Series 5000 EPRV (8 - 12”) Installation, Operation and Maintenance Guide - Oct-20212

PART B

OPERATING SERIES 5000 EPRV

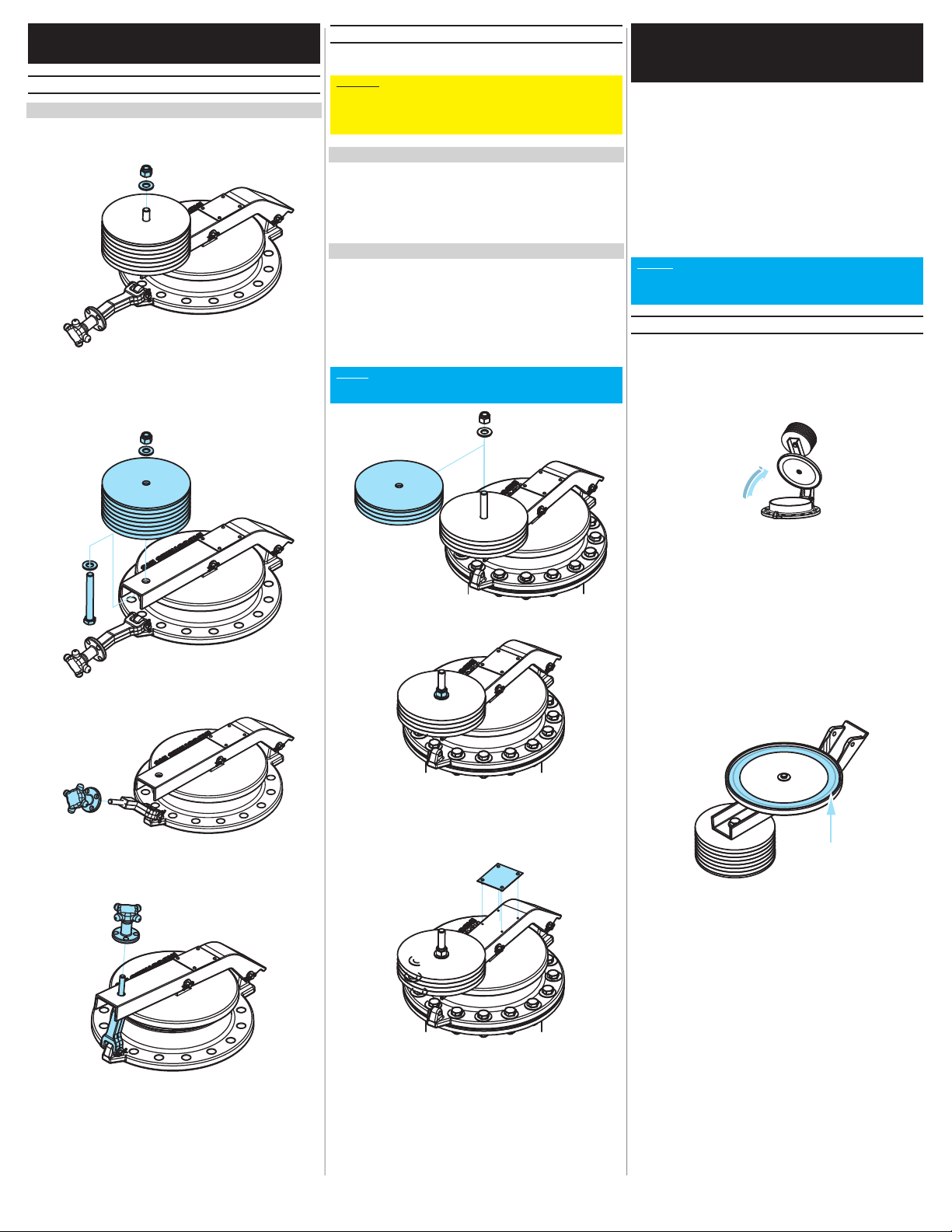

B1 OPERATING TRANSPORT LOCK

TOOLS

»2× 3/4 Box and/or Socket Wrench

1 Remove nut and top washer from weight hanger bolt.

2 Remove weights and weight hanger bolt. Keep these

parts together and transport along with the tank to be

reinstalled at the final destination before the tank is

placed into service.

3 Remove the locking knob.

4 Lift the EPRV arm and place the locking arm stud

through the weight hole in the EPRV arm and replace

the locking knob and tighten hand tight.

5 Once the tank has been moved, and before it is placed

into service, perform these steps in reverse to remove

the transport lock and replace the set pressure weights.

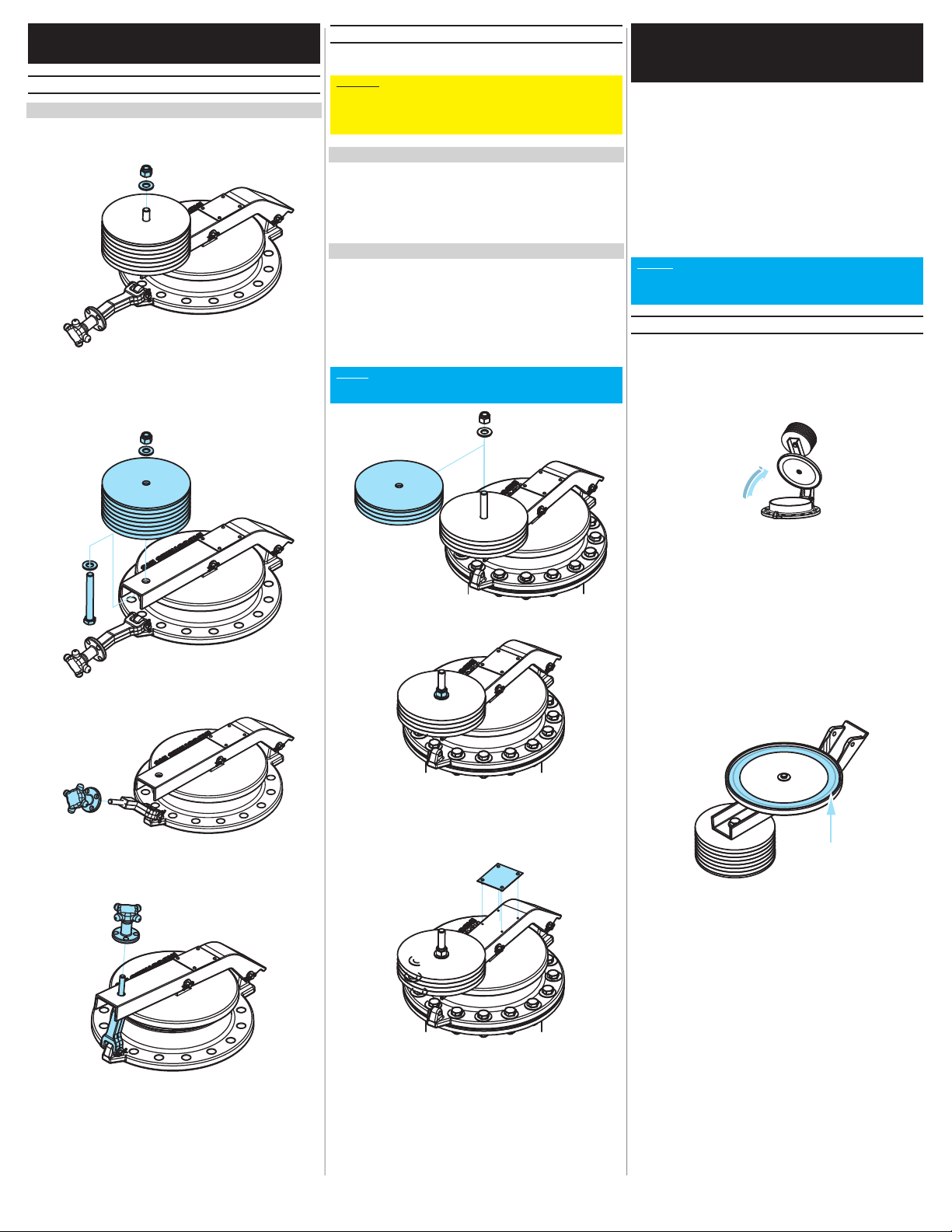

B2 CHANGING THE SET PRESSURE

The set pressure of the EPRV can be changed by adding or

removing weight plates.

NOTICE: WHEN THE SET PRESSURE IS CHANGED

FROM THE FACTORY SETTING THE PRODUCT TAG

MUST BE CHANGED TO REFLECT THE NEW SET PRES

SURE, RATED RELIEVING PRESSURE AND RELIEVING

CAPACITY.

TOOLS

»2× 3/4 Box and/or Socket Wrench

»1× Flat Head Screw Driver

»1× Pliers

»1× Small Hammer to drive rivets

PARTS REQUIRED

»1× Installed EPRV

»1× EPRV Weight Change Kit (*)

(*) Sized per application. Call for more information.

1 Remove the weight hanger nut and top washer, and

add or remove weights to achieve the desired new set

pressure.

NOTE: THE SET PRESSURE OF THE EPRV WITH NO

WEIGHTS INSTALLED IS 1 OZSI AND INCREASES WITH

THE ADDITION OF WEIGHT PLATES.

2 Replace the weight hanger nut and top washer.

3 Remove the product tag and drive rivets with the flat

head screw driver and pliers and replace with the new

product tag included in the weight change kit with new

drive rivets.

PART C

MAINTAINING SERIES 5000

EPRV

Generally, the more active the vent action of the EPRV,

the more frequent re-lubrication should be performed.

Re-lubrication requirements are application specific, and

influenced by the following variables:

»Chemical Exposure

»Presence of Contaminants

»Elevated Pressure

»High Flow Velocity

»Elevated Temperature

»Utilization

NOTE: 4561 SEVERE SERVICE GREASE IS FACTORYAP

PLIED AT THE TIME OF ASSEMBLY. RELUBRICATION

USING THE SAME PRODUCT IS STRONGLY RECOM

MENDED FOR FIELD RELUBRICATION.

C1 INSPECTION AND RELUBRICATION

1 For a thorough cleaning, inspection and re-lubrication

of the EPRV the lever arm can be removed following

part C2 steps 1-3. For a quick cleaning, inspection and

re-lubrication the EPRV arm and lid can be held open

by hand while maintenance is performed.

2 Inspect the seal. A ring shaped indentation from the

pallet seat in the seal is normal and improves the

sealing performance of the valve. If seal replacement

is required, proceed to part C2. The seal should be

replaced if there are any signs of

»cracking,

»erosion,

»swelling,

»multiple intersecting indentations

INDENT OK

3 If the seal does not require replacing, clean all

contaminants and old grease off of the seal.

4 Re-lubricate by applying an even coating of 4561

Severe Service Grease to the sealing surface.

Reassemble and lower the EPRV to its seated position.