Hawker Freedom User manual

•Pay attention to the operation instruction and

fix them close to the battery.

•Work on batteries to be carried out by skilled

personnel only!

•Use protective glasses and clothes when

working on batteries. Pay attention to the

accident prevention rules as well as

EN 50272-3 and EN 50110-1.

•No smoking!

•Do not expose batteries to naked flames,

glowing embers or sparks, as it may cause

the battery to explode.

•Acid splashes in the eyes or on the skin must

be washed with water. In case of accident

consult a doctor immediately!

•Clothing contaminated by acid should be

washed in water.

•Risk of explosion and fire, avoid short circuits!

•Caution: Metal parts of the battery are always

live. Do not place tools or other metal objects

on the battery!

•Electrolyte is highly corrosive.

•Batteries and cells are heavy. Ensure secure

installation!

•Useonly suitable handling equipment

•Dangerous electrical voltage!

•Pay attention to the hazards that can be

caused by batteries

ENGLISH

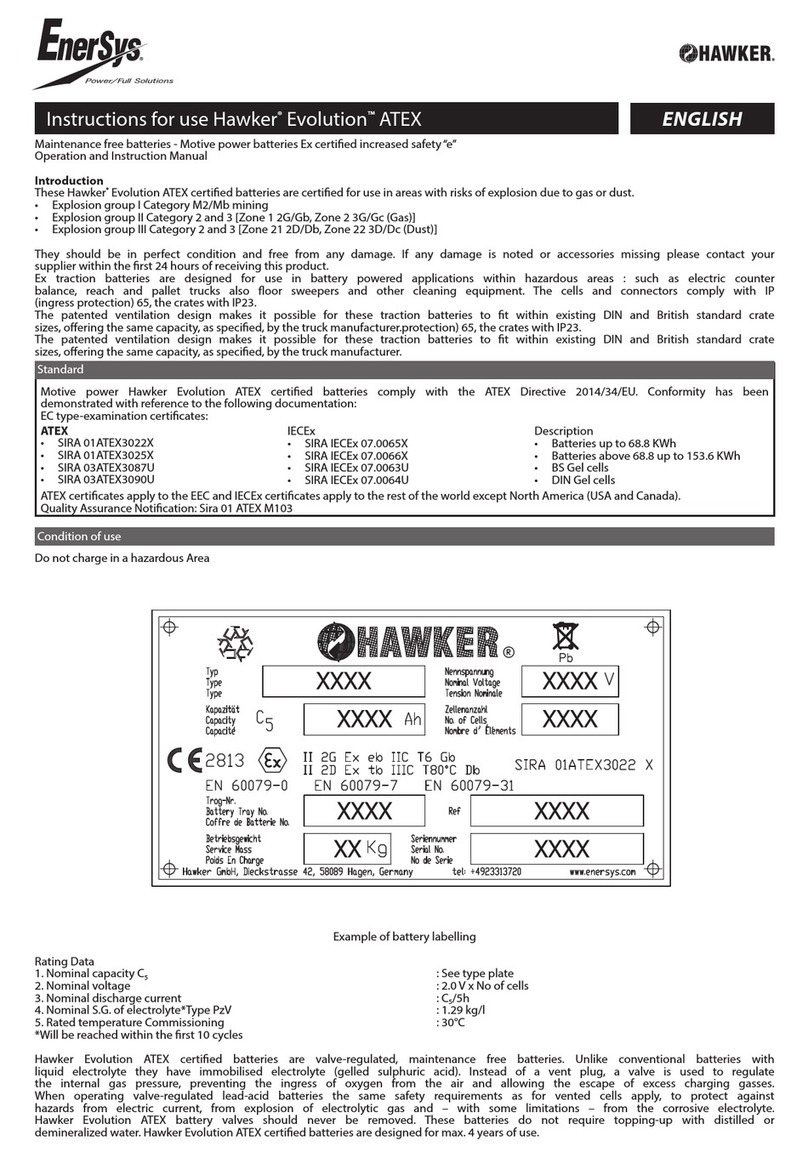

Instructions for use Hawker freedom system

Ignoring the operation instructions, repair with non-original parts or using additives for the electrolyte will render

the warranty void.

The Hawker freedom system integrates a battery with airmixing system, an on-board electronic device, the easyplus, for

checking temperature, electrolyte level and voltage balance, and for recording data on capacity and battery, this permitting

the communication with the HF charger, a Powertech easy.com charger (for instructions concerning the charger, please read

specific manual)

Rating Data

1. Nominal capacity C5: See type plate

2. Nominal voltage : 2.0 V x No of cells

3. Discharge current : C5/5h

4. Nominal S.G. of electrolyte* : 1.29 kg/l

5. Rated temperature : 30°C

6. Nominal electrolyte level : up to electrolyte level mark ”max.”

*Will be reached within the first 10 cycles.

1. Commissioning filled and charged batteries

(For commissioning of unfilled batteries see separate

instructions!)

The battery should be inspected to ensure it is in perfect

physical condition.

The charger cables must be connected to ensure a good

contact, taking care that the polarity is correct. Otherwise

battery, vehicle or charger could be damaged. The specified

torque loading for the polscrews of the charger cables and

connectors are:

steel

M 10 perfect connector 25 ± 2 Nm

The level of the electrolyte must be checked. If it is below

the anti-surge baffle or the top of the separator it must first

be topped up to this height with distilled or demineralised

water (DIN 43530 part 4).

The battery is then charged as in item 2.2. The electrolyte

should be topped up to the specified level with distilled or

demineralised water.

2. Operation

EN 50272-3 “Traction batteries for industrial trucks” is the

standard which applies to the operation traction batteries

in industrial trucks.

In normal working condition, the green LED on easyplus

must be ON, with fixed or flashing light.

LED DEFINITION ACTION

Off No power Check connection

Green LED flashing (slowly) Power and Hardware OK

Fixed green LED Complete charge

Fixed red LED Overdischarge Charge immediately

Red LED flashing Excessive temperature Cool down til normal

temperature is reached

Blue LED flashing (slowiy) Power and Hardware OK for voltage

balance and level indication

Blue LED flashing Difference of voltage balance Hawker Service action

Blue LED ON Low electrolyte level Topping up

The easyplus contains data on the battery (serial number,

capacity, technology), records data during the operation

(number of cycles, temperature, capacity, …) and transmits

the information to the charger with warnings appearing

on the charger’s display. (low electrolyte level, topping up

needed, overdischarge, daily cycle, excessive temperature,

voltage balance anomaly). Some of the information is

already indicated through the LEDs on the top of the

easyplus. When the blue led on easyplus is ON and stays

fixed, topping up must be carried out. Water topping up

should be done latest when the blue LED is ON or after

maximum 200 cycles.

2.1 Discharging

Be sure that all ventilation openings are not sealed or

covered. Electrical connections (e.g. plugs) must only be

made or broken in the open circuit condition. To achieve

the optimum life for the battery, operating discharges of

more than 80% of the rated capacity must be avoided

(deep discharge). This corresponds to an electrolyte specific

gravity of 1.15 kg/l at 30°C at the end of the discharge.

Discharged batteries must be recharged immediately and

must not be left discharged. This also applies to partially

discharged batteries.

2.2 Charging

Only direct current must be used for charging. The Hawker

freedom system is designed with a Hawker HF charger,

Powertech easy.com. In the system, the charger assigned

to the battery has been specifically determined for suiting

the size of the battery.

Hawker freedom batteries are low gas emission, so some

charging gasses are evolved.

Battery container lids and the covers of battery

compartments must be opened or removed.

The ventilation must comply to EN 50272-3 standard.

The vent plugs should stay on the cells and remain closed.

With the charger switched off connect up the battery,

ensuring that the polarity is correct. (positive to positive,

negative to negative). Now switch on the charger. When

charging the temperature of the electrolyte rises by about

10°C, so charging should only begin if the electrolyte

temperature is below 45°C. The electrolyte temperature of

batteries should be at least +10°C before charging otherwise

a full charge will not be achieved.

If a defect signal concerning the pump or the electrolyte

mixing system appears on charger’s display, check that the

piping system is connected and examine the piping circuit

for leaks or defects.(see 3. Maintenance). In the meantime,

the HF charger will adapt the profile.

The air pipe should never be removed during charge.

2.3 Equalising charge

Equalising charges are used to safeguard the life of the

battery and to maintain its capacity. They are necessary

after deep discharges or repeated incomplete recharges.

Equalising charges can be carried out manually, or will

be performed automatically after a rest following normal

charging.

Watch the temperature!

2.4 Temperature

An electrolyte temperature of 30°C is specified as the rated

temperature. Higher temperatures shorten the life of the

battery, lower temperatures reduce the capacity available.

55°C is the upper temperature limit and is not acceptable

as an operating temperature.

A temperature sensor is integrated in the easyplus device.

In case of excessive temperature the red LED is flashing.

Several hours of rest can be necessary to let the battery

cool down and to avoid damage.

2.5 Electrolyte

The rated specific gravity (S. G.) of the electrolyte is related

to a temperature of 30°C and the nominal electrolyte level

in the cell in fully charged condition. Higher temperatures

reduce the specific gravity of the electrolyte, lower

temperatures increase it. The electrolyte must conform

to the purity regulations in DIN 43530 part 2.

3. Maintenance

3.1 Daily

After each recharge, visual inspection after recharging for

signs of dirt and mechanical damage.

3.2 Weekly

Control all indications on easyplus and on charger’s display

for eventual warnings, defects, or need for water topping up

(especially if the battery remains in battery compartment in

the truck).

If the blue LED on the easyplus is ON, the battery needs to

be topped up in the shortest delay. In case of Hawker

Service contract, contact it immediately.

3.3 Annually

In accordance with EN 1175-1 and EN 50272-3 at least once

per year, the insulation resistance of the truck and the

battery must be checked by an electrical specialist.

After approx.200 cycles (one shift operation) or when the

blue LED on the easyplus is ON the Hawker freedom

batteries have to be topped up. In multiple shift and warm

ambient temperature operations, it may be necessary to

have shorter than 200 cycles topping up intervals

If you have a service contract, please contact the Hawker

Service!

After charging has ended the specific gravity and the

temperature of the electrolyte in all cells should be

measured and recorded. If significant changes from earlier

measurements or differences between the cells are found

further testing and maintenance by the service department

should be requested.

The filter of the air pump has to be checked during the

annual maintenance and eventually to be cleaned or

replaced. Earlier replacement of the filter is necessary if,

for undefined reasons (no leaks in the air pipes) the defect

signal of the air mixing system on the charger or on the

battery (on DC air pump or remote signal) is illuminated.

During the annual maintenance, check the correct

operation of the air pump.

4. Care of the battery

The battery should always be kept clean and dry to prevent

tracking currents. Any liquid in the battery tray must be

extracted and disposed of in the prescribed manner.

Damage to the insulation of the tray should be repaired

after cleaning, to ensure that the insulation value complies

with EN 50272-3 and to prevent tray corrosion. Repairs on

batteries have to be performed by Hawker service personnel

only.

5. Storage

If batteries are taken out of service for a lengthy period

they should be stored in the fully charged condition in a dry,

frost-free room. To ensure the battery is always ready for

use a monthly equalising charge as in point 2.3 can be made:

After a maximum of 6 weeks storage, proceed to a full

charge (see 2.2)

The storage time should be taken into account when

considering the life of the battery.

6. Malfunctions

If malfunctions are found on the battery or the charger

our service department should be called in without delay.

A service contract with us will make it easier to detect and

correct faults in good time.

freedom

OPTION

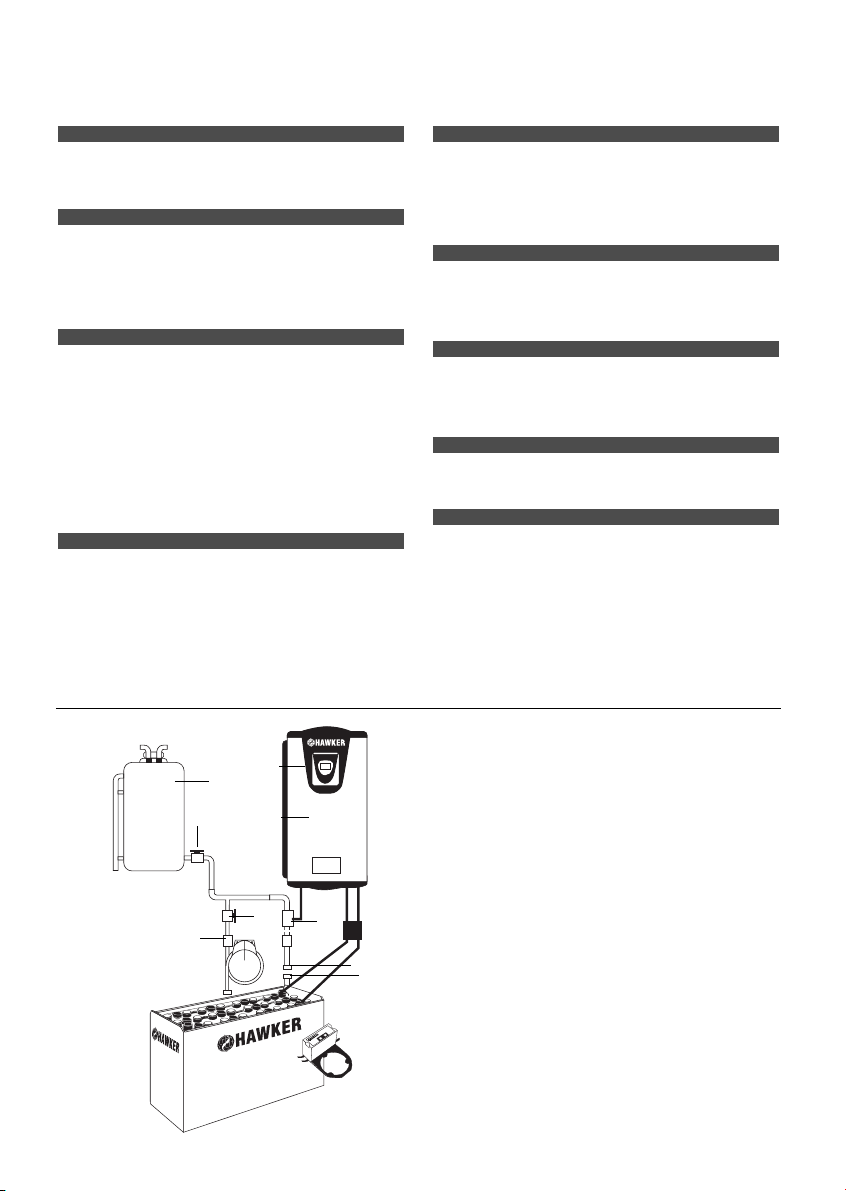

Aquamatic water refilling system (optional accessory)

1. Application

The water refilling system is used to automatically maintain

the nominal electrolyte levels.

2. Function

A valve and a float together control the topping up process

and maintain the correct water level in each cell. The valve

allows the flow of water into each cell and the float closes

the valve when the correct water level has been reached.

For fault-free operation of the water refilling system, please

note the instructions below:

2.1 Manual connection

The battery should be topped up shortly before completion

of a full charge, as at this point the battery has reached a

defined operational state resulting in satisfactory electrolyte

mixing. Filling takes place when the connector (7) from the

tank is connected to the coupling (6) on the battery. The

battery should only be connected to the filling system once

the easyplus BLUE Led is ON, or when.the need for water

topping is appearing on charger display, or when 200 cycles

are reached.

2.1.1. In multiple shift and warm ambient temperature

operations, it may be necessary to have shorter than

200 cycles topping up intervals.

2.2 Filling time

Filling time depends on the utilisation rate and the

corresponding battery temperature. Generally speaking, the

top up process takes some minutes and can vary according

to the battery capacity; after this, if manual filling is being

used, the water supply to the battery should be turned off.

2.3 Working pressure

The water refilling system should be installed in such a way

that a water pressure of 0.2 to 0.6 bar is obtained (with at

least 2 m height difference between the upper edge of the

battery and the lower edge of the tank). Any deviation from

this means that the system will not function properly.

2.4 Purity

The topping up water must be distilled or demineralised.

The water used to refill the batteries must have a

conductance of not more than 30 µS/ cm. The tank and

pipes must be cleaned before operating the system.

2.5 Pipe system on the battery

The plugs of each cell are connected in series or

series/parallel through a piping system.(EN 50272-3)

For safety reasons, the system must not be modified in

any way.

2.6 Working temperature

Batteries fitted with Aquamatic must only be charged

or refilled in a room temperature above 0°C.

2.7 Flow control

A flow indicator built into the water supply pipe to the

battery monitors the filling process. During filling the water

flow causes the built-in disc in the flow indicator to turn.

When all the plugs are closed the disc stops, indicating

that the filling process is complete.

1. tank

2. outflow connector with ball valve

3. plug with magnetic valve

4. plug with ball valve

5. flow control

6. coupling

7. connector

8. battery charger

9. charger main switch

1

2

3

4

5

76

8

9

The easyplus contains data on the battery (serial number,

capacity, technology), records data during the operation

(number of cycles, temperature, capacity, …) and transmits

the information to the charger with warnings appearing

on the charger’s display. (low electrolyte level, topping up

needed, overdischarge, daily cycle, excessive temperature,

voltage balance anomaly). Some of the information is

already indicated through the LEDs on the top of the

easyplus. When the blue led on easyplus is ON and stays

fixed, topping up must be carried out. Water topping up

should be done latest when the blue LED is ON or after

maximum 200 cycles.

2.1 Discharging

Be sure that all ventilation openings are not sealed or

covered. Electrical connections (e.g. plugs) must only be

made or broken in the open circuit condition. To achieve

the optimum life for the battery, operating discharges of

more than 80% of the rated capacity must be avoided

(deep discharge). This corresponds to an electrolyte specific

gravity of 1.15 kg/l at 30°C at the end of the discharge.

Discharged batteries must be recharged immediately and

must not be left discharged. This also applies to partially

discharged batteries.

2.2 Charging

Only direct current must be used for charging. The Hawker

freedom system is designed with a Hawker HF charger,

Powertech easy.com. In the system, the charger assigned

to the battery has been specifically determined for suiting

the size of the battery.

Hawker freedom batteries are low gas emission, so some

charging gasses are evolved.

Battery container lids and the covers of battery

compartments must be opened or removed.

The ventilation must comply to EN 50272-3 standard.

The vent plugs should stay on the cells and remain closed.

With the charger switched off connect up the battery,

ensuring that the polarity is correct. (positive to positive,

negative to negative). Now switch on the charger. When

charging the temperature of the electrolyte rises by about

10°C, so charging should only begin if the electrolyte

temperature is below 45°C. The electrolyte temperature of

batteries should be at least +10°C before charging otherwise

a full charge will not be achieved.

If a defect signal concerning the pump or the electrolyte

mixing system appears on charger’s display, check that the

piping system is connected and examine the piping circuit

for leaks or defects.(see 3. Maintenance). In the meantime,

the HF charger will adapt the profile.

The air pipe should never be removed during charge.

2.3 Equalising charge

Equalising charges are used to safeguard the life of the

battery and to maintain its capacity. They are necessary

after deep discharges or repeated incomplete recharges.

Equalising charges can be carried out manually, or will

be performed automatically after a rest following normal

charging.

Watch the temperature!

2.4 Temperature

An electrolyte temperature of 30°C is specified as the rated

temperature. Higher temperatures shorten the life of the

battery, lower temperatures reduce the capacity available.

55°C is the upper temperature limit and is not acceptable

as an operating temperature.

A temperature sensor is integrated in the easyplus device.

In case of excessive temperature the red LED is flashing.

Several hours of rest can be necessary to let the battery

cool down and to avoid damage.

2.5 Electrolyte

The rated specific gravity (S. G.) of the electrolyte is related

to a temperature of 30°C and the nominal electrolyte level

in the cell in fully charged condition. Higher temperatures

reduce the specific gravity of the electrolyte, lower

temperatures increase it. The electrolyte must conform

to the purity regulations in DIN 43530 part 2.

3. Maintenance

3.1 Daily

After each recharge, visual inspection after recharging for

signs of dirt and mechanical damage.

3.2 Weekly

Control all indications on easyplus and on charger’s display

for eventual warnings, defects, or need for water topping up

(especially if the battery remains in battery compartment in

the truck).

If the blue LED on the easyplus is ON, the battery needs to

be topped up in the shortest delay. In case of Hawker

Service contract, contact it immediately.

3.3 Annually

In accordance with EN 1175-1 and EN 50272-3 at least once

per year, the insulation resistance of the truck and the

battery must be checked by an electrical specialist.

After approx.200 cycles (one shift operation) or when the

blue LED on the easyplus is ON the Hawker freedom

batteries have to be topped up. In multiple shift and warm

ambient temperature operations, it may be necessary to

have shorter than 200 cycles topping up intervals

If you have a service contract, please contact the Hawker

Service!

After charging has ended the specific gravity and the

temperature of the electrolyte in all cells should be

measured and recorded. If significant changes from earlier

measurements or differences between the cells are found

further testing and maintenance by the service department

should be requested.

The filter of the air pump has to be checked during the

annual maintenance and eventually to be cleaned or

replaced. Earlier replacement of the filter is necessary if,

for undefined reasons (no leaks in the air pipes) the defect

signal of the air mixing system on the charger or on the

battery (on DC air pump or remote signal) is illuminated.

During the annual maintenance, check the correct

operation of the air pump.

4. Care of the battery

The battery should always be kept clean and dry to prevent

tracking currents. Any liquid in the battery tray must be

extracted and disposed of in the prescribed manner.

Damage to the insulation of the tray should be repaired

after cleaning, to ensure that the insulation value complies

with EN 50272-3 and to prevent tray corrosion. Repairs on

batteries have to be performed by Hawker service personnel

only.

5. Storage

If batteries are taken out of service for a lengthy period

they should be stored in the fully charged condition in a dry,

frost-free room. To ensure the battery is always ready for

use a monthly equalising charge as in point 2.3 can be made:

After a maximum of 6 weeks storage, proceed to a full

charge (see 2.2)

The storage time should be taken into account when

considering the life of the battery.

6. Malfunctions

If malfunctions are found on the battery or the charger

our service department should be called in without delay.

A service contract with us will make it easier to detect and

correct faults in good time.

freedom

OPTION

Aquamatic water refilling system (optional accessory)

1. Application

The water refilling system is used to automatically maintain

the nominal electrolyte levels.

2. Function

A valve and a float together control the topping up process

and maintain the correct water level in each cell. The valve

allows the flow of water into each cell and the float closes

the valve when the correct water level has been reached.

For fault-free operation of the water refilling system, please

note the instructions below:

2.1 Manual connection

The battery should be topped up shortly before completion

of a full charge, as at this point the battery has reached a

defined operational state resulting in satisfactory electrolyte

mixing. Filling takes place when the connector (7) from the

tank is connected to the coupling (6) on the battery. The

battery should only be connected to the filling system once

the easyplus BLUE Led is ON, or when.the need for water

topping is appearing on charger display, or when 200 cycles

are reached.

2.1.1. In multiple shift and warm ambient temperature

operations, it may be necessary to have shorter than

200 cycles topping up intervals.

2.2 Filling time

Filling time depends on the utilisation rate and the

corresponding battery temperature. Generally speaking, the

top up process takes some minutes and can vary according

to the battery capacity; after this, if manual filling is being

used, the water supply to the battery should be turned off.

2.3 Working pressure

The water refilling system should be installed in such a way

that a water pressure of 0.2 to 0.6 bar is obtained (with at

least 2 m height difference between the upper edge of the

battery and the lower edge of the tank). Any deviation from

this means that the system will not function properly.

2.4 Purity

The topping up water must be distilled or demineralised.

The water used to refill the batteries must have a

conductance of not more than 30 µS/ cm. The tank and

pipes must be cleaned before operating the system.

2.5 Pipe system on the battery

The plugs of each cell are connected in series or

series/parallel through a piping system.(EN 50272-3)

For safety reasons, the system must not be modified in

any way.

2.6 Working temperature

Batteries fitted with Aquamatic must only be charged

or refilled in a room temperature above 0°C.

2.7 Flow control

A flow indicator built into the water supply pipe to the

battery monitors the filling process. During filling the water

flow causes the built-in disc in the flow indicator to turn.

When all the plugs are closed the disc stops, indicating

that the filling process is complete.

1. tank

2. outflow connector with ball valve

3. plug with magnetic valve

4. plug with ball valve

5. flow control

6. coupling

7. connector

8. battery charger

9. charger main switch

1

2

3

4

5

76

8

9

Back to the manufacturer!

Batteries with this sign must be recycled.

Batteries which are not returned for the recycling process must be disposed of as hazardous waste!

When using motive power batteries and chargers, the operator must comply with the current

standards, laws, rules, and regulations in force in the country of use!

www.enersys-hawker.com - Subject to technical modification without any prior notice.

•Respecter la notice d’utilisation et l’afficher

visiblement près du site de charge!.

•Interventions sur batteries uniquement par

du personnel qualifié.

•Pour toute intervention sur la batterie, porter

des lunettes et des vêtements de protection.

•Observer les règlements de prévention des

accidents et les normes EN 50272-3,

EN 50110-1.

•Défense de fumer.

•Ni flamme, ni étincelles à proximité de la

batterie en raison du risque d’explosion et

d’incendie.

•En cas de projection d’acide dans les yeux

ou sur la peau, rincer abondamment à l’eau

claire. Consulter immédiatement un médecin.

•Rincer à l’eau les vêtements couverts d’acide.

•Danger d’explosion et d’incendie, éviter les

courts-circuits.

•Attention! Les parties métalliques des

éléments de batterie sont toujours sous

tension, pour cette raison ne jamais poser

d’outil ou d’objets métalliques sur la batterie.

•L’électrolyte est extrêmement corrosif

•Les batteries sont lourdes.Utiliser uniquement

les engins de levage et de transport autorisés.

•Tension électrique dangereuse

•Se méfier des risques liés aux batteries.

FRENCH

Notice d’utilisation Système Hawker freedom

Le droit à la garantie est supprimé en cas de non-observation de la notice d’utilisation, réparation avec des pièces de

rechange autres que des pièces d’origine, intervention arbitraires, utilisation d’additifs à l’électrolyte (soi-disant agents

d’amélioration).

Caractéristiques nominales

1. Capacité nominale C5: voir plaque signalétique

2. Tension nominale : 2,0 V x nombre d’éléments

3. Courant nominal de décharge [A] : C5/ 5h

4. Densité nominale de l’électrolyte * : 1.29 Kg/l

5. Température nominale : 30°C

6. Niveau d’électrolyte nominal : jusqu’au repère maxi de remplissage

* Est atteint pendant les 10 premiers cycles.

1. Mise en service des batteries remplies et chargées

(Mise en service d’une batterie non remplie, voir notice

séparée.)

Vérifier le bon état de la batterie. Toutes les vis du câblage

doivent être de façon à assurer un contact sûr.

Le couple de serrage est de :

acier

connexion perfect M 10 25 ± 2 Nm

Contrôler le niveau d’électrolyte Si celui-ci est inférieur au

déflecteur ou au bord supérieur du séparateur, ajouter de

l’eau distillée ou déminéralisée (DIN 43530, 4éme partie) jus-

qu’à ce niveau. Raccorder les fiches de la batterie et les

câbles de charge en respectant les polarités, sinon la batte-

rie et le chargeur risquent d’étre détruits. Recharger la batte-

rie conformément au point 2.2. Rétablir le niveau d’électro-

lyte avec de l’eau distillée ou déminéralisée.

2. Exploitation

L’exploitation de batteries de traction pour véhicules est

régie par la norme EN 50272 - 3 « batteries de traction pour

véhicules électriques ».

En condition normale de fonctionnement, la LED verte sur le

easyplus doit être allumée, lumière fixe ou clignotante

LED DEFINITION ACTION

Eteint Pas d’alimentation Vérifier les connexions

Led verte clignotante (lentement) Alimentation et Matériel OK

Led verte fixe Charge terminée

Led rouge fixe Surdécharge Charge immédiate

Led rouge clignotante Température excessive Refroidir jusqu’à température

normale

Led bleue clignotante (lentement) Alimentation et Matériel OK pour la tension 1/2

batterie et l’indication de niveau

Led bleue clignotante Différence de tension 1/2 batterie Action Service Hawker

Led bleue allumée Niveau d’électrolyte bas Remise en eau

Le système Hawker freedom inclut une batterie à brassage pneumatique, un boîtier électronique embarqué, le easyplus,

pour la mesure de la température, du niveau d’électrolyte et de la balance tension, ainsi que l’enregistrement des

informations concernant la capacité et la batterie. Ce contrôleur assure la communication avec le chargeur HF.

Un chargeur, Powertech easy.com (pour les instructions concernant le chargeur, voir notice spécifique)

Other Hawker Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual