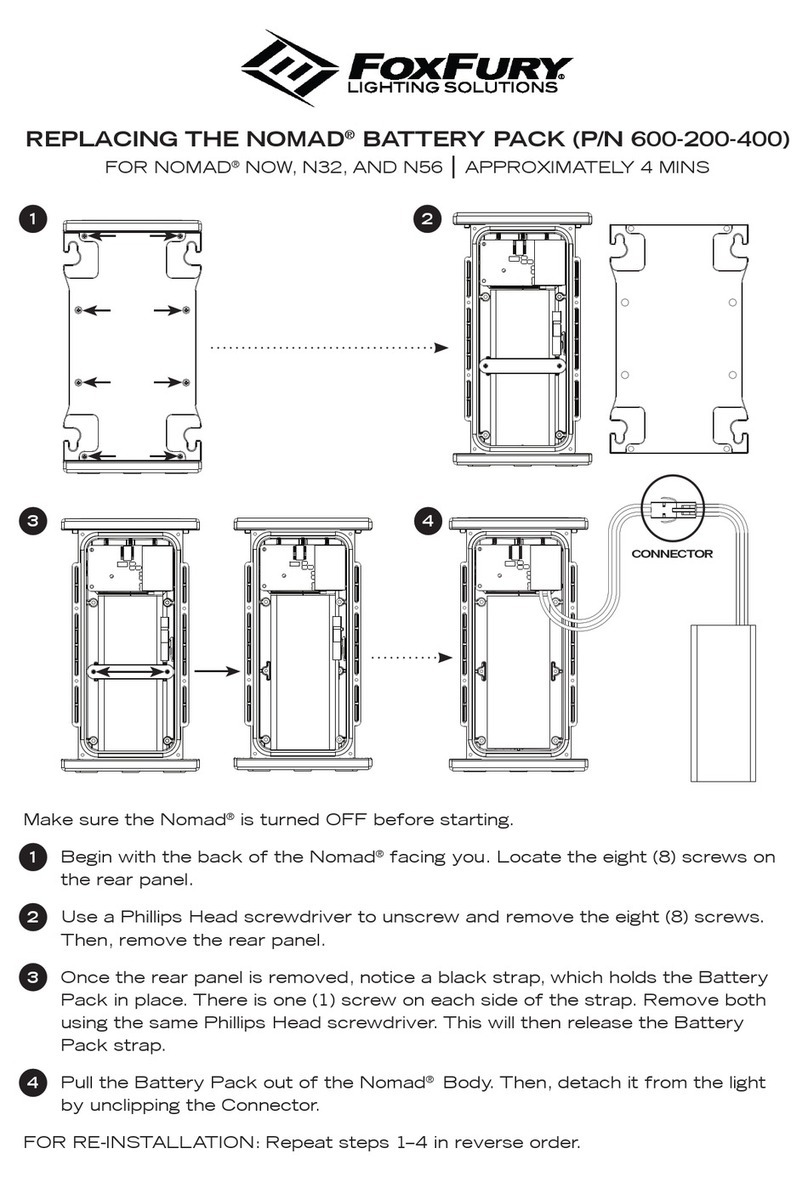

Electrical connection 1. Secure the unit against being switched on unintentionally.

2. Ensure that nobody is in the danger area.

3. Place the product in the higher-level machine, and secure it.

✓Make sure that when the battery pack is installed, the main connection of the battery pack does

not face upwards.

When replacing the battery

pack

1. Secure the unit against being switched on unintentionally.

2. Ensure that nobody is in the danger area.

3. Disconnect the main connection at the product.

4. Make the connection of the new battery pack as described in Electrical connection .

HAWE Hydraulik SE B 6130 - 02-2022 - 1.0en 19/39

6Start-up

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

CAUTION

Risk of re due to short circuit currents.

Touching live components, directly or indirectly, will cause injuries or death.

Electrical and electronic components must only be replaced and connected by trained specialist

personnel.

Comply with the relevant electrical safety regulations.

DAMAGE

Damage to equipment due to the EMC interference

Electromagnetic waves lead to malfunctions of electrical or electronic equipment.

To prevent this:

Twist and shield the conductors.

Route intersections at right angles.

Connect the shield at only one end and close to the control system at ground potential.

Route control cables and power cables separately.

Leave a 10 to 20 cm gap between the control cables and power cables.

Provide separate shields for analogue and digital control lines.

Only trained specialist personnel may perform commissioning.

The unit is secured against being switched on unintentionally.

1. Check the battery pack has been connected correctly:

✓Mechanical: Attachment to the higher-level machine, the frame and the base

✓Electrical: Wiring, power supply, control

✓Penetration of liquids into the device (for instance during installation work) must be prevent-

ed. (Penetration of liquids will lead to leakage currents or even outright short circuits, leading to

damage or destruction (by re) of the device.)

✓Cables must be sealed.

2. Set up the CAN interface. (page 21). Check

3. "Safety devices and performance limitations", page 21 .

20/39 B 6130 - 02-2022 - 1.0en HAWE Hydraulik SE

Table of contents

Popular Batteries Pack manuals by other brands

BYD

BYD Battery-Box C130 installation manual

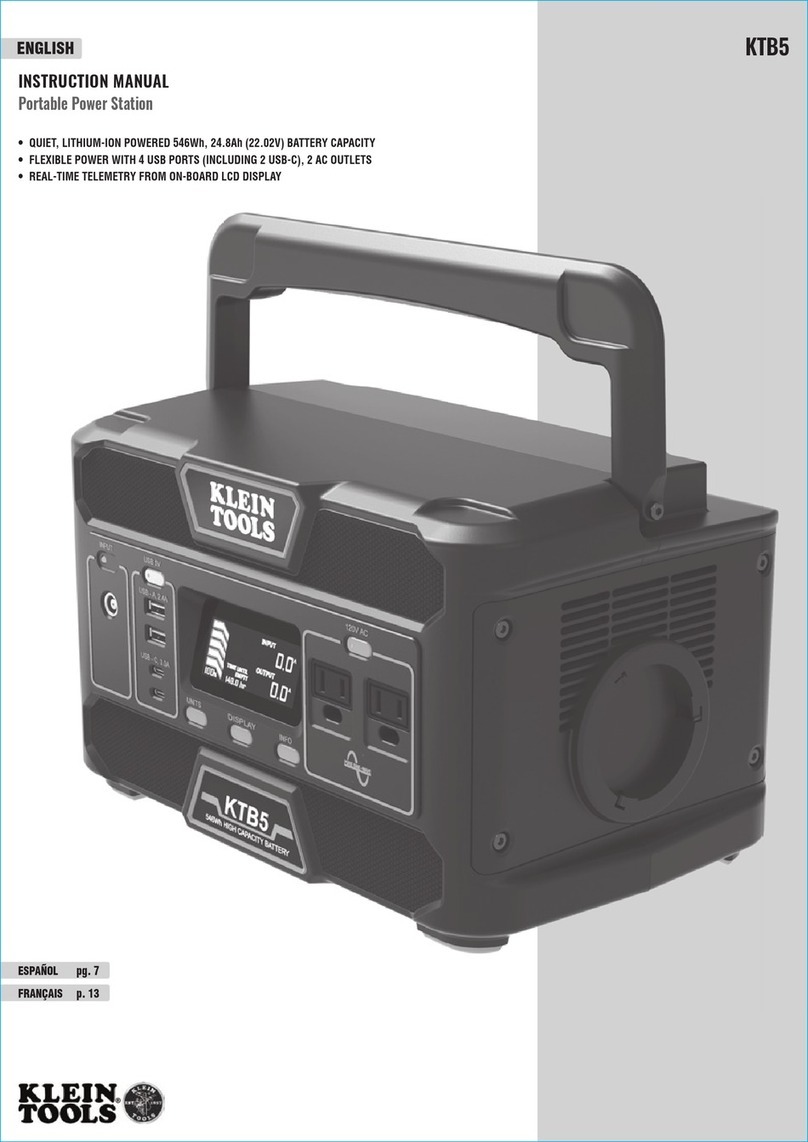

Klein Tools

Klein Tools KTB5 instruction manual

BYD

BYD Battery-Box Premium LVL 15.4 Service guidelines

Victron energy

Victron energy Lynx Ion BMS 400A manual

Kon-TEC

Kon-TEC KT-LFP1250 Operation and maintenance manual

C&D Technologies

C&D Technologies UPS12-100MR Maintenanse Instructions