HB Products HBLC User manual

Instruction manual - HBLC –Sensor & regulator (012-UK) 1 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Instruction manual

HBLC –SENSOR & CONTROLLER

For low and high pressure control of liquid levels in

industrial refrigeration systems

Instruction manual - HBLC –Sensor & regulator (012-UK) 2 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Table of contents

Safety Instructions...........................................................................3

Introduction.....................................................................................4

Measurement Principle ...................................................................4

Design ..............................................................................................4

Software ..........................................................................................4

Technical Data .................................................................................5

Design and Function ........................................................................5

Installation Guide ............................................................................6

Electrical connection .......................................................................7

Mounting Guide...............................................................................8

LED Indication & Calibration............................................................9

Installation of HB Configuration Tool ............................................10

PC Configuration............................................................................10

Setup and Connection of Valve .....................................................10

Fault Detection ..............................................................................11

Sensor Repair.................................................................................11

Spare parts.....................................................................................12

Further Information.......................................................................12

Instruction manual - HBLC –Sensor & regulator (012-UK) 3 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Safety Instructions

CAUTION! Read the instruction manual before commencing work! Heed all warnings to the letter!

Installation of HBLC requires technical knowledge of both refrigeration and electronics. Only qualified

personnel should work with the product. The technician must be aware of the consequences of an

improperly installed sensor, and must be committed to adhering to the applicable local legislation.

If changes are made to type-approved products, this type approval becomes void. The product's input and

output as well as its accessories may only be connected as shown in this guide. HB Products assumes no

responsibility for damages resulting from not adhering to the above.

Explanation of the symbol for safety instructions. In this guide, the symbol below is used to point out

important safety instructions for the user. It will always be found in places in the chapters where the

information is relevant The safety instructions, and particularly the warnings, must always be read and

adhered to.

CAUTION! Refers to a possible limitation of functionality or risk of use.

NOTE! Contains important information about the product and provides further tips.

The person responsible for operation must commit to adhering to all the legislative

requirements, preventing accidents, and doing everything so as to avoid damage to people

and materials.

Intended use, conditions of use. The HBLC sensor and controller is made to measure and control

refrigerant. If HBLC is to be used in a different way or with another purpose, and if the operation of the

product in this function is determined to be problematic, prior approval must be obtained from HB

Products

Prevention of collateral damage: Make sure that qualified personnel assess any faults and take necessary

precautions before attempting to make replacements or reparations, so as to avoid collateral damage.

Disposal instructions: HBLC is built so that the modules can easily be removed and sorted for disposal.

Instruction manual - HBLC –Sensor & regulator (012-UK) 4 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Introduction

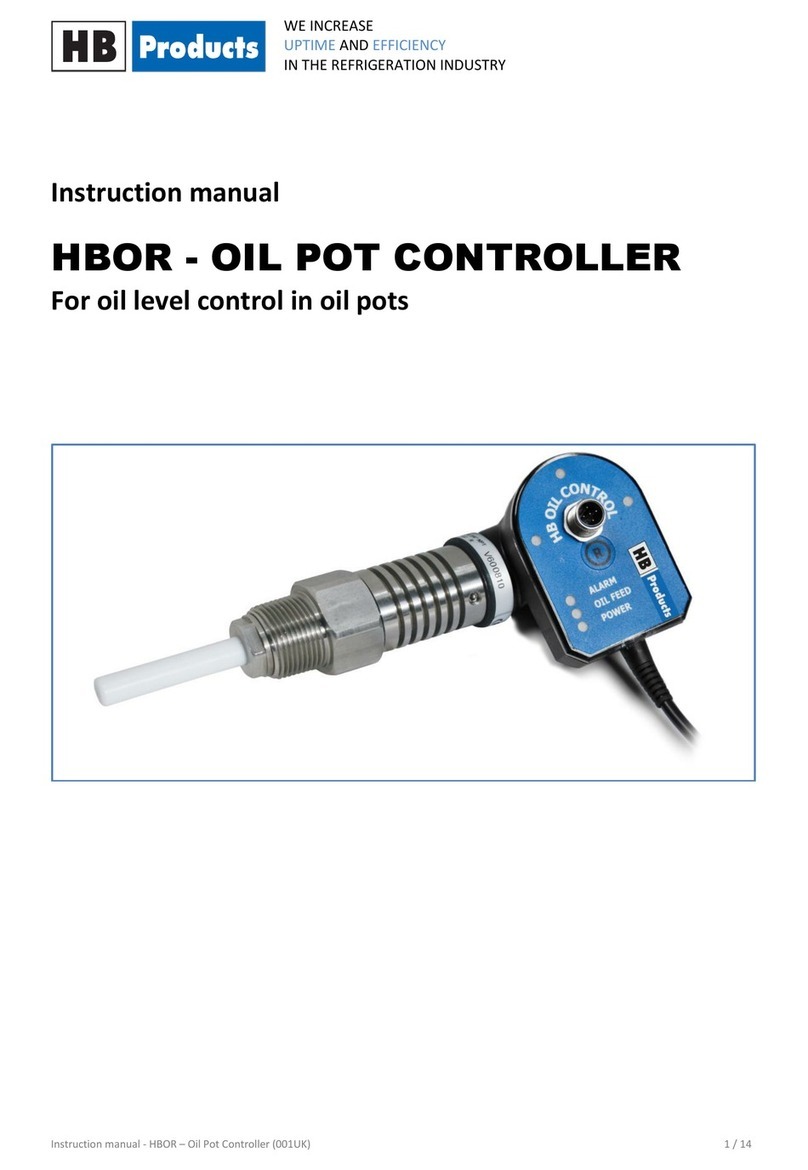

HBLC is an intelligent sensor with a built-in

microprocessor. It is designed to control

refrigerant levels in both low pressure and high

pressure systems. It emits a 4-20 mA signal,

which is proportional to the sensor's set range of

measurement.

Apart from the 4-20 mA signal, the sensor also

has a built-in controller.

The controller can be set-up with all the

parameters necessary for controlling a

modulating motor valve.

The sensor can be delivered with a cable for

direct supply to and control of motor valves.

Measurement Principle

The sensor is a capacitative sensor. The capacitative measurement principle is based on the electrical

properties in the proximity of a capacitor. A capacitor is an electrical component that is capable of building

and sustaining an electrical charge

Principally, a capacitor consists of two plates.

When a charge is applied to a plate, the other

plate will be charged with the opposite polarity

and retain the charge until it has been grounded.

The magnitude of the charge (the capacitance)

that can be generated depends, among other

things, on what is found between the plates.

The substance between the plates is referred to

as a dielectric.

Rather than two plates, the sensor for level

measurement is shaped as a cylindrical rod.

When liquid covers the sensor, the measured

capacity is changes.

The conductivity of a material can vary depending

on temperature, chemical composition, and the

homogeneity of the material, and therefore it can

in some cases require a different factory

calibration.

HB Products sensors are calibrated so that they differentiate between conductive and non-conductive

liquids.

In refrigeration systems, the oil and liquid CO2and HFC are not regarded as conductive fluids, whereas

refrigerants such as ammonia and brine are regarded as conductive.

Design

The sensor consists of a mechanical part and an electronic part. These are easily separated by loosening 2

grub screws, or for mechanisms with mounting tabs, by pressing the electronic part in towards the

mechanical part and turning the housing counter-clockwise until a wave washer pushes it from the

mounted position. The electronic part is designed in accordance with IP65 waterproof rating and so as to

withstand vibrations.

The mechanical part is produced in AISI304/PTFE and tested to withstand high pressure.

Software

The sensor is supplied with the latest firmware.

The sensor is configured with a configuration tool, "HB Tool", using a PC. It is capable of determining the

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 5 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

version which was supplied.

The latest version of the tool is backwards compatible.

It is not possible to update the software on a sensor which has already been supplied.

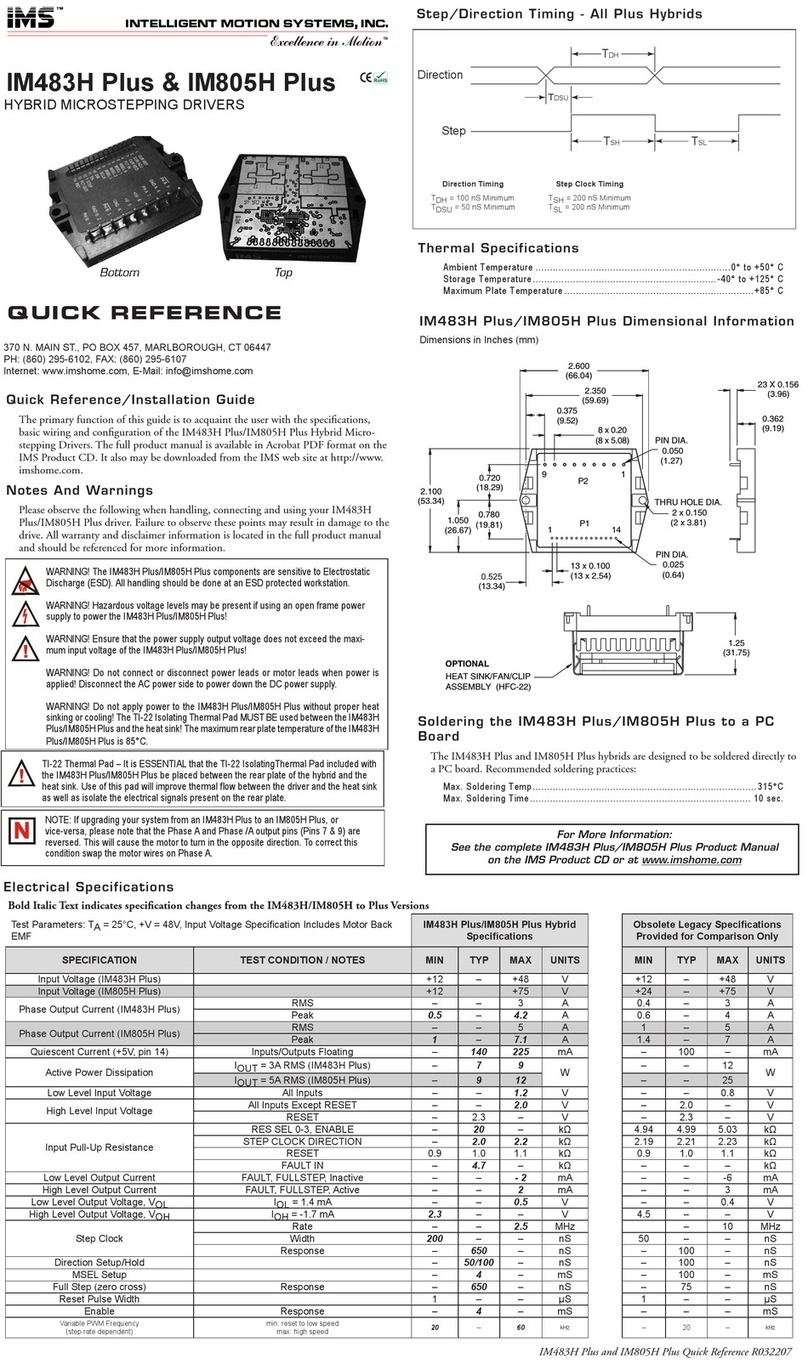

Technical Data

Supply:

Voltage: 24 V AC/DC ±10%*

Current draw: Max 50 mA

Power consumption: 30 VA*

Plug: M12, 5 pins

DIN 0627

Valve control:

Analogue output: 4-20 mA

Output function: P control

Alarm output: Max 1 A (24W)

Cable length: 3 m

Cable size: 2 x 0,75 mm2

Cable glands: PG7 / M8

Installation conditions:

Ambient temperatures: -30…+50°C

Refrigerant temperature: -60…+80°C

Max. operational pressure: 100/150 bar

Waterproof rating: IP65

Vibrations: IEC 68-2-6 (4g)

Authorisations:

EMC Emission: EN61000-3-2

EMC Immunity: EN61000-4-2

GOST R: No 0903044

*Power consumption is including consumption on

Siemens MVS661 valve.

Mechanical specifications:

Thread connection: ¾” NPT or BSPP

Sensor length: 300 mm

Materiale –mekaniske dele: AISI304

Materials –electronic parts: Nylon 6 (PA)

Housing design: Front

Configuration & indication:

Configuration With a PC

LED indication Green, yellow, and

red

Cable (included):

M12 cable –5 m: HBxC-M12/5

Cable size: 5 x 0,34 mm2

Cable glands: PG7 / M8

Plug type: Angle - 90°

Cable type: PUR-OB grey

Cable approval: CSA

Accessories:

Configuration tool: HB Tool

HBLC can be connected to other modulating 24 V

DC valves.

Design and Function

HBLC is designed for refrigerant level control in chillers, separators, coolers, and capacitors. If the sensor is

installed in an overflow pipe, it is important that there is adequate air around the sensor, so that gas

pockets do not form. The sensor is based on the capacitive measurement principle, which requires a

metallic connection to the overflow pipe or to the pipe segment where it is installed.

NOTE! All terminals are protected against incorrect termination with a supply voltage of up to

40V. If the supply voltage is greater than 40 V, the electronics will be damaged.

Please note! Supply Voltage may differ from the data given in the manuals. Applicable will

always be the sensor label.

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 6 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

The HBLC sensor also has a built-in controller. The parameters for controlling a modulating motor valve can

easily be set up in a configuration tool (HB Tool).

HBLC connected to a modulating valve –an alternative to low pressure float control.

An economiser with an HBLC connected to the modulating valve, type Siemens MVS661.

Installation Guide

The following applies to the design of the system:

1) It must be mounted vertically.

2) HBLC can be mounted on an overflow pipe or a pipe segment where flow and turbulence

are minimised.

3) The sensor is installed with a standard cable without a sheath. If EMC is higher than

described in EN 61326, a sheathed cable must be used.

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 7 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

CAUTION! In case of welding work on the unit, please make sure that proper earthing is carried

out to avoid damaging the electronics.

Electrical connection

HBLC: With common supply and control cable.

HBLC/C: With separate supply and control cable to the modulating valve.

HBLC/S: with separate supply and control cable to stepper motor:

Note! HBLC uses the overflow pipe or the pipe segment as reference material. Therefore, use

either conductive sealing material or make sure that the Teflon tape does not prevent a

metallic connection.

Note! The sensor element may not touch the tank or other metal parts in the installed

position. If so, the sensor will not give a correct signal.

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 8 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Please note! Supply Voltage may differ from the data given in the manuals. Applicable will always be the

sensor label.

”Run In” signal is used as a signal to indicate whether the system is running (start/stop function). It can be

(de)activated in the tool.

Mounting Guide

HBLC is installed on an overflow pipe or a pipe segment matching the sensor’s installation length.

Conductive sealing material or Teflon tape is applied to the thread, although one must ensure that there is

metallic contact between the sensor and the overflow pipe. The sensor is tightened with a torque

corresponding to the thread type and operational pressure.

For the installation of HBLC, there is required a 2.5mm

Allen key, a shifting spanner, as well as gasket material

depending on the thread type.

Loosen the two set screws that secure the electronic part to the

mechanical part.

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 9 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Separate the electronics from the mechanical part.

Apply liquid gasket / Teflon to the conical thread.

Install and mechanically tighten in the vessel, and

tighten depending on the thread type and size (80-150Nm).

Mount the electronic part again and secure with two set

screws.

LED Indication & Calibration

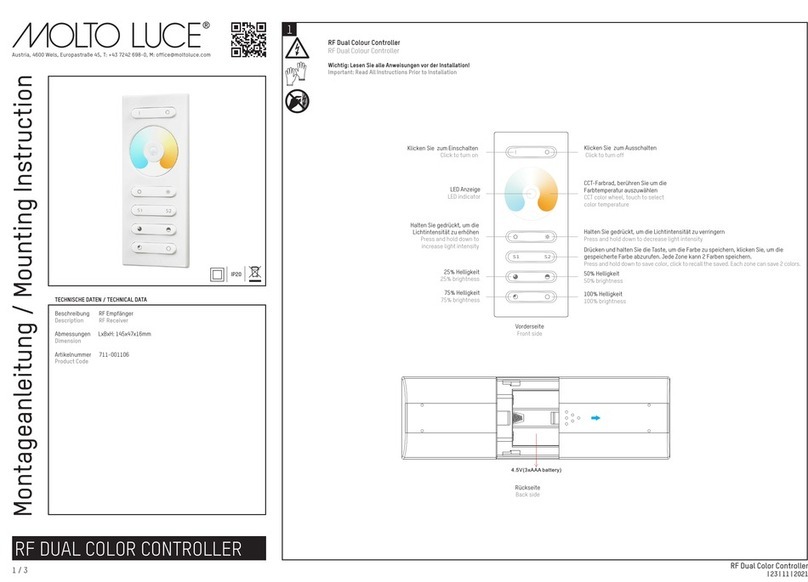

LED indication:

1) Green LED indicates 24 V DC supply; it blinks during operation. If "run-in" is not used, this function

must be deactivated in the tool.

2) Yellow LED indicates control.

The blink sequence indicates if the valve is closing or opening.

3) Red LED indicates high or low level alarm, depending upon the setup.

LED signal

ON/OFF/Frequency

Functionality

Green

ON

Supply voltage connected

Flash

Run In start signal / in operation.

OFF

No supply voltage

Yellow

ON

Activation of valve control / and during calibration

OFF

Valve control not active

Red

ON

Alarm, high or low level, depending upon the setup.

Flash

Does not detect and sensor probe

OFF

No alarm

Yellow +

Red

Flash

Power supply not sufficient

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 10 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Calibration:

0% or 100% calibration can be carried out independently of each other. HBLC level sensor is delivered pre-

calibrated. For normal use, calibration is not necessary. If the signal changes over time, we recommend a

0% calibration with an empty overflow pipe or container.

Instruction for 0% calibration:

1) The sensors calibration function shall be connected via the HB tool. See instruction for PC

connection and configurations parameters in separate manuals.

2) Connect the power cable.

3) Empty container/overflow pipe

4) Activate "R" for 5 seconds to activate "calibration mode" = Yellow LED turns on (ON) during the 5

seconds activation, and goes off (OFF) when the calibration mode is activated.

5) Activate "R" once = Yellow LED blinks once. The green LED then blinks to confirm calibration.

6) Connect PC Tool again and disconnect the calibration function in tool.

7) Connect the power cable.

"Calibration mode" is complete and the sensor is then running normally.

Instruction for 100% calibration:

1) The sensors calibration function shall be connected via the HB tool. See instruction for PC

connection and configurations parameters in separate manuals.

2) Connect the power cable.

3) Full container/overflow pipe up to a 100% level.

4) Activate "R" for 5 seconds to activate "calibration mode" = Yellow LED turns on (ON) during the 5

seconds activation, and goes off (OFF) when the calibration mode is activated.

5) Activate "R" twice = Yellow LED blinks twice. The green LED then blinks to confirm calibration.

6) Connect PC Tool again and disconnect the calibration function in tool.

7) Connect the power cable.

"Calibration mode" is complete and the sensor is then running normally.

Installation of HB Configuration Tool

See separate manual.

PC Configuration

See separate manual.

Setup and Connection of Valve

See separate manual.

NOTE! To be able to change the control parameters, you need a special USB/M12

configuration cable, as well as a configuration tool installed on a PC

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 11 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Fault Detection

General:

Fault

Reason

Correction of fault

No LED is on / not operating.

No supply to the sensor or

defective cable/plug

Check and find faults in the power

supply, or replace the supply

cable.

Yellow and red LED flash.

Power supply is not sufficient.

Install proper power supply.

Valve open and close to fast.

Refrigerant I boiling in standpipe

Increase “filter” settings and

eventually increase P-band as

well.

No contact activation

There may be dirt between the

electronic housing and the

mechanical housing.

Separate the two parts and clean

the spring tip. Remember to

apply silicone grease to the spring

tip so as to avoid problems with

moisture

Delay in sensor activation

May be caused by gas and

bubbles in the system.

Check if the sensor is placed

optimally so that gas is avoided.

The valve is not performing the

control function.

Wiring not done correctly, or

wrong dip switch setup.

Connect the valve correctly

and/or configure the valve's dip

switches according to the

instructions.

The valve is not performing the

control function well enough.

Oil has accumulated in the level

indicator glass which cannot

escape.

Drain the level indicator of oil

and, if necessary, clean the oil

from the rod.

There is no agreement between

the output signal and the level

in the level indicator.

The sensor is incorrectly

calibrated.

Perform calibration.

Practical measurement of output signals:

4-20 mA signal: Function and stability of the 4-20 mA signal can be controlled by connecting a hand-held

multimeter. The output signal must be between 3.6 mA and 22 mA. If not, the electronics are defective.

Sensor Repair

The sensor electronics are completely embedded and can therefore not be repaired.

In case of faults with the sensor, it will typically only be necessary to replace the electronics.

Complaint cases are handled by the HB Products dealers/distributors.

Their complain procedures must be followed before returning the sensor.

NOTE! Fault detection in the electronics and/or replacement of the electronics can be carried

out without releasing pressure on the system or removing the mechanical part of the sensor

Instruktionsmanual - HBLC –Sensor & regulator (012-UK) 12 / 12

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Spare parts

Position

Type

Specification

Part number

1

Mechanical parts

¾” NPT / 314 mm/NH3

HBLC-NH3-3.1-2-MEK

¾” BSPP / 314 mm/NH3

HBLC-NH3-3.1-6-MEK

¾” NPT / 314 mm/ CO2/HFC

HBLC-CO2/HFC-3.1-2-MEK

¾” BSPP / 314 mm/ CO2/HFC

HBLC-CO2/HFC-3.1-6-MEK

2

Electronic parts

Direct output (no cable)

HBLC-EL

For modulating valve

HBLC/C-EL

For stepper motor

HBLC/S-EL

Further Information

For further information, please visit our website, www.hbproducts.dk, or send an email

Other manuals for HBLC

2

Table of contents

Other HB Products Controllers manuals

Popular Controllers manuals by other brands

Muller

Muller 858 Operating and assembly instructions

Hanna Instruments

Hanna Instruments BL 983320-0 user manual

Kramer

Kramer K-NET RC-53D user manual

Vivo

Vivo DESK-V120EB instruction manual

NAVITAS

NAVITAS 440A Installation & service manual

Cisco

Cisco AIR-WLC4402-50-K9 Installation and configuration guide