IDEC HS6B Series User manual

B-1905-1(0)

INSTRUCTION SHEET - HS6B Series Safety Switch

( 1 / 4 )

2016.08

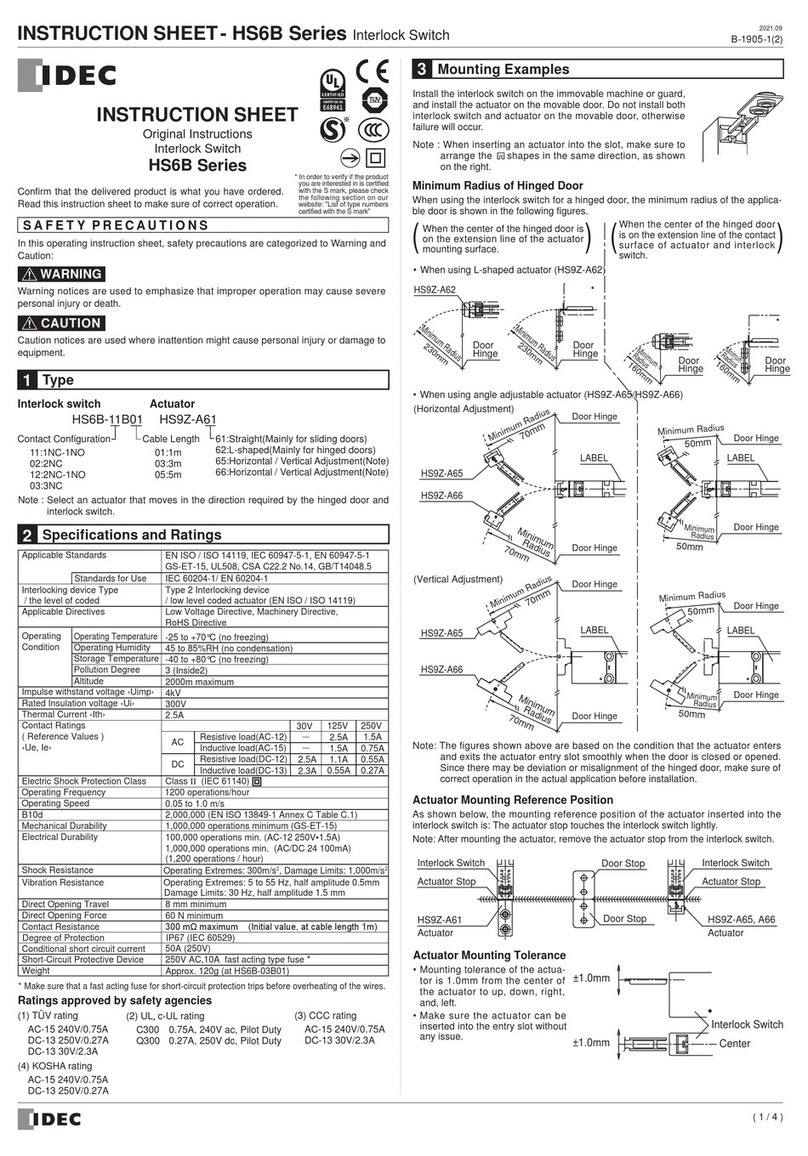

1Type

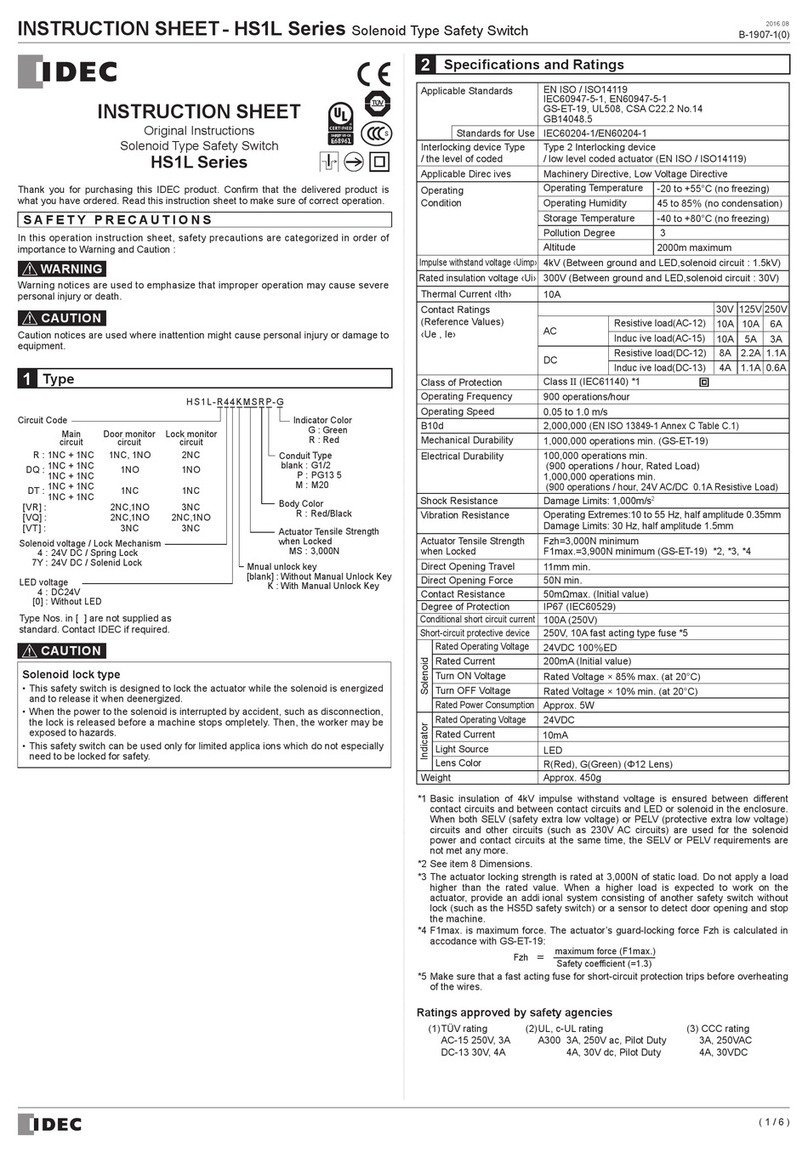

2Specifications and Ratings

Ratings approved by safety agencies

(1) TÜV ra ing

AC-15 240V/0.75A

DC-13 250V/0.27A

DC-13 30V/2.3A

(2) UL,c-UL rating

C300 0.75A, 240V ac, Pilot Duty

Q300 0.27A, 250V dc, Pilot Duty

(3) CCC rating

AC-15 240V/0.75A

DC-13 30V/2.3A

(4) KOSHA rating

AC-15 240V/0.75A

DC-13 250V/0.27A

Install the safety switch on the immovable machine or guard,

and install the actuator on the movable door. Do not install both

safety switch and actuator on the movable door, otherwise

failure will occur.

Note : When inserting an actuator into the slot, make sure to

arrange the shapes in the same direction, as shown

on the right.

Actuator Mounting Reference Position

As shown below, the mounting reference position of the actuator inserted into the

safety switch is: The actuator stop touches the safety switch lightly.

Note: After mounting the actuator, remove the actuator stop from the safety switch.

Actuator Mounting Tolerance

• Mounting tolerance of the actua-

tor is 1.0mm from the center of

the actuator to up, down, right,

and, left.

• Make sure the actuator can be

inserted into the entry slot without

any issue.

Door Stop

Door Stop

Safety Switch

HS9Z-A61

Actuator

HS9Z-A65, A66

Actuator

Actuator Stop

Safety Switch

Actuator Stop

*

Make sure that a fast acting fuse for short-circuit protection trips before overheating of the wires.

Center

Safety Switch

±1.0mm

±1.0mm

3Mounting Examples

2.5A

300V

4kV

2000m maximum

3 (Inside2)

-40 to +80°C (no freezing)

45 to 85%RH (no condensation)

-25 to +70°C (no freezing)

Low Voltage Directive, Machinery Direc ive

IEC60204-1/ EN60204-1

GS-ET-15, UL508, CSA C22.2 No.14 GB14046 5

EN ISO / ISO14119, IEC60947-5-1, EN60947-5-1

Resistive load(AC-12)

Inductive load(AC-15)

Resistive load(DC-12)

Inductive load(DC-13)

Weight

Short-Circuit Protec ive Device

Conditional short circuit current

Contact Resistance

Direct Opening Force

Direct Opening Travel

Electrical Durability

Mechanical Durability

B10d

Vibration Resistance

Shock Resistance

Electric Shock Protec ion Class

‹Ue, Ie›

( Reference Values )

Contact Ratings

Thermal Current ‹Ith›

Rated Insulation voltage ‹Ui›

Impulse wi hstand voltage ‹Uimp›

Condition

Operating

Applicable Directives

Standards for Use

Applicable Standards

Operating Temperature

Operating Humidity

Storage Temperature

Pollution Degree

Altitude

AC

DC

30V

-

-

2.5A

2.3A

125V

2.5A

1.5A

1.1A

0.55A

250V

1.5A

0.75A

0 55A

0 27A

Approx. 120g (at HS6B-03B01)

250V AC,10A fast acting type fuse *

50A (250V)

300 mΩ maximum (Initial value, at cable length 1m)

60 N minimum

8 mm minimum

(1,200 operations / hour)

1,000,000 operations min. (AC/DC 24 100mA)

100,000 operations min. (AC-12 250V•1.5A)

1,000,000 operations minimum (GS-ET-15)

2,000,000 (EN ISO 13849-1 Annex C Table C.1)

Damage Limits: 30 Hz, half amplitude 1 5 mm

Operating Extremes: 5 to 55 Hz, half amplitude 0.5mm

Operating Extremes: 300m/s2, Damage Limits: 1

,

000m/s2

Class II (IEC61140)

Minimum Radius of Hinged Door

When using the safety switch for a hinged door, the minimum radius of the applicable

door is shown in the following figures.

• When using L-shaped actuator (HS9Z-A62)

• When using angle adjustable actuator (HS9Z-A65/HS9Z-A66)

• When using angle adjustable actuator (HS9Z-A65/HS9Z-A66)

When the center of the hinged door is

on the extension line of the actuator

mounting surfase.

When the center of the hinged door

is on the extension line of the contact

surface of actuator and safety switch.

Note: The figures shown above are based on the condition that the actuator enters

and exits the actuator entry slot smoothry when the door is closed or opened.

Since there may be deviation or dislocation of the hinged door, make sure of

correct operation in the actual application before installation.

Door

Hinge Door

Hinge

HS9Z-A62

230mm

Minimum Radius

Minimum Radius

230mm

Door

Hinge Door

Hinge

Minimum

Radius

Minimum

Radius

160mm

160mm

(Horizontal Adjustment) Door Hinge

Door Hinge

Door Hinge

Door Hinge

LABEL LABEL

70mm

Minimum Radius

70mm

Minimum

Radius

50mm

Minimum Radius

50mm

Minimum

Radius

HS9Z-A65

HS9Z-A66

(Vertical Adjustment) Door Hinge

Door Hinge

LABEL

Door Hinge

Door Hinge

LABEL

50mm

50mm

70mm

Minimum Radius

70mm

Minimum

Radius

HS9Z-A65

HS9Z-A66

Minimum Radius

Minimum

Radius

Interlocking device Type

/ the level of coded

Type 2 Interlocking device

/ low level coded actuator (EN ISO / ISO14119)

Operating Speed

Operating Frequency

0 05 to 1.0 m/s

1200 opera ions/hour

Degree of Protection IP67 (IEC60529)

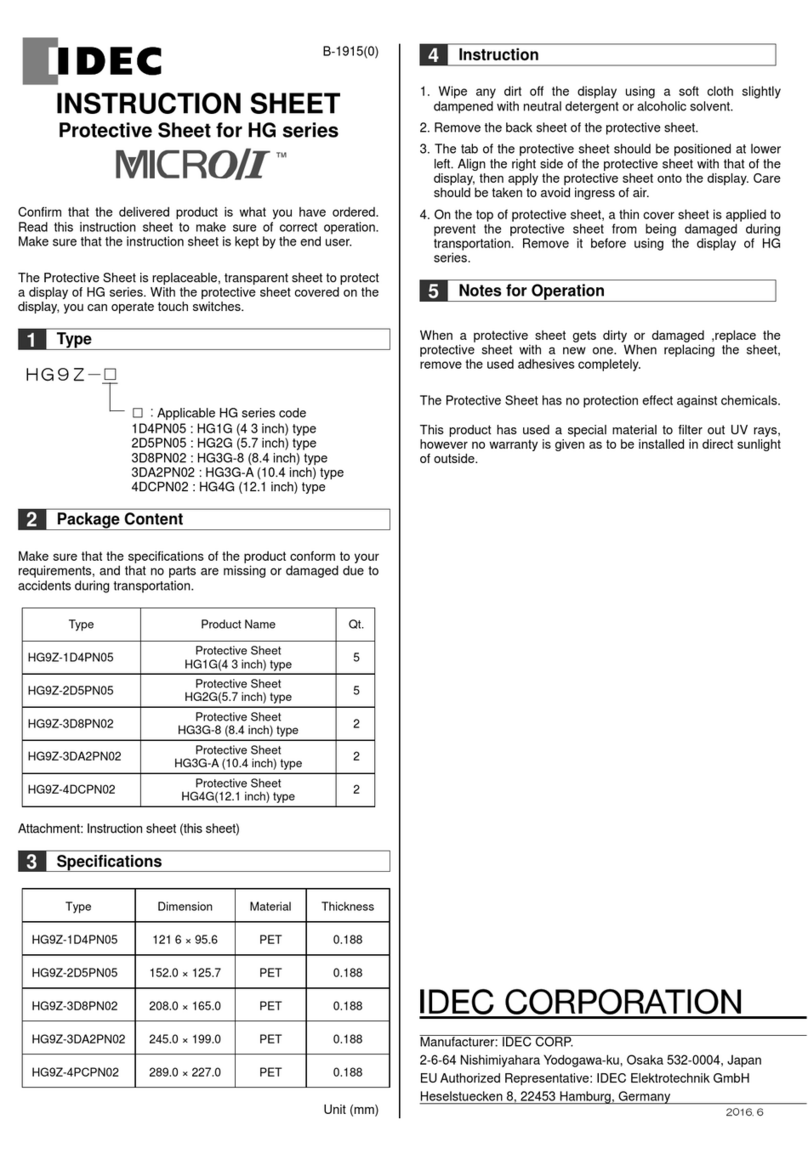

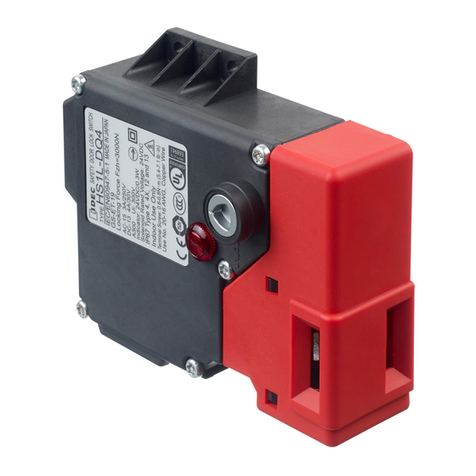

Confirm that the delivered product is what you have ordered.

Read his instruction sheet to make sure of correct operation.

In this operating instruction sheet, safety precautions are categorized to Warning and

Caution:

Warning notices are used to emphasize that improper operation may cause severe

personal injury or death.

Caution notices are used where inattention might cause personal injury or damage to

equipment.

INSTRUCTION SHEET

Original Instructions

Safety Switch

HS6B Series

SAFETY PRECAUTIONS

CAUTION

WARNING

Contact Configuration

11:1NC-1NO

02:2NC

12:2NC-1NO

03:3NC

HS6B-11B01 HS9Z-A61

Safety switch Actuator

Cable Length

01:1m

03:3m

05:5m

61:Straight(Mainly for sliding doors)

62:L-shaped(Mainly for hinged doors)

65:Horizontal / Vertical Adjustment(Note)

66:Horizontal/ Vertical Adjustment(Note)

Note : Select an actuator that moves in the direction required by the hinged door and

safety switch.

* In order to verify if the product

you are interested in is certified

with the S mark, please check

the following section on our

website: "List of type numbers

certified with the S mark"

※

B-1905-1(0)

INSTRUCTION SHEET - HS6B Series Safety Switch

( 2 / 4 )

2016.08

• Actuator can move 2.1mm from the mounting position without affecting the contact

operation.

Deviation of

actuator position Deviation of

door position ≤2.1mm

+

Recommended Screw Tightening Torque

Adjusting the Angle Adjustable (vertical/horizontal) Actuator

• Using the angle adjustment screw (M3 hexagon socket set screw), the actuator

angle can be adjusted up to 20°(refer to dimensions).

• The larger the actuator angle, the smaller the applicable radius of the door swing.

After installing the actuator, open the door. Then adjust the actuator angle so that the

actuator enters the entry slot of he safety switch properly.

• After adjusting the actuator angle, apply loctite or the like on the adjustment screw to

prevent loosening. Use screw locking agent that is compatible with the base material.

Base: PA66 (66 nylon) of glass reinforced grade

Angle adjustment screws: stainless steel

For mounting the safety switch (M4 screw) *1

For mounting the actuator (M4 screw) *1

Screw Tightening Torque

1.0 to 1.5N•m

1.0 to 1.5N•m

Name or Use

2.1mm

HS9Z-A61, HS9Z-A62 ACTUATOR

• When there is a displacement of safety switch and actuator, the actuator may hit the

entry lot of safety switch hardly, thus damaging the entry slot and actuator. The

rubber cushions on the HS9Z actuator prevent the actuator from damaging the entry

slit by absorbing the shock with movement flexibility. Do not, however, exert exces-

sive shocks, otherwise the failure of safety switch may be caused.

• The rubber cushions may deteriorate depending on the operatiing environment and

conditions. Immediately replace the deformed or crasked rubber cushions with new

ones.

5Contact Operation

Identification of wire

• The identification of wire is made by the color and white line printed on the wire.

No.

1

2

3

4

5

6

Color of Insulator

Orange / White

Blue / White

Brown / White

Brown

Blue

Orange

Specifications of cable

• UL style 2464, 6c×No.20AWG, ( 80°C 300V )

Dummy Insulator (black)

Jacket

Colored Insulator

Identification of terminal numbers

• When wiring, the identification of terminal number on each contact is made by

colored wire.

• The following shows a safety (main) contact and an auxiliary contact for three

contacts and two contacts types.

• When wiring, cut unnecessary wires such as dummy insulator (black) and / or

unused wire to avoid incorrect wiring.

2NC

3NC

1NC-1NO

2NC-1NO

11

33

12

34

BU

OG

BU / W

OG / W

BU

OG

BU / W

OG / W

11

31

12

32

11

21

31

12

22

32

11

21

33

12

22

34

BU / W

BN / W

OG / W

BU

BN

OG

BU / W

BN / W

OG / W

BU

BN

OG

4Precautions for Operation

Installation

• Do not apply an excessive shock to the safety switch

when opening or closing the door. A shock to the

safety switch exceeding 1,000 m/s2may cause

failure.

• Provide a door guide, and ensure that force is applied

on the safety switch only in the actuator insertion

direction.

• Entry of foreign objects in the actuator entry slot may

affect the mechanism of the switch and cause a

breakdown. If the operating atmosphere is contaminated, use a protective cover to

prevent the entry of foreign objects into the switch through the actuator entry slots.

• Make sure to install the product in a place where it cannot be damaged. Make sure

to conduct a proper risk assessment evaluation before using the product, and use a

shield or a cover to protect the product if need be.

• Do not fasten and loosen the conduit at the bottom of the safety switch.

• When wiring, make sure that liquid such as water and oil dose not intrude from the

tip of cable.

• When bending cable at wiring, secure the cable radius of 40mm at the minimum.

• Be sure to use the dedicated actuator only, and do not operate the HS6B safety

switch with anything other than the dedicated actuator. Otherwise, the safety of the

system may not be maintained.

Minimum Radius

40mm

Conduit

*1 When the torque is not enough to recommended screw tightening torque, make

sure that the screw do not become loose by using adhesive sealants etc. to

keep right operation and mounting positioning.

CAUTION

6Wiring

Contact Configuration and Operation

1NC-1NO

HS6B-11□

HS6B-02□

HS6B-12□

HS6B-03□

Contact Configuration Contact OperationType

2NC

2NC-1NO

3NC

11

33

12

34

11

21

31

12

22

32

11

21

33

12

22

34

11

31

12

32

11-12

33-34

11-12

31-32

11-12

21-22

33-34

11-12

21-22

31-32

(Actuator Completely Inserted) (Actuator Pulled Out)

0 8 (Actuator Mounting Reference Position)

0 Approx. 5.8 Approx. 28.2

(Travel: mm)

Approx. 5.5

: Contact closed : Contact open

WARNING

• Turn off the power to the safety switch before starting installation, removal, wiring,

maintenance, and inspection on the safety switch. Failure to turn power off may

cause electrical shocks or fire hazard.

• Do not disassemble or modify the switch. Also do not attempt to disable the safety

switch function, otherwise a breakdown or an accident will result.

CAUTION

• HS6B Series Safety Switches are Type 2 low-level coded interlocking devices (EN

ISO / ISO14119). The following system installation & mounting instructions are EN

ISO / ISO14119 requirements to prevent function failure from the interlock switch.

1. Using permanent fixing methods (e.g. welding, rivets, special screws...etc) to

prevent dismantling or de-positioning of the interlock device. However, perma-

nent fixing methods are not an adequate solution if you expect the interlock

device to fail during the machinery lifetime, or if you need to replace the prod-

uct in quick manner. In these situations, o her measures (see 2.) should be put

in place to reduce the risks of function failure.

2. At least one of the following measures should be applied to prevent function

failure.

(1)Mounting the interlock device in a place out of reach from workers

(2) Using shielding protection to prevent physical obstruction of the device

(3)Mounting the interlock device in a hidden position

d vice

(4) Integrate status monitoring & cycling testing of the device to the control

system to prevent product failure.

• Regardress of door types, do not use the safety switch as a door stop. Install a

mechanical door stop at the end of the door to protect the safety switch against an

excessive force.

• Mount the actuator so that it will not hit the operator when the door is open,

otherwise injury may be caused.

• Pay attention to the management of spare actuator. Safety function of door safety

switch will be lost in case the spare actuator is inserted into the safety switch.

Ensure that the actuator is firmly fastened to the door (welding, rivet, special

screw) in the appropriate location, so that the actuator cannot be removed easily.

• Do not cut or remodel the actuator, otherwise failure will occur.

• If multiple safety components are wired in series, the Performance Level to EN

ISO 13849-1 will be reduced due to the restricted error detection under certain

circumstance.

• The entire concept of the control system, in which the safety component is

integrated, must be validated to EN ISO 13849-2.

B-1905-1(0)

INSTRUCTION SHEET - HS6B Series Safety Switch

( 3 / 4 )

2016.08

7Example of wiring Diagram realizing Safety Category

S1: HS6B-12 Safety Switch

S2: Starting Switch (HW Series Momentary)

S3: Safety limit Switch

ESC: Outside start condi ion

K3, 4: Safety Contactor

F1: Outside fuse of safety relay module at power supply line

Note: Use the monitoring device(Safety relay module) provided the capavility to

detect a cross short circuit. The insulation of the cable has to wi hstand

environmental influences. If a control device other than the one shown in the

draft is used, the used control device has to be equipped with a cross short

circuit monitor.

Output Circuit Output Circuit

One of the example of

the circuit ; Safety

relay module, HR1S-AF

series manufactured

by DEC CORPORATION

One of the example of

the circuit ; Safety

relay module, HR1S-AF

series manufactured

by IDEC CORPORATION

Example of a circuit diagram for Safety Category 4

(attainable PL = e)

Example of a circuit diagram for Safety Category 3

(attainable PL = d)

(Condition 1: To apply he fault exclusion of mechanical structural parts including he actuator

→ Make sure to use the product within the product specification range described in this

manual and the version of the manual provided with the product.)

(Condition 2: Documentation of he reason for the machine/equipment manufacturer to have

applied the fault exclusion based on ISO13849-1, ISO13849-2 or IEC62061.)

DC24V

F1

K4

K3

DC0V

S1 S1

12

11

HR1S-AF Safety relay module

13

14

ESC

K4

K3 S2

S33 S34 13 23A1

S11

S22

14 24

A2

S12 S21

34

33

DC24V

F1

K4

K3

DC0V

13

14

ESC

K4

K3 S2

S3

1

2

HR1S-AF Safety relay module

S33 S34 13 23A1

S11

S22

14 24

A2

S12 S21

22

21

12

11

34

33

22

21

L1(+)

N(−)

L1(+)

N(−)

Used as open/close

monitor of guard

Used as open/close

monitor of guard

Guard Open Guard Open

HS9Z-A61 Actuator HS9Z-A61 Actuator

HS6B-12

Safety Switch HS6B-12

Safety Switch

B-1905-1(0)

INSTRUCTION SHEET - HS6B Series Safety Switch

( 4 / 4 )

2016.08

8Dimensions

*2 The actuator stop is used

when adjusting the actuator

position. Remove after the

actuator position is deter-

mined.

*3 The direction of adjustable

angle can be changed (verti-

cal or horizontal) by changing

the insertion direction of the

joint (white plastic part). See

the figures below. Do not lose

the joints. Actuators do not

operate normally without a joint.

Joint

(Horizontal Adjustment) (Vertical Adjustment)

Factory defalut

(Supplied)

(Supplied)

(Supplied with actuator)

(Supplied with actuator)

(Supplied with actuator)

(Supplied wi h actuator)

13 28.2

7.5

2.5

15

34

25

16.8

5.5

2

20°

R2.1

20°

0.8

1.2

3.5

25

20°

20°

Type:HS6B-□

Slot Plug (Supplied)

Note: Use the slot plug attached

to the safety switch to close

the unused actuator entry slot.

Safety Switch Mounting Hole Layout

(Can be installed either frontwards or

backwards)

2-M4 Screws

(Φ4.3 or M4 Tap)

Actuator

Stop *2

Actuator

Stop*2

Type:HS9Z-A61

Type:HS9Z-A62

Type:HS9Z-A65

Type:HS9Z-A66

Joint

Joint

Actuator Stop *2

(Horizontal Adjustment)

(Horizontal Adjustment) (Vertical Adjustment)

Angle Adjusting Screw

(M3 Hexagon Socket Set Screw)

Actuator Stop *2

Actuator Stop *2

Actuator Mounting Hole Layout

(Horizontal / Vertical Adjustment)

2-M4 Screws

(Φ4.3 or M4 Tap)

Actuator Mounting Hole Layout

(Straight, L-shaped)

2-M4 Screws

(Φ4.3 or M4 Tap)

Angle Adjusting Screw

(M3 Hexagon Socket Set Screw)

Angle Adjusting Screw

(M3 Hexagon Socket Set Screw)

Note: HS9Z-A65 and HS9Z-A66 are different in he insertion direction of the metal

key(180°).

Factory defalut *3

(Vertical Adjustment)

Angle Adjusting Screw

(M4 Holes)

Base

Base

Actuator Stop *2

(M3 Hexagon Socket Set Screw)

Factory defalut *3

9Precaution for Disposal

Dispose of HS6B Safety Switch as an industrial waste.

http://www.idec.com

Manufacturer: IDEC CORP.

2-6-64 Nishimiyahara Yodogawa-ku, Osaka 532-0004, Japan

EU Authorized Representative: IDEC Elektrotechnik GmbH

Heselstuecken 8, D-22453 Hamburg, Germany

DECLARATION OF CONFORMITY

We, IDEC CORPORATION 2-6-64, Nishimiyahara Yodogawa-ku,Osaka 532-0004, Japan declare

under our sole responsibility that the product:

Description: Safety Switch

Model No: HS6B

to which this declaration relates is in conformity with the EC Directive on the following standard(s)

or other normative document(s). In case of alteration of the product, not agreed upon by us, this

declaration will lose its validity.

Applicable EC Directive : Low Voltage Directive (2014/35/EU)

Machinery Directive (2006/42/EC)

Applicable Standard(s) : EN 60947-5-1,GS-ET-19

Accessories dimensions

Dimensions

15

10.1

10.4

5 5

1

30.8

R2.2

(9)

78

(30.1±1)

30

1

( )14 50.8

35

0.8

(12.6±1)

0.8

(5)

20

(58)

(41.4)

22.6±1

0.8

40.1±1

(21.4)

(14)

(5)

0.8

20 to 22

35.9 28.2

(8.4)

14

3.5

1.2

2-Φ4.3

2-Φ9

14 15

14

28.2

1.2

14

13.1

(8.4)

3.5

34

14

2-Φ4.3

2-Φ9

(Supplied with actuator)

Actuator Stop *2

When

installed on

the door (5)

When installed on

the door (33 8)

When installed on

he door (5)

This manual suits for next models

4

Other IDEC Switch manuals

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS1E Series User manual

IDEC

IDEC HS1L Series User manual

IDEC

IDEC HE1B Series User manual

IDEC

IDEC HS5E-K User manual

IDEC

IDEC HS3A Series User guide

IDEC

IDEC MICRO/I HG9Z-1D4PN05 User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC HS6E Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS1C Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS6B Series User manual

IDEC

IDEC SX5E Series User manual

IDEC

IDEC HS1L Series User manual

IDEC

IDEC SA1E-L Series User manual

IDEC

IDEC HS5E Series User manual

IDEC

IDEC SA1U Series User manual

IDEC

IDEC HS5E Series User manual