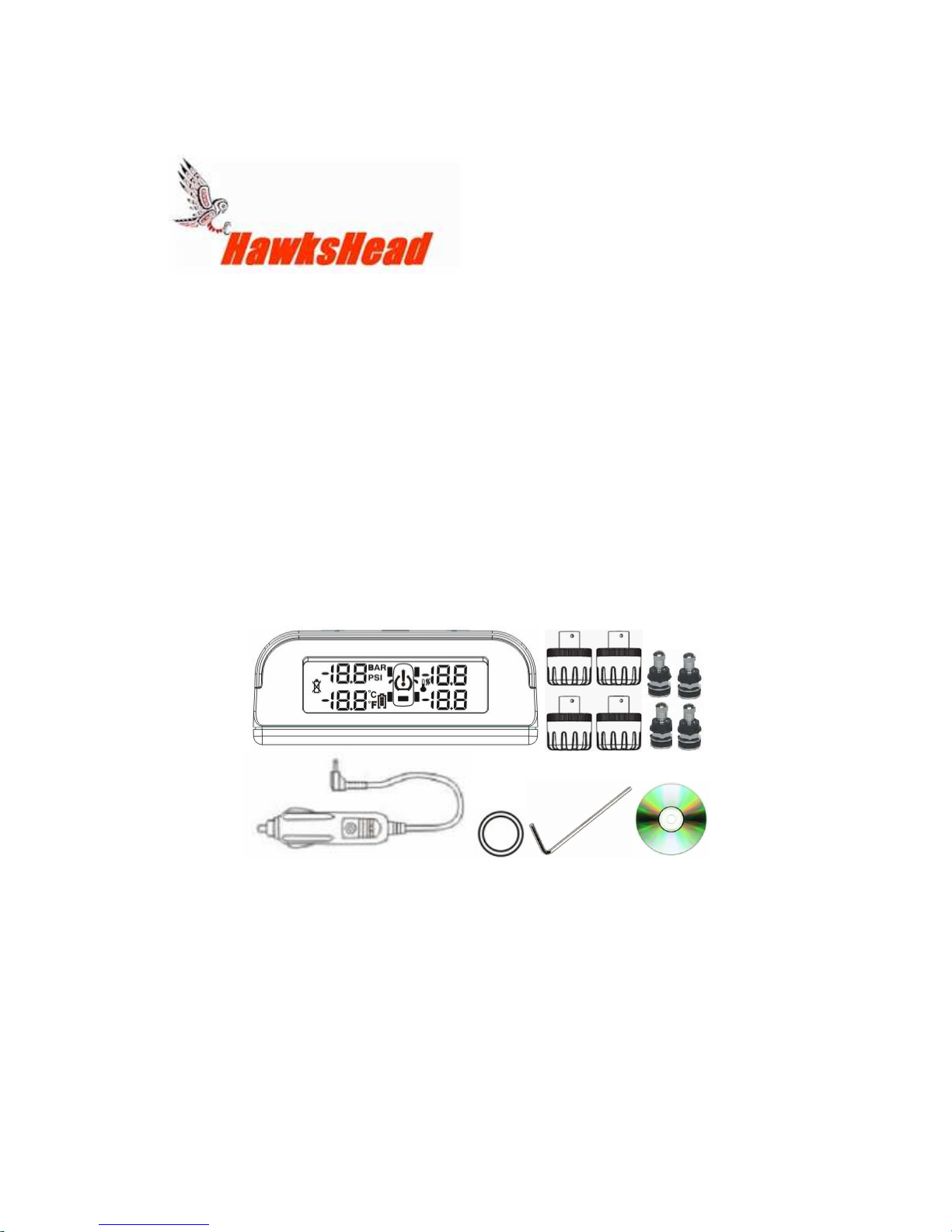

HawksHead TRACK MASTER User manual

Thank you for your purchase of The HawksHead TRACK MASTER TPMS

System

With ease of installation and a compact data monitor with clear LCD display and

built in rechargeable lithium battery, The Track Master monitor has an automatic

backlight for both day and night use. The monitor can handle up to 5 wheels by

the addition of an extra sensor (purchased separately) beyond our 4 wheel base

system for monitoring a spare tire. Designed for pressures from 16 to 50psi and

temps up to 199 F

High and low pressure warnings along with high temperature warnings can be

set by the user. The monitor gives both visible and audible alerts for High

pressure, Low Pressure, Rapid pressure drop and high temperature. Pressure

and Temperature units can be displayed in PSI, Bar and Temperature in degrees

F & C..

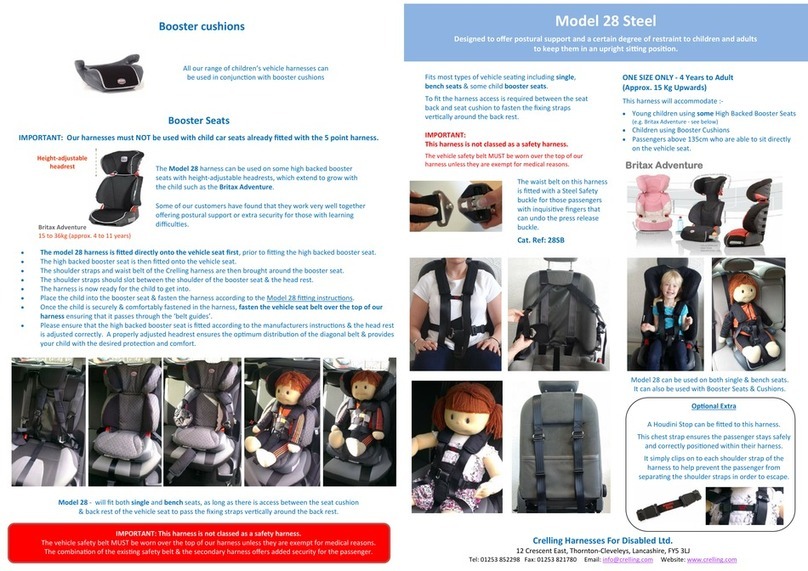

System Components

Sensors Feature

Replaceable CR1632 batteries, Simply fits to valve stem, Water and dirt

resistant, Unique codes.

Monitor Features

Super compact screen, Automatic sleep mode, rechargeable power pack, Auto

backlight

MONITOR BUTTONS & DISPLAY

OPERATION & SET UP

Charge the monitor for 6 hours using the charger.

Turning the monitor on or off can be achieved by holding down the LEFT

BUTTON for 5 seconds.

The monitor can be mounted in view of the driver by using the two sided tape

supplied.

Factory presets are PSI, High Pressure alarm 46 psi, Low pressure alarm 26psi,

Temp unit Degree C, Hi Temp alarm 70 degrees C. To restore factory defaults

turn off the monitor , press the SET BUTTON and turn ON the monitor at the

same time.

Parameter Setting

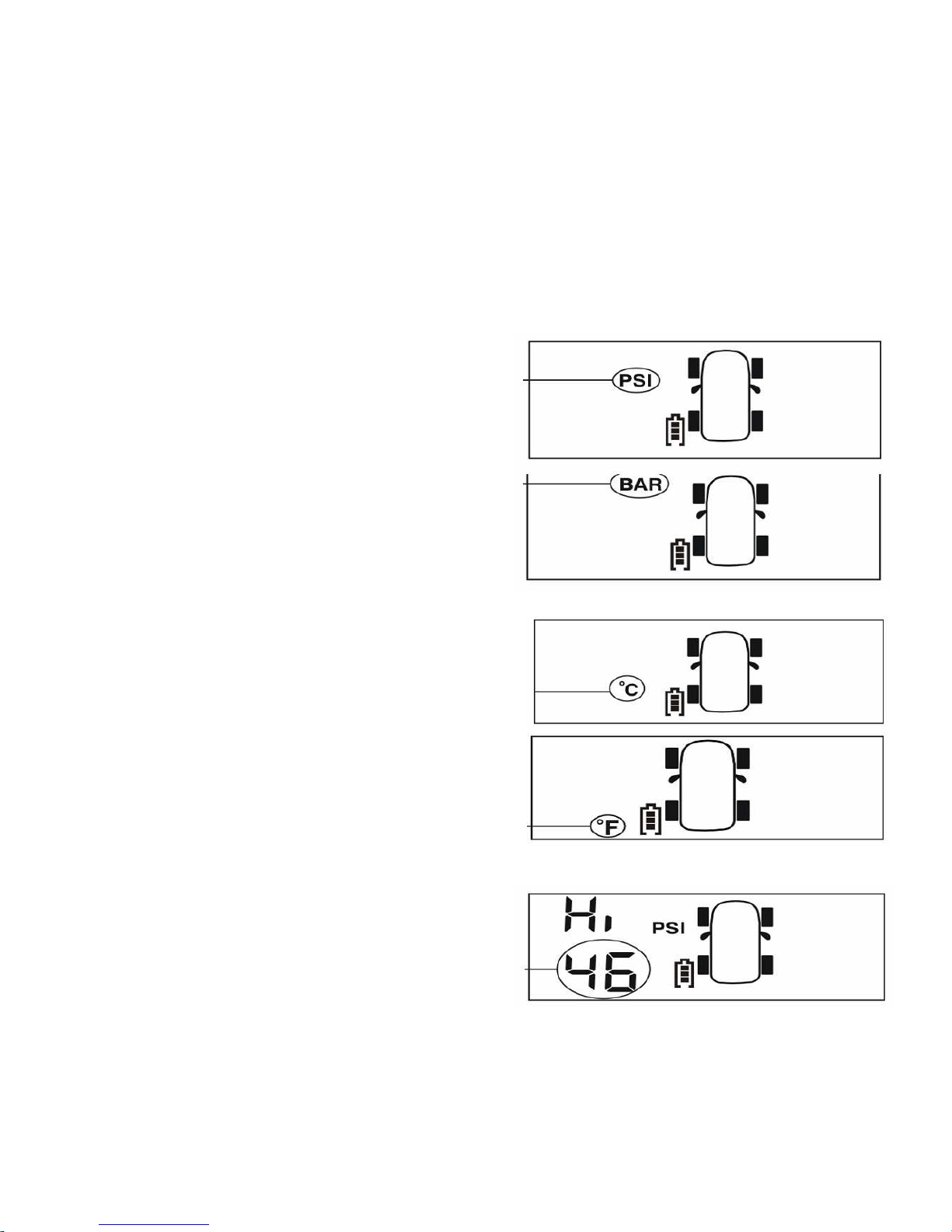

Turn on the monitor. Press the SET

BUTTON for 3 seconds. It will Beep and

flash the pressure setting . This can be

switched between PSI & BAR by pressing

the LEFT or RIGHT BUTTON

After PSI or BAR has been selected Press

the SET BUTTON again to enter the

Temperature setting mode. It will Beep and

flash the Temperature setting. This can be

switched between C & F by pressing the

LEFT or RIGHT BUTTON

After the Temperature type has been

selected Press the SET BUTTON again to

enter the High Pressure setting mode. It will

Beep and flash the High Pressure alarm

setting. This can be increased or decreased

by pressing the LEFT or RIGHT BUTTON

After the High alarm has been set Press

the SET BUTTON again to enter the

Low Pressure setting mode. It will Beep

and flash the Low Pressure alarm

setting. This can be increased or

decreased by pressing the LEFT or

RIGHT BUTTON

After the Low alarm has been set Press

the SET BUTTON again to enter the Hi

Temperature setting mode. It will Beep

and flash the High Temperature alarm

setting. This can be increased or

decreased by pressing the LEFT or

RIGHT BUTTON

Whilst in this mode both the UP and DOWN KEYS can be pressed together to

quit this setting and not save the parameters.

If there is no user operation while in the Set Up mode the monitor will

automatically return to the Standby mode.

Once all parameters have been set hold down the SET BUTTON for 3 Seconds

to get out of the Set Up Mode

SETTING THE VEHICLE TIRE PRESSURES

Using a good quality tire gauge adjust the tire pressures to the desired inflation

as recommended by the vehicle manufacturer. Set these pressures when tires

are cool and out of the sun.

SENSOR INSTALLATION

This should be done one at a time when you read Programming the Sensors

below, do not just screw them all on at once. Remove any existing tire valve caps

and screw the sensor on the valve, ensure the locking screw is backed off

enough to allow the sensor to be screwed on without it rubbing the threads. Hand

tighten the sensor do not use any wrenches or tools to tighten. The locking screw

can be tightened if required as a security measure. Ensure you keep the hex

wrench to remove the locking screws. The sensor simply screws onto the tire

valve (Dill Valve) it is critical that the complete valve be in good condition with no

cracks, be correctly assembled with no wear or side play. Metal valve stems that

are supplied with this system should be used and installed by a tire shop. Use a

small amount of lubrication/anti seize on stem threads ensure none enters the

Sensor or valve. A water/soap solution should be applied to the valve thread

area after installation to ensure there are no air leaks. Most wheels do not need

to be rebalanced after sensor installation. Secure the sensors with their locking

screw if desired.

We have already set up the codes for the 4 sensors

provided and each sensor is marked with the

corresponding tire position.

Should you wish to set up the sensors yourself,

change/add/replace a sensor etc please see below.

Programming the Sensor code if needed.

In the standby mode press the RIGHT BUTTON for 3 seconds. The monitor will

Beep and the relevant Hex code and the wheel position will flash.

Mount the sensor to be aligned on the valve

at the location of the flashing wheel.

The sensor will send the sensor code to the

monitor and the monitor will display the

sensor code associated with the installed

sensor and Beep

Select the other tires by

pressing the LEFT BUTTON and repeat this sequence. The

additional number 5 wheel will also be displayed which can be

used for the spare wheel with the addition of an extra sensor.

By pressing both the LEFT and RIGHT button simultaneously

in this mode the monitor will return to the standby mode

without storing the code.

If there is no operation for a while the monitor will return to the

standby mode

After programming press the SET BUTTON for 3 seconds and release to store

the settings. The monitor will also Beep.

.

Data Display 1

Updated data is sent to the display after the sensors detect the motion of the

wheel.

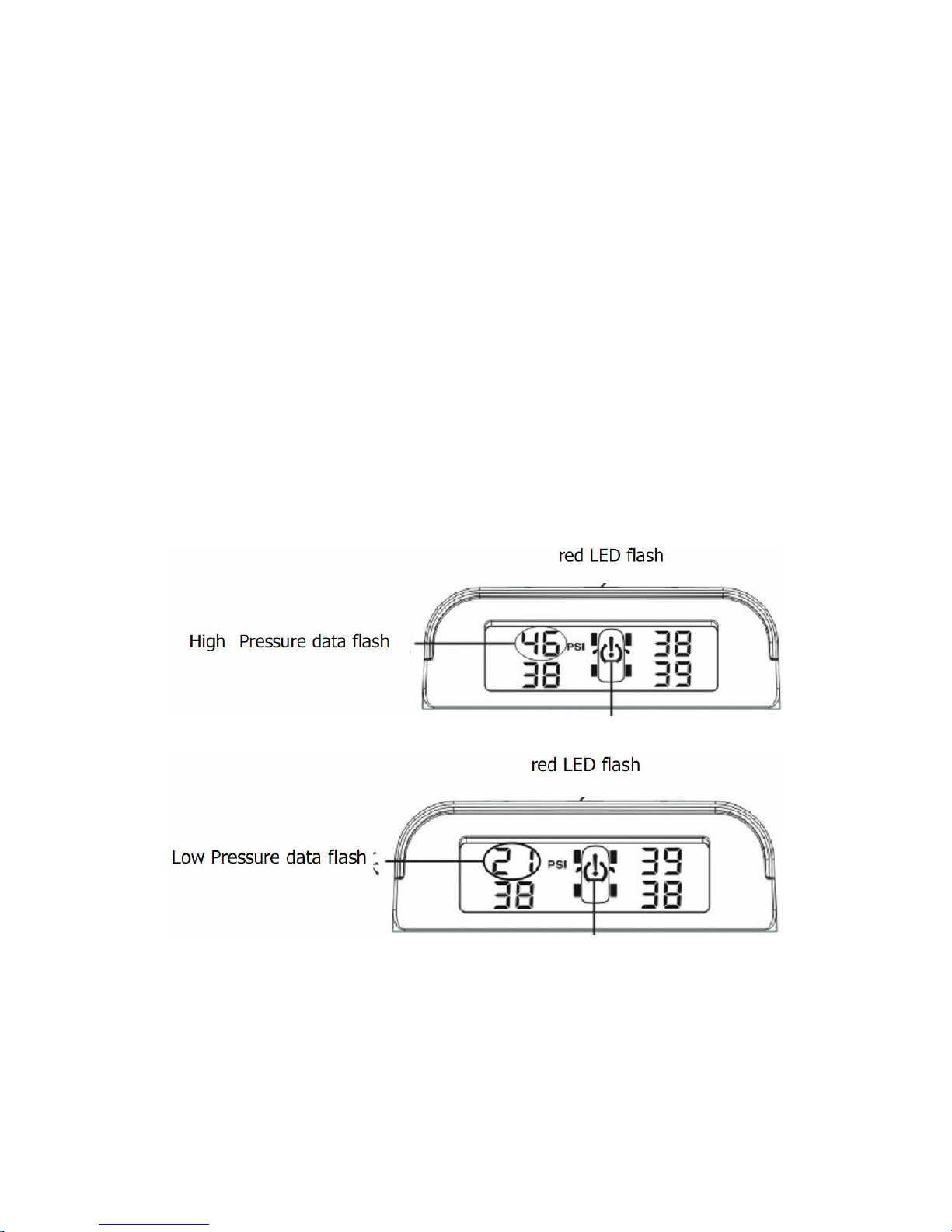

HIGH PRESSURE/LOW PRESSURE?HIGH TEMPERATURE ALERT

If a reading is outside of the users set parameters an audible alarm will sound

and the red LED will flash on the monitor. The alarm can be silenced by pressing

any button on the monitor. However the red LED will continue to flash until the

fault is removed and the monitor is back in the accepted settings range.

As an example

The settings are as follows

High Pressure alarm 46 psi

Low Pressure alarm 26 psi

Hi Temperature alarm 70 C

High Pressure alert Front Left Wheel

Low Pressure alert Front Left Wheel

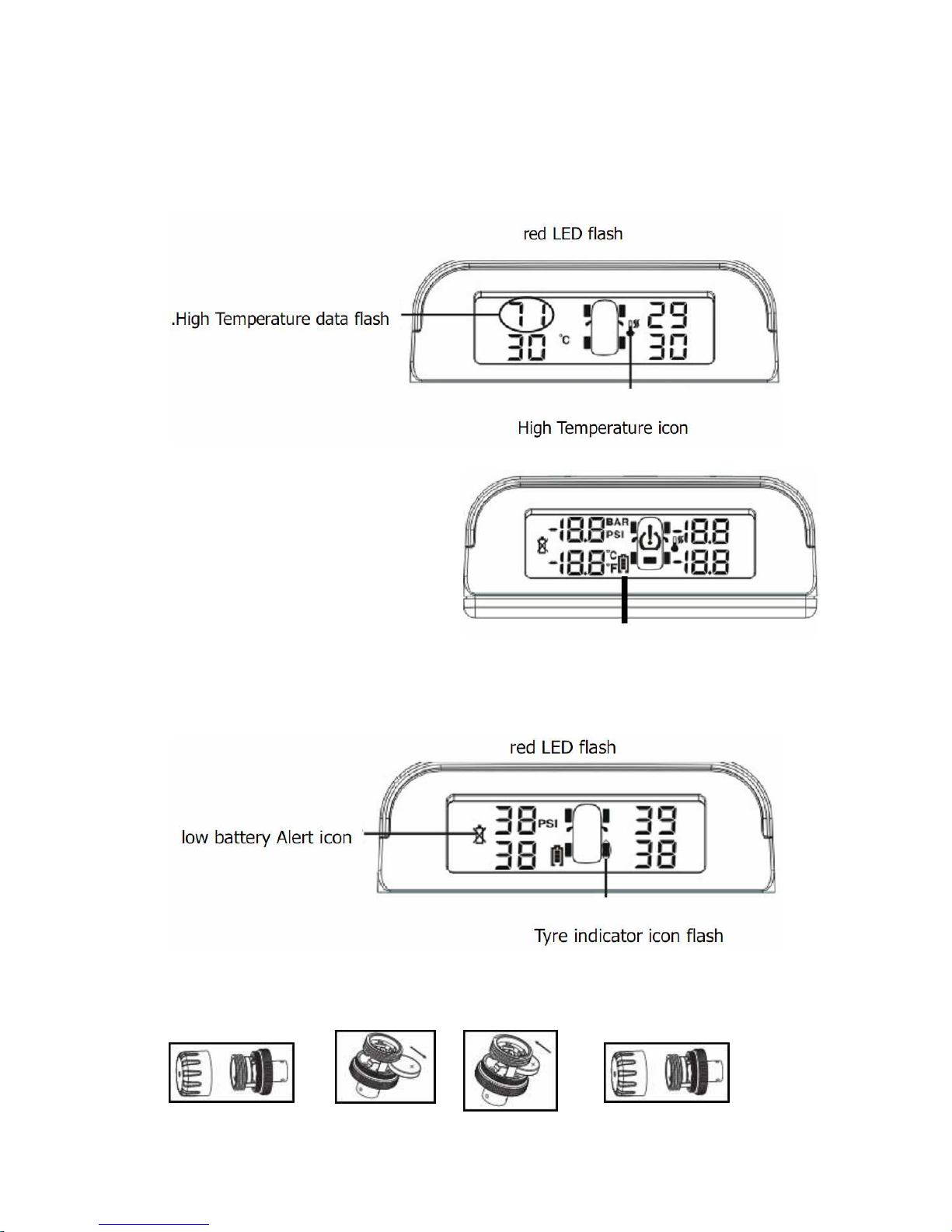

High Temperature alert Front Left Wheel

Monitor Low Battery

When the Monitor detects a low

Monitor battery level the low battery

icon will come on, however the low

battery icon will remain until the

monitor is recharged

Sensor Low Battery

When the Monitor detects a low Sensor battery level the low sensor battery icon

will come on and the location of the sensor will flash. There will also be an

audible warning and the red light will flash. Pressing any button will silence the

alarm, however the low battery icon and light will remain until the sensor battery

has been replaced

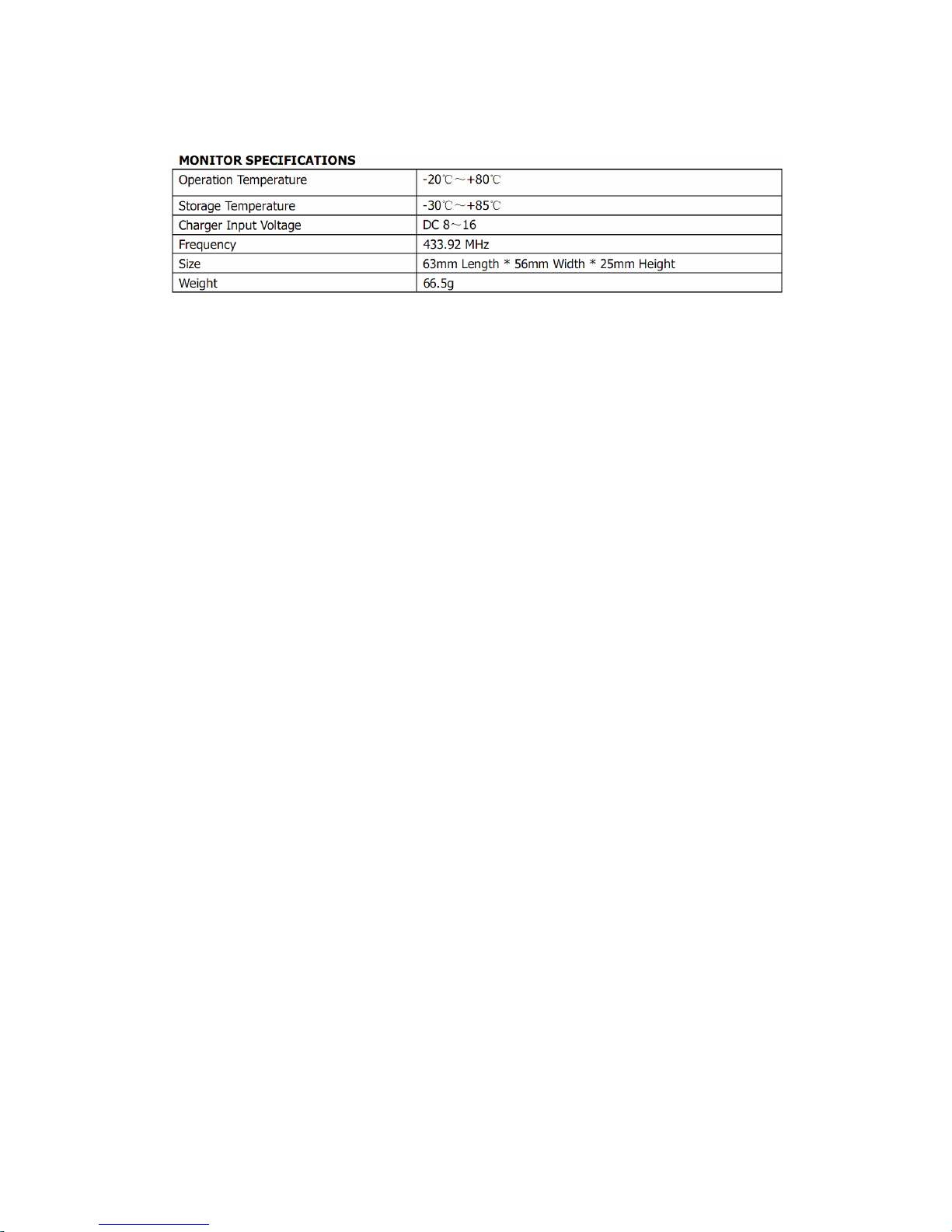

Replacing the Sensor Battery

Unscrew the sensor plastic cap slide out the CR1632 battery slide in a new

battery (POSITIVE UPWARDS) replace cap.

Data Display 2

The monitor will continually display the pressure settings for all tires and will

switch screens if an extra 5th sensor is installed.

By Pressing the SET button the Monitor will show the temperatures of each tire

as below for 5 seconds then switch back to pressure. The high temp alarm will

show if a tire reaches 70 degrees C

GENERAL INFORMATION

Tire pressure recommended operating pressures should be set when the ambient temperature is

low or cold or where the tire has cooled down and is at a low temperature, out of the sun etc.

Dramatic changes in tire pressure can occur because of increased or decreased ambient

temperature; tire contact surface temperature etc, these and other situations should be taken into

consideration when setting initial tire operating pressures. This system cannot warn you of

impending side wall failures or blowouts, however it can supply you with irregular pressures and

temperature information that may help to prevent this. To test fast leakage response, unscrew a

sensor with monitor in range. The Track Master System, relies on a good air connection

between the Sensors and the tire valve (known as the Dill Valve) which is located inside the tire

valve stem.

The Dill Valve should be the correct size, be in good condition and be able to be depressed fully

to allow the release of air to the sensor so it can operate.

Some valve stem extensions may cause inaccurate readings if they do not allow the sensor to

operate correctly, standard short metal bodied stems are recommended for best performance.

Should you have difficulty with a pressure sensor not operating correctly we recommend that you

contact a tire professional to ensure that the tire stem and Dill Valve are installed and operating

correctly.

Do not use tire sealants when using this system. Over a period of time tires may lose pressure

naturally, through the tire itself or for other reasons such as rim leakage etc.

However after the Track Master valve sensors (including locking mechanism, if fitted) are

installed it is recommended that the sensor and valve stem be completely covered in a soapy

solution of 1 part liquid soap to 2 parts water, to see if there are any air bubbles coming from the

valve and sensor area indicating that the tire is leaking air.

If air bubbles are visualized in any of these areas, the tire may deflate and the Track Master,

system will not operate correctly. The wheel sensors are weatherproof and can be run in the rain.

A tire professional should be consulted should any of these areas prove to be a problem

Please note,Track Master Systems, operates on an RF system, as with many RF tire systems

this system can suffer from interference depending on the systems location thus causing the

system to be inaccurate or not operate at all. We cannot guarantee that the display will receive

the sensor signal accurately.

Purchasers of this product should not rely on this tire pressure monitoring system for safety and

should check the condition and pressure of their vehicles tires on a regular basis as described by

the manufacturer of the vehicle or tire manufacturer.

Tire pressures and temperatures are not the only things that can affect tire safety; we suggest

daily visual inspections and checks by tire professionals.

LIMITED WARRANTY

HawksHead will, within 12 months from date of original purchase, repair or replace free of charge

any defective component (except batteries) which upon careful inspection is found, in our sole

judgment, to have material or manufacturing defects, provided it is received freight prepaid,

accompanied by the original purchasers sales slip and an authorized Return Merchandise

Authorization number (RMA #.). You may obtain an RMA # by emailing RMA@TPMS.CA

DISCLAIMER OF WARRANTY: Neither the seller nor the manufacturer will be liable for any loss

damage or injury directly or indirectly arising from the use or inability to determine the use of this

product. Before using, the user shall determine the suitability of the product for its intended use,

and the user shall assume all responsibility and risk in connection herewith.

PLEASE NOTE: SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG IMPLIED

WARRANTIES MAY LAST OR DO NOT ALLOW EXCLUSIONS OR LIMITATIONS OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THOSE EXCLUSIONS OR LIMITATIONS

MAY NOT BE APPLICABLE TO YOU.

© HawksHead Systems Inc

NOTES

Table of contents

Popular Automobile Accessories manuals by other brands

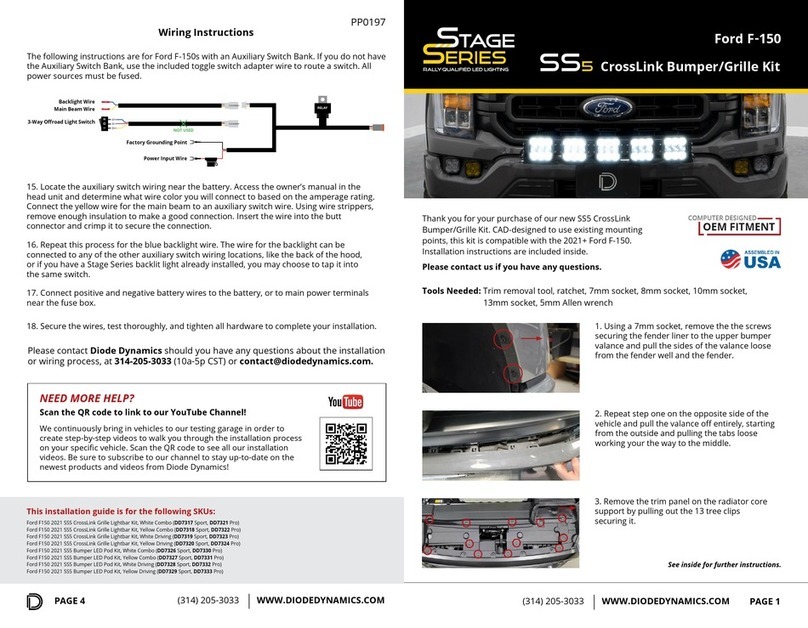

Diode Dynamics

Diode Dynamics SS5 quick start guide

Mazda

Mazda 0000-8K-R08 Installation and user instructions

QA1

QA1 52894 installation instructions

IHC suspension

IHC suspension GM 1500 instructions

MobiSolution

MobiSolution MobiFren GBC-1000 user manual

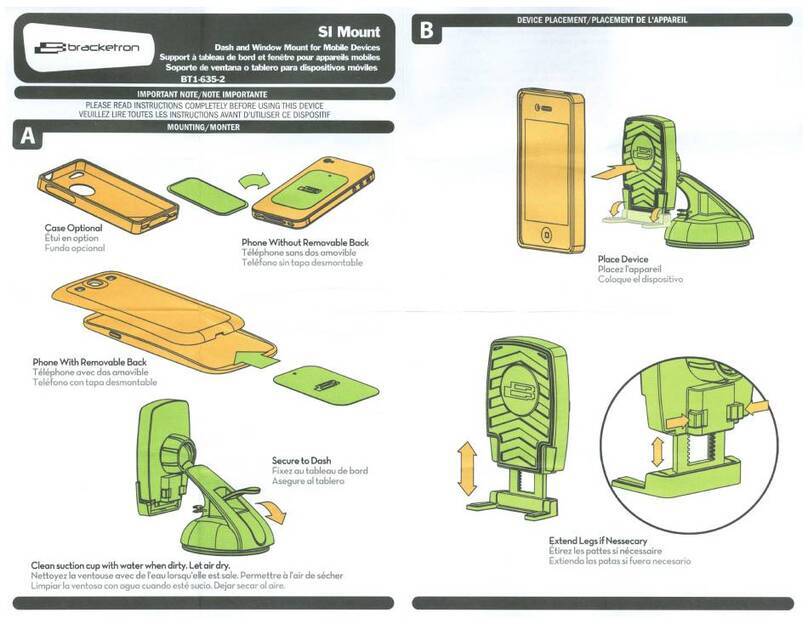

Bracketron

Bracketron SI Mount BT1-635-2 quick start guide