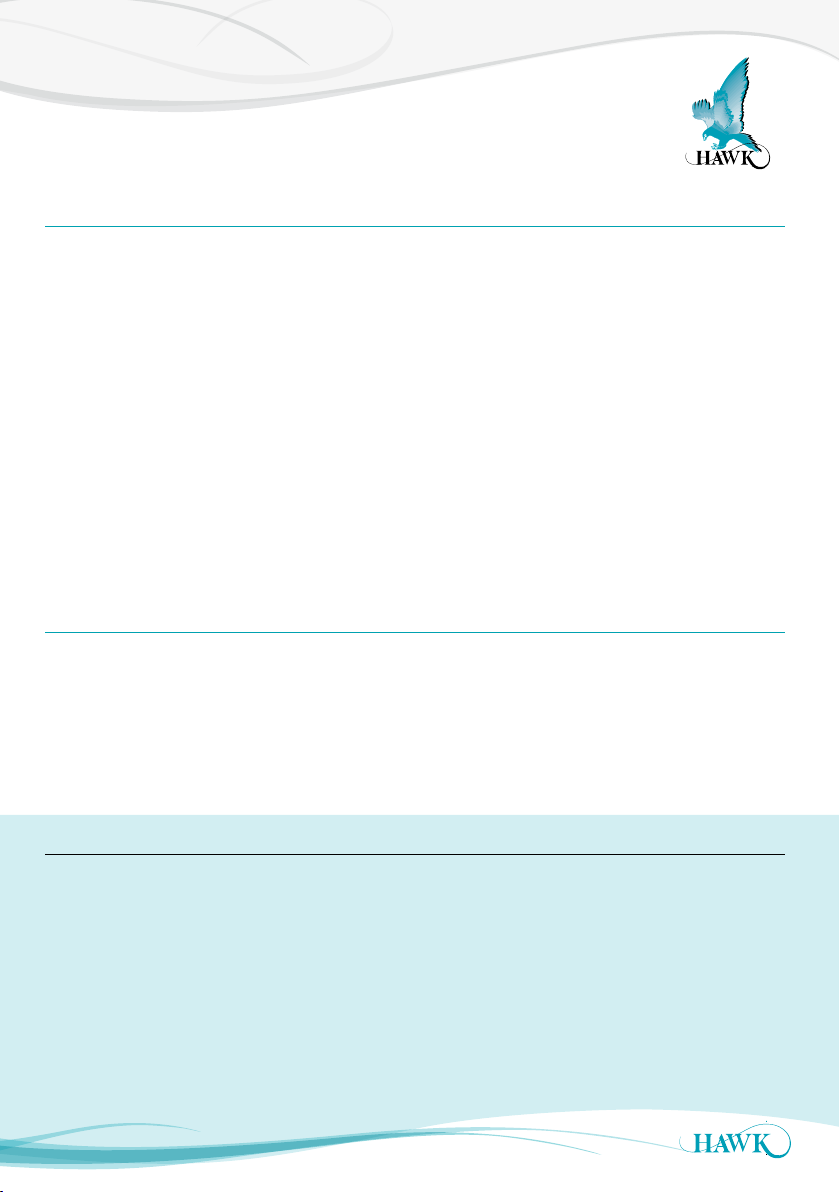

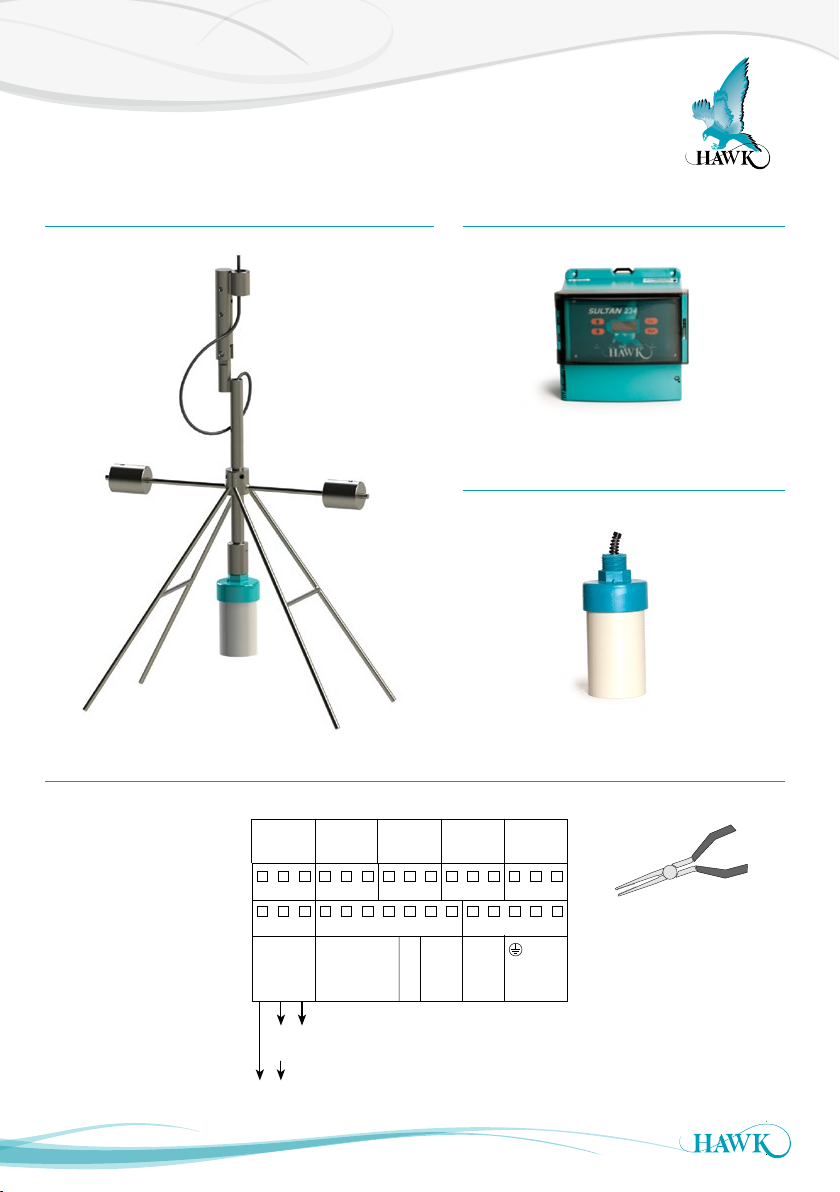

Sultan Sonar System

Overview

3

Principle of Operation

The Hawk Sultan Sonar uses state of the art Sonar technology to measure and control Waste Water

Clarifiers and Thickeners.

The system is easy to use and the innovative design provides critical plant control to optimize performance.

In the water, wastewater industry process conditions will vary greatly between a primary sedimentation tank,

secondary / final clarifier and a gravity thickener. Thickener bed levels, secondary RAS blanket, flocculent

blanket etc, all have different densities and the water above these interface levels are subject to different

process conditions that change.

To optimize performance in each interface application under all process environments:

HAWK has developed a low frequency transducer to penetrate through the suspended solids and capable of

measuring the lightest floc using one single transducer.

To optimize performance under all process environments in each interface application:

HAWK uses one transducer with a frequency and power level that is applicable to the density of the interface

and process conditions expected in the tank. Also, HAWK can guarantee performance for controlling pumps

etc, rather than for monitoring purposes only.

• Simple and easy calibration to track specic densities

• Tune Sensor to 5 preset factory densities or ne tune

to the required density in-situ

• Sonar transducer developed to optimize detection of

heavy and light density interfaces

• Easy calibration to track specic density interfaces,

eg: RAS blanket - 4g/l, oc / uff layer - 1g/l, Bed 10g/l+

• Industrial scum cleaning mechanisms that do not

require maintenance

• No wiper blade assemblies

• Wide range of communications: Modbus, HART,

Foundation Fieldbus, DeviceNet, Probus DP and

Probus PA

• 3G remote support capability for calibration,

commissioning or technical back-up from

HAWK Service Engineer

• 5 Relay alarms

• 1640 feet (500 metre) separation possible between

transducer and Sultan Sonar transmitter.

Benets

• Improved efficiency and control of the

treatment process

• Fully automated plant systems with reliable blanket

level monitoring

• Advanced warning of biological upset or hydraulic

in-balance

• Reduced maintenance with 5 year cleaning

mechanism warranty (no blades to replace)

• Reduced site operational costs significantly with

improved process control

• Improved health and safety on site

(no manual dips required).

Features