07/08 Model TWBS.SH Page 2 of 6

I. WHAT IS THE HAWS TWBS.SH?

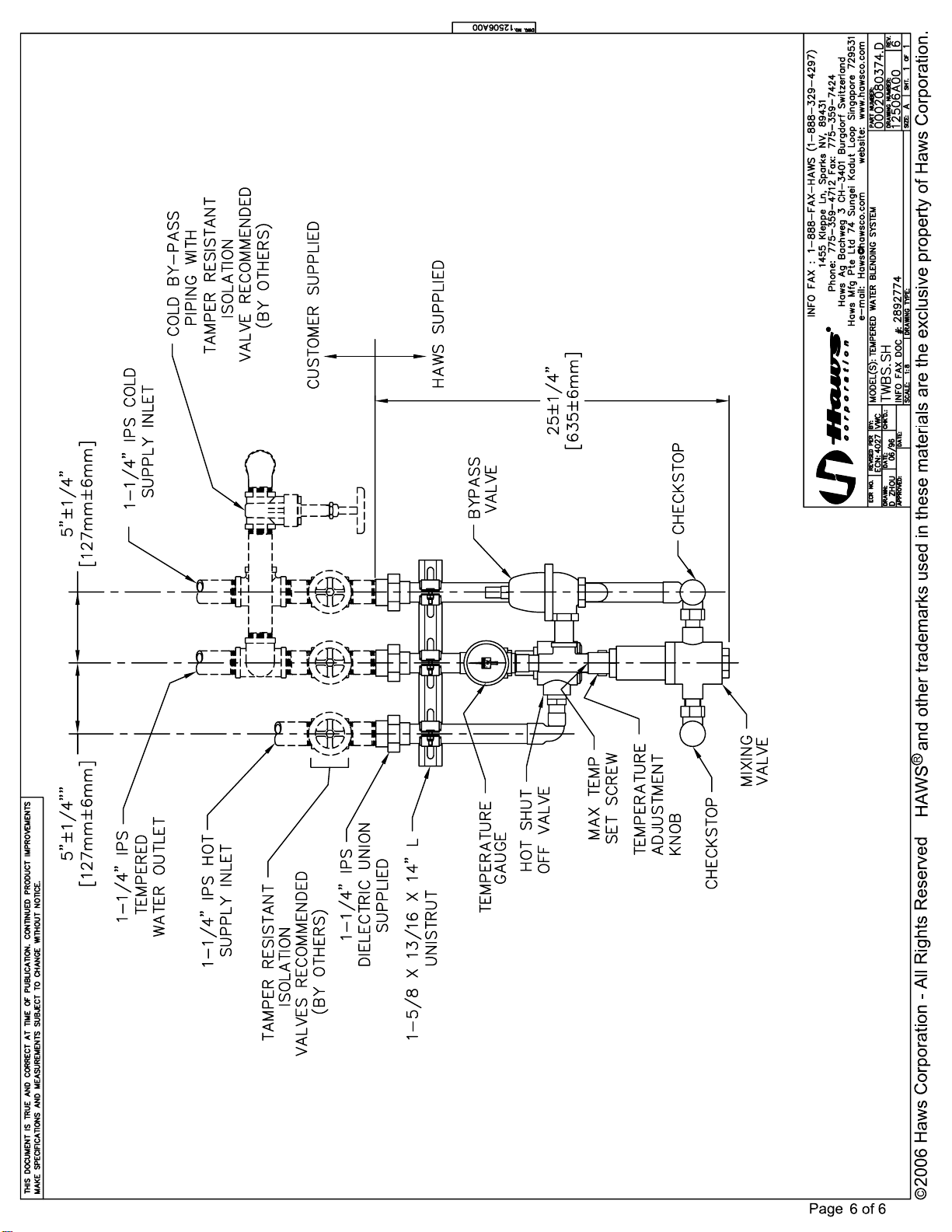

The HAWS TWBS.SH is a patented tempered water mixing system (US Patent # 5350112) for use with

emergency drench shower and eyewash stations where cold and hot water is thermostatically blended to

provide a discharge of tempered water at a selected temperature. The TWBS.SH is a thermo-mechanical

system with thermally activated and pressure-activated safety features, which do not require electricity for

operation. These safety features utilize back-up control valves that ensure a substantial water flow

without the risk of scalding, even in the event of main mixing valve failure. Additionally, a temperature limit

control valve detects the outflow temperature and helps to reduce the discharge temperature should

excessive temperature conditions occur.

II. HOW DOES THE TWBS.SH OPERATE?

The heart of the WTWBS.SH system is the thermostatically controlled mixing valve. It includes an integral

strainer and check valves, and has an adjustable temperature control, which is typically set at 80°F. The

main mixing valve includes a connection to a cold water supply and a hot water supply, with the ability to

provide a discharge outflow of water at a selected/blended temperature level. On the hot water inlet side

of this mixing valve we include a high limit temperature control valve, which senses the temperature of the

discharge flow. When the discharge flow temperature exceeds our factory pre-set limit of 85°F, this

control valve closes and/or modulates, thus reducing the hot water flow being sent to the mixing valve.

On the cold-water inlet side, we include a flow control bypass valve, which is responsive to the pressure

differential between the cold water supply and the discharge of the tempered water. Should the main

mixing valve fail to produce the required mixed flow through the discharge line, the bypass valve senses

this and opens up, allowing the incoming cold water to bypass the system and proceed directly to the

emergency shower and/or eyewash. These two back-up components permit the temperature level of

tempered water to be maintained without undesirable temperature reductions/fluctuations experienced in

most failures. They also permit the flow of cold water should the mixing valve fail altogether.

III. PERFORMANCE FEATURES OF THE HAWS TWBS.SH SYSTEM

Essentially, the HAWS TWBS.SH provides fail-safe protection against scalding or blocked flow. There are

three types of failures that can occur with any mixing valve system. They are as follows:

1) The mixing valve can stick in an open position and provide an unregulated flow of hot

water.

2) The mixing valve can stick in a position, which allows an unregulated flow of cold water.

3) The mixing valve can fail so as to provide an insufficient and/or blocked flow of either hot

or cold water.

The unique HAWS TWBS.SH answers the above three failure modes in the following manner:

Fail-safe Performance Mode # 1 Too much Hot Water

The primary safety in the HAWS TWBS.SH is the high limits hot shut-off valve, or the temperature limit

control valve, which senses outlet temperatures and modulates the incoming hot water to maintain an

outlet temperature below 85°F. This high limit shut-off valve is non-adjustable (tamperproof) and provides

a regulated reduction in the temperature level of the discharge flow. This high temperature limit valve

provides the first backup for regulating the temperature of the discharge flow in the event of mixing valve

malfunction (i.e., too much hot water).

Fail-safe Performance Mode # 2 Unregulated Full Flow of Cold Water

The HAWS TWBS.SH answers this condition in two ways. When improper mixing valve operation occurs

and produces a restricted flow (i.e., a pressure differential between the cold water supply and the

discharge tempered water outflow), the flow limit control valve opens to permit the direct flow of cold

water past the main mixing valve and into the system. Additionally, the temperature control valve will

sense a reduction in the temperature of the discharging tempered water and will open to permit an

increased flow of hot water into the system. In this case, the HAWS TWBS.SH can help to produce warm

water even when the pressure relief bypass valve is operating. (The high temperature valve opens so as

to assist in maintaining a degree of tempered water out).