Overhaul

Prior to performing any maintenance on

equipment, the following safety precautions

must be observed. Personal injury may

occur.

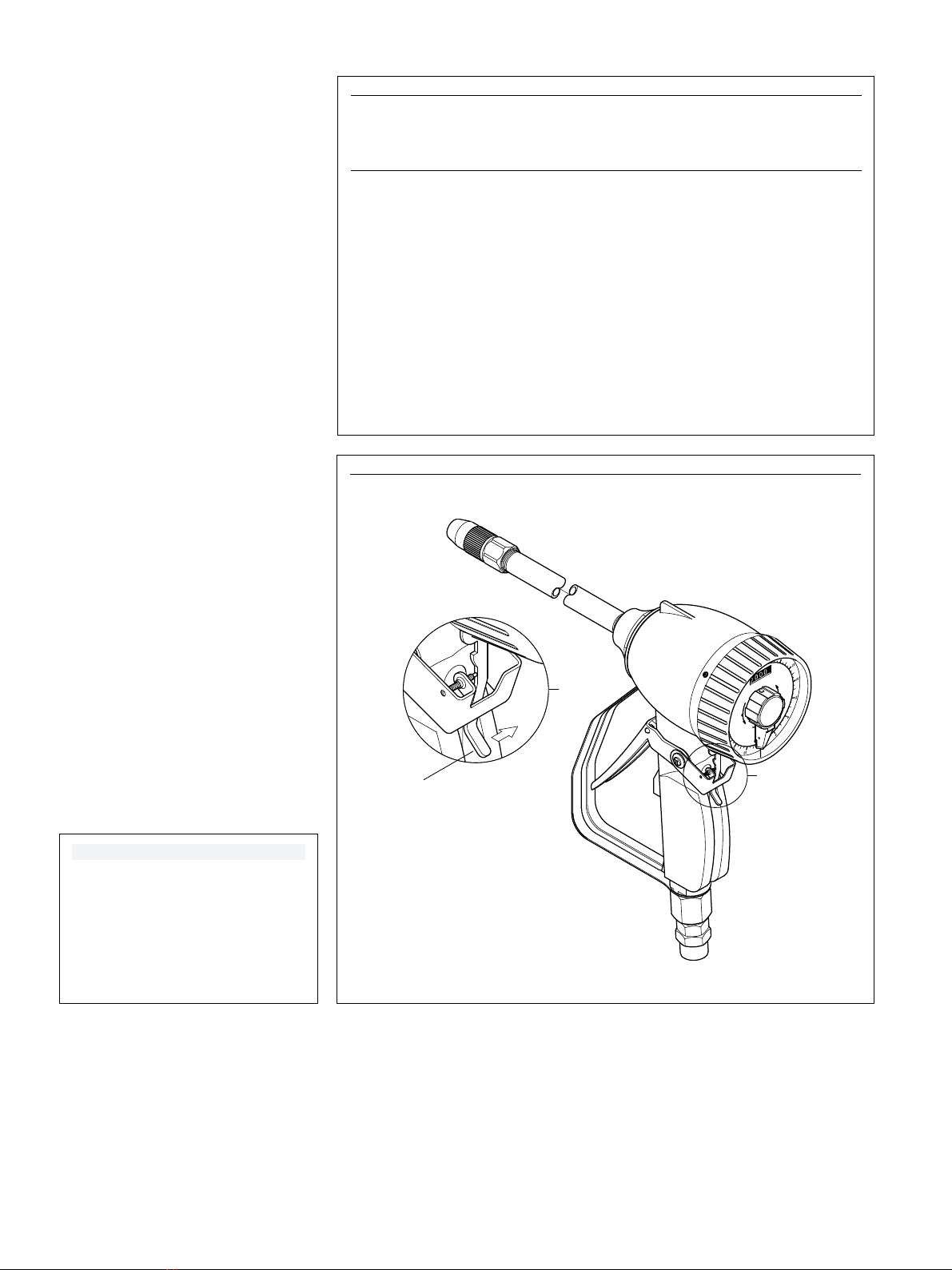

WARNING

Do not use halogenated hydrocarbon

solvents such as methylene chloride or

,,- trichloroethane in this valve.

Explosion can result when aluminum

and/or zinc-plated parts in valve come

in contact with halogenated

hydrocarbon solvents.

Release all pressure within system

prior to performing any overhaul

procedure.

•Disconnect air supply line from pump

motor.

• Operate control valve to discharge

remaining pressure within system

into appropriate container.

Never point control valve at any portion

of body or another person. Accidental

discharge of pressure and/or material

can result in injury. Read each step of

instructions carefully. Make sure proper

understanding is achieved before

proceeding.

Failure to comply may result in death

or serious injury.

Metering mechanism

assembly

17 Unscrew cap (3) from housing (8).

18 Remove o-ring (4) from cap (3).

19 Remove chamber and pinion assembly (5),

planetary gear (6), and spindle and gear

assembly (7) from housing (8).

20 Remove gland nut (11) from housing (8).

21 Remove o-ring (10) from gland nut (11).

22 Remove washer (9) from housing (8).

Inlet swivel, valve, guard,

and lever assembly

23 Unscrew swivel assembly (35) from

adapter (34).

24 Unscrew adapter (34) from housing (8).

25 Remove hand guard (32) and o-ring (33)

from adapter (34).

26 Remove screen (31), spring (30), valve

assembly (28), and valve sleeve (29)

from housing (8).

27 Remove screws (38) that secure lever

assembly (40) and lock bar and screw

assembly (39) to cam (37).

28 Remove lever assembly (40) and lock bar

and screw assembly from cam (37).

29 Push cam (37) from housing (8).

30 Remove quad rings (36) from cam (37).

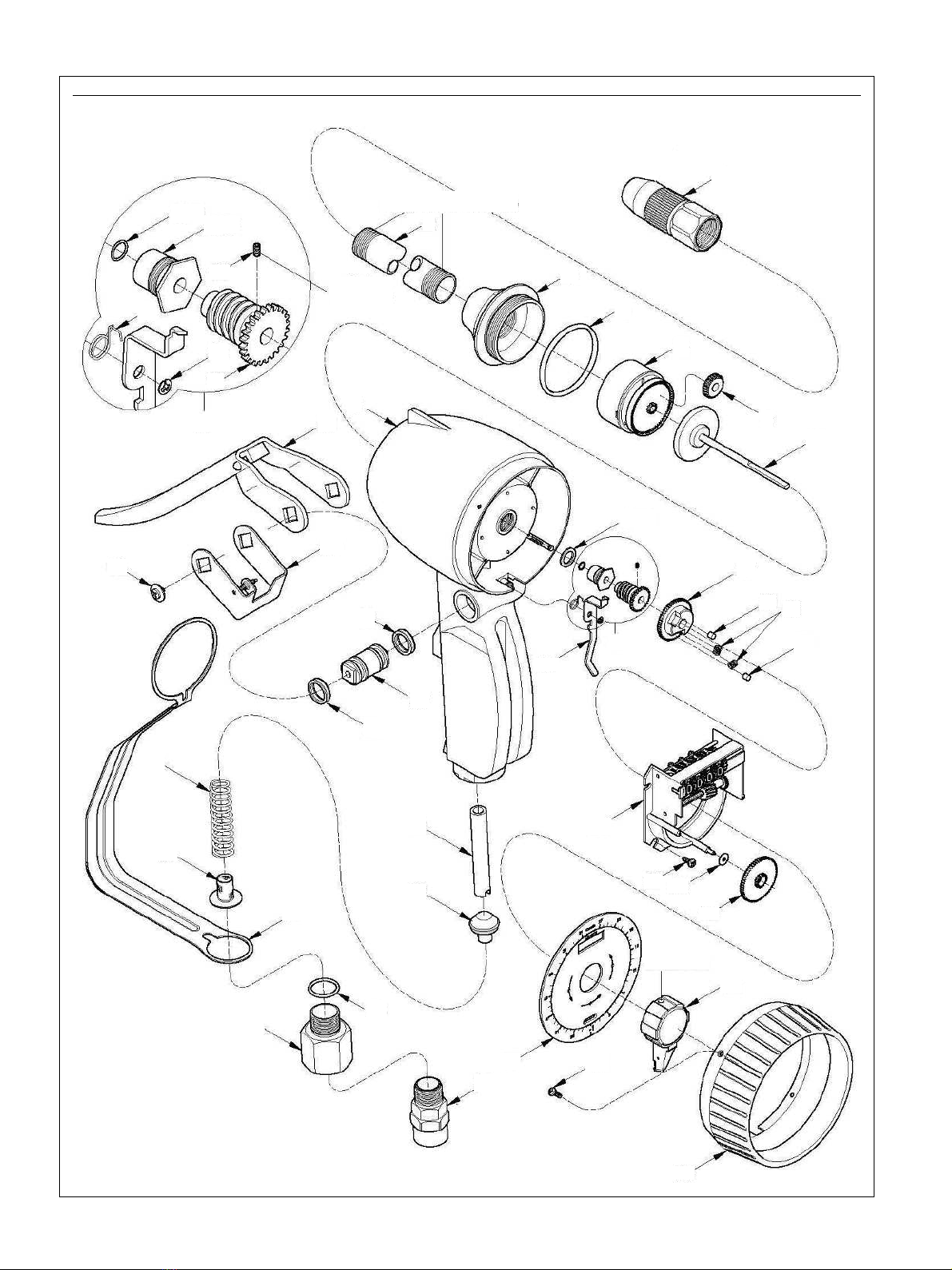

Disassembly

NOTE

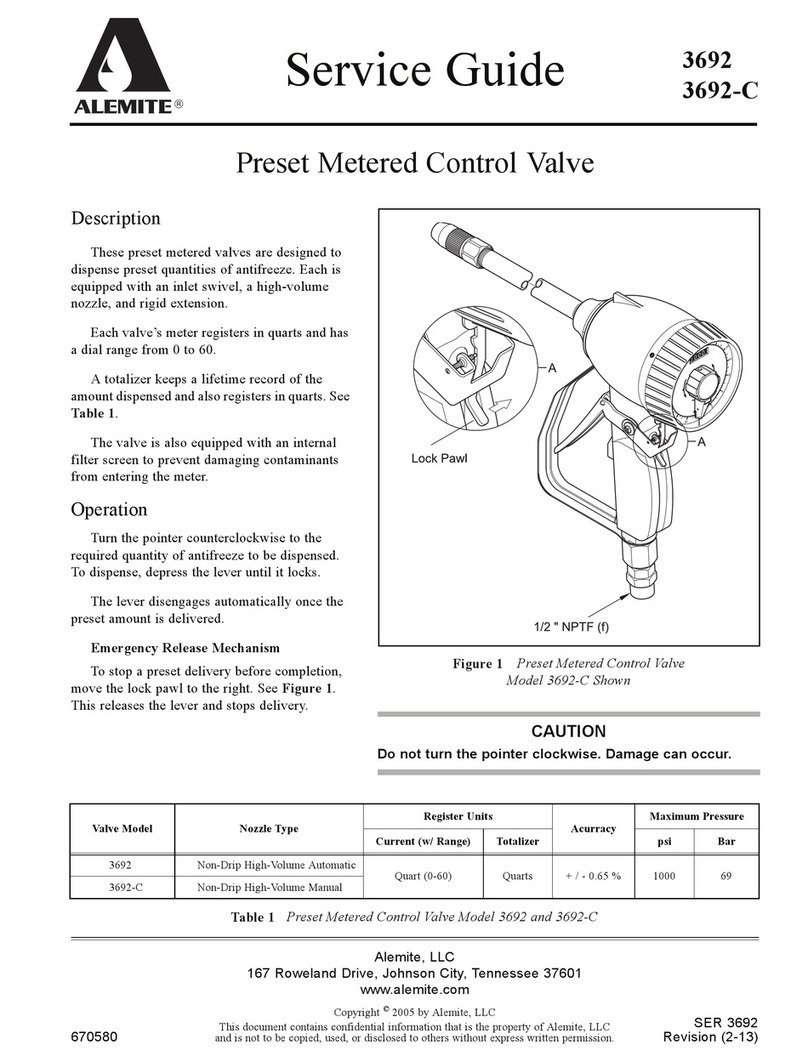

Refer to Fig. IPB 1, page 10 for

component identification on all overhaul

procedures.

Metered control valve

1 Unscrew extension (2) from cap (3).

2 Unscrew nozzle assembly (1) from

extension (2).

Shroud, pawl, and register

assembly

3 Unscrew screws (26) that secure

shroud (25) to housing (8).

4 Remove shroud (25) from housing (8).

5 Turn pointer (24) counter-clockwise until

access hole in pointer lines up with

setscrew.

6 Loosen setscrew that secures pointer to

spindle and gear assembly (7).

7 Remove dial (27) cam (17), and

pointer (24) as assembly from spindle

and gear assembly (7).

8 Carefully pry pointer (24) from cam

assembly (17) and dial (27) to separate

components.

9 Remove springs (18) and rollers (19)

from cam (17).

10 Remove retaining ring (15) that secures

lock pawl (14) to housing (8).

11 Remove lock pawl (14) and spring (16)

from housing (8).

12 Remove pointer gear (23) and

washer (22) from register assembly (20).

13 Loosen setscrew (12) that secures worm

gear (13) to spindle and gear

assembly (7).

14 Remove worm gear (13) from spindle

and gear assembly (7).

15 Remove screws (21) that secure register

assembly (20) to housing (8).

16 Remove register assembly (20) from

housing (8).