HAWE Hydraulik DG 1 R User manual

Pressure switch type DG

Product documentation

D 5440

10-2020-1.1

Piston-type pressure switch

Operating pressure pmax: 00 bar

Pressure switch type DG

Product documentation

D 5440

10-2020-1.1

Piston-type pressure switch

Operating pressure pmax: 00 bar

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorisation is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

Printing date / document generated on: 04.11.2020

2/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

Contents

1 Overview of pressure switch type DG...................................................................................................................4

2 Available versions, main ata............................................................................................................................. 5

3 Parameters......................................................................................................................................................... 8

3.1 General and hydraulic........................................................................................................................................... 8

3.2 Electrical data....................................................................................................................................................10

4 Dimensions...................................................................................................................................................... 12

5 Assembly, operation an maintenance recommen ations.....................................................................................17

5.1 Intended use..................................................................................................................................................... 1

5.2 Assembly information......................................................................................................................................... 1

5.2.1 Preparing the base plate for DG 3........................................................................................................................ 1

5.3 Operating instructions.........................................................................................................................................18

5.4 Maintenance information..................................................................................................................................... 18

5.5 Adjustability and switching pressure.....................................................................................................................19

6 Other information.............................................................................................................................................20

6.1 Accessories, spare parts and separate components.................................................................................................. 20

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 3/21

1Overview of pressure switch type DG

Pressure switches open and close an electrical contact at a previously dened

pressure. As soon as the pressure is reached, a further work step is started or

stopped by an electrical signal.

Features an benets:

■Compact design

■Option of integration into the HAWE modular system

■Operating pressures up to 1000 bar

Inten e applications:

■General hydraulic systems

■Machine tools

Pressure switch type DG 1

Pressure switch type DG 3

4/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

2Available versions, main ata

Circuit symbol: DG 1 DG 3

Or er co ing example:

DG 1 RF

DG 33

DG 35

DG 34 M

- KB

V

- YS 8

300 F

Pressure setting (factory-set, optional), bar ■Series: setting with increasing pressure

■Coding F: setting with decreasing pressure

Hy raulic connection "Table 4"

A justment evices "Table 3"

Low-temperature seal congurable only with DG 35 -X. and DG 364 -X.

Their micro switches are installed with gold contacts.

Electrical connection "Table 2"

Basic type "Table 1"

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 5/21

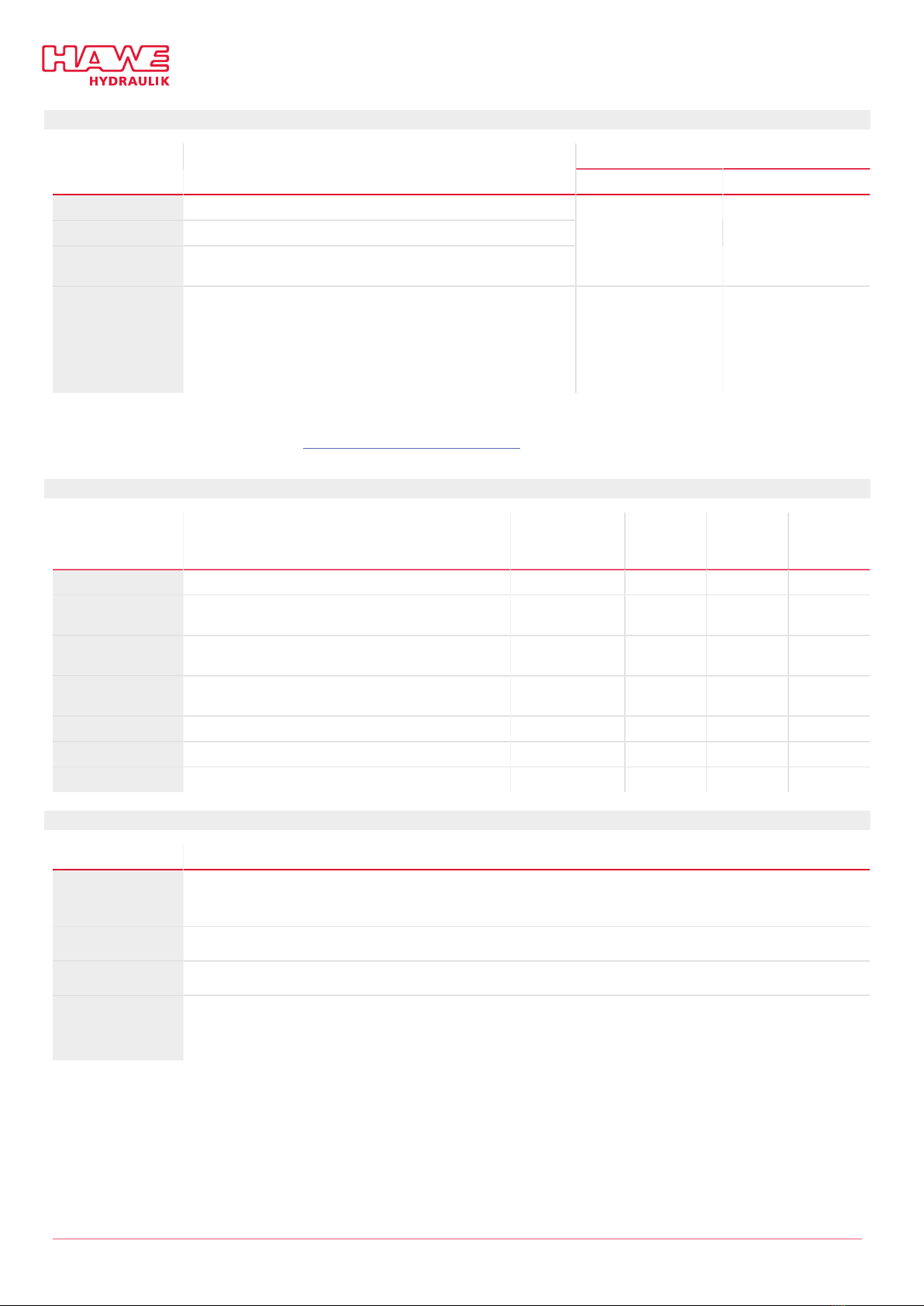

Table 1 Basic type

Pressure setting (range) (bar)Basic type Description

pmin–max pmax

DG 1 R Scale, pipe connection

DG 1 RF Scale, front ring for control panel installation, pipe connection

DG 1 RU

DG 1 RUFS Scale mounted with 180° rotation, for “suspended” installation

20 ... 600 600

DG 33

DG 34

DG 35 *

DG 36

DG 364 *

DG 365

Manifold mounting 200 to 00

100 ... 400

20 to 250

4 to 12

4 to 50

12 to 1 0

00

*DG 35 and DG 364 in version -X.-KB have different hydraulic data depending on the temperature.

For further information, please look at Chapter 3.1, "General and hydraulic".

Table 2 Electrical connection

Co ing Electrical connection Protection class

(IEC 60529)

DG 1 R

DG 1 RF

DG 1 RU

DG 1 RS

DG 1 RFS

DG 1 RUFS

DG 3

-- Terminal connection IP 54 o

-- Line connector

DIN EN 1 5 301-803 A

IP 65 o o

- X DIN EN 1 5 301-803 A

(without line connector)

IP 54 o

- X1 DIN EN 1 5 301-803 A

(without line connector)

IP 54 o

- AMP AMP Junior Timer IP 6 o

- S SCHLEMMER (bayonet PA 6) IP 6 o

- M M12x1 (in compliance with DESINA) IP 6 o

Table 3 A justment evices

Co ing Version

No esignation - Turn knob for DG 1 R(S), DG 1 RF(S)

- Adjusting screw for DG 3..

- DG 35.. - KB and DG 364..- KB with gold contacts only have an adjusting screw

Ronly DG 3.. : Adjustable by hand (wing bolt and wing nut)

Vonly DG 3.. : Turn knob

Honly DG 3.. : - Lockable turn knob (BKS lock)

- Key in line with factory specifications for the automotive industry; a key is included in the scope

of delivery (with an additional key held by authorised plant personnel).

6/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

Table 4 Hy raulic connection

Suitable for DG 1 R..

For combination with various ttings, see D 065

Co ing Connection type

Directly using a type-B pipe screw connection in accordance with DIN 3852-2

G 1/4 or G 1/2 A connection thread (ISO 228-1 (BSPP))

No esignation

With union nut DIN 16283 (pressure gauge screw tting, e.g. DIN 162 0)

Suitable for DG 3..

Co ing Connection type

No esignation Manifold mounting

- 1/4 Pipe connection G 1/4 (BSPP)

- Y1 Tapped journal G 1/4 A (BSPP)

- Y2 Tapped journal M12x1.5

- Y3 Tapped journal G 1/8 (BSPP)

- YS 6

- YS 8

Tapered cone #6 and #8 for a cutting ring and union nut

- Y6

- Y8

Pipe bracket #6 and #8 for a pipe screw connection

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 /21

3Parameters

3.1 General an hy raulic

Description Pressure switch

Design Spring-loaded piston-type pressure switch

Mo el Pipe connection, manifold mounting

Material DG 1: Galvanised steel housing

DG 3: Zinc die casting housing

Tightening torques See Chapter 4, "Dimensions"

Installation position DG 1 R.. = Vertical, sideways scale, hydraulic part at the bottom

DG 3.. = As desired

Hy raulic ui Hydraulic oil: according to part 1 to 3;

ISO VG 10 to 68 according to DIN ISO 3448

Viscosity limits: min. approx. 4, max. approx. 1500 mm2/s

opt. operation approx. 10... 500 mm2/s.

Also suitable for biologically degradable hydraulic uids type HEPG (polyalkylene glycol)

and HEES (synthetic ester) at operating temperatures up to approx. + 0°C.

Cleanliness level ISO 4406

21/18/15...19/1 /13

Temperatures Ambient: approx. -40 ... +80°C, Fluid: -25 ... +80°C, Note the viscosity range!

Start temperature: down to -40°C is permissible (observe start viscosities!),

as long as the steady-state temperature is at least 20K higher during subsequent operation.

Biologically degradable pressure uids: Observe manufacturer's specifications. By considera-

tion of the compatibility with seal material not over + 0°C.

Hy raulic ata of DG 35 -X.-KB an

DG 364 -X.-KB Temperature range -30°C < x < 0°C 0°C < x < 50°C

Speed of pressure change < 6 bar/s

DG 35 80 ... 250 bar 20 ... 250 barPressure setting pmin to pmax

DG 364 35 ... 50 bar 12 ... 50 bar

DG 35Maximum pressure pmax

DG 364 500 bar 500 bar

8/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

Weight

Type

DG 1 R.. = 1.3 kg

DG 33 = 0.3 kg

DG 34 = 0.3 kg

DG 35 = 0.3 kg

DG 36 = 0.3 kg

DG 364 = 0.3 kg

DG 365 = 0.3 kg

DG 3.. - 1/4 = 0.4 kg

DG 3.. - Y.. = 0.4 kg

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 9/21

3.2 Electrical ata

Switching operations/h Reference values approx. 2000 switching operations/h max. (roughly equally distributed).

Note the number of possible switching cycles; see below. Switching accuracy * 2 to 3%

(repeat accuracy for increasing pressure!)

DG 1 R

DG 1 RF

DG 1 RU

DG 1 RS

DG 1 RFS

DG 1 RUFS

DG 3. - X

DG 3. -S

DIN EN 1 5 301-803 ATerminal connection

Cable 3x0. 5

See also the product assembly

instructions

3-pole 3-pole

Electrical connection

DG 3. - AMP DG 3. - M DG 3. - X1

AMP Junior Timer DIN EN 1 5 301-803 A

4-pole 4-pole 3-pole

1+24 V

2PNP switching signal

3GND

4IO-Link

10/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

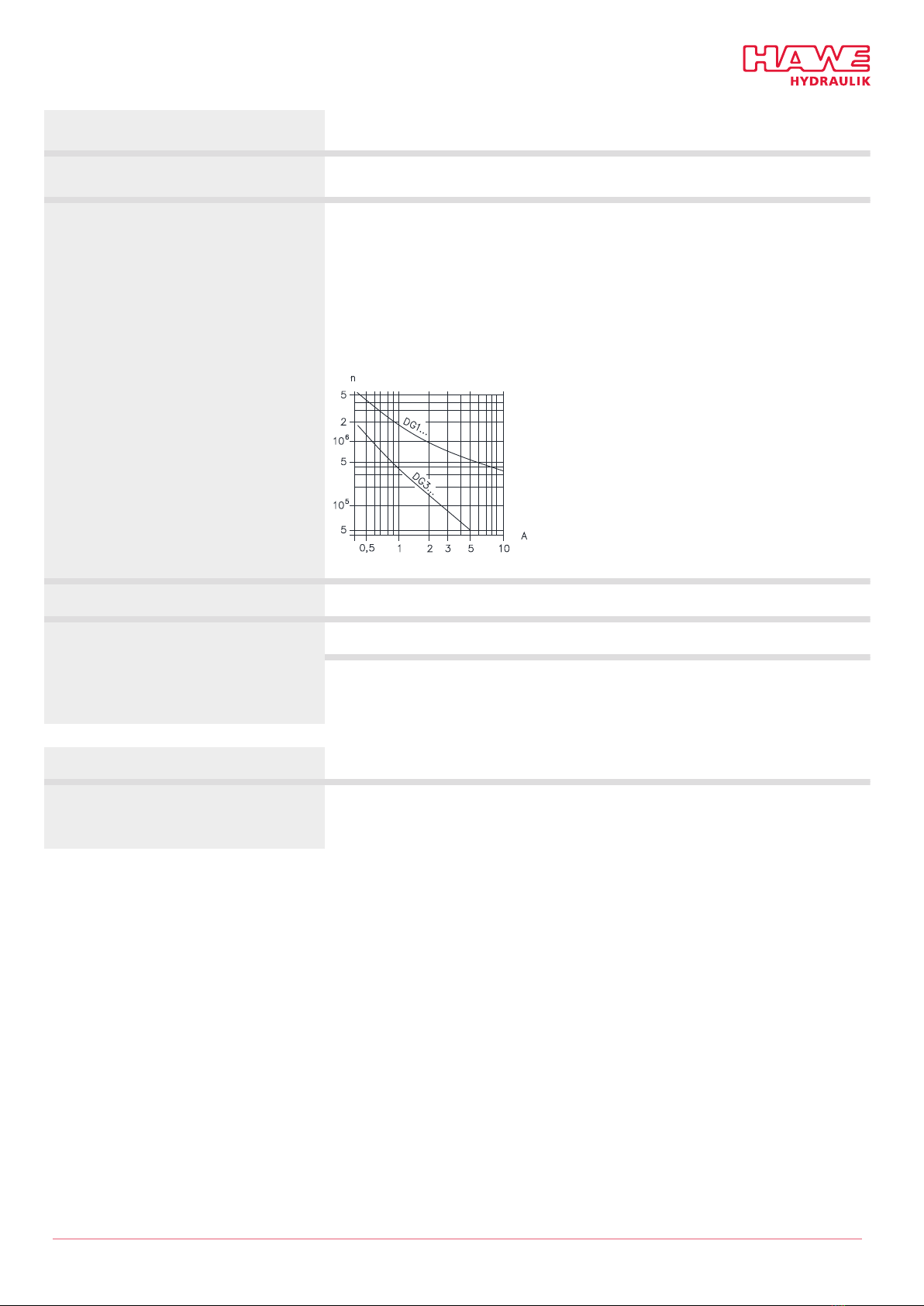

Pressure switch DG 1.. DG 3..

Micro switch type X 04-Z 25 XCG 3

Mechanical lifetime approx./switching cycles 10 x 10610 x 106

For 12 V DC = 4 A and L/R = 10 ms

1 x 1060.35 x 106

For 230 V, 1 A and cos. 9 = 0.3

A current at 230 V AC; n switching cycles

Maximum supply voltage Umax < 50 V AC or 5 V DC

2 ASwitching current Imin

To ensure a safe contact, the current must not fall below certain minimum values:

24 V DC = Imin = 10 mA

12 V DC = Imin = 100 mA

Version DG 3. -X. -KB

Switching current Imin To ensure a safe contact, the current must not fall below certain minimum values:

24 V DC = Imin = 5 mA

12 V DC = Imin = 100 mA

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 11/21

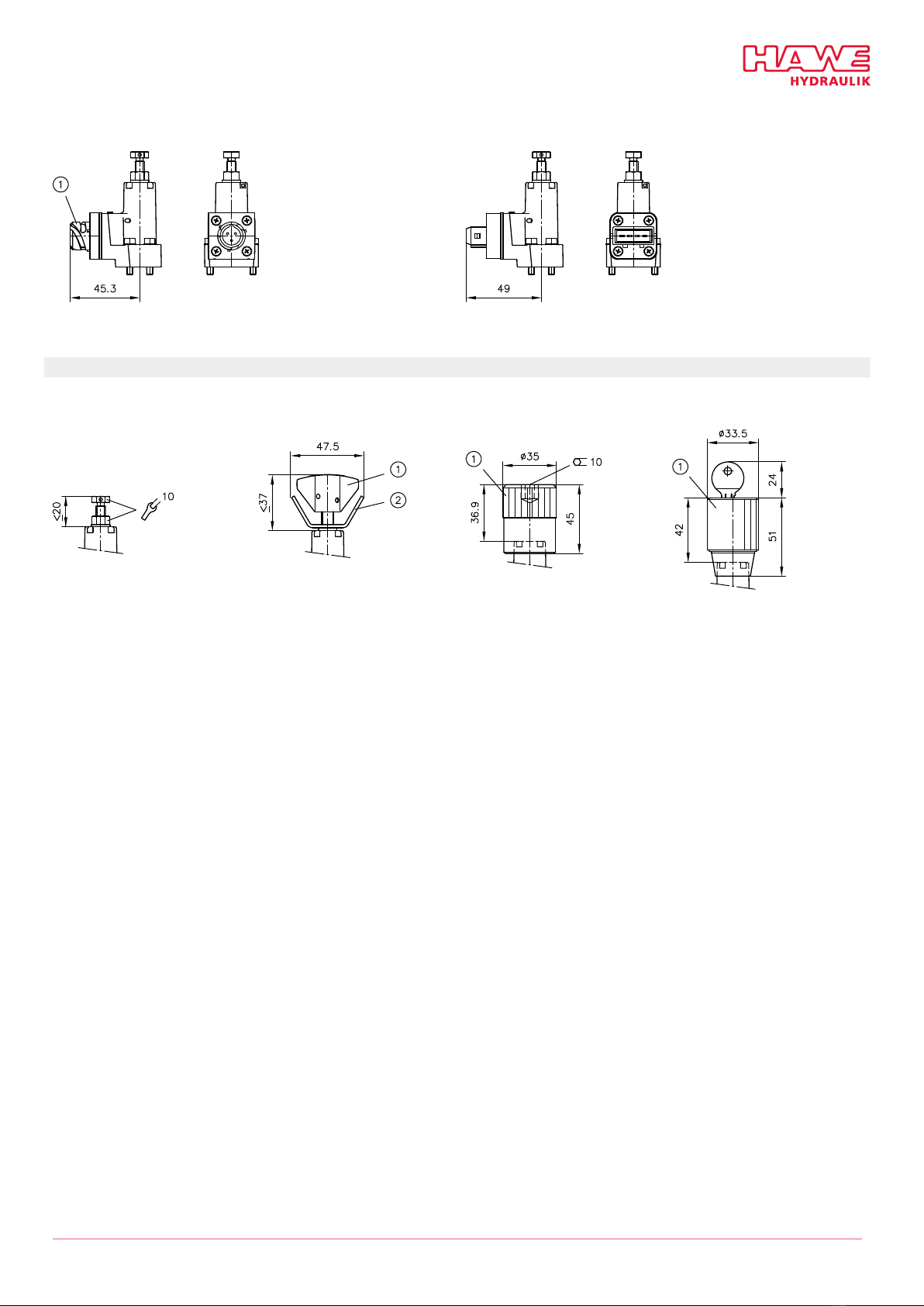

4Dimensions

All dimensions in mm, subject to change.

DG 1 R

1Cable fitting PG 9

2Ground connection

3Actuation cylinder

4Scale housing

5Setting knob for main switch

NOTE

For types DG 1.., the scale housing > must not be twisted relative to the hex (width across ats 2 ) = for functional-technical

reasons!

DG 1 RS

1Line connector can be mounted offset by 4x90°

DG 1 RU

12/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

DG 1 RF

With front ring for switch panel installation

1Cable fitting PG 9

2Ground connection

3Actuation cylinder

4Scale housing

5Setting knob for main switch

6Fixing holes are rotated by 180° in version “U”.

NOTE

For types DG 1.., the scale housing > must not be twisted relative to the hex (width across ats 2 ) = for functional-technical

reasons!

DG 1 RFS (DG 1 RUFS)

1Line connector can be mounted offset by 4x90°

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 13/21

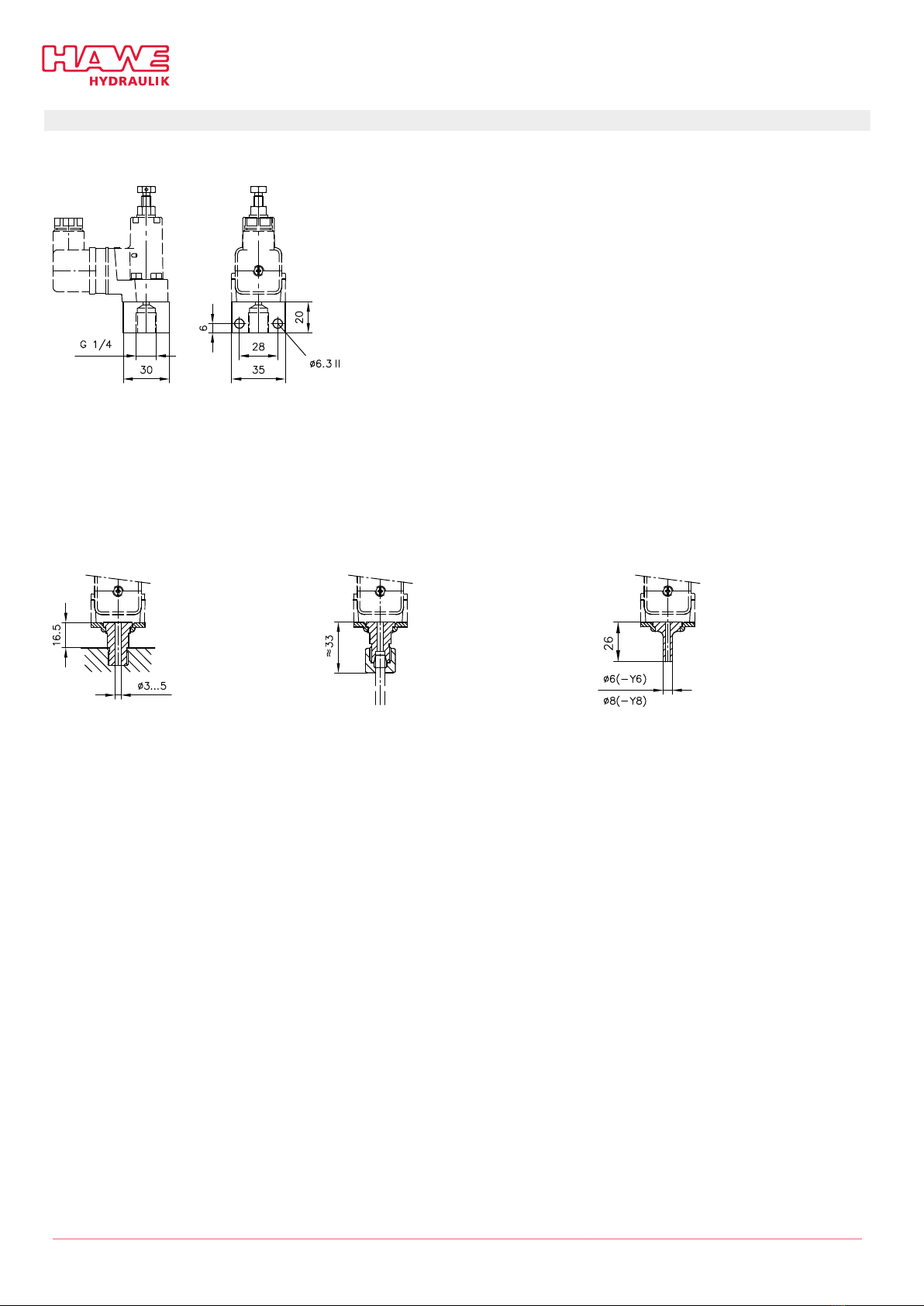

Hy raulic connection

G 1/4 (BSPP) thread

for pipe screw connection

G 1/2 (BSPP) thread

e.g. pressure gauge screw tting

G 1/2 (BSPP) thread

Fitting type X1 (example) from D 065

DG.. can be tted in any direction

1Cu sealing ring DIN 7603

Base plate hole pattern

1Hydraulic connection

DG 3..

Series (adjustment device without designation)

1Plug can be mounted offset by 4x90°

2Sealing option

3Sealing with O-ring

DG 3..X DG 3..M

1Light ring (yellow)

14/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

DG 3..S

1Bayonet PA 6 (Schlemmer)

DG 3..AMP

A justment

No designation Coding RCoding VCoding H

1Wing bolt

2Wing nut 1Turn knob

1Turn knob

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 15/21

Hy raulic connection

DG 3.. - 1/4

DG 3.. - Y1 (G 1/4 (BSPP))

DG 3.. - Y2 (M12x1.5)

DG 3.. - Y3 (G 1/8 (BSPP))

DG 3.. - YS6

DG 3.. - YS8

DG 3.. - Y6

DG 3.. - Y8

Tapped journal with sealing edge Pipe connection with EO progressive ring

and union nut

Pipe connection pieces

DG 3.. can be rotated in any direction around the pipe axis after loosening the clamping plate (by loosening M4).

16/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

5Assembly, operation an maintenance recommen ations

5.1 Inten e use

This productis exclusively intended for hydraulic applications (uid engineering).

The user must observe the safety measures and warnings in this documentation.

Essential requirements for the pro uct to function correctly an safely:

– All information in this documentation must be observed. This applies in particular to all safety measures and warnings.

– The product must only be assembled and put into operation by qualied personnel.

– The product must only be operated within the specied technical parameters. The technical parameters are described in detail in this

documentation.

– All components must be suitable for the operating conditions in the event of application in an assembly.

– The operating and maintenance manual of the components, assemblies and the specic complete system must also always be

observed.

If the product can no longer be operated safely:

1. Remove the product from operation and mark it accordingly.

✓It is then not permitted to continue using or operating the product.

5.2 Assembly information

The product must only be installed in the complete system with standard and compliant connection components (screw ttings, hoses,

pipes, xtures etc.).

The product must be shut down correctly prior to dismounting (in particular in combination with hydraulic accumulators).

DANGER

Risk to life cause by su en movement of the hy raulic rives when ismantle incorrectly!

Risk of serious injury or death.

■Depressurise the hydraulic system.

■Perform safety measures in preparation for maintenance.

5.2.1 Preparing the base plate for DG 3

See description in Chapter 4, "Dimensions".

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 1 /21

5.3 Operating instructions

Purity an ltering of the hy raulic ui

Fine contamination can significantly impair the function of the hydraulic component. Contamination can cause irreparable damage.

Examples of ne contamination inclu e:

– Metal chips

– Rubber particles from hoses and seals

– Dirt due to assembly and maintenance

– Mechanical debris

– Chemical ageing of the hydraulic uid

NOTE

New hydraulic uid from the manufacturer does not necessarily have the required level of purity.

The hydraulic uid must be ltered during lling.

Pay attention to the cleanliness level of the hydraulic uid to maintain faultless operation.

(Also see cleanliness level in Chapter 3, "Parameters").

Additionally applicable document: D 5488/1 Oil recommendations

5.4 Maintenance information

Conduct a visual inspection at regular intervals, but at least once per year, to check if the hydraulic connections are damaged. If

external leakages are found, shut down and repair the system.

Clean the device surface of dust deposits and dirt at regular intervals, but at least once per year.

18/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

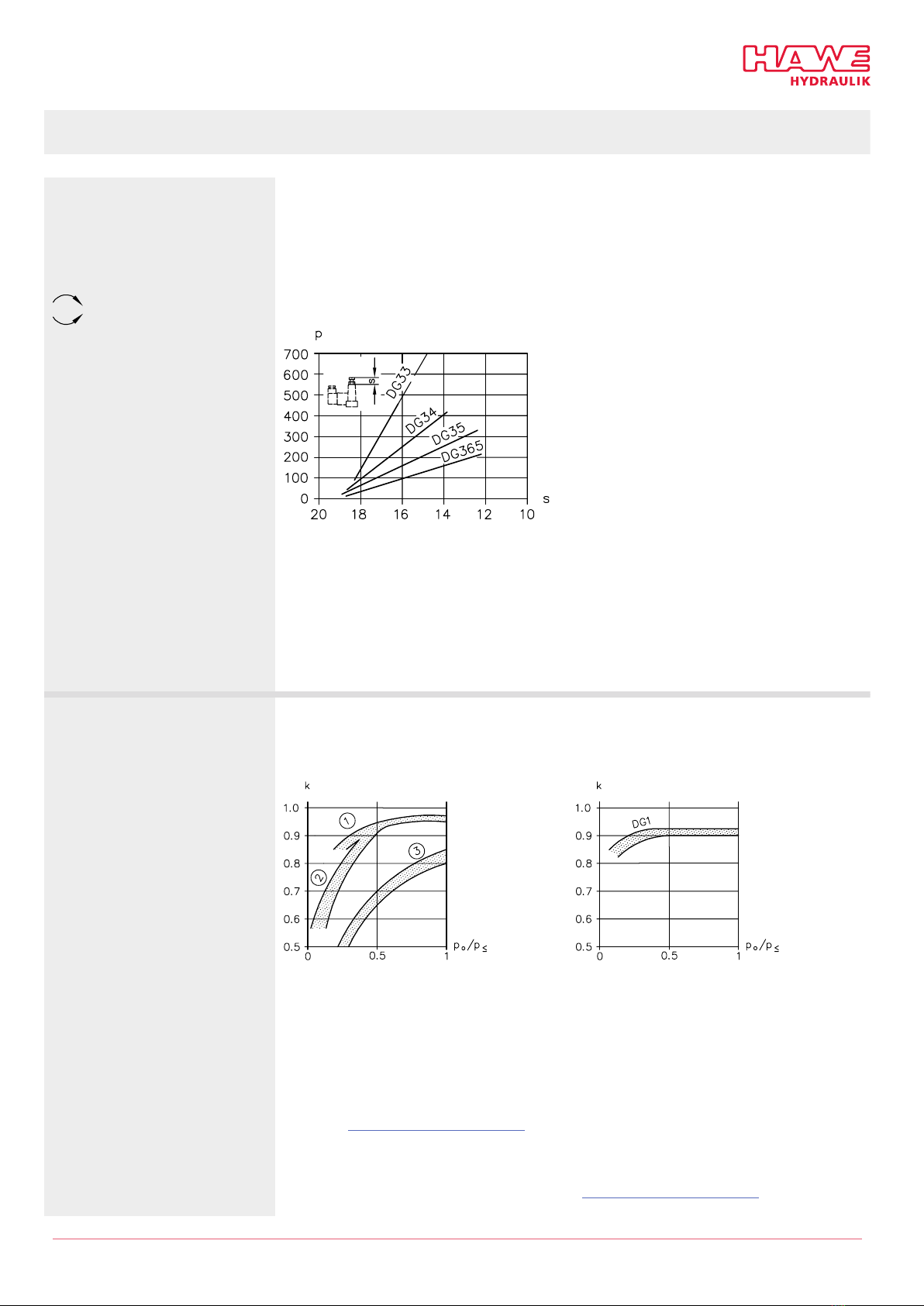

5.5 A justability an switching pressure

A justability

Pressure increases

Pressure rops

When deactivating pumps directly, be aware of a potential afterrun caused by mass action. Also

available for delivery with preset pressure.

Type coding, e.g.

DG 33–600 (setting for increasing pressure)

DG 33–600 F (setting for decreasing pressure)

The tables only contain approximate reference values. Use a pressure gauge to establish a more

accurate switching point!

p pressure setting (bar); s adjustment dimension (mm)

■DG 1 R..: Using a setting knob on the pressure selection scale (there may be slight deviations

between the scale value and the pressure value measured with the pressure gauge).

■DG 3..: With adjusting screw, after unfastening the counter screw (wrench, width across ats 10)

■DG 3..R: By hand with the wing bolt, after unfastening the wing nut

■DG 3..V: With the turn knob

■DG 3..H: With the turn knob, after unlocking (key)

Switching pressures Switching differential between the upper switching point po as the pressure increases and the lower

switching point as the pressure drops.

The calculated pressure value pu = k · po can only be considered an approximate reference value.

po/p Ò set response pressure; k factor

1DG 33, DG 34

2DG 35, DG 364, DG 365

3DG 36

po/p Ò set response pressure; k factor

po= Upper switching point at which the device jumps from its idle position to its switching

position during a pressure increase (response pressure, adjustment range pmin to pmax

"Available versions, main data", Table 1)

pu= Lower switching point at which the device reverts from its switching position back to its

idle position during a pressure drop

pmax = Max. pressure setting in accordance with "Available versions, main data", Table 1

© HAWE Hydraulik SE D 5440 - 10-2020-1.1 19/21

6Other information

6.1 Accessories, spare parts an separate components

Line connectors

Co ing Description Or er co ing

G.. Line connector MSD 3-309

L.. Line connector with LED SVS 296100

L5K - DG Line connector with LED, 5 m cable L5K - DG

L10K - DG Line connector with LED, 10 m cable L10K - DG

SAngled plug for bayonet PA6

Straight plug for bayonet PA6

846 010 A

846 010 B

Co ing Description

K Kostel, 03888005

S Schlemmer, cone with bayonet 10 SL

AMP AMP, AMP Junior 2-pole code number 1

20/21 D 5440 - 10-2020-1.1 © HAWE Hydraulik SE

This manual suits for next models

9

Table of contents