HB Products HBOR User manual

Instruction manual - HBOR –Oil Pot Controller (001UK) 1 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Instruction manual

HBOR - OIL POT CONTROLLER

For oil level control in oil pots

Instruction manual - HBOR –Oil Pot Controller (001UK) 2 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Table of contents

Safety Instructions...........................................................................3

Introduction.....................................................................................4

Measurement Principle ...................................................................4

Design ..............................................................................................4

Software ..........................................................................................4

Technical Data .................................................................................5

Functionality.................................................................................... 5

Installation Guide ............................................................................6

Mounting Guide...............................................................................6

Electrical connection .......................................................................8

LED Indication & Calibration............................................................8

Installation of HBOC Configuration Tool .......................................10

PC Configuration............................................................................11

Function description –setup parameters .....................................11

Fault Detection ..............................................................................13

Spare parts.....................................................................................14

Further Information.......................................................................14

Instruction manual - HBOR –Oil Pot Controller (001UK) 3 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Safety Instructions

CAUTION! Always read the instruction manual before commencing work! Heed all warnings to the letter!

Installation of HBOR requires technical knowledge of both refrigeration and electronics. Only qualified

personnel should work with the product. The technician must be aware of the consequences of an

improperly installed sensor, and must be committed to adhering to the applicable local legislation.

If changes are made to type-approved products, this type approval becomes void. The product's input and

output as well as its accessories may only be connected as shown in this guide. HB Products assumes no

responsibility for damages resulting from not adhering to the above.

Explanation of the symbol for safety instructions. In this guide, the symbol below is used to point out

important safety instructions for the user. It will always be found in places in the chapters where the

information is relevant The safety instructions, and particularly the warnings, must always be read and

adhered to.

CAUTION! Refers to a possible limitation of functionality or risk of use.

NOTE! Contains important information about the product and provides further tips.

The person responsible for operation must commit to adhering to all the legislative

requirements, preventing accidents, and doing everything so as to avoid damage to

people and materials.

Intended use, conditions of use. HBOR level controller is made for continuous control of oil level in oil pots.

If HBOR is to be used in a different way or with another purpose, and if the operation of the product in this

function is determined to be problematic, prior approval must be obtained from HB Products

Prevention of collateral damage Make sure that qualified personnel assess any faults and take necessary

precautions before attempting to make replacements or reparations, so as to avoid collateral damage.

Environmentally correct behaviour, disposal instruction: HBOR is built so that the modules can easily be

removed and sorted for disposal.

Instruction manual - HBOR –Oil Pot Controller (001UK) 4 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Introduction

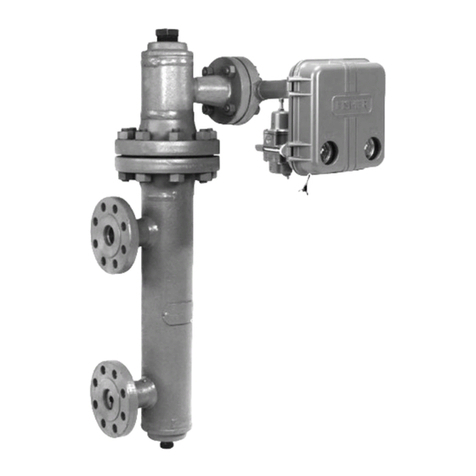

HBOR is an intelligent sensor with a built-in

microprocessor. It is designed to detect and

control oil levels in oil pots.

Apart from the sensor function, it also has a built-

in controller.

The controller can be setup with all the

parameters that are necessary to directly

regulate solenoid valves for oil level control.

Measurement Principle

The sensor is a capacitative sensor. The capacitative measurement principle is based on the electrical

properties in the proximity of a capacitor. A capacitor is an electrical component that is capable of building

and sustaining an electrical charge

Principally, a capacitor consists of two plates.

When a charge is applied to a plate, the other

plate will be charged with the opposite polarity

and retain the charge until it has been grounded.

The magnitude of the charge (the capacitance)

that can be generated depends, among other

things, on what is found between the plates.

The substance between the plates is referred to

as a dielectric.

In front of the two plates, the sensor for level

measurement is shaped as a cylindrical rod.

When liquid covers the sensor, the measured

capacity is changes.

.

The conductivity of a material can vary depending

on temperature, chemical composition, and the

homogeneity of the material, and therefore it can

in some cases require a different factory

calibration.

Design

The sensor consists of a mechanical part and an electronic part. These are easily separated by loosening 2

grub screws, or for mechanisms with mounting tabs, by pressing the electronic part in towards the

mechanical part and turning the housing counter-clockwise until a wave washer pushes it from the

mounted position. The electronic part is designed in accordance with IP65 waterproof rating and to resist

vibrations.

The mechanical part is produced in AISI304/PTFE and tested to withstand high pressure.

Software

The sensor is supplied with the latest firmware. The sensor is configured with a configuration tool, using a

PC. It is capable of determining on its own the current version which was delivered.

The newest version of the tool is backwards compatible.

It is not possible to update the software on a sensor which has already been delivered.

Instruction manual - HBOR –Oil Pot Controller (001UK) 5 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Technical Data

Supply:

Voltage: 24 V DC ±10%

Current draw: Max 30 mA

Connector: M12 –5 pins

DIN 0627

Valve control:

Potential-free relay output: Max 1 A (24W)

Cable length: 3 m

Cable size: 3 x 0,75 mm2

Cable connection: Screw terminals

Cable glands: PG7 / M8

Installation conditions:

Ambient temperatures: -30…+50°C

Max. operational pressure: 150 bar

Waterproof rating: IP65

Vibrations: IEC 68-2-6 (4g)

Authorisations:

EMC Emission: EN61000-3-2

EMC Immunity: EN61000-4-2

Mechanical specifications:

Thread connection: ¾”

Materials –mechanical parts: AISI304/PTFE

Materials –electronic parts: Nylon 6 (PA)

Weight: 500 g

Housing design: Angled

Configuration & indication:

Configuration With a PC

LED indication green, yellow, and red

Supply cable specifications:

M12 cable –5 m: HBxC-M12/5

Plug type –cable: Angle - 90°

Cable type: PVC-OB grey

Cable size: 5 x 0,34 mm2

Cable glands: PG7 / M8

Cable approval: CSA

Accessories:

Magnetic valve: V150

Functionality

HBOR is designed for oil detection and control in oil pots

NOTE! All terminals are protected against incorrect termination with a supply voltage of up to

40V. If the supply voltage is greater than 40 V, the electronics will be damaged.

Instruction manual - HBOR –Oil Pot Controller (001UK) 6 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Installation Guide

The following applies:

1) The sensor must be installed in a horizontal position.

2) During installation, check the sensor's length as well as its placement with the refrigeration

compressor manufacturer or the oil separator producer. Oil pockets may not form around

the sensor, and there must be a gap of at least 2mm between the sensor and the other

mechanical parts.

CAUTION! In case of welding work on the unit, please make sure that proper earthing is carried

out to avoid damaging the electronics.

Accessories:

The sensor can be supplied with the following accessories:

1) Solenoid-V100 - ¼” magnetic valve for opening/closing inflow or outflow of oil. The valve has a 24

VDC supply and is designed for pressures up to 100 bar. The valve has a Kv value of 1.5 l/min.

Installation of the magnetic valve: So as to be able to supply the magnetic valve directly, it must be

installed within 3 metres of the sensor.

Mounting Guide

HBOR is mounted on an oil pot. The sensor is sealed with Teflon tape or liquid gasket before installation.

Dependent upon the thread type, the gasket consists of:

NPT thread = Teflon tape or liquid gasket

BSPP thread = Gasket

Instruction manual - HBOR –Oil Pot Controller (001UK) 7 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

For installation, there is required a 2.5mm Allen key, a

shifting spanner, as well as gasket material depending on

the thread type.

Loosen two set screws, or for mechanisms with

mounting tabs, press the electronic part in towards

the mechanical part and turn the housing counter-

clockwise until a wave washer pushes it from the

mounted position.

Separate the electronic part from the mechanical part.

Teflon or liquid gasket is applied to the conical

thread. Cylindrical thread is installed with gasket.

Mount the sensor on the oil pot. Tighten thread,

depending on thread type.

The electronic part is installed on the mechanical

part and secured with 2 screws.

Instruction manual - HBOR –Oil Pot Controller (001UK) 8 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Electrical connection

HBOR can be supplied with direct control of the magnetic valve, or it can be connected to the central

control via the sensor's control/alarm output. See the diagram below.

The sensor has a control function and regulates the flow of oil independent of other parts of the system.

The function starts to work when the supply is connected. The control function can be

activated/deactivated via an external run signal with "Run in" (clamp 5) and -24 V (clamp 2).

LED Indication & Calibration

LED indication:

1) 3 x green LEDs indicate oil level

2) Green Power LED indicates 24 V DC supply; blinks during

operation. If "run-in" is not used, this function must be

deactivated in the tool.

3) Yellow LED indicates supply is open to magnetic valve

4) Red LED indicates ALARM

Instruction manual - HBOR –Oil Pot Controller (001UK) 9 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

LED signal

ON/OFF/Frequency

Functionality

Green (3x)

ON

Oil detected

Flash

Turbulence in the compressor housing

OFF

Oil is not detected

Green POWER

ON

Supply

Flash

In operation or

when the sensor is connected to HBOC Tool. (Red and yellow LED

also blink)

OFF

No supply

Yellow

ON

Activation/supply to the magnetic valve

OFF

Magnetic valve is not being supplied

Red

ON

Alarm. Activated automatically according to a calculated time

span if oil has not been detected (oil cycle x alarm counter = Time

before alarm goes off). Output relay (pin 3 & 4) is activated.

OFF

Oil level reached in accordance with the calculated time span /

number of oil cycles.

Calibration:

"R" for factory reset and calibration:

Alarm is reset by pressing "R" for 5 seconds.

Calibration instructions:

HBOC is pre-calibrated upon delivery. If one uses common lubricating oils in the refrigeration compressor,

calibration is normally not necessary. If the sensor is too sensitive or does not register oil at all, calibration

should be carried out.

Calibration can only be carried out if the function "Calibration" is set to ON in HBOC Tool. It is carried out

during normal system operation.

The sensor is calibrated by pressing "R" 5 times.

Calibration can alternatively be carried out before start-up or during fault detection, by having an extra

mechanism. Without stoppages or loss of pressure.

The electronics are installed on the extra mechanism and calibrated when vertically submerged to 50% in

the same type of oil that is used in the compressor housing. The electronics can then be re-installed in the

system.

After final calibration, one should consider setting "Calibration" to OFF

Instruction manual - HBOR –Oil Pot Controller (001UK) 10 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Installation of HBOC Configuration Tool

1) The tool can be downloaded for free. Request access

to download the tool by sending an email to

Instructions for installation are sent together with the

password.

2) Download HBOC Tool and install it on a PC. System

requirements: Windows-based PC with Java installed.

If Java is not installed, it is possible to do this in

connection with the installation of the HBOC tool.

An internet connection is required to download it.

Minimum screen resolution is 1366x768

3) Follow the instructions during setup of the program.

4) Connect the USB cable, HBxC-USB, to the PC. Give Windows a moment to find a driver for the USB

cable; for this to happen automatically an internet connection is required, otherwise follow the

instructions on the installation of drivers in the program "Configurations Instructions".

5) Search for USB com port. Select USB COM port in the window below. For example COM3. In the

lowermost bar, one can see that the USB com port is selected and open for communication with

the sensor. The bar changes colour from red to green when there is a connection between the

program and the USB cable.

6) Connect the cable to the sensor. The software program records the current version (see SW

xx.x.xx).

7) Connection to the sensor is complete when the green, yellow, and red sensors blink in a set

pattern.

8) The sensor's current setup can be retrieved by pressing (Show current configuration).

9) The sensor's factory settings can be reset by pressing (Reset to default).

10) All parameters can now be input. After the final selection, press "Set configuration". The selected

parameters are transferred and saved in the sensor. When this transfer is complete, an image of

the sensor appears with a message that the transfer was successful. Press OK to complete the

process.

NOTE! To be able to change the control parameters, it is necessary to have a special USB/M12

configuration cable as well as a configuration tool installed on a PC.

Instruction manual - HBOR –Oil Pot Controller (001UK) 11 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

PC Configuration

The sensor is supplied with the following configuration options and factory settings:

General settings

Output signal, oil feed

NO/NC

NO

Alarm delay (separator mode)

10…10.000 min

60 min

Oil cycle periods/time

1…300 s

60 s

Oil valve open time

1…300 s

10 s

Oil feed, switching hysteresis

1….10 mm

5 mm

Alarm counter (no of oil cycles)

1…100

30

Oil sensor dwell

1…30 s

10 s

Calibration function

ON / OFF

OFF

Oil cycle function

ON/OFF

ON

CAUTION! Factory settings do not guarantee safe operation, since the configuration parameters

depend on the type of compressor/separator.

NOTE! If the program is shut down and started up again, the cable to the sensor must be

disconnected (M12 plug) and reconnected.

Function description – setup parameters

Oil pot alarm delay in minutes:

Time that elapses before the sensor triggers the alarm for low oil level.

During normal system operation, the oil will be released in the separator; if this does not occur, it is likely

that the oil has accumulated in other areas of the system. Therefore one wants the alarm to trigger when a

certain amount of oil has not been separated within a defined period.

Oil cycle periods/time in sec:

The time for the frequency with which the sensor checks for oil. Typically, one wants a certain period

between when the oil-return-valve lets oil into the crankshaft housing and how long the level is accepted

under.

If the period is (too) short, oil will be filled up more frequently.

Oil valve open time in sec:

Number of seconds during which the supply voltage to the oil-return-valve is open.

This should be aligned to the system pressure, pipe dimension, and size of valve.

Instruction manual - HBOR –Oil Pot Controller (001UK) 12 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Filter func/time cons in sec:

An average measurement is made in programmed seconds. Can be increased in case of unstable

measurement.

Switching hysteresis factor:

Hysteresis for the contact function. Hysteresis indicates how many mm of oil can drop before the contact

function ceases. Popularly called a type of "backlash" in the system.

Oil sensor dwell:

Indicates the time from the end of hysteresis to the start of the oil cycle period.

Calibration function:

Must be connected if one wants to re-calibrate the sensor.

Following calibration, one can switch back to OFF by connecting the tool again.

The sensor is factory calibrated in PAG68. If a different oil type is used, it may need to calibrated.

Alarm output signal:

Is selected depending on whether the magnetic valve has the contact function NC or NO (Normally

closed/Normally open)

Instruction manual - HBOR –Oil Pot Controller (001UK) 13 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Fault Detection

General:

Fault Detection

Fault

Reason

Correction of fault

No LED is on.

No supply to the sensor or

defective cable/plug

Check and find faults in the power

supply. Change the supply cable.

Sensor does not trigger even

though there is oil.

Quality/type of oil is different

from that used during factory

calibration.

Recalibrate the sensor.

Red alarm

Oil level has not been attained

during a number of oil cycles.

Check system oil return. Check oil

filter and magnetic valve if

necessary.

3 x Green blinks

There is oil turbulence in the

compressor housing.

Change "prel delay" to a higher

value.

No output (3 x green LED are on,

but the output signal is not

active)

Check the setup of the

parameters/which contact

function has been selected, NC or

NO (Normally closed/Normally

open)

Change the setup using the tool.

Delay in sensor activation

May be caused by gas and foam

bubbles in the system.

Check if the sensor is placed

optimally.

No detection

Fault in the electronics

Send the sensor to be repaired.

Sensor Repair

The sensor electronics are completely embedded and can therefore not be repaired.

In case of faults with the sensor, it will typically only be necessary to replace the electronics.

Complaint cases are handled by the HB Products dealers/distributors.

Their complain procedures must be followed before returning the sensor.

NOTE! Fault detection on the electronics and/or replacement of the electronics can be

carried out without releasing pressure on the system or removing the mechanical part of the

sensor

Instruction manual - HBOR –Oil Pot Controller (001UK) 14 / 14

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Spare parts

Position

Type

Specification

Part number

1

Mechanical part

¾” NPT

HBSR-MEK-2

¾” BSPP

HBSR-MEK-6

2

Electronic part

PC-programmable

HBOR/C-EL

Further Information

For further information, please visit our website, www.hbproducts.dk, or send an email to:

Other manuals for HBOR

1

Table of contents

Other HB Products Controllers manuals

Popular Controllers manuals by other brands

MESA ENGINEERING

MESA ENGINEERING MIDI MATRIX owner's manual

OEZ

OEZ SM1003 Series Instructions for use

ABB

ABB ACS55-01E-01A4-2 user guide

Athena

Athena RMB/1 Operation manual

Johnson Controls

Johnson Controls VFD66 Series Product/Technical Bulletin

Siemens

Siemens SINUMERIK ONE PPU 1740 Series Equipment manual