Hawker F20/4H1C-R Operating instructions

1

AEROSPACE

Nickel – Cadmium

Batteries

Operating and

Maintenance Manual

UK

The document reference is online, please check the correspondence between the online documentation and the printed version.

Nickel – Cadmium Airborne Batteries

Operating and Maintenance Manual

HISTORY O REVISION

This manual replaces the issues:

53003 d/e 05.2009 3; 53003 R and 53003 RE

2

SAP number: 4635536

Date of issue: 01/01/13

Index of Revision: 01

Name of the Manufacturer: HAWKER GmbH, Dieckstrasse 42, 58089 Hagen

© Copyright

This document and all information contained herein is the property of EnerSys. Its use is

restricted solely to the maintenance of EnerSys Safety Plus Power batteries referenced in table 2

of section 1.6.3.

IM ORTANT

Please read this manual immediately on receipt of the battery(ies) before unpacking and

installing.

ailure to comply with these instructions will render any warranties null and void to the

extent permitted under applicable law. Manufacturer has not created any obligations

under this manual in the event the battery is damaged or destroyed as a result of any

misuse or not following the instructions

@ 2013 EnerSys. All rights reserved.

Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted.

Date Modification Version

The document reference is online, please check the correspondence between the online documentation and the printed version.

Coversheet 1

History of revisions 2

Update 2

Copyright 2

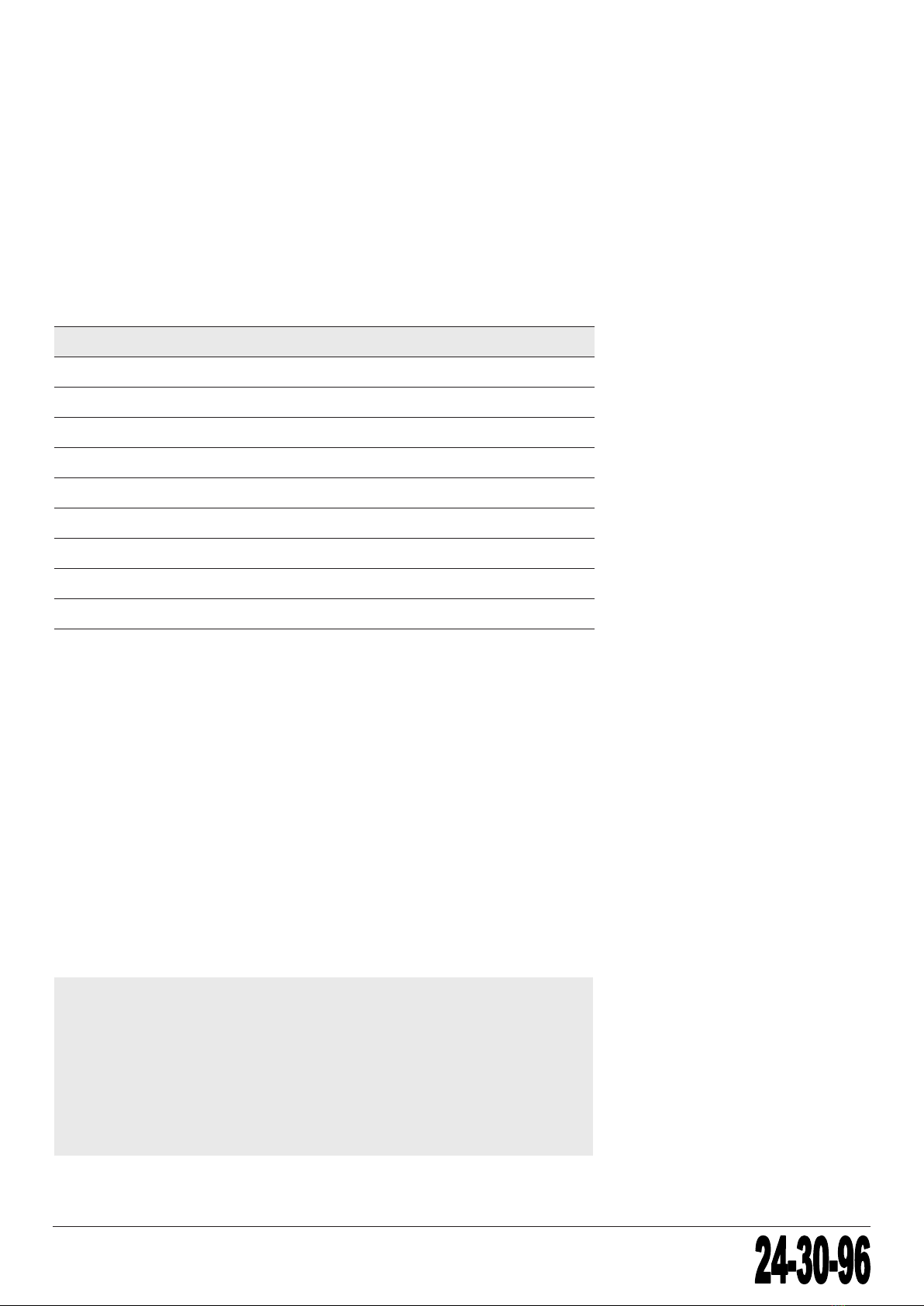

Table of effective contents 3

Abbreviations 5

Units (physical) 5

1.0 Maintenance Manual for the HAWKER®

Ni/Cd Airborne Battery – urpose

and Use 6

1.1. Application of Ni/Cd aircraft atteries 6

1.2. Features and designation of the attery 6

1.2.1 The battery 6

1.2.2. The cells 7

1.2.2.1 Positive and negative electrodes 7

1.2.2.2 Separators 7

1.2.2.3 Electrolyte 7

1.2.2.4 Vents 7

1.2.2.5 Pole terminals and connectors 7

1.3 Basic electrochemical reactions in cells 7

1.3.1 Conversion of energy 8

1.3.2 Electrolysis and evolution of gas during

overcharge and reversal charge 8

1.3.3 Oxygen recombination 8

1.4 Specified definitions 8

1.4.1 Current Rates 8

1.4.2 Rated Current (I1)8

1.4.3 Rated Capacity 8

1.4.4 Constant voltage current Ipr 8

1.4.5 EPV = End point voltage 8

1.5 Commonly used terms 8

1.5.1 Constant (low) Current Charging 8

1.5.2 IUI Charging 8

1.5.3 End of charge voltage 8

1.5.4 Constant Voltage Charging 8

1.5.5 Capacity test 8

1.5.6 Open circuit voltage 9

1.5.7 Deep discharge 9

1.5.8 Reconditioning 9

1.5.9 Capacity reduction during service

of the battery 9

1.5.10 Aging and loss of performance 9

1.5.11 Airworthiness 9

1.5.12 End of life capacity. 9

1.6 Technical data 9

1.6.1 Operational parameters and range

of application 9

1.6.2 Technical cell data: table 1 9

1.6.3 Technical battery data: table 2 10

2.0 Safety measures and instructions

for aircraft batteries 11

2.1 Instructions, warnings and notes 11

2.2 General safety instructions and

recommendations 11

3.0 Commissioning of new and

prolonged stored batteries 12

3.1 Log ook 12

3.2 Goods Inwards inspection Task for

new atteries 12

3.3 Commissioning Task for new atteries 13

3.4 Release to aircraft Task for atteries 16

4.0 Maintenance Intervals 17

4.1 Unscheduled maintenance procedures 17

4.2 Scheduled maintenance procedures 17

4.2.1 Monthly check on aircraft 17

4.2.2 Quarterly maintenance 17

4.2.3 Annual maintenance 17

4.3 Maintenance facility 17

4.4 Spare parts for repair 17

4.5 Equipment, Tools and Consuma les

for maintenance 17

3

Contents

The document reference is online, please check the correspondence between the online documentation and the printed version.

5.0 Storage Tasks airworthy batteries 18

5.1 Short-term storage of charged atteries 18

5.2 Long-term storage (up-to 5 years) of

discharged atteries 18

Task 5.1 Storage of maintained

(overhauled) charged batteries

up to 3 month 18

Task 5.2 Preparation for long-term

storage 19

Task 5. 3 Commissioning of prolonged

stored batteries 19

6.0 Transportation of batteries 22

Task 6.1: Shipment of batteries 22

7.0 Maintenance Tasks 23

Task 7.1: Monthly on aircraft check 23

Task 7.2: Quarterly maintenance

of airborne batteries 23

Task 7.3: Annual maintenance

of airborne batteries 26

8.0 Sub Tasks for Maintenance /

Commissioning procedures 30

Task 8.1 Reconditioning of cells

underperforming Discharge

requirements 30

Task 8.2 Check and adjust the torque

of the lower pole nuts 31

Task 8.3 Insulation resistance

measurement 32

Task 8.4 Check of electrolyte density 32

Task 8.5 Testing vents response

pressure after cleaning 33

Task 8.6 Battery cleaning procedure

of any disassembled battery

component 33

Task 8.7 unctional Test on

thermostats /

thermistors and temperature

switch assemblies 34

9.0 Fault finding ( for unscheduled

maintenance) 36

10.0 Unscheduled Maintenance - Repair 37

& Replacement – Overhaul Task

Task 10.1 Inspection and diagnostic 37

Task 10.2 Replacement of upper

pole nuts, spring washers

and links 39

Task 10.3 Replacement of lower pole

nuts, sealing caps and seals 40

Task 10.4 Replacement of the

Thermostat Switch Assembly 41

Task 10.5 Replacement of the Main

Battery Connector 41

Task 10.6 Replacement of the Battery

Case and or Battery Lid 42

Task 10.7 Replacement of Cell(s) 43

Task 10.8 Replacement of insulating

material (=liners / empty

containers ) 43

Task 10.9 Commissioning of repaired

batteries 44

Appendix 1:

IUI charge 45

Appendix 2:

Constant Current Charge 45

Appendix 3:

II-Charge 46

Appendix 4:

thermostats in temperature switch

harnesses 47

Appendix 5:

Recommended Tools and Consumables

for battery maintenance 48

Appendix 6:

Consumable for maintenance 49

Appendix 7:

Disposal of Airborne batteries 49

4

The document reference is online, please check the correspondence between the online documentation and the printed version.

5

AC Alternating Current

CHC’s Chlorinated hyro-carbons

DC Direct Current

DDP Declaration of Design and

Performance

EPV End point voltage

I Current

I-Charge Constant current charge

IPL Illustrated parts list

IU-charge Constant voltage charge with

a current limitation

IUI-Charge Combination of constant voltage

and constant current charge with

two current limitations

MSDS Material Safety Data Sheet

Ni/Cd Nickel/Cadmium

h / hrs Hour / Hours

min Minutes

A Ampere

Ah Amperehour

CA Rated Current

CAh Rated Capacity

V Volt

ΩOhm

M MegOhm

W Watt

Abbreviations

OCV Open circuit voltage

P/N Part number

P Power

PPE Personal Protective

Equipment

R Resistance

S/N Serial number

T Task = Maintenance Task

TOCV Top of charge voltage

TR Technical Requirement

U Voltage

NCC Normally closed contact

(type of thermostat)

NOC Normally opened contact

(type of thermostat)

Units

°C °C (temperature)

° ° ahrenheit (temperature)

bar bar

kPA kiloPascal

Nm Newtonmeter

g Gram

l Litre

kg/l Kilogram per Litre (density)

The document reference is online, please check the correspondence between the online documentation and the printed version.

1.1.

Applications of Ni/Cd aircraft batteries

HAWKER®airborne batteries are used for:

• starting engines or APUs,

• operations on ground and in flight

• emergency back up.

1.2 Features and designation of the

battery

1.2.1. THE BATTERY

The 24V battery is made up of 20 cells connected in series,

which are assembled in a battery case. The battery

container and the lid are typically made of stainless steel.

Some battery types have a container of stainless steel and

a lid of polymer material. The interior container walls are

lined with heat resistant plastic plates. The lid is lined with

a ribbing, which acts as a pressure pad for the cells. The

electrical connector typically is mounted on the front of the

battery container; but on some battery types the electrical

connector is mounted at the side. It enables electrical

connection of the battery to the power supply system. All

batteries can be additionally fitted with heater and

temperature sensors or temperature sensors only.

6

1. M inten nce M nu l for the HAWKER®Ni/Cd

Airborne B ttery – Purpose nd Use

Figure one: Batteries

The manual describes the processes

for trained technicians to maintain

Hawker®nickel-cadmium airborne

batteries. It informs about their basic

design features and details structured

tasks for visual inspection, diagnostic,

testing, performance reconditioning,

repair and the necessary care to

maintain best endurance and useful

life of these batteries.

Trained staff only should have access

to the manual, which always shall be

of latest revision and kept in good

condition by the battery owner.

Number of cells

Number of cells

Battery Capacity

Battery with thermostats

Number of thermostats

Special designed batteries

Cells designed for high rate applications

20

20

25 H1C (BER)1T

FP

F

Type of electrodes

Type of electrodes

Elements of the Battery designation:

The Hawker®aircraft battery designations

consist of the following elements

The document reference is online, please check the correspondence between the online documentation and the printed version.

1.2.2 THE CELLS

7

17

18

4

3

6

5

7

8

9

10

11

12

2

1

13

14

15

16

1 negative electrode 10 lid

2 positive electrode 11 seal (vent)

3 separator 12 vent (plug)

4 plate stack 13 upper terminal nut

5 negative pole terminal 14 springwasher

6 positive pole terminal 15 lower terminal nut

7 electrolyte level indicator 16 sealing cap

8 spacer 17 seal

9 seal 18 cell case

The cell comprises an assembly of positive (2) and

negative (1) sintered electrodes, alternately arranged and

meander-like separated with very thin hydrophilic layers of

polymer materials (3). The plate stack (4) with the two pole

terminals (5, 6) is placed in a prismatic plastic container

(18) which is leak-proof welded with a cell lid (10) that has

two bores for the poles and a centric threaded hole for the

vent (12). The vent closes the cell house filled with alkaline

electrolyte.

1.2.2.1. ositive and negative electrodes

The positive and negative electrodes are made of a

sintered metallic structure containing electrochemically

active masses in its pores. The metallic tabs welded to the

electrodes are acting as current collectors.

1.2.2.2 Separators

Three layers of oxidations-resistant separator made of

non-degradable synthetic materials separate the positive

and negative electrodes, arranged alternately. The outer

layers are of nonwoven fabric, whereas the inner layer is

a very thin hydrophilic polymer film. The film acts as

a gas barrier that is reducing the exothermic oxygen

recombination during charge and thus ensures excellent

charge stability of the cells.

1.2.2.3 Electrolyte

The electrolyte is a solution of potassium hydroxide in

deionised water with a typical density of 1.28 ± 0.02 kg/l

at 20°C.

Figure two: The cell

1.2.2.4 Vent plugs

The cell vents release the gas generated during float

charge, whilst also preventing electrolyte leakage and

contamination of electrolyte.

1.2.2.5 ole terminals, connectors and terminal nuts

Pole terminals, nuts and connectors used for the inter-cell

connection are made of highly conductive nickel-plated

copper material.

1.3 Basic electrochemical reactions in

cells

Positive Electrode = Nickel hydroxide – electrode

Negative Electrode = Cadmium/Cadmiumhydroxide –

electrode

Due to the very small changes in density by charge and

discharge operation, the density of the electrolyte cannot

indicate cell’s state of charge.

POSITIVE

ELECTRODE

NEGITIVE

ELECTRODE

POSITIVE

ELECTRODE

CHARGE

DISCHARGE

NEGITIVE

ELECTRODE

2Ni(OH)2Cd(OH)2

++

2NiO(OH) Cd+2H20

The document reference is online, please check the correspondence between the online documentation and the printed version.

1.3.1 CONVERSION O ENERGY

During charging, the active masses of the electrodes

convert electrical energy into chemical energy. The

discharge process reaction reverses it.

1.3.2 ELECTROLYSIS AND EVOLUTION O

GAS DURING OVERCHARGE AND

REVERSAL CHARGE

During overcharge, the water of the electrolyte is

decomposed. The hydrogen generated at the negative

Cadmium electrodes and oxygen generated at the positive

Nickelhydroxide electrodes escape through the vent of

the cell.

1.3.3

OXYGEN RECOMBINATION BY INTERNAL

ELECTROCHEMICAL REDUCTION ON

ELECTROLYTE-WET LIVE PARTS

A part of the oxygen generated, reduces according to the

two side reactions below. According to 1.3.2, the reduced

oxygen is equivalent to an amount of hydrogen that is not

generated. In total, the recombination of oxygen

suppresses the decomposition of water, but it heats

the cells.

Chemical reduction of oxygen at electrolyte-wetted

Cadmium during normal overcharge.

1.4 Specified definitions

1.4.1 CURRENT RATES

The current rates express values of current in ampere (A)

used to charge and discharge cells and batteries as a

multiple of its (nominal) current. or example, a current of

20 A used to charge a cell with a rated capacity of 100 Ah

would be expressed as C5= 0.2*I1or 0.2 C1= 0.2*I1.

1.4.2 RATED CURRENT (I1)

The rated discharge current of the battery returns not

less than its rated C1capacity in 1 hour.

8

2 H20 +

2H2 02

+++

4 0H° Heat

O

2

2 H

2

0

4e°

+++

2 Cd (OH)

2

Heat

2 Cd

0

2

2 H

2

0

1.4.3 RATED CAPACITY C1

The rated capacity is the minimum capacity, expressed in

Ah, obtained from a charged battery when discharged at

the I1rate to the EPV.

1.4.4 CONSTANT VOLTAGE CURRENT IPR

The Ipr is the discharge current, which the battery delivers

at the conclusion of a 15sec power discharge, controlled

as maintained a constant voltage of half the nominal

battery voltage.

1.4.5 EPV = END POINT VOLTAGE O

THE BATTERY

Unless otherwise stated during discharge the EPV of the

battery corresponds roughly to 1 Volt * number of cells.

1.5 Commonly used terms

1.5.1 CONSTANT (LOW) CURRENT

CHARGING (APPENDIX 2)

The constant current charging is a method used to charge

a fully discharged battery with a predefined current and

duration. The recommended rates for charge are 0.2*I1for

7 hours, or 0.1*I1for 14 hours. or the commissioning and

reconditioning of cells 8 hours at 0.2*I1is strongly

recommended.

1.5.2 IUI CHARGING – ( AST CHARGING IN

ACCORDANCE WITH APPENDIX 1)

The IUI-charge recommended in this manual is a general

method for recharging the batteries from an unknown

state of charge. It shall not be applied at battery

temperatures below 0°C and on batteries stored inactive

for more than 3 month.

1.5.3 END O CHARGE VOLTAGE

The end of charge voltage is the voltage of a battery or

cell prior to the charge current being switched off.

1.5.4 CONSTANT VOLTAGE CHARGING

Constant voltage charges (e.g. at 1.425 Volt per cell) shall

not be used to maintain and recondition the cells of

batteries as the overcharge at constant current (section

1.5.1) is more efficient to condition cells imbalanced from

cyclic services with constant voltage charges and shallow

discharges.

1.5.5 CAPACITY TEST

A capacity test is the measurement of the discharge time

and the discharge voltage at a constant discharge current

until the defined EPV is met. The product of discharge time

and discharge current calculates the capacity.

The document reference is online, please check the correspondence between the online documentation and the printed version.

1.5.6 OPEN CIRCUIT VOLTAGE

The open circuit voltage is the voltage of the battery,

without being connected to any units that can provide or

consume electrical power.

1.5.7 DEEP DISCHARGE

The deep discharge is a part of the maintenance process

“Reconditioning” to recover reversible losses of battery

capacity and discharge voltages, which might have been

created in service.

1.5.8 RECONDITIONING

Reconditioning is a process to recover reversible capacity

losses on cells imbalanced during shallow cycling and

discharge voltage reduction by continuous float charge, or

storage.

1.5.9 CAPACITY REDUCTION WHILE THE

BATTERY IS IN SERVICE

The battery capacity can reduce, if the on board charging

voltage is too low. This capacity reduction can be reversed

by battery maintenance.

9

1.5.10 AGEING AND LOSS O PER ORMANCE

Ageing causes battery’s irreversible losses of energy

conversion. These losses cannot be cured by electrical

treatments. One effect of cell’s ageing is the accumulation

of impurities, and of corrosion products in the electrolyte

and the electrodes of the cells. Any removal of such

effects, by undefined measures is inadmissible.

1.5.11 AIRWORTHINESS

Airworthiness is the compliance of battery component(s)

with all conditions and regulations required by the

approving authorities for their safe operation and

performance.

1.5.12 END O LI E CAPACITY.

The end of life capacity of maintained cells is defined as

≤80% of the rated capacity (compare section 1.4.3)

1.6 Technical data

1.6.1 OPERATIONAL PARAMETERS

• Operational temperature range limited from -50°C to 71°C;

• Continuous voltage controlled charges procedures should not be performed above 60°C (battery

temperature)

• Due to potential risk of any ice formation in the electrolyte of the cells should not be charged below -30°C

(battery electrolyte temperature)

• or any specific technical data refer to the relevant DDP (Declaration of Design and Performance) or Technical

Specification which can be requested from the authorised Hawker®representative.

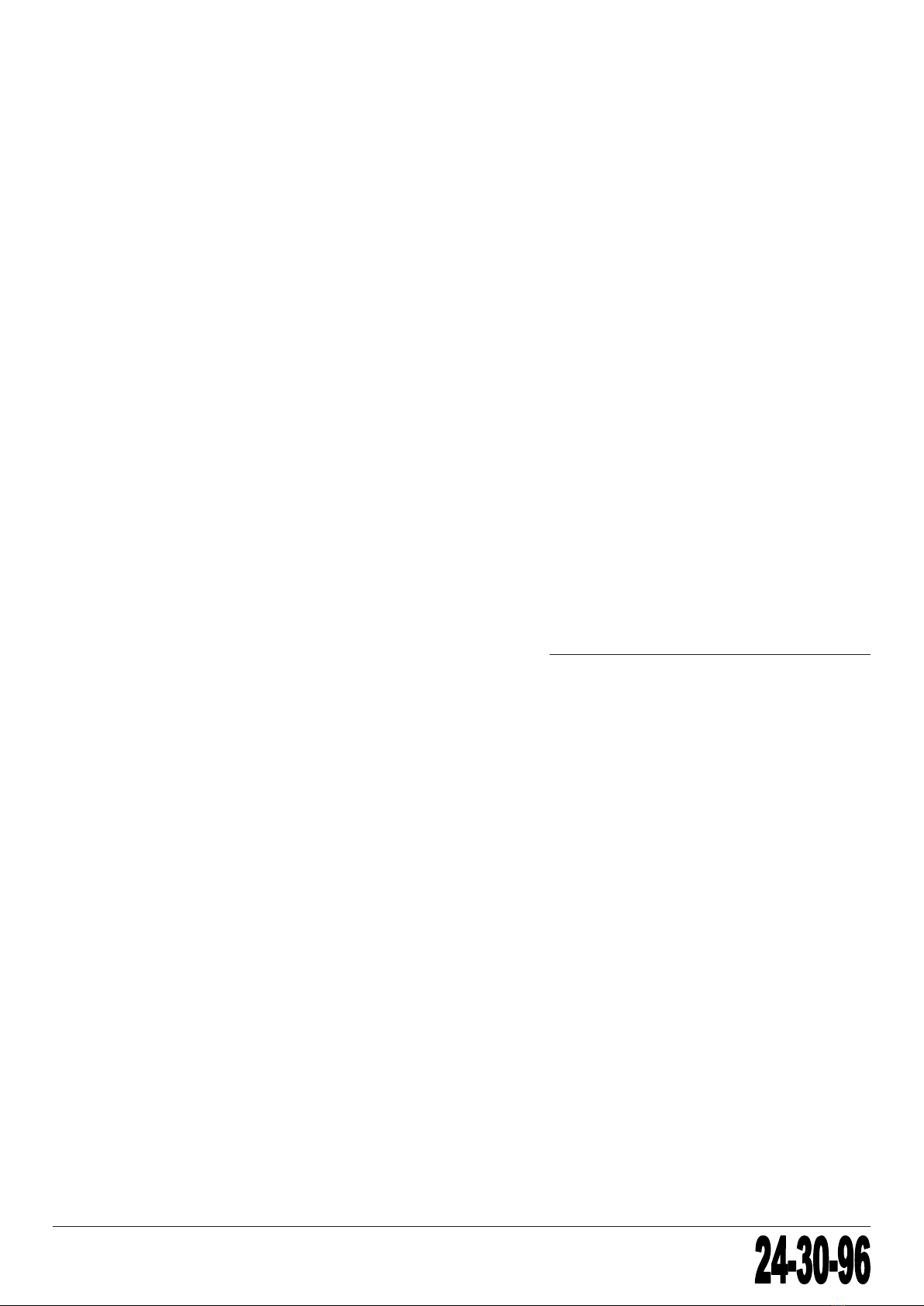

1.6.2 TECHNICAL CELL DATA, TABLE 1

Cell designation FP44H1C FP40H1C FP38H1C FP27H1C FP25H1C FP22H1C FP17H1C FP7H1C FP4H1C

Rated voltage. (V) 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2

Electrolyte – density Potassium hydroxide solution, density at 20°C: 1.28 kg/l ± 0.02 kg/l

Thread of upper pole nut M10 M10 M10 M10 M8 M8 M8 M8 M4

Torque of: lower pole nut

Torque of upper pole nut

7 Nm (70 kpcm)

10 Nm (100 kpcm)

4 Nm (40 kpcm)

5 Nm (50 kpcm)

0.9 Nm (9 kpcm)

1.6 Nm (16 kpcm)

Venting pressure Green vents 0.35 ± 0.2 bar;

Venting pressure Blue vents: 0.4 to 0.7 bar

The document reference is online, please check the correspondence between the online documentation and the printed version.

Battery

type

Type

No.

SAP

No*

Cell

type

Nominal

voltage (V)

Rated

capacity (Ah)

pr(A)

to 25°C

Length

(mm)

Width

(mm)

Height

(mm)

Typ. Weight

kg)

F20/4H1C-R 3349004 910 2314772 FP4H1C 24 4 150 166 118 109 4.5

F20/7H1C-E2 3349007 9000 2314845 FP07H1C 24 7 450 325 180 130 13.0

F20/15H1C 3349015 910 2314918 FP15H1C 24 15 600 198 195 196 16,7

F20/17H1C 3349017 910 2315047 FP17H1C 24 17 700 198 195 196 16.9

F20/17H1CT 3349017 960 2315096 24 17 700 198 195 196 17.1

F20/17H1C-1 3349017 920 2315055 24 17 700 253 158 188 16.9

F20/17H1CT2-1 3349017 900 2315039 24 17 700 253 158 188 17.2

F20/17H1C-2 3349017 930 2315063 24 17 700 260 147 188 17.0

F20/17H1CT-2 3349017 950 2315088 24 17 700 260 147 188 17.1

F20/17H1C-3 3349017 940 2315071 24 17 700 321 125 200 17.3

F20/22H1C-1 3349022 900 2315144 FP22H1C 24 22 900 424 119 180 23.5

F20/25H1C 3349025 900 2315274 FP25H1C 24 25 1025 254 197 223.5 25.5

F20/25H1CT 3349025 910 2315322 24 25 1025 254 197 223.5 25.6

F20/25H1C-L39 3349025 990 2315444 24 25 1025 402 207 250 28.5

F20/25H1CT2 3349025 920 2315355 24 25 1025 254 197 223.5 25.7

20FP25H1C-R 3349025 940 2315371 24 25 1025 363 174 226 24.5

20FP25H1CT-R 3349025 950 2315396 24 25 1025 363 174 226 24.5

F20/27H1C 3349027 920 2315622 FP27H1C 24 27 1125 254 248 204 27.5

F20/27H1CT 3349027 910 2315599 24 27 1125 254 248 204 27.6

F20/27H1C-T2 3349027 940 2315647 24 27 1125 254 248 204 27.7

F20/27H1C-E1 3349027 900 2315582 24 27 1125 363 168.5 218 28

F20/27H1C-M1 3349027 9600 2315703 24 27 1125 478.5 168.5 237.5 28.6

F20/27H1C-M1T 3349027 7000 2315509 24 27 1125 478.5 168.5 237.5 28.7

F20/27H1C-M3 3349027 8000 2315574 24 27 1125 478.5 168 218.5 29.4

20-FP38H1C-R 3349038 900 2315752 FP38H1C 24 38 1350 495 174 226 34.9

20FP38H1CT-R 3349038 901 2315769 24 38 1350 495 174 226 35.0

20FP38H1CT-R 3349038 9011 2315785 24 38 1350 495 174 226 35.0

20FP38H1CT2-R 3349038 9010 2315777 24 38 1350 495 174 226 35.1

F11/40H1C 3349040 100 2315793 FP40H1C 13.2 40 1500 223.5 182.5 253.5 21.7

F20/40H1C 3349040 910 2315914 FP40H1C 24 40 1500 254 248 262 36.4

F20/40H1CT 3349040 9206 2316002 24 40 1500 254 248 262 36.5

F20/40H1CT2(P) 3349040 9201 2315955 24 40 1500 254 248 262 36,6

F20/40H1C-AC 3349040 960 2316092 24 40 1500 254 248 262 36.5

F20/40H1C-E1 3349040 900 2315882 24 40 1500 363 168.5 268 38.5

F20/40H1CT/A 3349040 9200 2315947 24 40 1500 254 248 262 37.6

F20/40H1CT3 3349040 9209 2316035 24 40 1500 254 248 262 36.7

F20/44H1C 3349045 910 2316181 FP44H1C 24 44 1500 254 248 262 37,4

F20/44H1CT 3349045 920 2316198 24 44 1550 254 248 262 37.5

10

1.6.3 TECHNICAL BATTERY DATA: TABLE 2

The document reference is online, please check the correspondence between the online documentation and the printed version.

2.1 Safety Instructions, Warnings

and Notes

“CAUTION” is necessary, if non-adherence or

incorrect adherence to the service or working

instructions could cause injuries or fatal

accidents.

“ATTENTION” applies, if non-adherence or

incorrect adherence to the service or working

instructions might cause damage to the unit and

potential safety issues.

“NOTE” draws attention to important points.

2.2 General safety instructions:

• Observe the (local) instructions for battery

use and position them visibly near the

battery

• Trained personnel must only carry out

work on batteries

• Read the Material Safety data sheet.

• Use protective glasses and wear safety

clothing when working on batteries

• Adhere to the current accident prevention

rules in the country where the battery is

used.

• No smoking

• Do not expose batteries to naked flames,

glowing embers or sparks, as it may

cause the battery to explode. Avoid

sparks from cables or electrical apparatus

as well as electrostatic discharges.

• Avoid any contact of electrolyte with the

eyes, open wounds / skin and clothing

• Avoid ingestion of electrolyte. In case of

skin contact with electrolyte and/ or

ingestion of electrolyte as well as burns

consult a doctor immediately or “ irst

Aid”, flush skin and eyes with plenty of

water or a solution of boric acid in water,

11

2. S fety me sures nd instructions

• Remove electrolyte contaminated

clothes, immediately wash in excess of

acetic water

• The potassium hydroxide electrolyte

solution is highly corrosive.

• Avoid any spilling of electrolyte

• Do not disassemble cells since cadmium

and cadmium oxide is poisonous and is

believed to be carcinogenic. Nickel can

cause serious skin allergic reactions and

skin irritations to nickel sensitive and

exposed persons.

• Batteries are heavy.

• Use suitable transportation / lifting

equipment

• Battery vent tubes are not intended for

use as lifting handles.

• Risks of explosion and fire

• Do not use any inflammable organic

solvents, CHC’s and mixtures of it for

cleaning

• Do not dismantle cells

• Avoid conditions for electrical shocks by

using insulated tooling. Electrical short

circuits and sparks may injure the

operator, damage the battery and ignite

gases from charging

• Do not wear clothes with static fibres and

metallic accessories (rings, watches, belts

jewellery) when working on batteries. Use

a plastic brush and antistatic cleaning

cloth for dry wiping off adhesive dirt from

the battery

• Never place any conductive parts on

metallic parts of the battery

• Do not block the battery outlet pipes with

the liners

• Remove battery lid from container prior to

charging.

• Pay attention to the hazards that can be

caused by batteries.

The document reference is online, please check the correspondence between the online documentation and the printed version.

3.1 Log book

The operator shall record and confirm by signature in the log book the process steps and data measured on

the battery and its cells. These records are required to provide evidence of the airworthiness of the battery.

ailures to comply with this instruction may invalidate the warranty conditions.

3.2 Goods inwards inspection Task for new batteries

12

3. Commissioning of new b tteries

Task 3.1 – Goods inwards inspection of a new battery on receipt

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

1.

Visually check the delivered packing boxes with batteries for signs

of transportation and thermal damage as well as for moisture.

2. Unpack the boxes and check the delivery is

complete according to the accompanied documentation.

Contact the supplier.

3. Visually inspect the battery internally and externally

for signs of impact damage, corrosion and leakage.

Record the findings into the log book

Any defects quarantine the battery and contact the supplier.

4. For any additional goods inwards inspection refer

to the local regulations.

Record the findings into the log book.

5. Record the results in the battery log book.

The document reference is online, please check the correspondence between the online documentation and the printed version.

13

3.3 Commissioning Task 3.2 for new batteries

Task 3.2 – Commissioning of new batteries

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

ATTENTION

Never charge, discharge or adjust electrolyte on cells connected in

series outside the battery case.

1. Remove the lid from the battery case.

2.

Remove the caps from the main connector pins using insulated tools

Contact the supplier

3. Tighten the upper pole nuts with the correct torque as indicated in

Table 1 of section 1.6.2

Record the findings into the log book.

Any defects quarantine the battery and contact the supplier.

4. Measure the insulation resistance with a MΩ-meter at 250 V DC

between the + pin of the battery connector and the battery case

and the insulation resistances with same device at 250 V DC

between the + terminal of each cell and the battery case.

f R ≤ 10 MΩ due to moisture, remove the lid and store the

battery for 24 hours in an air-conditioned room and repeat the

test.

n case of failure: return the new battery to the supplier.

5. Undo the vents and keep them aside on the cells mouth.

ATTENTION

Do not top up the discharged cells at this stage

ATTENTION:

• Do not use mercury thermometer.

• Place none-insulated thermocouple probes between the cells.

6. nstall a thermometer or suitable insulated temperature probe in a

cell placed at the centre of the battery. The device shall touch the

separators of the plate stack.

7. Connect the battery to the charge / discharge unit.

8. Charge the battery for 8 hours at 0.2 1as shown in Appendix 2

(commissioning charge).

f necessary, adjust the electrolyte level of the cells

15 to 10 minutes prior to the end of charge.

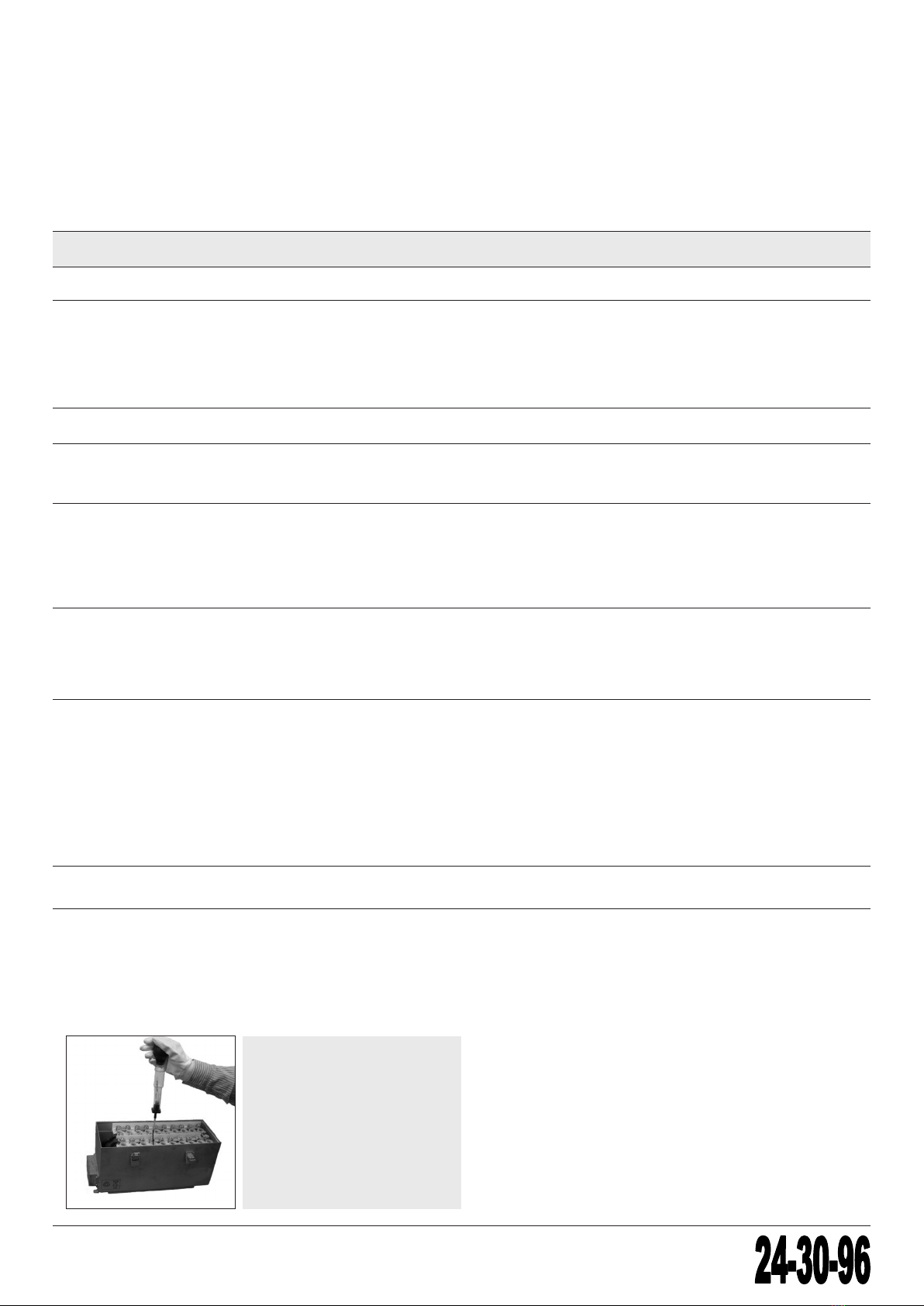

Figure 3: adjusting electrolyte level

CA TION

Always wear protective goggles

and gloves when working on the

battery

ATTENTION

For adjusting the electrolyte level

use distilled water

The document reference is online, please check the correspondence between the online documentation and the printed version.

14

Figure 4: Electrolyte level indicator

ATTENTION

The electrolyte level of charged cells decreases after charge while

the gas is escaping. Do not adjust electrolyte level further.

9. Stand the battery for one hour on open circuit.

10. Check the battery temperature is below 35°C

11.

Ensure that the battery is connected to the charge/discharge unit.

12. Discharge the 24V Battery at

1

to 20 V.

Requirement: The voltage of each cell after 60 minutes must be equal

or greater than 1.0 V.

Note: f the discharge at the

1

rate is not feasible, select a different

set of discharge rate and criteria from the table below.

Record the cell voltages (column 3) in the log book.

f any battery does not meet the requirement contact

the supplier.

13. Soak the battery to room temperature for up to 8 hours before

recharging.

ATTENTION

f necessary, adjust the

electrolyte level to the

height that touches the

edge of the spacer.

Discharge current rate Time (min) cell voltage

reading

Voltage requirement for

cells (V)

0.2* 1300 ≥1.0

0.4* 1150 ≥1.0

0.6* 1100 ≥1.0

0.8* 175 ≥1.0

160 ≥1.0

The document reference is online, please check the correspondence between the online documentation and the printed version.

15

14.

Recharge the battery using a method indicated in section 14.1 or 14.2

or 14.3

• Adjust the electrolyte level at a current of 0.2* 115 minutes to 10

minutes prior to end of the charge methods, 14.1, 14.2, and 14.3

• Afterwards measure the voltage on each cell prior to the end of

charge at 0.2* 1

.

Requirement: cell voltage shall be ≥ 1.56 V

• Record the values in the log book.

Note:

f the battery has to be charged below 0°C, apply 7 hours charge

at 0.2* 1

.

ATTENTION:

• Do not charge the battery with currents higher than I1

• If you cannot fully supervise, do not use method described

in 14.3.

14.1 IUI charge – method (Appendix 1)

• Charge the battery at 1until voltage has increased to 1.55V times

number of cells and charge for 2 hours at 0.2* 1

• After about 1 hour charge, check that battery has reached the

voltage level to switch the charge current to 0.2* 1.

14.2 I charge method (Appendix 2)

• Charge the fully discharged battery for seven hours at 0.2* 1.

14.3 II charge method (Appendix 3)

ATTENTION:

• Charge the fully discharged battery with parameters selected

from the table below and afterwards charge for two hours at

0.2*I1

• Check battery current switching to 0.2*I1at the stage 1(max) time

presented in the table below.

n case cells fail this requirement, contact the supplier

15. Stand the battery for 1 hour minimum and 24 hour maximum and

then refit the vents on the cells and fit the lid in its correct

orientation as indicated by the arrowhead which points in the

direction of the main connector.

current Stage 1 time (max)

0.4* 1180

0.6* 1120

0.8* 190

The document reference is online, please check the correspondence between the online documentation and the printed version.

16

Task 3.3 – Specific release requirements

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

1. nstall the battery into the aircraft as described in the flight

manual.

NOTE

This manual does not provide aircraft-specific working instructions.

2. Carry out the pre-flight testing on ground as defined in the flight

manual, if required.

f the battery fails, reject it from service and send it to workshop

for maintenance.

3. Recharge the battery in the battery workshop, if more than

20% is discharged during the pre-flight tests as described in

the flight manual.

f charging is not described in the flight manual, remove the lid and

refresh charge battery for 7h at 1.425V per cell, with closed cell

vents.

3.4 Release to aircraft Task 3.3:

or any additional specific release requirement refer to Task 3.3 below

The document reference is online, please check the correspondence between the online documentation and the printed version.

4.2 Scheduled maintenance

procedures

4.2.1 MONTHLY CHECKS ON AIRCRA T.

If a monthly check is specified in the flight manual, then

carry out Monthly on "aircraft" check in accordance with

Task 7.1.

4.2.2 QUARTERLY MAINTENANCE

Quarterly maintenance shall be carried out 3 months after

installing the maintained battery into the aircraft. Tasks to

be undertaken are listed below and shall be carried out in

accordance with

Quarterly maintenance Task 7.2

Release-Inspection check Task 3.3.

17

4.1 Unscheduled maintenance

procedures

ollowing an unscheduled removal from aircraft the battery

shall be taken to the battery workshop for investigation in

accordance with the following steps.

• ault inding: refer to Section 9

• Inspection and Diagnostic: Task 10.1

• Repair: (repair the battery as necessary in accordance

with Tasks below:).

Task 10.2 – replacement of upper pole nuts, spring

washers and intercell links

Task 10.3 – replacement of lower pole nuts, sealing

caps and seals

Task 10.4 – replacement of the thermostat switch

assembly

Task 10.5 – replacement of the main battery

connector

Task 10.6 – replacement of the battery case and or

battery lid

Task 10.7 – replacement of the cell(s)

Task 10.8 – replacement of the insulating materials

Task 10.9 - Commissioning of repaired battery:

4. M inten nce Interv ls

4.2.3 ANNUAL MAINTENANCE

Annual maintenance overhaul shall be carried out

every 12 months.

Tasks to be undertaken are listed below and shall be

carried out in the presented sequence.

Annual maintenance Task 7.3

Release-Inspection check Task 3.3.

4.3 Maintenance Facility.

The maintenance on Hawker®batteries shall be

carried out in a dedicated battery shop by trained

technicians. Requirements for battery maintenance

shops are defined in specifications.

4.4 Spare parts for repair

Any battery components used for replacing defective

parts at repair shall comply with part number as

identified in the battery-specific IPL. Only Hawker®

approved spare parts shall be used.

4.5 Equipment, Tools and

Consumables for maintenance

Hawker®recommends the use of equipment, tools

(listed in Appendix 5) and consumable (listed in

Appendix 6) for maintenance and repair on Hawker®

batteries.

The document reference is online, please check the correspondence between the online documentation and the printed version.

5.1 Short-term storage of charged

batteries

Maintained and charged batteries can be stored for 3

months at ≤35°C in a secured area.

Refer to Task 5.1 - Storage of maintained (overhauled)

charged batteries up to 3 month.

The batteries shall be stored:

• without being trickled charged

• in upright position

• with vents tightened

• with the lid locked on the battery case,

• plastic caps are mounted on both pins of the

connector

• in a well-ventilated or air-conditioned room

between 10°C and 35°C and a relative humidity

between 45 and 75%

• protected from dust, moisture, corrosive gases

and excessive heat

• in an area with authorised access, only.

Prior to installing the battery on the aircraft, it shall be

recharged for 7 hours with a constant voltage of 1.425

V per cell.

After 3 months storage the battery shall be subjected

to quarterly maintenance.

18

5.0 Stor ge T sks for irworthy b tteries

5.2 Long-term storage (up-to 5 years) of

discharged batteries

Batteries can be stored between 3 months and 5 years

only in a discharged state.

Refer to Task 5.2 for long-term storage preparation

procedures.

The batteries shall be stored:

• Always in maintained and discharged condition

• in upright position

• with vents tightened

• with the lid locked on the battery case

• plastic caps are mounted on both pins of the

connector

• in a well-ventilated or air-conditioned room

between 10°C and 35°C and a relative humidity

between 45 and 75%

• protected from dust, moisture, corrosive gases

and excessive heat

• in an area with authorised access, only.

W

hen returning the battery back into service, carry out Task

5.3 “Commissioning of prolonged stored batteries”.

Task 5.1 – Storage of maintained (overhauled) charged batteries up to 3 month

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

1. Carry out the scheduled maintenance procedure on the battery,

either Task 7.2 or Task 7.3.

2. Store the battery in a ventilated room at temperatures

recommended 10°C and 35°C and at relative humidity between

45% and 75%.

3. f returning the battery to service within the 3 months storage time,

recharge with a constant voltage of 1.425 V per cell at 20°C ± 5°C

without opening the vents.

f the charged battery is stored for longer than 3 months and shall

be returned to service, subject it to quarterly maintenance

procedure Task 7.2.

4. f required, release the battery to service according to Task 3.3.

The document reference is online, please check the correspondence between the online documentation and the printed version.

19

Task 5.2 - reparation for long term storage

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

1. Carry out the scheduled maintenance procedure on the battery in

accordance with Task 7.3.

2. Discharge the battery to an average of 1V per cell using current

rates between 1and 0.1* 1.

3. Store the battery in a well-ventilated or air-conditioned room at

temperatures between 10°C and 35 °C and at relative humidity

between 45% and 75% up-to a maximum of 5 years.

Task 5.3 – Commissioning of prolonged stored batteries

OPERAT NG NSTRUCT ON AND TECHN CAL REQU REMENTS (TR) NSTRUCT ONS / EV DENCE WHEN DEV AT ONS FROM TR

1. Remove the lid from the battery case.

2. Remove the caps from the main connector pins using

insulated tools.

ATTENTION:

• Do not top up the discharged cells at this stage

• ndo the vents and keep them aside on the cells mouth.

ATTENTION:

• Do not use mercury thermometer

• Place none-insulated thermocouple probes between the cells.

3. nstall a thermometer or suitable insulated temperature probe

in a cell placed at the centre of the battery. nstall non-insulated

temperature probe between the cells.

4. Connect the battery to the charge / discharge unit.

5. Charge the battery for 8 hours at 0.2* 1as shown in

Appendix 3 (commissioning charge).

f necessary, adjust the electrolyte level of the cells prior to

the end of charge.

Figure 3: adjusting electrolyte level

CA TION

Always wear protective goggles

and gloves when working on the

battery

ATTENTION

For adjusting the electrolyte

level use distilled water

The document reference is online, please check the correspondence between the online documentation and the printed version.

20

Figure 4: Electrolyte level indicator

ATTENTION

The electrolyte level of charged cells decreases after charge

while the gas is escaping. Do not adjust electrolyte level

further.

6. Stand the battery for one hour.

7. Check the battery temperature is below 35°C. f battery temperature above, soak it to ambient

room temperature.

8. Ensure that the battery is connected to the charge/

discharge unit.

9. Discharge the 24V Battery at 1to 20 V.

Requirement: The voltage of each cell after 48 minutes must be

equal or greater than 1.0 V.

Note: f the discharge at the 1rate is not feasible, select a different

rate and criteria from the table below.

f any battery does not meet the requirement contact

the supplier.

10. Soak the battery to room temperature for up to 8 hours before

recharging.

ATTENTION

f necessary, adjust the

electrolyte level to the

height that touches the

edge of the spacer.

Discharge current rate Time (min) cell voltage

reading

Voltage requirement

for cells (V)

0.2* 1240 ≥1.0

0.4* 1120 ≥1.0

0.6* 180 ≥1.0

0.8* 160 ≥1.0

148 ≥1.0

Record the cell voltages (column 3) in the log book.

The document reference is online, please check the correspondence between the online documentation and the printed version.

This manual suits for next models

36

Table of contents

Other Hawker Camera Accessories manuals