HBK TIM-PN User manual

TIM-PN

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0103.0003

DVS: A04341 06 Y00 00

01.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

TIM-PN

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

TIM-PN

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 4................................................

1.1 Safety rules 4......................................................

1.2 General dangers of failing to follow the safety instructions 4...............

1.3 Conditions at the site of installation 4..................................

1.4 Maintenance and cleaning 4..........................................

1.5 Residual dangers 5..................................................

1.6 Conversions and modifications 5......................................

1.7 Qualified personnel 5................................................

2 Markings used 6....................................................

2.1 The markings used in this document 6.................................

2.2 Symbols on the device 6.............................................

3 Scope of delivery 8.................................................

4 Application 8.......................................................

5 Structure and mode of operation 9....................................

6 Mounting 10........................................................

6.1 Mounting 10........................................................

6.2 Dismounting 10......................................................

7 Electrical connection 11..............................................

7.1 General information 11...............................................

7.2 Shielding design 11..................................................

7.3 Pin assignment 11...................................................

7.4 Supply voltage 14....................................................

7.5 Ethernet connection 15...............................................

7.6 PROFINET connection 16..............................................

8 Status display 17....................................................

9 Connection to a PC or network 18......................................

9.1 Change IP address 18................................................

9.2 Restore IP address 19................................................

9.3 Activating DHCP 19..................................................

10 Settings 20.........................................................

10.1 Home window 20....................................................

10.2 Device settings TIM 20................................................

3

TIM-PN

TABLE OF CONTENTS

10.2.1 Network 23.........................................................

10.2.2 Parameter Save/Load 27..............................................

10.3 Parameter settings TIM 28............................................

10.3.1 Passcode 28........................................................

10.3.2 Project 29..........................................................

10.3.3 Units and filters 30...................................................

10.3.4 Fieldbus interface 36.................................................

10.3.5 Supporting points approximation 39....................................

10.3.6 Intercommunication 44...............................................

10.3.7 Input mode 49.......................................................

10.4 Torque transducer parameters 51......................................

10.4.1 Passcode 51........................................................

10.4.2 Frequency / Analog output 52..........................................

10.4.3 Speed Encoder 53....................................................

10.5 Measuring 56.......................................................

10.6 Service 57..........................................................

10.6.1 Status 57...........................................................

10.6.2 Firmware update 58..................................................

10.6.3 Hardware Information 59..............................................

10.6.4 Service File 59.......................................................

11 PROFINET configuration 61...........................................

12 PROFINET configuration with the TIA portal 66..........................

12.1 Installing the GSDML file 67...........................................

12.2 Creating a project 68.................................................

12.3 Creating TIM-PN modules 70..........................................

12.4 Networking 70.......................................................

12.5 Configuring the TIM-PN module 73.....................................

12.6 Parameter set 74....................................................

12.7 Diagnosis status 74..................................................

13 Order numbers, Accessories 78........................................

14 Specifications 79

....................................................

TIM-PN

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

The TIM-PN torque interface module must only be used for torque measurement tasks in

combination with T40 family torque flanges from Hottinger Brüel & Kjaer GmbH and for

directly associated control and regulating tasks. Use for any purpose other than the

above is deemed to be non-designated use.

In the interests of safety, the module must only be used as described in the operating

manual. It is also essential to comply with the legal and safety requirements for the appli

cation concerned during use. The same applies to the use of accessories.

The interface module is not a safety element as defined by its intended use. For safe and

trouble-free operation, this module must not only be correctly transported, stored, sited

and mounted, but must also be carefully operated.

1.1 Safety rules

The module must be operated with a separated extra-low voltage (supply voltage DC 18

to 30 V DC).

Before commissioning, make sure that the mains voltage and type of current match the

mains voltage and type of current at the place of operation and that the circuit used is

sufficiently protected. Connecting electrical devices to low voltage: only separated extra-

low voltage may be used (safety isolating transformer according to DIN VDE 0551 /

EN 60742). Do not operate the device if the supply lead is damaged. Only operate built-in

devices once they are installed in the housing provided. The device complies with the

safety requirements of DIN EN 61010 - Part 1; protection class I. The module must be

mounted on a support rail connected to grounded conductor potential. Both the support

rail and the module must be free of paint, varnish and dirt at the point of installation.

1.2 General dangers of failing to follow the safety instructions

The TIM-PN module is a state-of-the-art unit and as such is safe and reliable to operate.

The module may give rise to dangers if it is inappropriately installed and operated by

untrained personnel. Any person instructed to carry out installation, commissioning, main

tenance or repair of the modules must have read and understood the mounting instruc

tions and in particular the technical safety instructions.

1.3 Conditions at the site of installation

Protect the device from direct contact with water (device degree of protection IP20).

1.4 Maintenance and cleaning

The TIM-PN module is maintenance-free. Please note the following points when cleaning

the housing:

SBefore cleaning, disconnect the device from the power supply.

5

TIM-PN

SAFETY INSTRUCTIONS

SClean the housing with a soft, slightly damp (not wet!) cloth. Never use solvents as

they could damage the labeling on the front panel.

SWhen cleaning, ensure that no liquid gets into the device or connections.

1.5 Residual dangers

The scope of supply and performance of the TIM-PN covers only a small area of torque

measurement technology. In addition, system planners, installers and operators should

plan, implement and respond to the safety engineering considerations of torque mea

surement technology in such a way as to minimize remaining dangers. On-site regula

tions must be complied with at all times. Reference must be made to remaining dangers

associated with torque measurement technology.

Remaining dangers are indicated in these mounting instructions, see also Chapter 2

Markings used.

1.6 Conversions and modifications

The TIM-PN module must not be modified from the design or safety engineering point of

view except with our express agreement. Any modification shall exclude all liability on our

part for any damage resulting therefrom.

1.7 Qualified personnel

This device is only to be installed and used by qualified personnel, strictly in accordance

with the specifications and the stated safety rules and regulations. It is also essential to

comply with the legal and safety requirements for the application concerned during use.

The same applies to the use of accessories.

Qualified personnel means persons entrusted with siting, mounting, starting up and oper

ating the product who possess the appropriate qualifications for their function.

SKnowledge of the safety concepts of automation technology is a requirement and as

project personnel, you must be familiar with these concepts.

SAs automation plant operating personnel, you have been instructed how to handle the

machinery and are familiar with the operation of the equipment and technologies

described in this documentation.

SAs commissioning engineers or service engineers, you have successfully completed

the training to qualify you to repair the automation systems. You are also authorized

to activate, ground and label circuits and equipment in accordance with safety engi

neering standards.

It is also essential to comply with the legal and safety requirements for the application

concerned during use. The same applies to the use of accessories.

TIM-PN

MARKINGS USED

6

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

NOTICE This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

Device -> New Bold text indicates menu items, as well as dialog and

window titles in the user interfaces. Arrows between

menu items indicate the sequence in which the menus

and sub-menus are called up

Sampling rate Bold text in italics indicates inputs and input fields in

the user interfaces.

uThis marking indicates an action in a procedure

2.2 Symbols on the device

CE certification

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EC direc

tives (the Declaration of Conformity can be found on the HBM

website (www.hbm.com) under HBMdoc).

7

TIM-PN

MARKINGS USED

Statutory waste disposal mark

In accordance with national and local environmental protection

and material recovery and recycling regulations, old devices that

can no longer be used must be disposed of separately and not

with normal household garbage.

If you need more information about waste disposal, please contact your local authorities

or the dealer from whom you purchased the product.

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

TIM-PN

SCOPE OF DELIVERY

8

3 SCOPE OF DELIVERY

SOne TIM-PN torque interface module

SPlug-in terminals for transducer connection and supply voltage (4 in total)

STIM-PN operating manual

4 APPLICATION

The TIM-PN module receives the digital data flow from the TMC interface, processes the

data and transfers the measured values (torque, speed, etc.) to the PROFINET interface.

The same applies to connecting frequency signals. The TIM-PN is set up and parameter

ized by an integrated web server that shows all the parameters in a web browser via an

Ethernet connection. The Ethernet connection can be automatically initialized via UPnP.

The IP address is set in the factory to 192.168.1.2.

This state can be restored by pressing and holding the Reset button for 10 s while turning

on the power supply.

9

TIM-PN

STRUCTURE AND MODE OF OPERATION

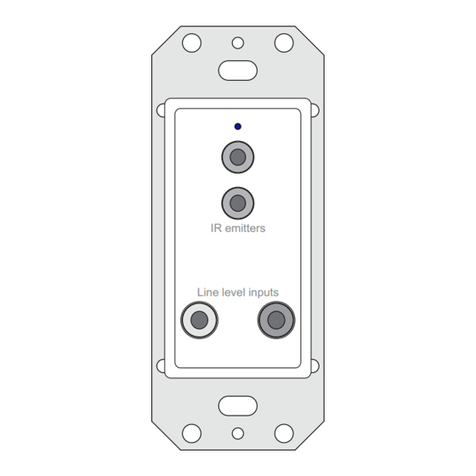

5 STRUCTURE AND MODE OF OPERATION

Magnetic

TIM-PN

HBM torque transducer

The TIM-PN receives the measured data flow of the connected torque transducer and

provides it as scaled measured values to an PROFINET and an Ethernet interface (UDP).

Two digital filters that can be shut off are provided for all signal paths. The low-pass filter

is parameterized via the Ethernet interface using an integrated web server.

When the TMC digital signal is connected, the internal shunt signal of the connected

torque transducer can be activated either by a control bit of the PROFINET or the web

server. The shunt signal produces an output signal corresponding to about 50% of the

nominal (rated) measuring range by means of a misalignment of the strain gauge bridge

in the transducer. It is used to monitor the entire signal path and can be activated by the

user for this purpose.

The supply voltage can be forwarded without extra circuitry measures to supply the con

nected torque.

TIM-PN

MOUNTING

10

6 MOUNTING

The interface module TIM-PN is mounted on a DIN EN 60715 rail.

A spring on the back holds the housing in position.

6.1 Mounting

1. Hook the interface module into the upper guide of the DIN rail.

2. Press the housing against the DIN rail until the spring engages in the lower guide.

6.2 Dismounting

1. Push the housing up vertically and then tilt it slightly forward.

2. Pull the housing out downwards from the DIN rail.

11

TIM-PN

ELECTRICAL CONNECTION

7 ELECTRICAL CONNECTION

7.1 General information

To make the electrical connection between the torque transducer and the amplifier, we

recommend using shielded, low-capacitance measurement cables from HBM.

With cable extensions, make sure that there is a proper connection with minimum contact

resistance and good insulation. All plug connections or swivel nuts nuts must be fully

tightened.

Do not route the measurement cables parallel to power lines and control circuits. If this

cannot be avoided (in cable pits, for example), maintain a minimum distance of 50 cm

and also draw the measurement cable into a steel tube.

Avoid transformers, motors, contactors, thyristor controls and similar stray-field sources.

Notice

Transducer connection cables from HBM with attached connectors are identified in accor

dance with their intended purpose (Md or n). When cables are shortened, inserted into

cable ducts or installed in control cabinets, this identification can get lost or become con

cealed. If this is the case, it is essential for the cables to be re-labeled!

7.2 Shielding design

The cable shield is connected in accordance with the Greenline concept. This encloses

the measurement system in a Faraday cage. It is important that the shield is laid flat on

the housing ground at both ends of the cable. Any electromagnetic interference active

here does not affect the measurement signal.

In the case of interference due to potential differences (compensating currents), operat

ingvoltage zero and housing ground must be disconnected on the amplifier and a poten

tial equalization line established between the stator housing and the amplifier housing

(copper conductor, 10 mm2wire crosssection).

7.3 Pin assignment

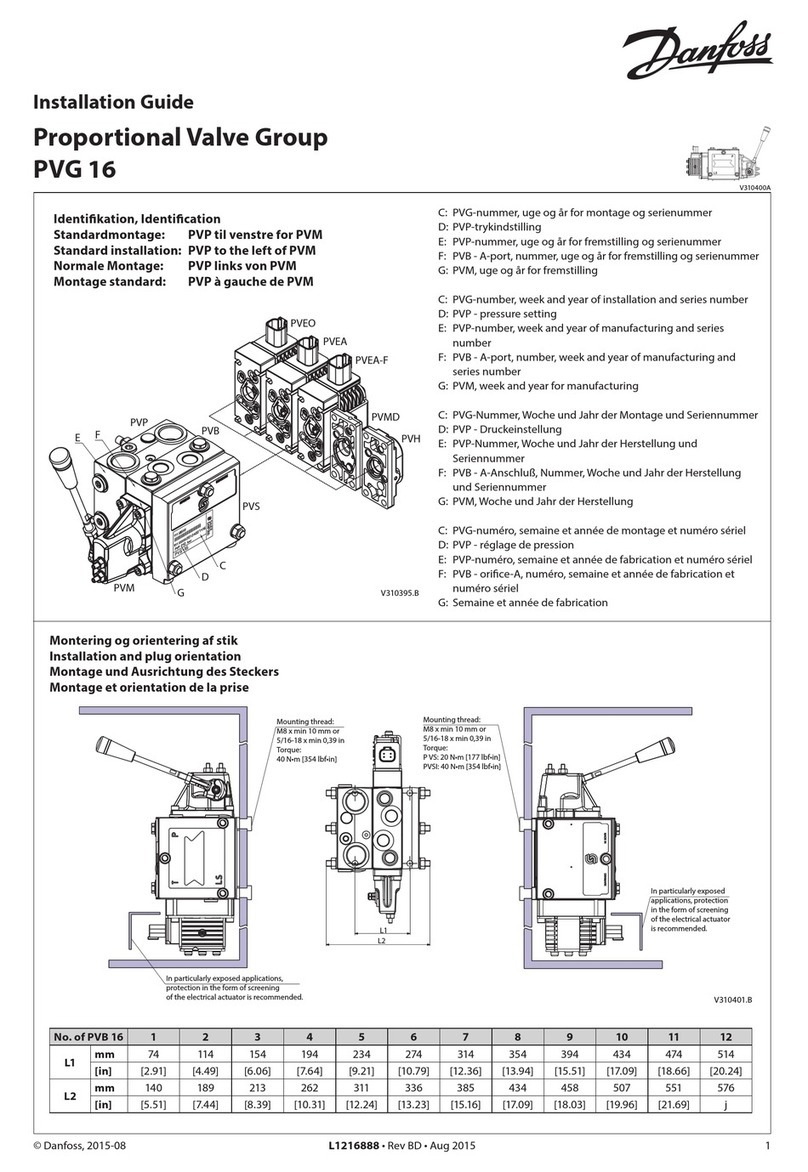

The housing of the TIM-PN has 4 Phoenix Combicon connector blocks, one Ethernet

socket, two PROFINET sockets and two 10+2 sockets/connectors. In delivery condition

the spring-loaded terminals are plugged into the connector blocks.

TIM-PN

ELECTRICAL CONNECTION

12

PN

++

AB

++

0DOUT

X1 X3

X2 X4

RA

RB

TX

RX

IN OUT

0V

24V

0V

24V

TIM...

TIM...

13

14 11

12

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

X1 X3

X2 X4

X6 X7

Terminal X1, speed encoder

Pin Assignment

1DGND (digital GND), color code black1)) / brown2))

2A+F1 rotational speed measurement signal, pulse sequence,

5V, 0°, color code red

3A-F1 rotational speed measurement signal, pulse sequence,

5V, 0°, color code white

4B+F2 rotational speed measurement signal, pulse sequence,

5V, phase-shifted by 90°, color code gray

5B-F2 rotational speed measurement signal, pulse sequence,

5V, phase-shifted by 90°, color code green

1) KAB154 rotational speed cable

2) KAB164 rotational speed cable

B-

A+

A-

B+

13

TIM-PN

ELECTRICAL CONNECTION

Terminal X2, voltage supply frequency connection

Pin Assignment

Connection for energy supply, input

1GND (TIMPN and stator supply)

2+24V ±10% supply (TIMPN and stator)

Output for the supply voltage of the torque transducer

3GND (looped through from X21): color code black

4+24V (looped through from X22): color code blue

5Shield (TMC), connected with ground

Terminal X2, voltage supply TMC connection

Pin Assignment

Connection for energy supply, input

1GND (TIMPN and stator supply)

2+24V ±10% supply (TIMPN and stator)

Output for the supply voltage of the torque transducer

3GND (looped through from X21): color code blue

4+24V (looped through from X22): color code black

5Shield (TMC), connected with ground

Terminal X3, speed encoder

Pin Assignment

1Shield (speed), connected with ground

2+, reference signal (1 pulse/revolution), 5V, color code blue

3-, reference signal (1 pulse/revolution), 5V, color code black

4 Reserved

5 Reserved

Terminal X4, torque transducer frequency

Pin Assignment

1Measurement signal 0V; symmetrical, color code gray

2RA, torque measurement signal 5V, color code red

0V

IN

24V

0V

OUT

24V

0V

IN

24V

0V

OUT

24V

+

0

-

+

DO

-

RX

RA

RB

TX

TIM-PN

ELECTRICAL CONNECTION

14

AssignmentPin

3RB torque measurement signal 5V, color code white

4Not in use

5Not in use

Terminal X4, torque transducer TMC

Pin Assignment

1DGND (digital GND), color code purple

2RS422-RA, color code red

3RS422-RB, color code white

4RS‐232‐TX, color code gray

5RS‐232‐RX, color code green

7.4 Supply voltage

The module must be operated with a separated extra-low voltage (nominal supply volt

age 18 to 30V DC ), which usually supplies one or more consumers within a test bench.

Should the device be operated on a DC voltage network, additional precautions must be

taken to discharge excess voltages.

7.4.1 Operating multiple TIM-PN modules

A maximum of 4 TIM-PN modules can be operated with 4 torque transducers in master

mode/individual mode with only one supply point. The left interface module should al

ways be selected for the supply point in this operating mode.

Notice

Multi-point supply of the devices operating in series is not permitted.

RX

RA

RB

TX

15

TIM-PN

ELECTRICAL CONNECTION

… max. 4x TIM-PN

Fig. 7.1 Operating multiple TIM-PN modules connected in series

Information

If multiple TIM-PNs modules are operated in series, make certain the power supply is ad

equate.

7.5 Ethernet connection

You must use an Ethernet crossover cable with older computers. Newer PCs/laptops

have Ethernet interfaces with autocrossing function. Ethernet patch cables can also be

used here.

TIM-PN

ELECTRICAL CONNECTION

16

7.6 PROFINET connection

Compatible devices All devices that are compatible with PROFINET

Cable type 100BASETX

STermination: Internal

SNetwork cable: CAT 5 FTP or

CAT 5 STP3)

SConnector: RJ45

SMaximum networksegment length:

100 m

Type of serial data transmission Full duplex

Transmission speed 100 Mbits/s

Protocol PROFINET

3) Shielded cables are expressly recommended

17

TIM-PN

STATUS DISPLAY

8 STATUS DISPLAY

LED Function Color/status Significance

Status TIM-PN status Green Transmission of measured

values OK

Orange/flashing

irregularly

Firmware update

Red Error, no transmission of

measured values

Ethernet link Network Yellow/green Link status

Flashing red 1 Hz Firmware update is running

Ethernet

communication

Network Green Transmission/reception

activity

PROFINET Slave status Green

Flashing green

Off

Operational

Pre-operational

Init

PROFINET Network Flashing yellow Transmission/reception

activity

Information

Press the reset button to reset the TIM-PN to the default IP address 192.168.1.2.

TIM-PN

CONNECTION TO A PC OR NETWORK

18

9 CONNECTION TO A PC OR NETWORK

You can operate the interface module either in a network or directly connected to a PC/

laptop. The interface module has an Ethernet interface (RJ45 socket) for the connection.

The TIM-PN has the default IP address 192.168.1.2 in the factory setting.

9.1 Change IP address

1. Open a web browser (e.g. Internet Explorer) and enter the current IP address, e.g.

http://192.168.1.2.

2. Under Device settings ³Network, open the network settings and enter a new IP

address.

3. Click on Accept settings to activate the new IP address. The change takes effect

immediately. To obtain access again, you must now enter the new IP address in the

web browser.

Fig. 9.1 Network settings

This manual suits for next models

1

Table of contents

Languages:

Other HBK Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson Fisher EWNS instruction manual

VAT

VAT 162 Series Installation, operating, & maintenance instructions

Siemens

Siemens WF 725 Planning Instructions

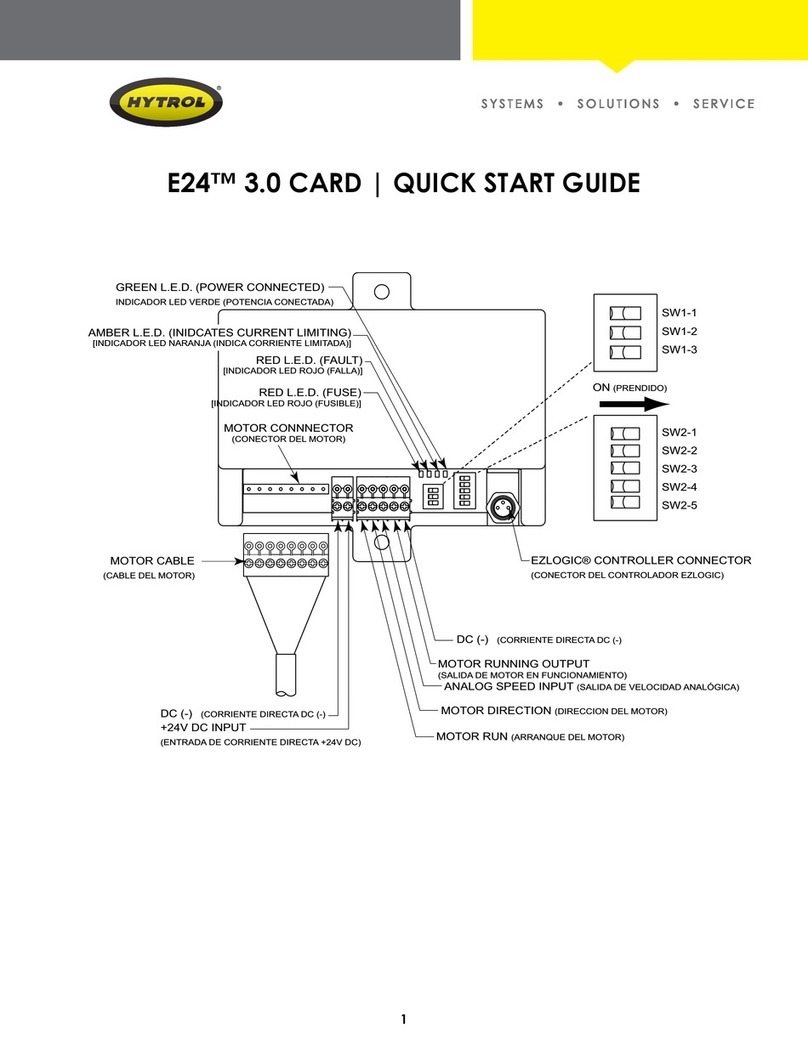

HYTROL

HYTROL E24 3.0 CARD quick start guide

Eaton

Eaton EU1E-SWD Series Instruction leaflet

WAGNER

WAGNER EPG S2 Translation of the original operating manual