HBK Z6M User manual

Z6/M

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.6001

DVS: A01063 06 Y00 01

02.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Z6/M

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Z6/M

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the product 5............................................

3 General 6..........................................................

4 Prior to mounting 7.................................................

5 Mounting 8........................................................

6 Operation 10........................................................

7 Mounting examples 11...............................................

8 Connection 12.......................................................

8.1 Connecting several weighing modules in parallel 13.......................

8.2 Connection using four‐wire circuitry 13..................................

8.3 Cable extensions 13..................................................

9 Dimensions 14......................................................

10 Specifications Z6/M weighing module 15...............................

11 Specifications for the Z6... load cells 16................................

3

Z6/M

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

In cases where a breakage would cause injury to persons or damage to equipment, the

user must take appropriate safety measures (such as fall protection, overload protection,

etc.). For safe and trouble‐free operation, weighing modules must not only be correctly

transported, stored, sited and installed but must also be carefully operated and main

tained.

It is essential to comply with the relevant accident prevention regulations. In particular

you should take into account the limit loads quoted in the specifications.

Use in accordance with the regulations

Z6/M... type weighing modules are conceived for weighing applications. Use for any

additional purpose shall be deemed to be not in accordance with the regulations.

In the interests of safety, the weighing modules should only be operated as described in

the Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of

accessories.

The weighing modules are not safety elements within the meaning of its use as intended.

Proper and safe operation of this transducer requires proper transportation, correct

storage, assembly and mounting and careful operation and maintenance.

General dangers due to non‐observance of the safety instructions

The Z6/M... weighing modules correspond to the state of the art and are fail‐safe. The

tank weighing modules can give rise to residual dangers if they are inappropriately

installed and operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a force

transducer must have read and understood the Mounting Instructions and in particular

the technical safety instructions.

Residual dangers

The scope of supply and performance of the weighing modules covers only a small area

of weighing technology. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of weighing

technology in such a way as to minimize residual dangers. Prevailing regulations must be

complied with at all times. There must be reference to the residual dangers connected

with weighing technology.

Z6/M

SAFETY INSTRUCTIONS

4

Environmental conditions

In the context of your application, please note that all materials which release chlorine

ions will attack all grades of stainless steel and their welding seams. In such cases the

operator must take appropriate safety measures.

Prohibition of own conversions and modifications

The weighing modules must not be modified from the design or safety engineering point

of view except with our express agreement. Any modification shall exclude all liability on

our part for any damage resulting therefrom.

Qualified personnel

These weighing modules are only to be installed by qualified personnel strictly in

accordance with the technical data and with the safety rules and regulations which

follow. It is also essential to observe the appropriate legal and safety regulations for the

application concerned. The same applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their

function.

Accident prevention

Although the specified nominal capacity in the destructive range is several times the full

scale value, the relevant accident prevention regulations from the trade associations

must be taken into consideration.

5

Z6/M

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EC direc

tives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc

).

Z6/M

GENERAL

6

3 GENERAL

HBK supplies Z6/M... weighing modules for max. capacities from 30 kg to 200 kg and

500 kg. The weighing modules are designed mainly for use in tank weighing applications.

These weighing modules are fitted with lateral stay rods. An integral over‐load stop is

also fitted.

The modules consist of a base plate, the load cell complete with load application

elements, and the cover plate. A pendulum support is used for the load application,

providing compensation for horizontal load shifts (such as may occur as a result of

thermal strain, for example). The weighing modules are pre‐assembled and a grounding

cable is supplied.

7

Z6/M

PRIOR TO MOUNTING

4 PRIOR TO MOUNTING

SCare should be taken to ensure that all surfaces for siting and mounting are clean,

smooth and level. Depending on the mounting conditions, any leveling error can be

compensated for by using suitable wedges and compensation plates (permanently

welded) or by grinding away the mounting surface, for example.

Important

On no account must the module plates be ground.

SThe base or foundation frame must be sufficiently rigid to prevent unacceptable de

formation under load (such as sagging).

SIn order to keep the mounting as free of constraining forces as possible, the fastening

holes on the foundation frame and container joint must be suitably aligned.

SEvery effort should be made to ensure uniform loading on the support points. Care

should be taken to adjust the height on the support points correctly (compensating

shims need to be available). This is especially important in the case of statically unde

fined supports.

Z6/M

MOUNTING

8

5 MOUNTING

SThe module is delivered with lifted cover plate. Prior to mounting, the cover plate has

to be lowered by unscrewing the nut.

SWhen mounting the container it is important to ensure that no sudden heavy loads are

applied to the module, for instance when lowering it onto the supports. Even transient

loads can damage the load cell if they exceed its limit values.

Notice

The factory‐fitted overload stop is designed for handling overloads during normal opera

tion. It is not designed to deal with short, sharp loads imposed during mounting, as these

commonly amount to a multiple of the permissible limit values.

SIn the case of statically undefined supports, non‐uniform loading of the modules oc

curs due to flexibility as the load is taken up or due to inaccuracy in the height adjust

ment. This non‐uniformity should be checked on the individual load cells by applying

an excitation voltage and comparing the output voltages. To prevent overloads, any

large non‐uniformity should be compensated for by inserting shims under the sup

ports that are least loaded.

SWhen tanks are heavy or mounting conditions are unfavorable, the use of mounting

aids such as auxiliary supports or lifting equipment is recommended.

SThe weighing modules must be installed so that they are not exposed to lateral forces

in the initial state. This means the built‐in pendulum support must be aligned as near

to the perpendicular as possible. This is the case when the foundation and tank joint

are horizontal and the fastening holes on the foundation and container joint are suit

ably aligned.

SThe base plate and cover plate should be firmly fastened to the foundation and tank

respectively.

SThe fitted EEK4 grounding cable is used to protect against welding currents that can

damage the electronic parts of the transducers.

9

Z6/M

MOUNTING

Notice

If the load cell is to be replaced, the upper module plate can be lifted by max. 1.5 mm.

Lock the nut in place to hold the upper module plate in this position. Dismounting the tank

itself is not required.

The following tightening moments prescribed for the fastening bolts must be adhered to

when replacing the load cell:

up to 200 kg max. Capacity

Galvanized version: 34 N·m

Stainless steel version: 23 N·m

500 kg max. Capacity

Galvanized version: 76 N·m

Stainless steel version: 45 N·m

The setting of the overload stop must be checked after the replacement load cell has been

installed. Please refer to the specifications for the weighing module: ”Setting range for the

overload stop”.

Z6/M

OPERATION

10

6 OPERATION

SDust, dirt and other foreign bodies must not be allowed to collect in such a way that

movement of the transducer (bellows) is restricted.

SThe gap for the overload stop and lateral stops must also be kept free of

contamination.

SThe play of the overload stop (for details see table ”Specifications for the weighing

module”) should be checked at regular intervals, for instance with a feeler gage, and

be readjusted if necessary.

SThe weighing modules should not be completely relieved of load. This prevents the

load application elements from lifting out.

SLateral displacements which exceed the maximum permissible value and do not act in

the direction of the stay rods should be avoided by aligning the other modules appro

priately, or should be absorbed by other stops or retention devices.

SThe play in the stay rods should be regularly checked and if necessary readjusted.

11

Z6/M

MOUNTING EXAMPLES

7 MOUNTING EXAMPLES

Stay rod

Load introduction

Degree of freedom

120°120°

120°

90°90°

90°90°

Attention:

The represented bearing

arrangements consider

only weighing‐technical cri

teria.

The carrying and stability

must be examined and

guaranteed in each case by

the operator.

Fig. 7.1 Mounting examples for weighing modules with stay rods

Z6/M

CONNECTION

12

8 CONNECTION

The load cells on weighing modules can be connected to:

SCarrier‐frequency measuring amplifiers or

SDC meas. amplifiers suitable for strain‐gage based measurement systems.

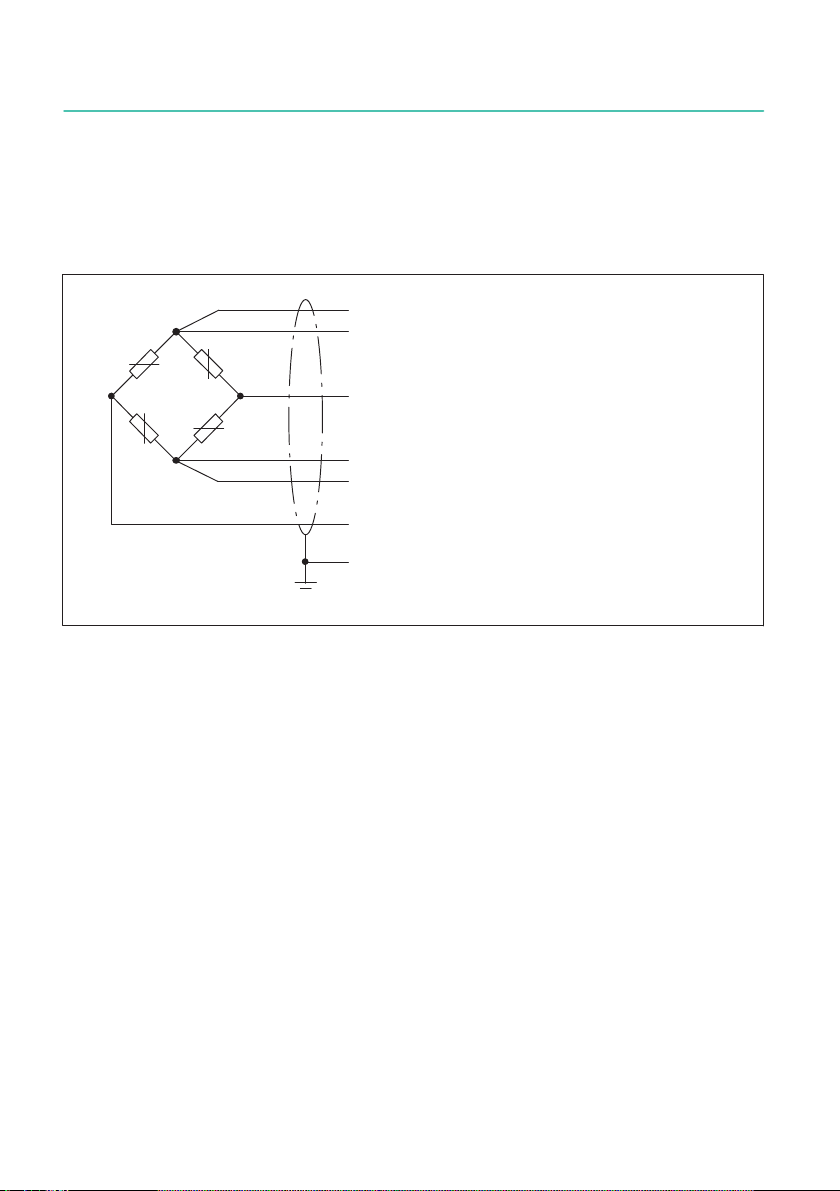

The wiring assignment of the load cell is shown in Fig. 8.1.

(white)

(black)

(gray)

Feeding (+)

(green)

(red)

(wire strand)

Feeding (-)

Sense (-)

Sense(+)

(blue)

Sense(+)

Signal (-)

Shield, filler connected with housing,

in the case of type Z6F and Z6G load

cells

Fig. 8.1 Wiring assignment of the load cell (six‐wire circuitry)

13

Z6/M

CONNECTION

Electrical and magnetic fields often induce interference voltages in the measurement

circuit. Therefore:

Suse shielded, low‐capacitance measurement cables only (HBK cables fulfill both con

ditions)

Sdo not route the measurement cables parallel to power lines and control circuits. If

this is not possible, protect the measurement cable with steel conduit for example

Savoid stray fields from transformers, motors and contact switches

8.1 Connecting several weighing modules in parallel

Load cells can be wired in parallel by joining the load cell cable core ends of the same

color. In this case the HBK range offers terminal boxes of the VKK... series. The output

signal is then the average of the individual output signals.

CAUTION

Overloading of an individual load cell cannot then be detected from the output signal.

8.2 Connection using four‐wire circuitry

In the event of connections to amplifiers using four‐wire circuitry, the cores bl (blue) and

gn (green) should be connected together, as should bk (black) and gr (gray). The follow

ing deviations occur in the case of cable of original length (3 m): Sensitivity -0.2 % and

temperature coefficient -0.01 %/10 K.

8.3 Cable extensions

Extension cables must be shielded and of low capacitance. We recommend the use of

HBK cables, which satisfy these requirements.

With cable extensions it is important to ensure that a good connection is provided, with

minimum contact resistance and good insulation.

When using six‐wire circuitry, the effects of resistance changes in the extension cable are

compensated. If you extend the cable using four‐wire circuitry, the sensitivity deviation

can be rectified by adjusting the amplifier. However, temperature effects are only be

compensated when operating with six‐wire circuitry.

Route the load‐cell connection cable so that any condensed water or dampness forming

on the cable can drip off. It must not be able to reach the load cell. In addition ensure that

no dampness can penetrate the open ends of the cable.

Z6/M

DIMENSIONS

14

9 DIMENSIONS

110 100

155

75

14 17.5

17.5 65

190

93.6 ±0.8

15 15

Lifting device

For removing the load cell,

the upper plate can be lifted

by max. 1.5 mm.

Dimensions

(in mm; 1 mm = 0.03937 inches)

15

Z6/M

SPECIFICATIONS

10 SPECIFICATIONS Z6/M WEIGHING MODULE

Typ Z6/M

Maximum capacity kg 30 50 100 200 500

Limit load (of load cell) % of max.

capacity

150

Restoring force, for 1 mm

side offset

% of ap

plied load

6,1

Max. permissible side off

set transverse to the stay

rod axis 1)

mm "1.5

Max. permissible horizon

tal force in the stay rod di

rection

kN 5

Max. permissible lift‐off

force

kN 5

Material galvanized2) or stainless steel

Weight (depending on ver

sion, including load cell)

kg 8 ... 9

Play on overload stop mm v0.36 v0.35 v0.25 v0.45 v0.80

1) With horizontal alignment of upper module plate

2) As per EN 10088-1

Z6/M

SPECIFICATIONS

16

11 SPECIFICATIONS FOR THE Z6... LOAD CELLS

Type Z6FD1 Z6FC3

Accuracy class according to OIML R 60

Max. numbers of load cell verification intervals (nLC)

D1

1000

C3

3000

Max. capacity (Emax)kg 50; 100; 200;

500

50; 100; 200;

500

t 1 1

Minimum load cell verification interval

(vmin)

% of Cn0.0360 0.0090

Nominal sensitivity (Cn)mV/V 2 2

Tolerance on sensitivity for load applica

tion in specified direction

%t+(1;-0.1) "0.05

Temperature effect on sensitivity (TKC)3) % of

Cn/10 K

t"0.0500 t"0.0080

Temperature effect on zero balance (TK0)t"0.0500 t"0.0125

Hysteresis error (dhy)3)

%

t"0.0500 t"0.0170

Non‐linearity (dlin)3) t"0.0500 t"0.0180

Creep (dDR) in 30 min. t"0.0490 t"0.0166

Input resistance (RLC)

Ω

350...480

Output resistance (R0)356 "0.2 356 "0.12

Reference voltage (Uref)

V

5

Nom. (rated) range of excitation voltage

(Bu)

0.5...12

Isolation resistance (Ris)GΩu5

Nominal (rated) temperature range (BT)

°C [°F]

-10...+40 [+14...+104]

Service temperature range (Btu)-30...+70 [-22...+158]

Storage temperature range (Btl)-50...+85 [-58...+185]

Safe load limit (EL)% of

Emax

150

Breaking load (Ed)300

Maximum capacity kg 50 100 200 500

Permissible dynamic load

(vibration bandwidth to DIN 50100)

% of

Emax

100 100 100 100

Nominal (rated) displacement, approx. mm 0.27 0.31 0.39 0.6

Weight, approx. kg 0.5 0.5 0.5 0.5

17

Z6/M

SPECIFICATIONS

Z6FC3Z6FD1Type

Degree of protection according to

EN60529 (IEC529)

IP 68

(severe test conditions: 1 m

water column;100 h)

Material

Measuring body

Bellows

Screwed cable gland

Cable sheath

Stainless steel4)

Stainless steel4)

Stainless steel / Viton®

PVC

3) The values for linearity deviation, relative reversibility error and temperature effect on sensitivity are

typical values. The sum of these values is within the cumulative error limits laid down by OIML R60.

4) As per EN 10088‐1

Z6/M

SPECIFICATIONS

18

Table of contents

Languages:

Other HBK Control Unit manuals